Cable clamping device

A technology for clamping devices and cables, applied in the directions of pipe supports, electrical components, pipes/pipe joints/fittings, etc., can solve problems such as cable sheath damage, prevent damage and reduce the possibility of deformation of connection points The effect of reducing the possibility of damage and the possibility of bending of the bolt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

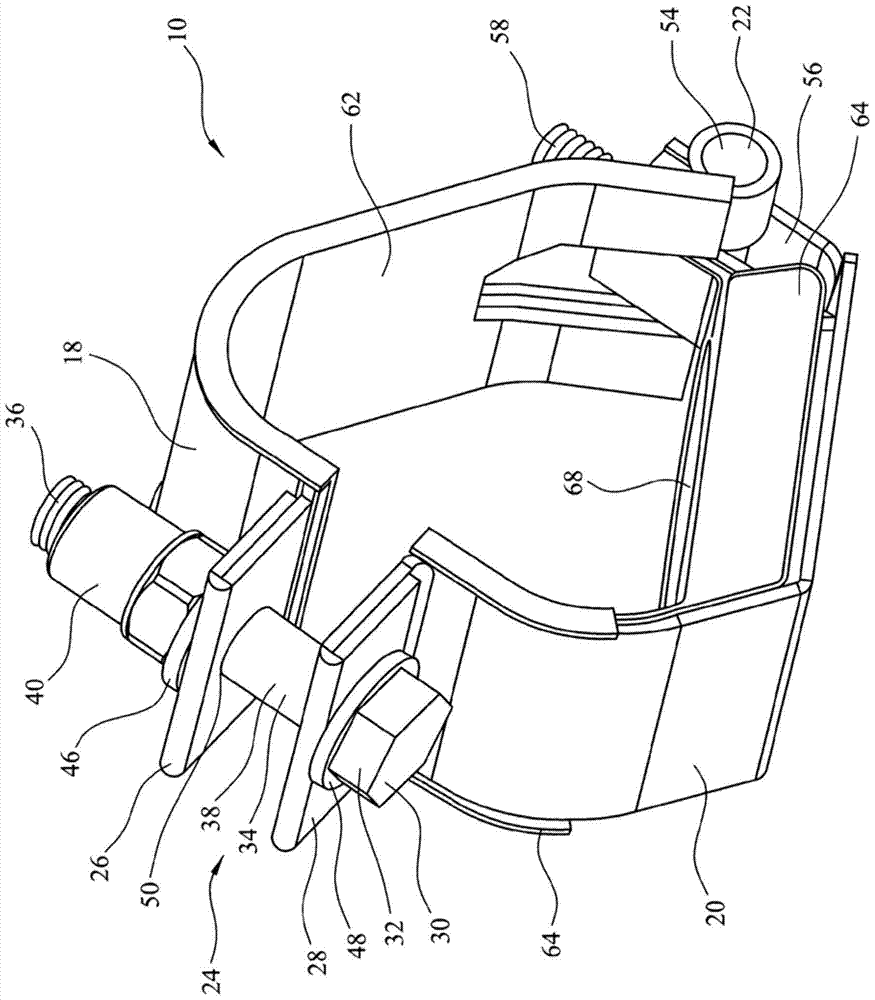

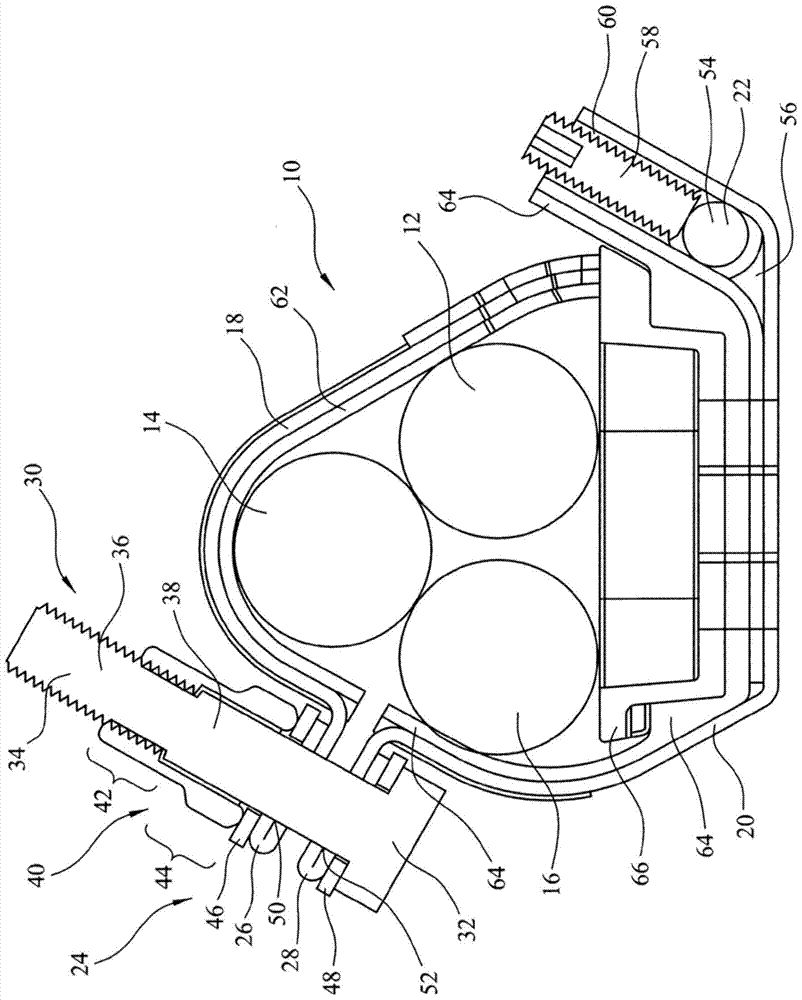

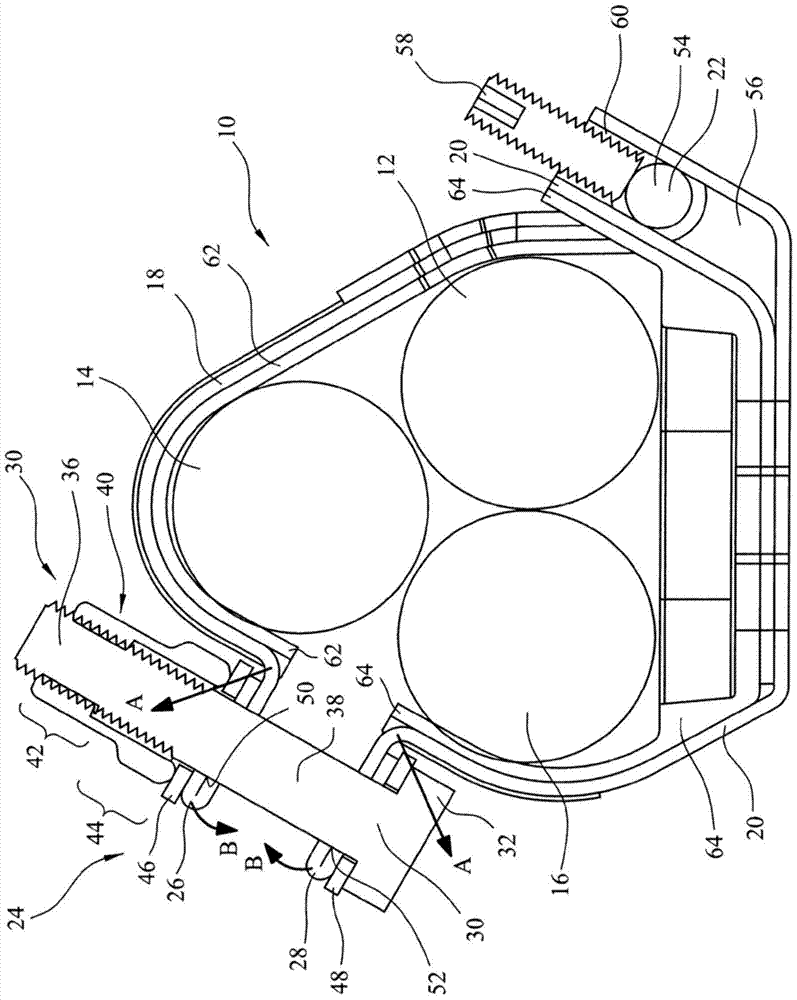

[0044] See Figure 1 to Figure 3 The present invention provides a cable clamping device in the form of a cable clamp 10, which is used to clamp at least one cable. In the example, there are three cables, which are cables 12, 14, and 16, respectively. The cable clamp 10 includes a first cable clamping assembly 18 that engages the cables 12 and 14 in use. The cable clamp 10 further includes a second cable clamping assembly 20 that contacts the cable 12 and the other cable 16. in Figure 1 to 3 In the illustrated embodiment, the first and second cable clamping assemblies 18 and 20 are obtained by bending and welding steel plates into the shapes shown in these figures. The first and second cable clamping assemblies 18 and 20 are hingedly connected to each other by a pivot in the form of a hinge 22.

[0045] The cable clamp 10 further includes a clamping portion generally indicated at 24. The clamping portion 24 includes a first flange 26 mounted on the first cable clamping assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com