Mechanical-damping-type yarn tensioner without skimming wear

A technology of mechanical damping and tensioner, which is applied in looms, textiles, textiles, and papermaking, etc. It can solve the problems of complex structure, hairiness, and large bending curvature of the tensioner, and achieve practical and reliable adjustment methods, simple adjustment methods, and flexible bending. The effect of small curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

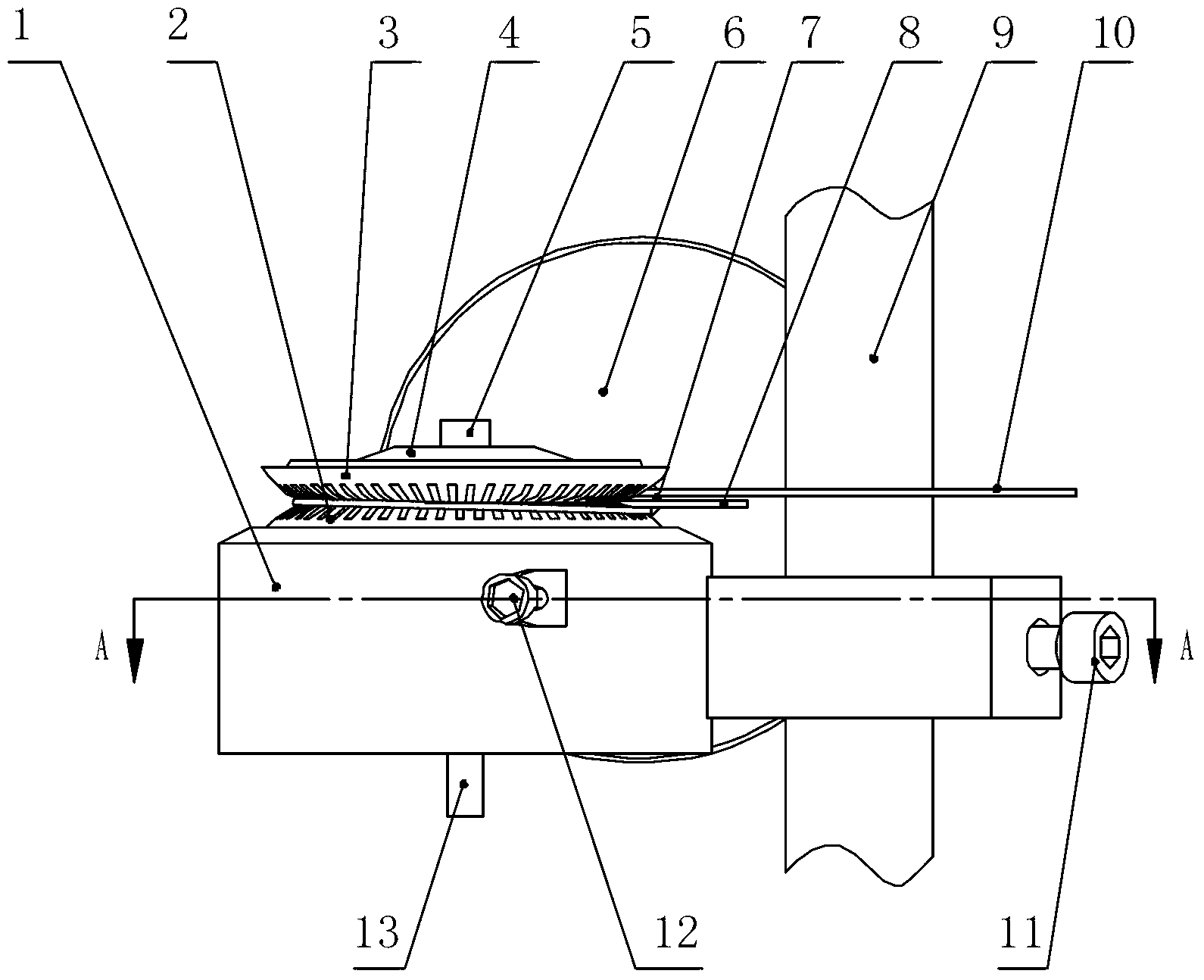

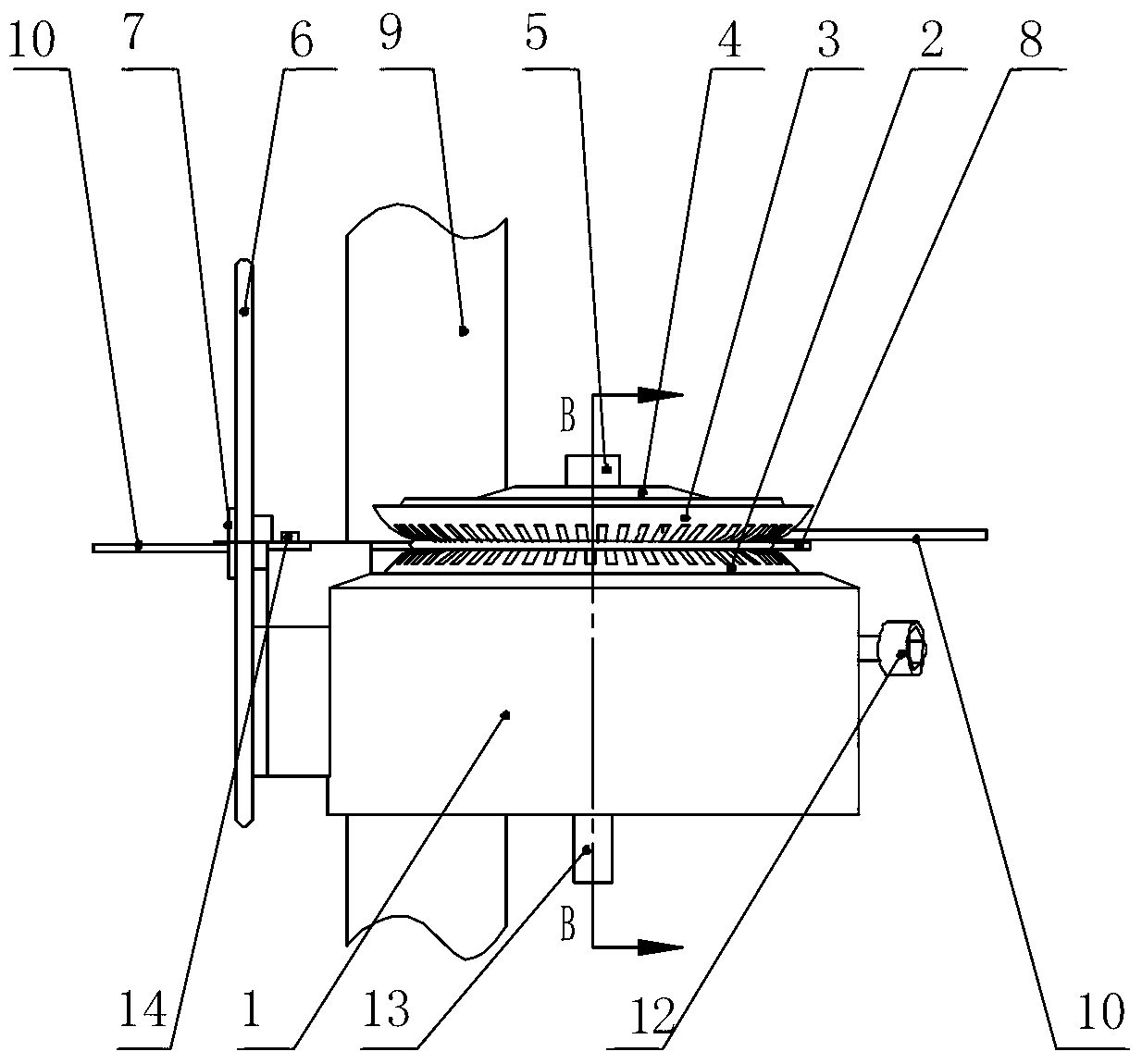

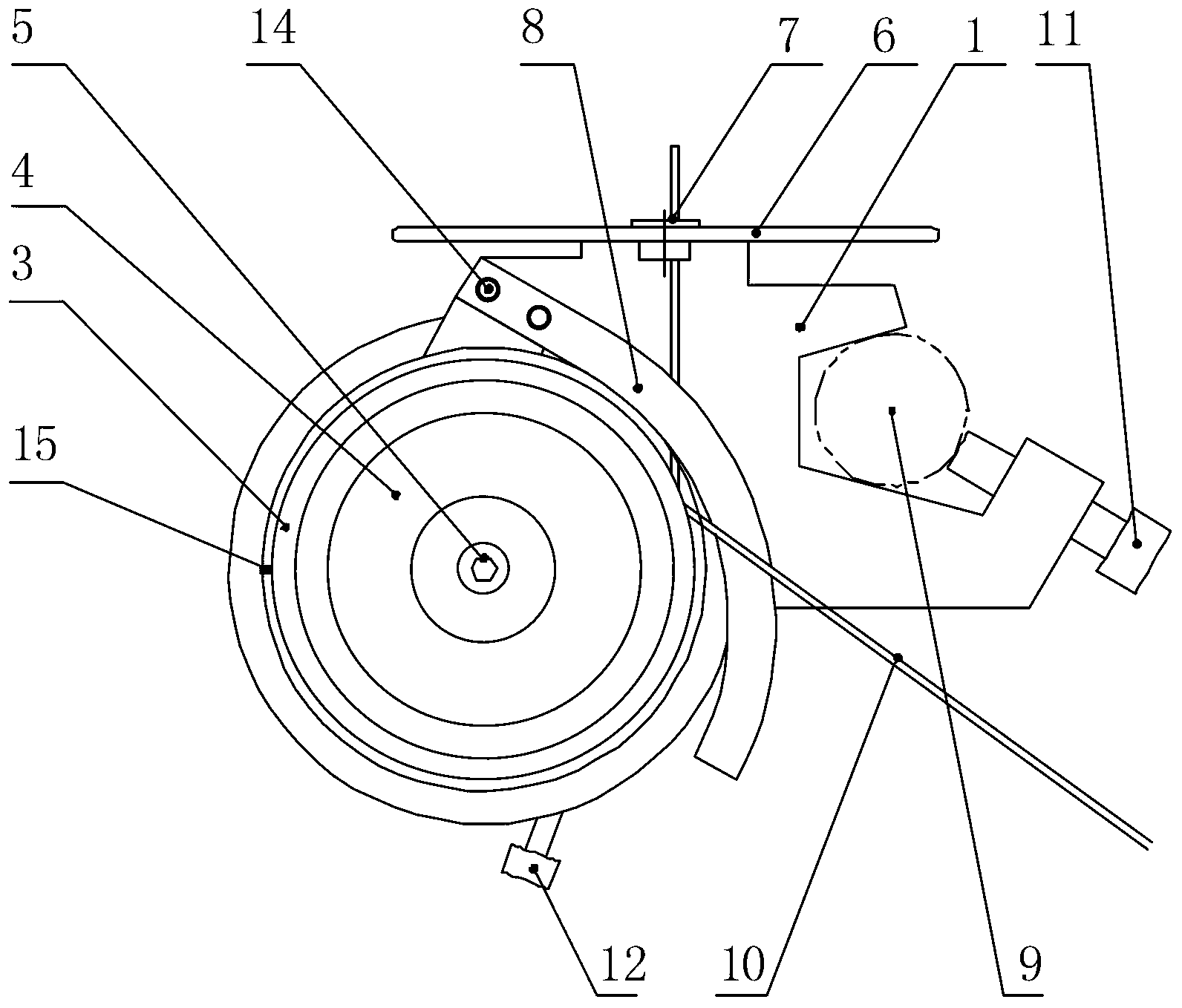

[0016] Describe the present invention in detail below in conjunction with accompanying drawing:

[0017] This kind of tensioner comprises the lower tension disc 2 of the prior art, the upper tension disc 3, the tension disc pressing plate 4, the pressing plate fixing screw 5, the yarn dividing sheet 8, the yarn retaining plate 6, and the porcelain eye 7; Figure 1-6 As shown, the characteristics of this tensioner are: the lower tension disc 2 and the upper tension disc 3 are arranged on the shoulder of the rotor 13 through the center hole, and the tension disc pressing plate 4 is arranged on the top of the upper tension disc 3, and the tension disc pressing plate 4 passes through The pressure plate fixing screw 5 fixes the lower tension disc 2 and the upper tension disc 3 on the rotor 13; a cylinder is arranged under the shoulder of the rotor 13, and an annular hole is arranged in the cylinder, and the central axis of the annular hole is the rotor shaft; the tensioner The seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com