Door sheet embossing device

A printing and door panel technology, which is applied in decorative arts, leather surface mechanical treatment, embossed decorations, etc., can solve the problems of reduced service life, damage to the surface of the pressed material, and softening of the embossing roller surface, so as to prolong the service life, Guarantee the calendering effect and avoid the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

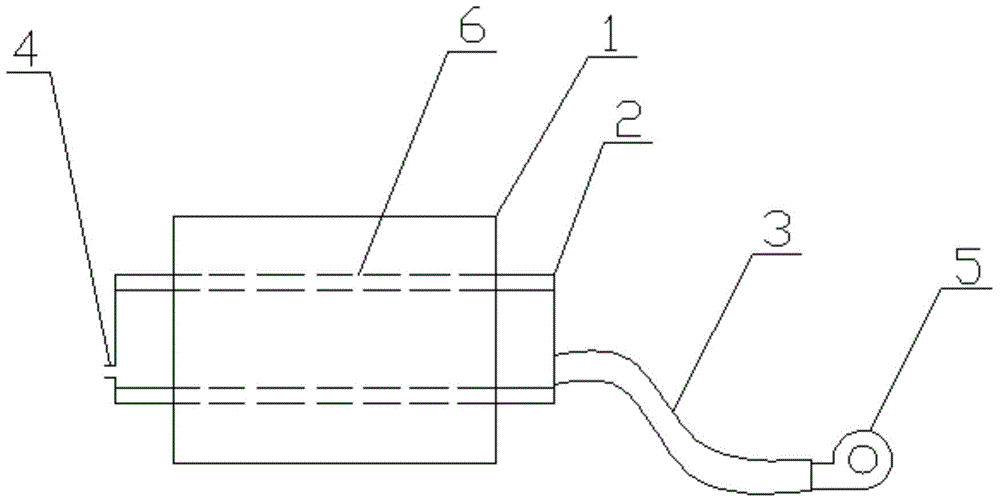

[0012] Such as figure 1 As shown, a door panel printing device of the present invention includes a door panel printing device cylinder 1 and a roller shaft 2, the door panel printing device cylinder 1 and the roller shaft 2 are connected by a flange, the roller shaft 2 is a hollow structure, and the The two ends of the roller shaft 2 are closed, one end is connected with an air intake hose 3, and the other end is provided with an exhaust port 4, and the other end of the air intake hose 3 is provided with a blower 5, and the air intake hose 3 and the air blower The air outlet of 5 is connected, and the wall of the contact part between the roller shaft 2 and the door printing device barrel 1 is provided with a through air hole 6, and the inner wall diameter of the door printing device barrel 1 is adapted to the outer wall diameter of the roller shaft 2.

[0013] The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com