Rapid crushing device for corn kernel processing

A pulverizing device and corn kernel technology, applied in the direction of grain processing, etc., can solve the problems of inability to achieve corn kernel crushing and refinement, low corn kernel processing efficiency, limited corn range, etc. The effect of the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

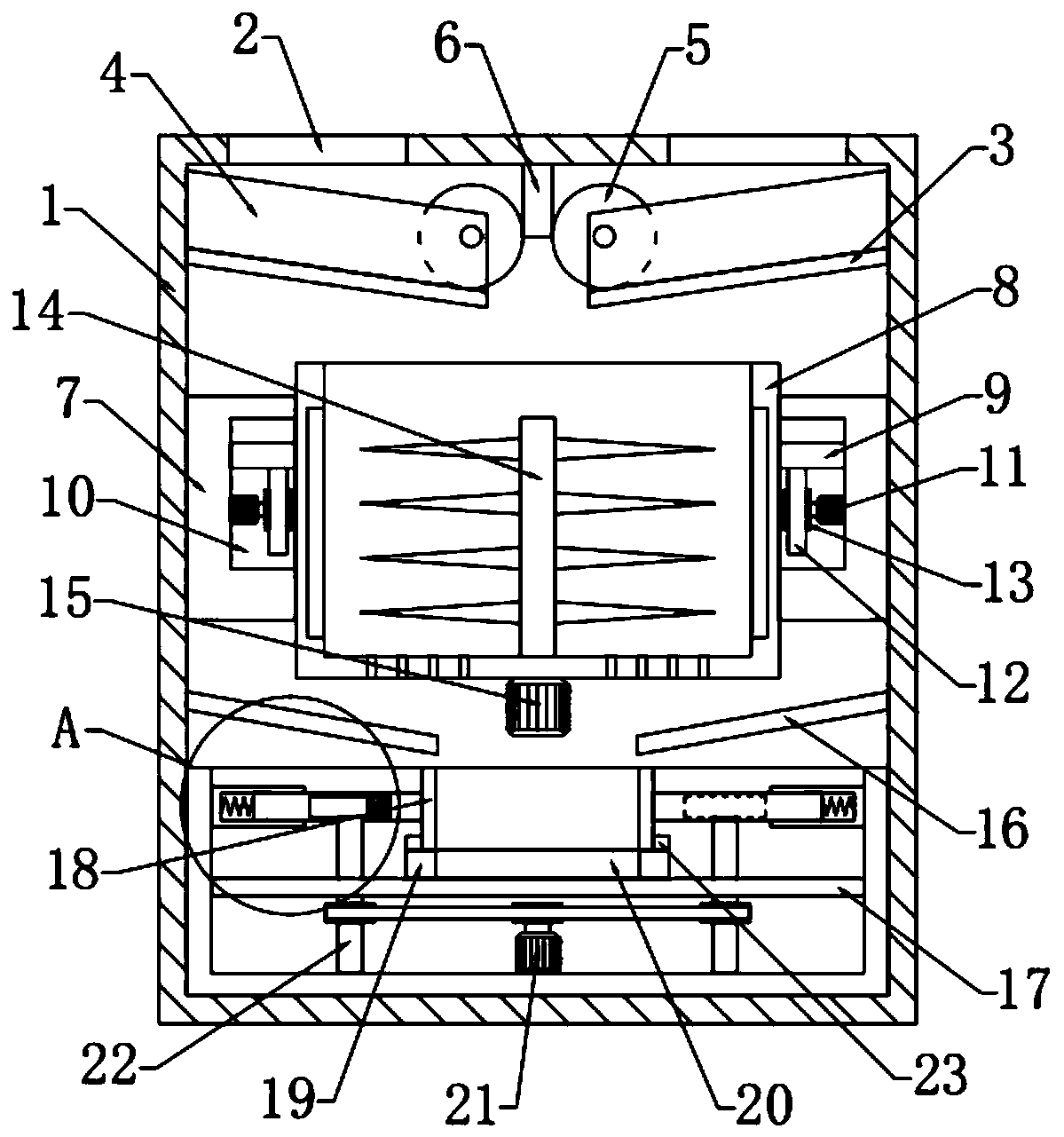

[0025] see Figure 1-3 , in the embodiment of the present invention, a kind of quick pulverizing device for corn grain processing, comprises housing 1, and the top left and right sides of described housing 1 are provided with feed port 2, and the lower side of described feed port 2 is provided with mill A crushing mechanism, a crushing mechanism is arranged on the lower side of the crushing mechanism, and a secondary crushing mechanism is arranged on the lower side of the crushing mechanism.

Embodiment 2

[0027] In this embodiment, the rolling mechanism includes a material guide plate 3, and the material guide plate 3 fixedly connected to the housing 1 is provided on the lower side of the feed port 2 on both sides, and the material guide plate 3 on both sides is A scraper 6 fixedly connected to the housing 1 is arranged between them, the left and right sides of the scraper 6 are provided with rollers 5 abutting against the material guide plate 3, and the inner side of the roller 5 is fixedly connected with a connecting rod, The connecting rod is connected with the baffle plate 4 bearings arranged on the front and rear ends of the material guide plate 3. By setting the rolling mechanism, the corn kernels can be crushed by the roller 5, so that the corn kernels can be broken more thoroughly. The plate 6 can prevent the corn kernels from adhering to the surface of the roller 5 and ensure the rolling effect.

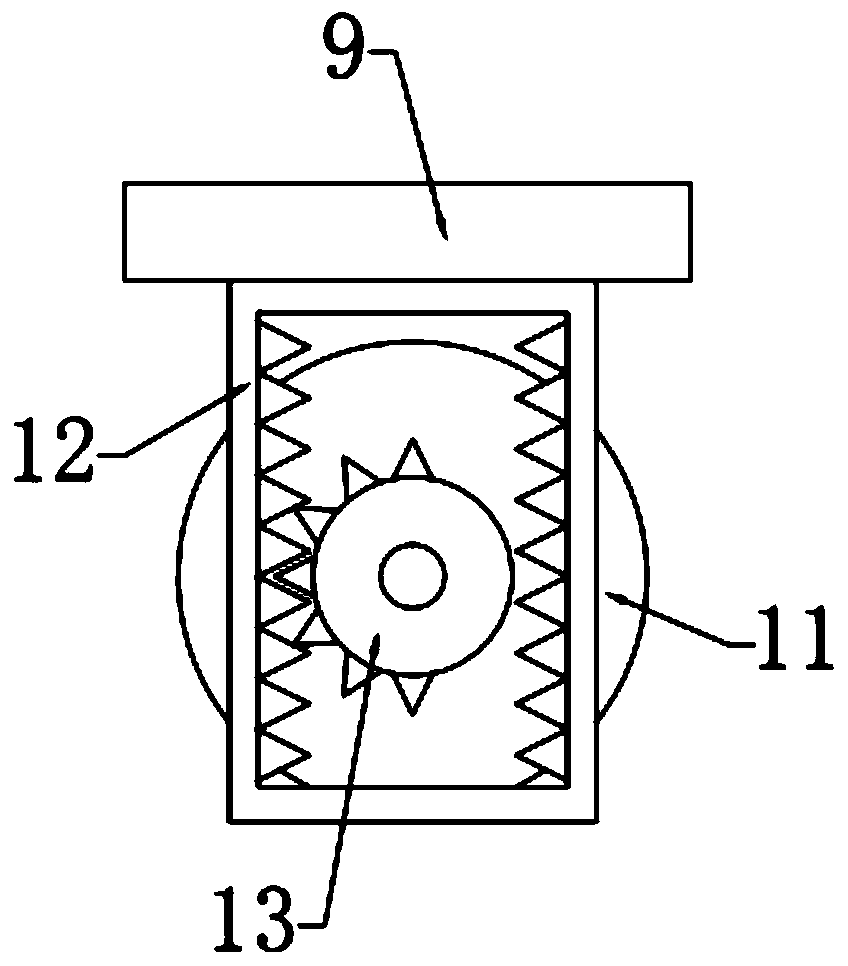

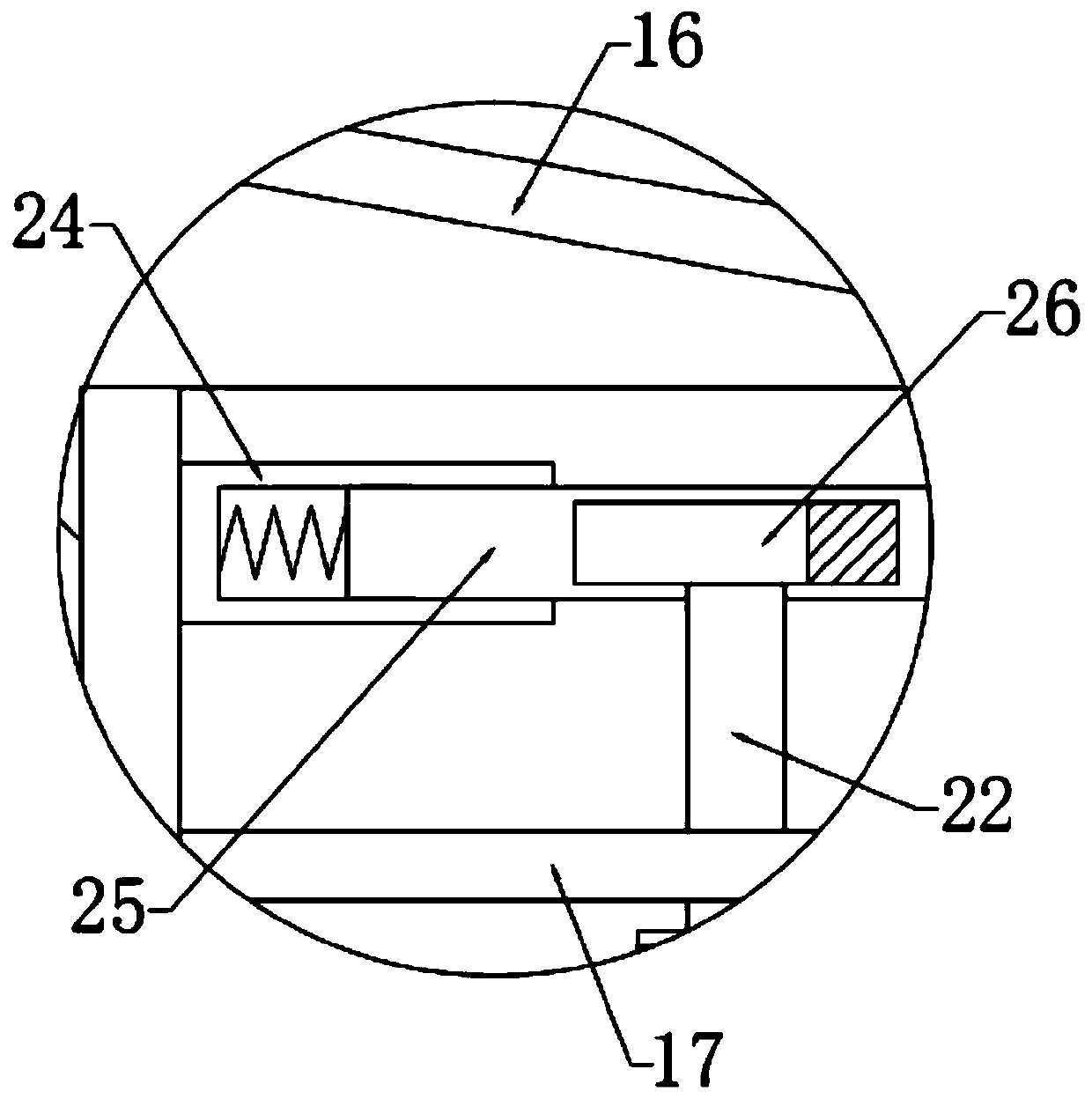

[0028] In this embodiment, the crushing mechanism includes a crushing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com