Industrial hazardous waste incineration line pretreatment crushing device

A hazardous waste and crushing device technology, applied in grain processing, incinerators, combustion methods, etc., can solve the problems of poor crushing effect and reduced efficiency of subsequent waste crushing, so as to improve efficiency, ensure sharpness and service life, improve The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

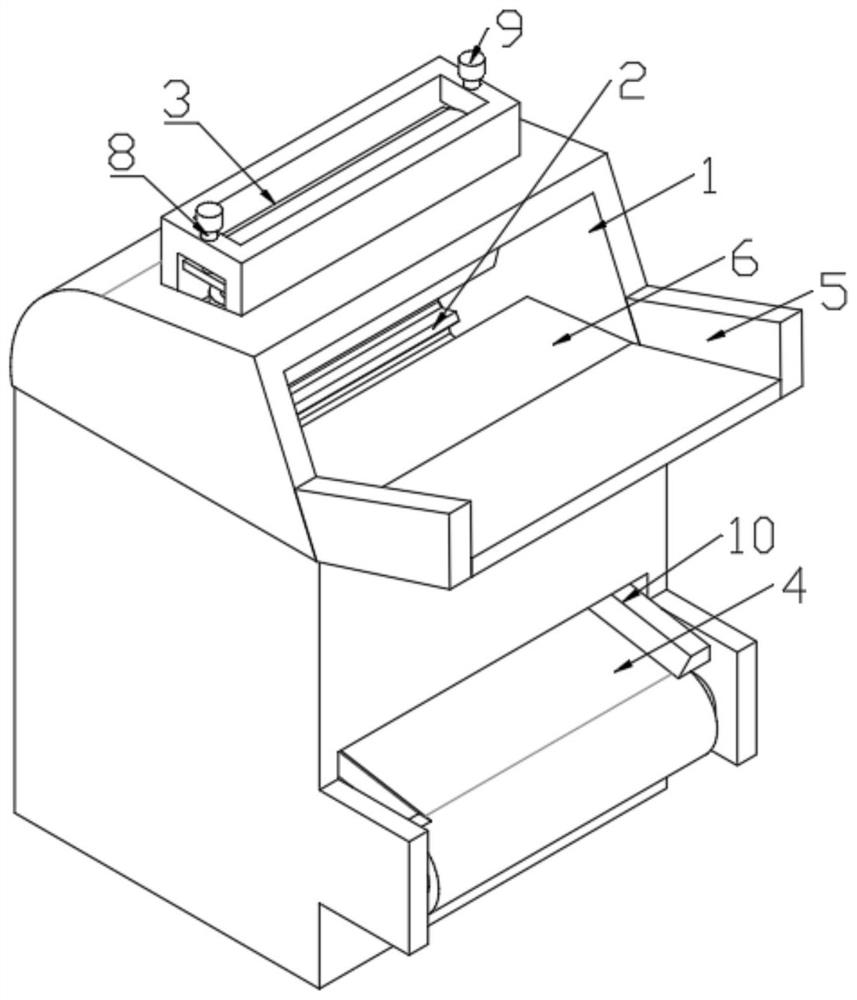

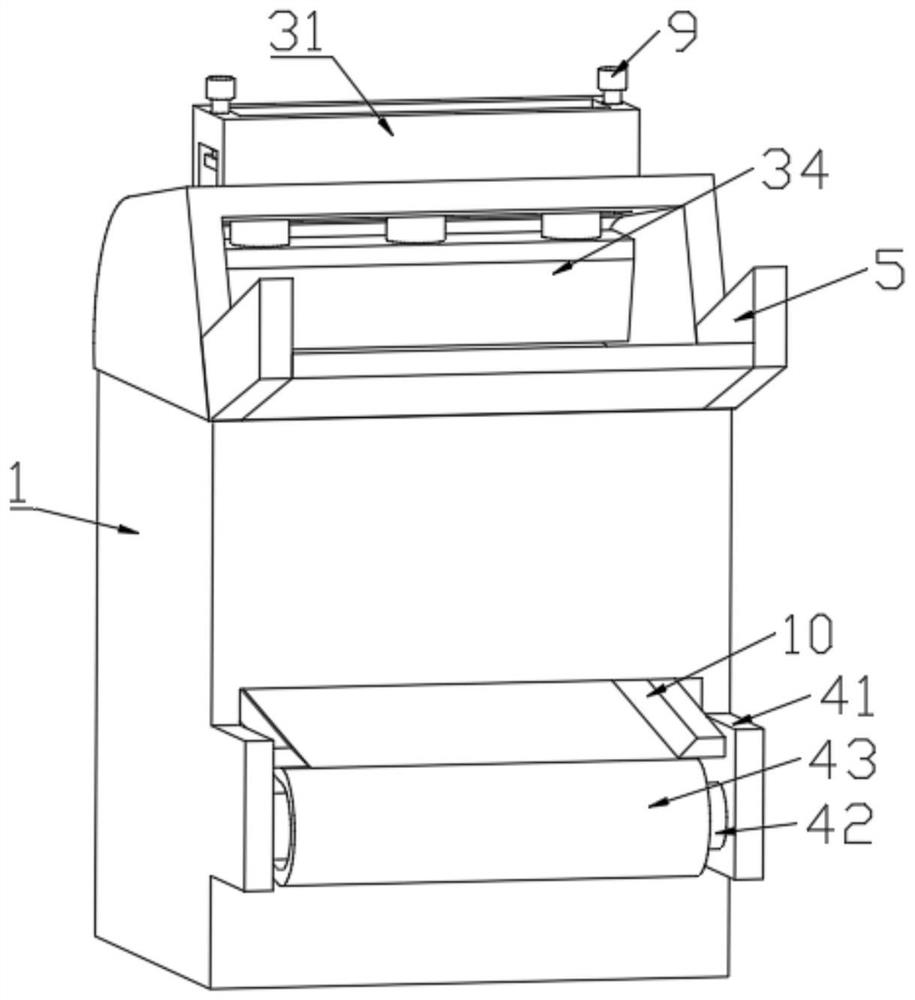

[0031] refer to Figure 1-5 , an industrial hazardous waste incineration line pretreatment and crushing device, including:

[0032] Crushing cabinet 1, the crushing cabinet 1 is in the shape of a rectangular vertical cabinet, and one side is set in an arc shape, the upper end of the side of the crushing cabinet 1 away from the arc edge is provided with a feed port, and the bottom of the same side is provided with a discharge port;

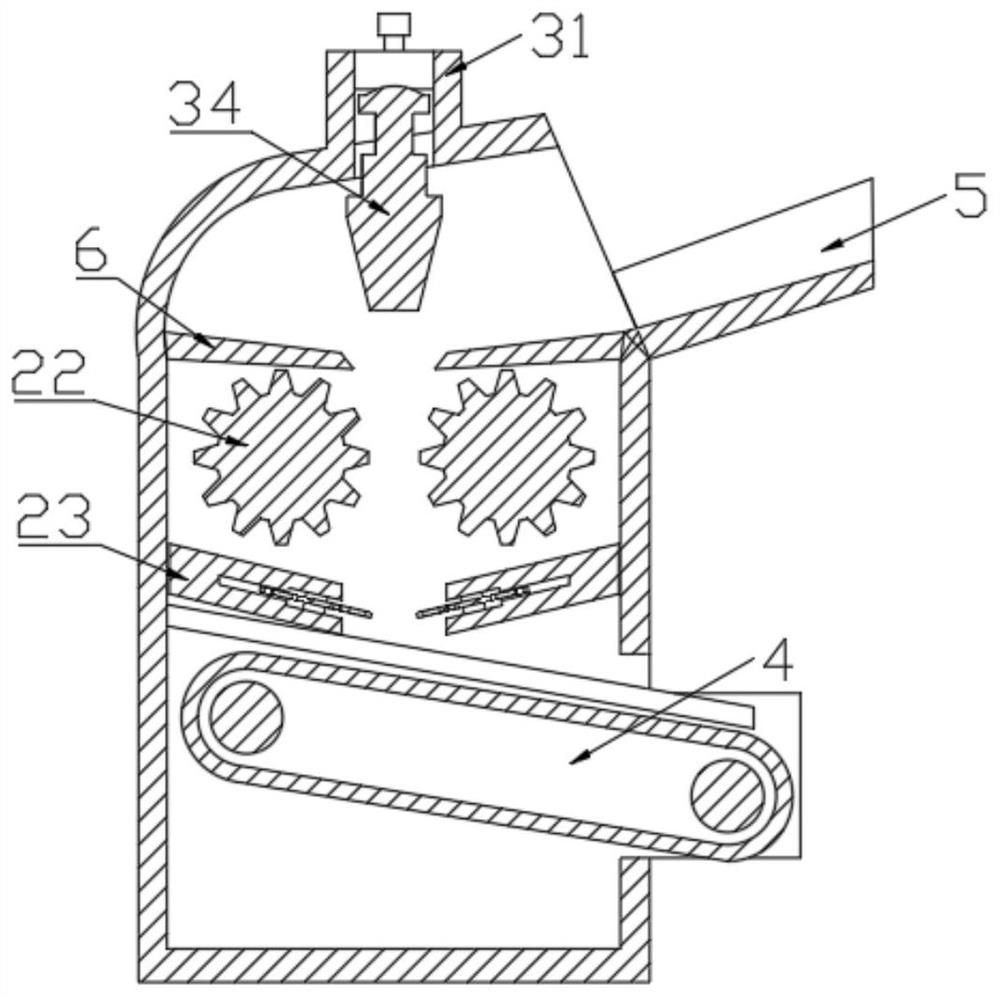

[0033] Crushing assembly 2. The crushing assembly 2 includes a rotating shaft 21, a roller 22, a mounting frame 23 and a cutter 24. The two rotating shafts 21 are symmetrically installed on both sides of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com