An improved roll-forming device for a non-woven fabric dyeing production line

A production line and improved technology, applied in the direction of coiling strips, transportation and packaging, thin material handling, etc., can solve the problems of reduced coiling speed, easy slippage, and reduced transmission rate of the coiling device, and avoid position changes. , to ensure the transmission rate, to ensure the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

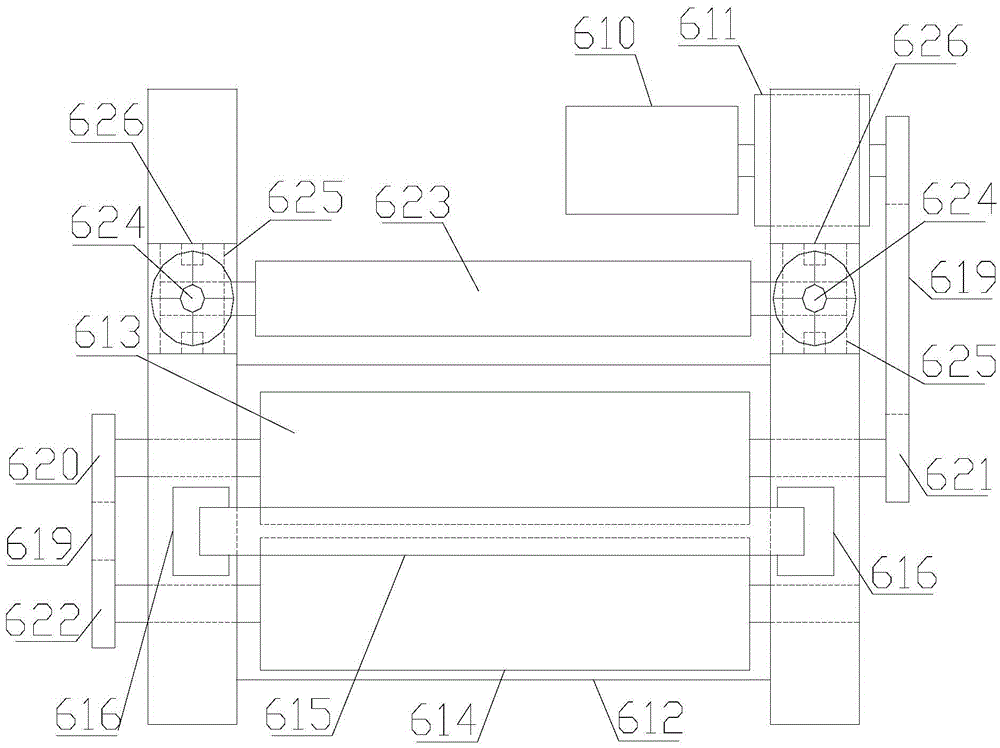

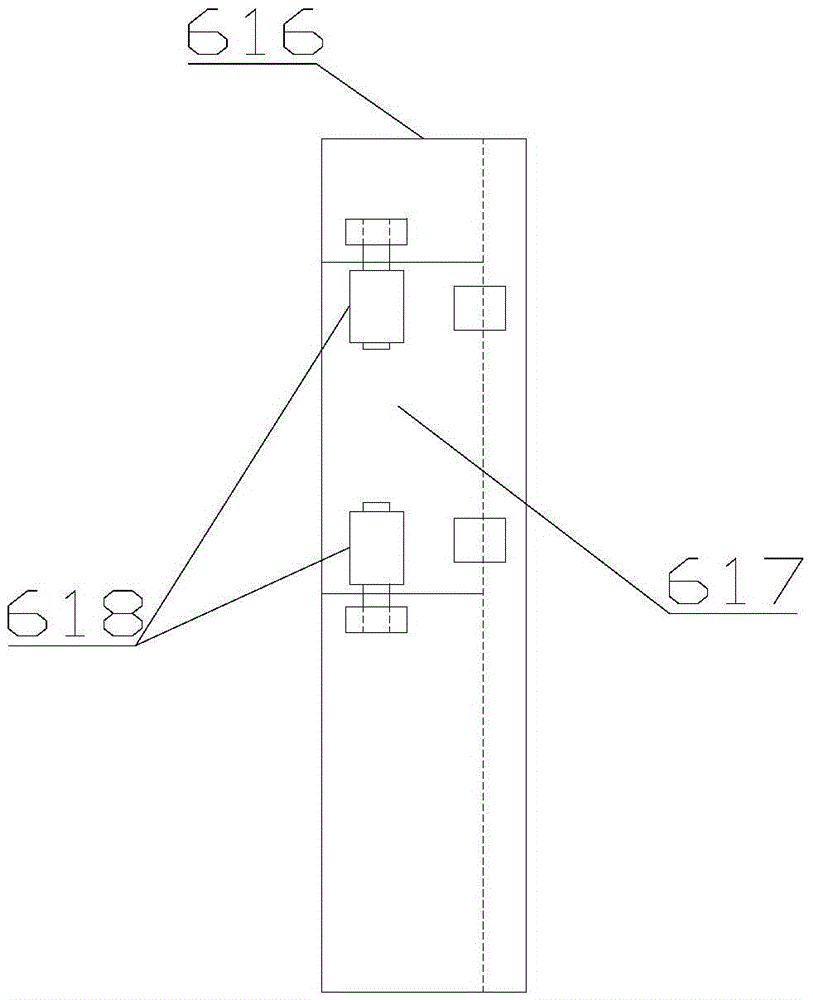

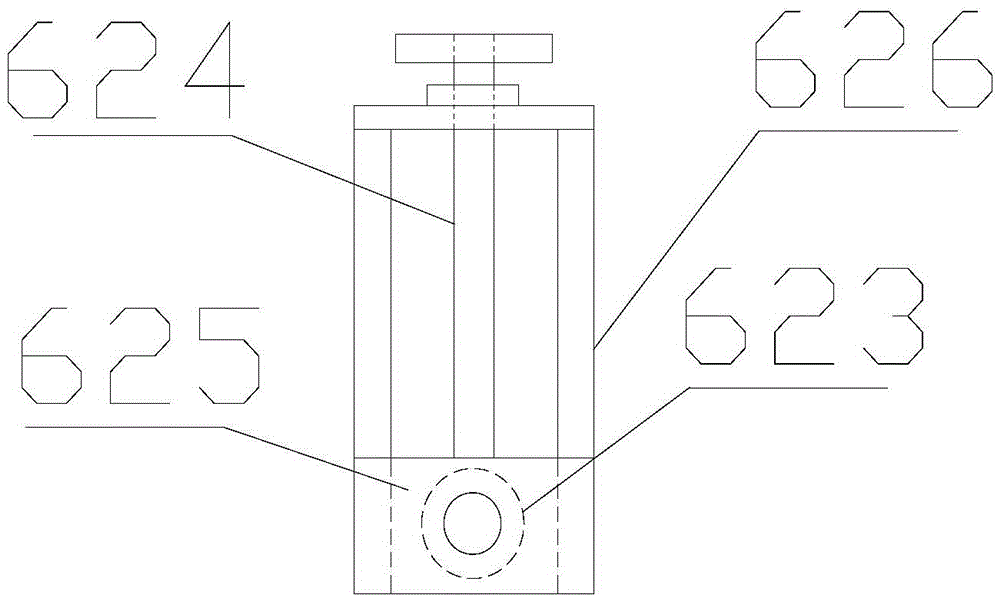

[0019] refer to figure 1 , figure 2 with image 3 , an improved rolling device for a non-woven dyeing production line of the present invention, including a motor 610, a transmission 611, a frame body 612, a first driving roller 613, a second driving roller 614, a winding shaft 615, a guide groove 616, and a baffle 617, latch 618, chain 619, the first gear 620, the second gear 621, the third gear 622 and the anti-error mechanism, the first driving roller 613, the second driving roller 614 and the error-proofing mechanism are installed on the frame body 612 Edge mechanism, the top of the first driving roller 613 is provided with an anti-mistake mechanism, the front end of the shaft of the first driving roller 613 is provided with a first gear 620, and the rear end of the shaft of the first driving roller 613 is provided with There is a second gear 621, the front end of the shaft of the second driving roller 614 is provided with a third gear 622, the motor 610 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com