Turntable type UV laminator

A film lamination machine and turntable technology, which is applied to lamination devices, lamination, and surface pretreatment, etc., can solve the problems of increased equipment and labor input, increased production process links, and high comprehensive realization costs, and achieves an increase in the yield rate , reducing the bonding process, and the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

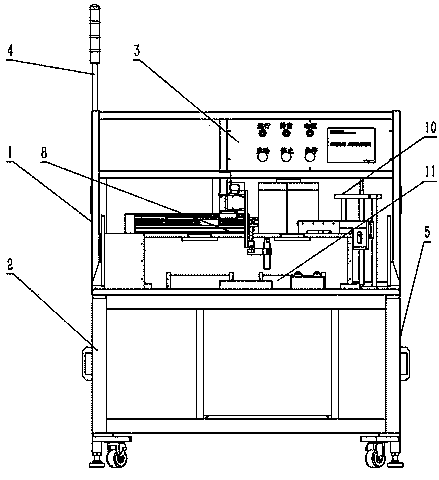

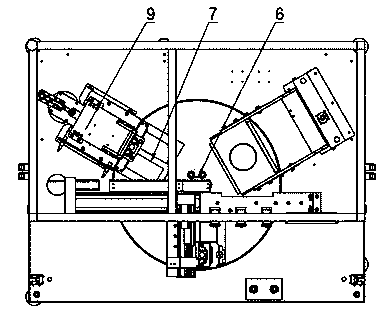

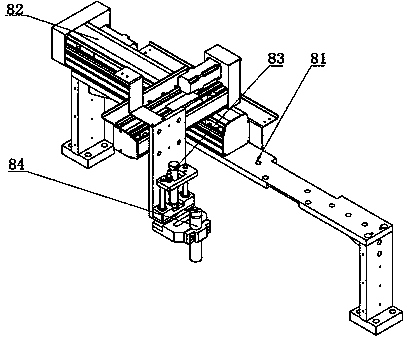

[0025] refer to figure 1 with figure 2 , the present embodiment comprises an upper frame 1 and a lower frame 2, an operation panel 3 is installed on the upper frame 1, and the lower side of the operation panel 3 is provided with a dispensing machine module 8 and a rolling module successively from left to right 9 and UV hardening machine module 10; a control box 5 is installed on the lower frame 2, and the middle part of the table top of the lower frame 2 is provided with a divider 6 connected with the control box 5, and a mold 7 is fixed on the divider 6.

[0026] The upper frame 1 in this embodiment adopts an aluminum profile structure and an acrylic plate outer seal, which plays the role of safety protection and anti-ultraviolet light leakage, and is convenient for maintenance and repair. The lower frame 2 adopts a high-strength aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com