Solid waste treatment system with pre-treatment step

A solid waste, treatment system technology, applied in the direction of grain processing, etc., to reduce the possibility of burnout, improve stability, and increase the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

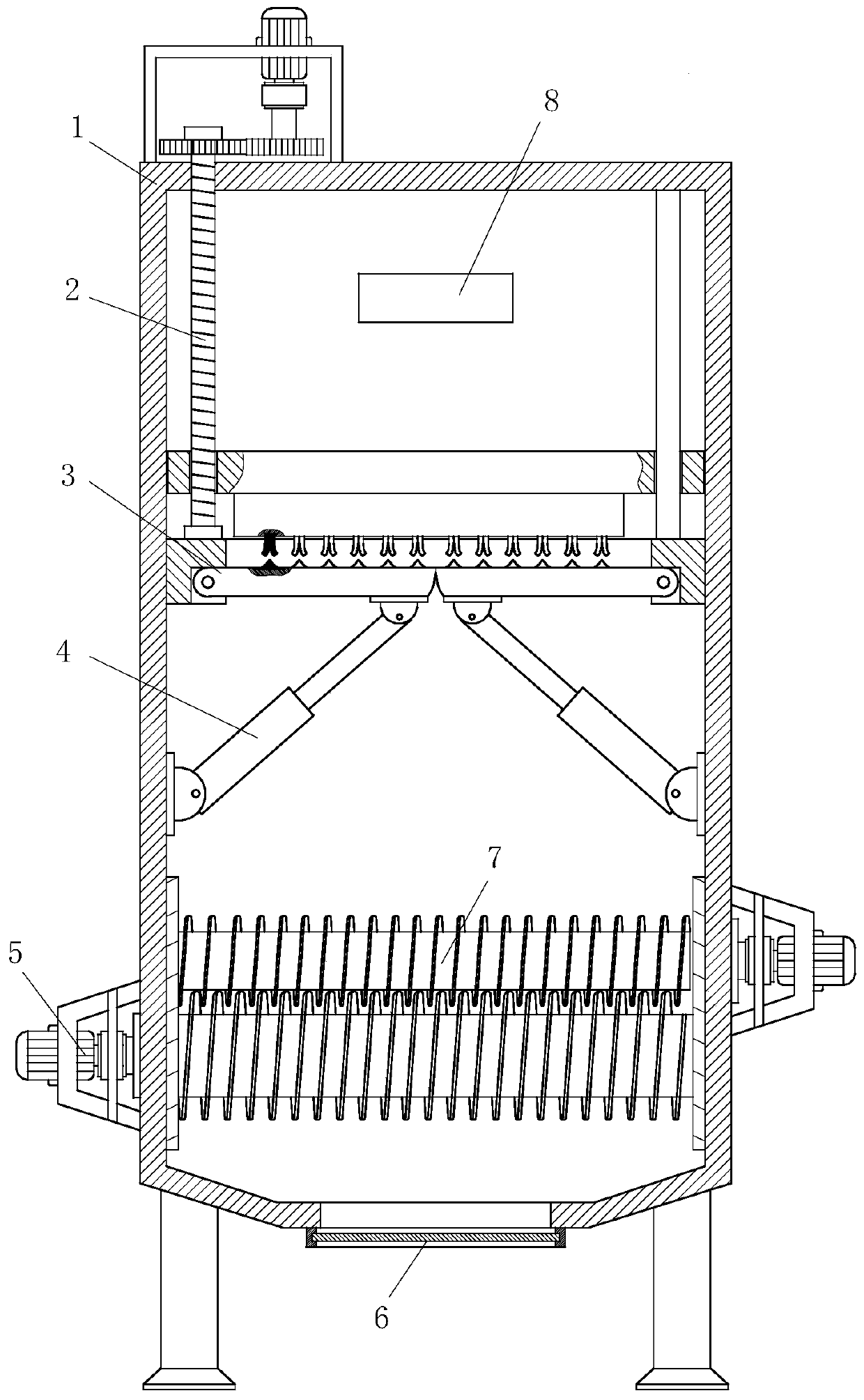

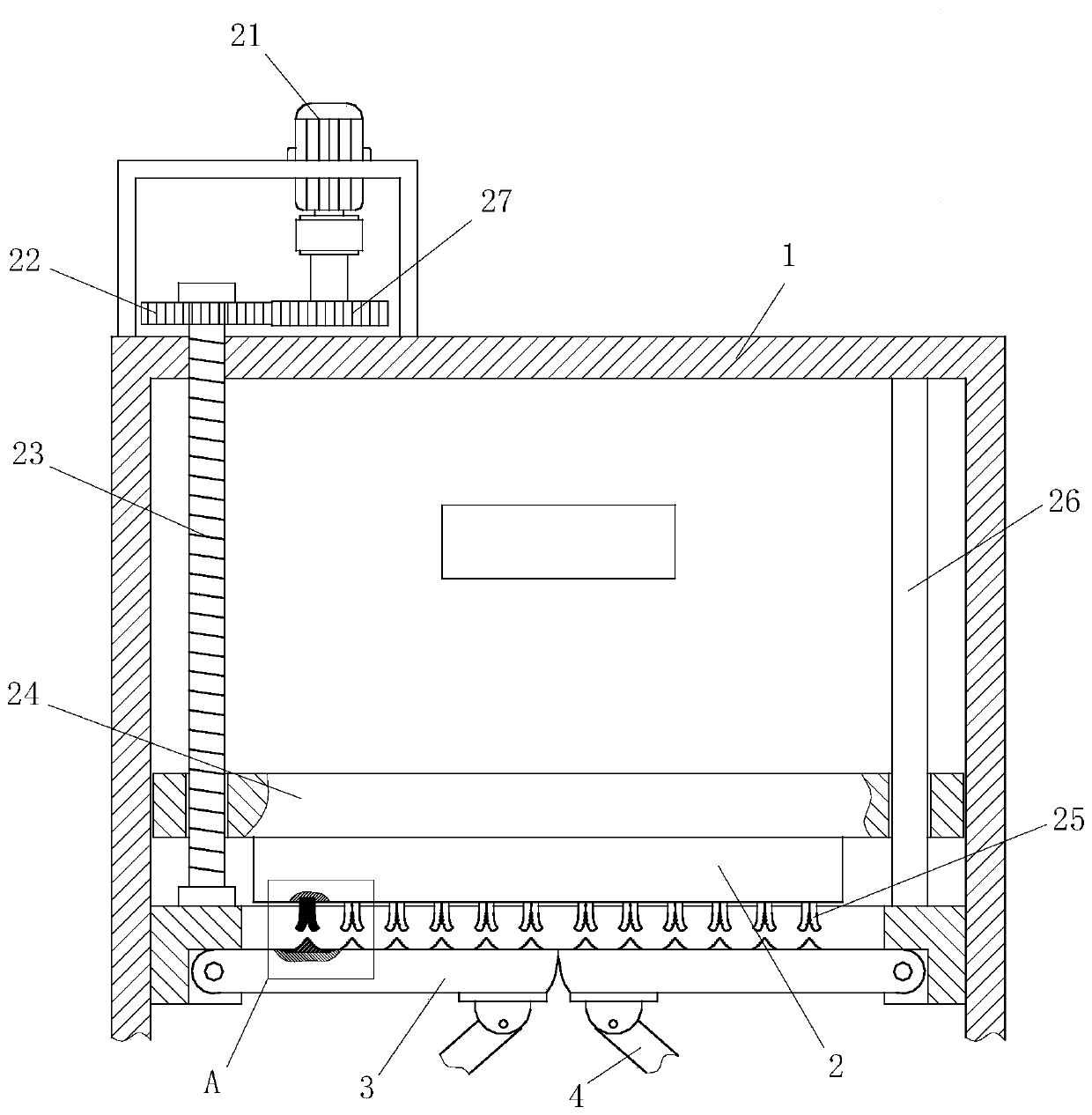

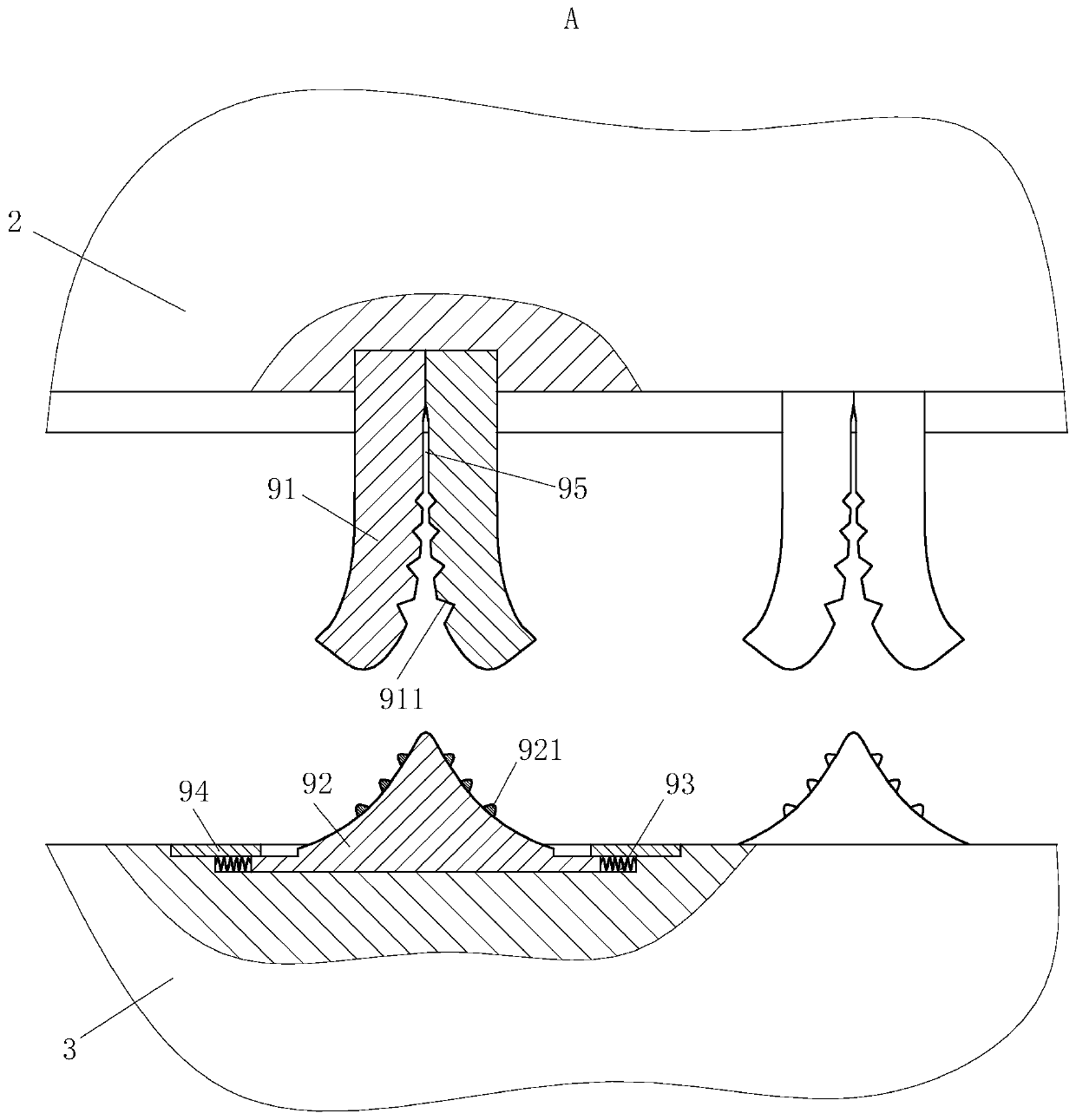

[0023] use Figure 1-Figure 3 A solid waste treatment system with a pretreatment process according to an embodiment of the present invention will be described as follows.

[0024] Such as figure 1 As shown, a solid waste treatment system with a pretreatment process according to the present invention includes a treatment box 1, a primary crushing assembly 2 and a crushing roller 7, and the inside of the treatment box 1 is provided with a further step near the upper end. A feed opening 8, a rotating sealing plate 3 is arranged in the middle of the lower interior of the processing box 1, and a primary crushing assembly 2 is arranged above the rotating sealing plate 3, and the lower end of the rotating sealing plate 3 is connected to the processing box 1. An electro-hydraulic telescopic rod 4 is connected between them. Two crushing rollers 7 are evenly arranged near the lower end of the processing box 1. A crushing motor 5 is installed on the side of the crushing roller 7. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com