Full-automatic high-speed coil type wire winding machine

A winding machine, fully automatic technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the unsatisfactory production needs, long response time of the cylinder action, and low working efficiency of the coiler etc. to achieve the effect of saving time, shortening action time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

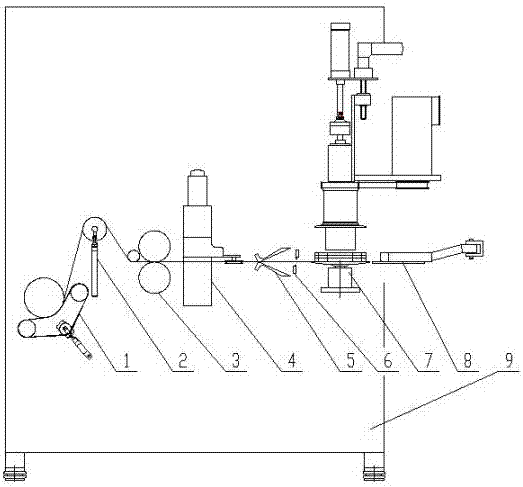

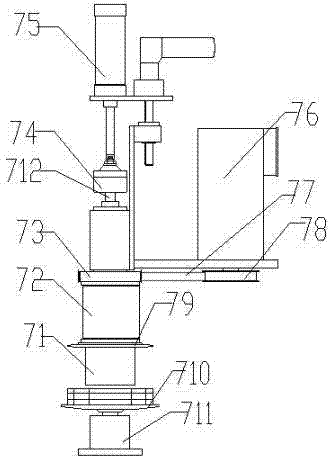

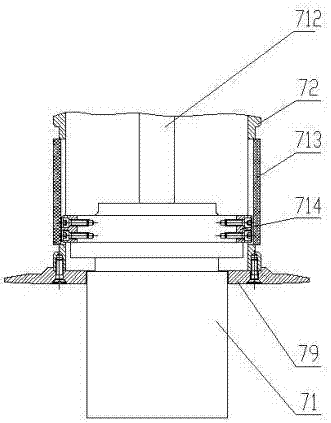

[0030] Such as figure 1 A fully automatic high-speed coiling and winding machine shown includes a frame 9 on which a wire transmission mechanism, a tension mechanism 1, a meter counter 3, a positioning device 4, and a fast clamping wire are arranged. Device 5, thread cutting device 6, mechanical gripper 8 and coiling device 7. Wherein the tension mechanism 1 adopts a magnetic powder tension device, and a buffer device 2 is arranged between the tension mechanism 1 and the meter counter 3 .

[0031] Such as Figure 5 and Figure 6 Shown is a schematic diagram of the structure of the quick clamping device 5, including a rotating base 511, wherein the rotating bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com