Miniature plate rolling machine

A plate rolling machine, miniature technology, applied in the field of hardware production, can solve the problems of high practical cost, large size, high power, etc., and achieve the effect of simple structure of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described:

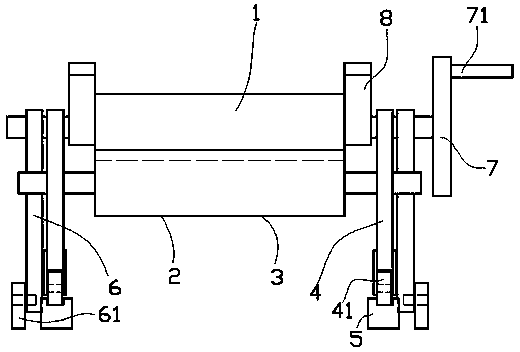

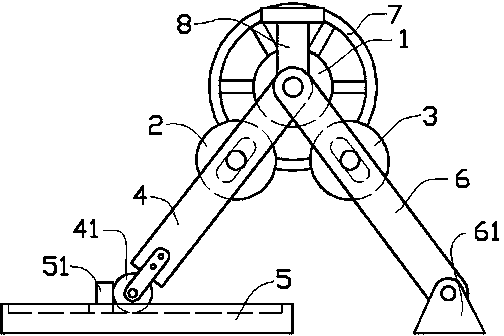

[0016] Such as figure 1 and figure 2 As shown in the embodiment, the miniature plate rolling machine includes a main pressure roller 1, a rotating roller 2, and a passive roller 3. The three rollers of the main pressure roller 1, the rotating roller 2, and the passive roller 3 are parallel to each other. The centers of the three rollers on the side of the machine are arranged in an isosceles triangle; the lower part of the driving roller 1 is lower than the upper parts of the rotating roller 2 and the driven roller 3; 4 connection, the lower part of the rotating arm 4 is assembled on the moving track 5 through the roller 41 that can rotate from the axis, and the two ends of the main pressure roller 1 and the passive roller 3 respectively pass through the passive arm 6 symmetrically to connect the passive The lower end of the arm 6 is fixed to the ground through a hinged fixing seat 61;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com