Device and method for preparing spherical metal powder through laser-assisted grinding

A metal powder and laser-assisted technology, applied in the field of material processing, can solve problems such as low production efficiency, high cost, and burning of alloy elements, and achieve the effects of easy operation, low-consumption processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

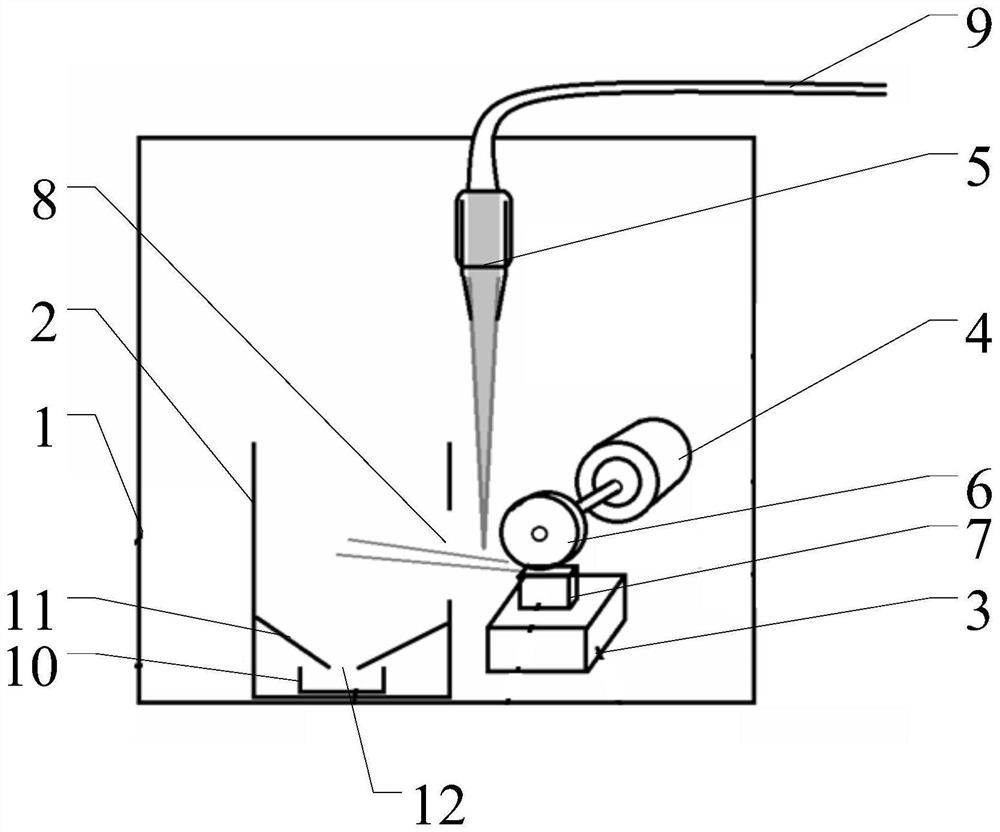

[0029] figure 1 It is a schematic structural diagram of a device for preparing spherical metal powder by laser-assisted grinding according to the present invention. As shown in the figure, the present invention provides a device for preparing spherical metal powder by laser-assisted grinding, including an atmosphere chamber 1, a collector 2, The workbench 3, the grinding motor 4 and the laser head 5 are connected with an optical fiber 9 above the laser head 5. The laser head 5, the grinding motor 4, the worktable 3 and the collector 2 are all arranged inside the atmosphere chamber 1, and the workbench driver is connected to the workbench 3; the grinding head 6 is connected to the grinding motor 4, and the grinding knife The head 6 is arranged on the top of the workbench 3, and the metal block 7 is placed on the workbench 3; the side of the collector 2 close to the workbench 3 is provided with a collection port 8, and the center of the collection port 8 is connected with the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com