Durable cylinder valve

A durable, bottle valve technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of short service life, large valve stem holding force, easy damage to seals, etc., to achieve a simple structure, The effect of good pressure cap centering and durable seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

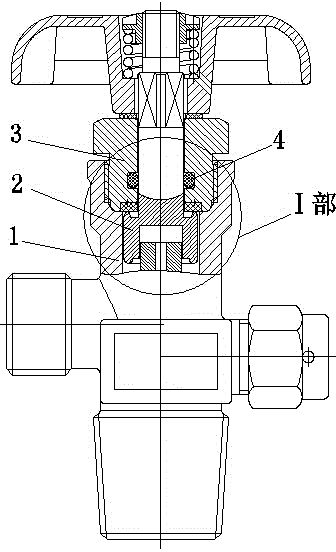

[0017] The present invention includes a valve body 1, a hand wheel is installed on the upper part of the valve body 1 and a valve stem 2 driven by the hand wheel extends into the valve body 1;

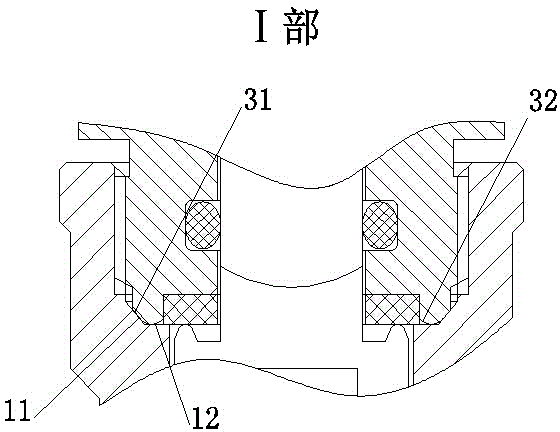

[0018] The valve body 1 is provided with a pressure cap 3 sleeved on the outside of the valve stem 2. The outer ring surface of the lower end of the pressure cap 3 is an outer tapered surface 31, and the inner ring surface is a smooth outer ring surface 31. transitional outer arcuate surface 32;

[0019] Correspondingly, the valve body 1 is provided with an inner tapered surface 11 supporting the outer tapered surface 31 and an inner stepped surface 12 supporting the outer circular arc surface 32 .

[0020] A seal 4 is provided between the pressure cap 3 and the valve stem 2 .

[0021] The pressure cap 3 and the valve body 1 are connected by threads.

[0022] The valve stem 2 is provided with an annular boss 21 at the lower part of the pressure cap 3 , and a sealing ring 5 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com