Rectifier B and screw rod pressing clamp

A rectifier and screw technology, which is applied in the field of rectifier B+screw press-fit fixtures, can solve problems such as difficult to fit tightly, achieve the effect of convenient and quick mold change, save mold change time, and ensure press-fit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

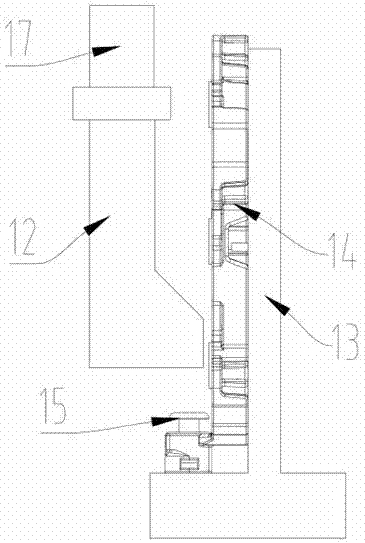

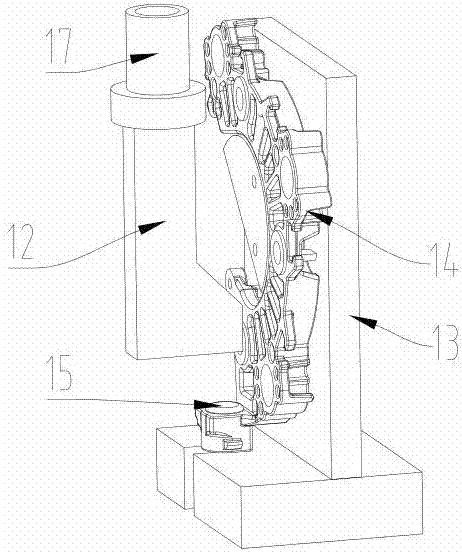

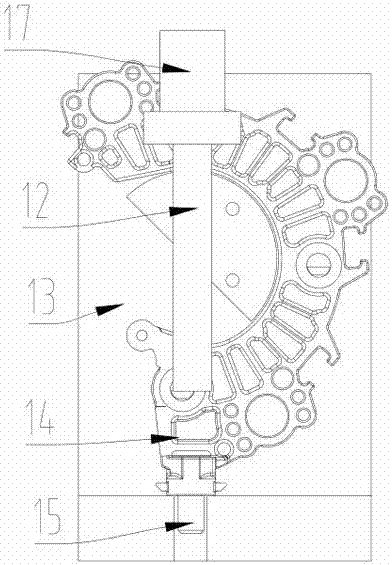

[0033] Such as Figure 4 and Figure 5 As shown, the present invention includes a mold handle 1, a pressure head 2, a base 3, a slider 4, a guide column 5, a spring 6, a special-shaped pin 7, a positioning pin 8, a limit block 9, a linear bearing 10, and a hard limit 11 And backing plate 16. Wherein, the die handle 1 is fixed on the upper die of the press-fitting equipment, and the die handle 1 is provided with a counterbore for connecting the pressure head 2 . Such as Figure 9 As shown, the threaded hole at the thick end of the pressure head 2 cooperates with the bolt to connect the die handle 1, and the space at the thin end of the pressure head 2 is used to allow the B+ screw rod 15 to pass through during pressing. The base 3 is fixed on the lower mold of the press-fitting equipment through gaskets,

[0034] Such as Figure 4 and Figure 10 As shown, the upper end surface of the base 3 is provided with a groove 301 for placing the head of the B+ screw 15, so the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com