Coil inserting die for coil inserting machine

A technology of wire embedding mold and wire embedding machine, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of no modularization, a lot of time, and inconvenient replacement, so as to improve the use efficiency and save mold replacement time, convenient effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

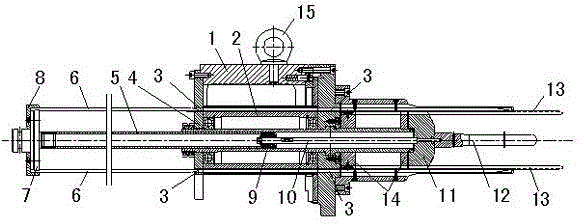

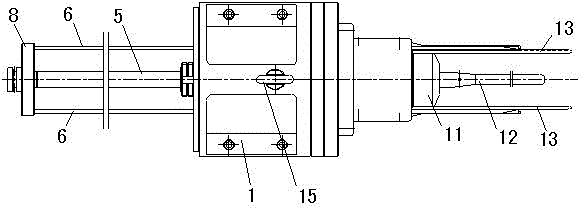

[0014] as attached figure 1 , 2 Shown is the wire embedding die for wire embedding machine according to the present invention, which includes a box body 1, a push rod sleeve 5, a pull rod 10, and a guide bar 13; the center of the box body 1 is provided with a mandrel 4; the core A material storehouse 2 is arranged rotatably around the shaft 4; the material storehouse 2 is arranged in the inner cavity of the box body 1; the mandrel 4 is hollow; one end of the push rod sleeve 5 is inserted into the mandrel 4, and connected to one end of the pull rod 10 through the push rod sleeve nut 9, the other end of the pull rod 10 is connected to the copper push head 11, and the outer end surface of the copper push head 11 is provided with a splitting needle 12, so The other end of the push rod sleeve 5 is provided with a push rod constellation 7; the push rod constellation 7 is horizontally provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com