Water-cooling bending mould for automobile accessory machining

A technology for auto parts and molds, which is applied in the field of water-cooled bending molds for auto parts processing, which can solve the problems of difficult control of the size of the bent plate, low production efficiency, and low precision of the bent plate, and achieve flexible and controllable pressing and flexible use Convenience and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

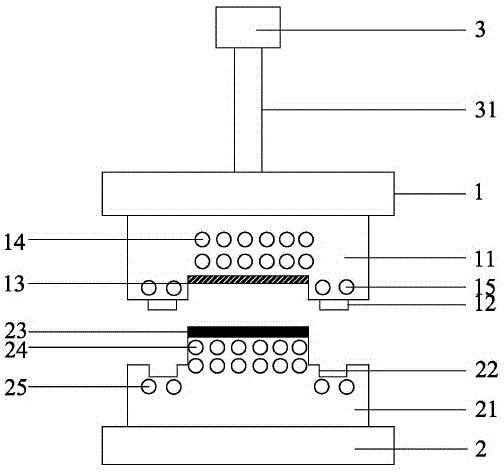

[0014] figure 1 It shows the water-cooled bending mold for auto parts processing provided by the present invention, which is characterized in that the water-cooled bending mold for auto parts processing includes a punch processing part and a punching part placed on the upper end of the punch processing part. The mold processing part is matched with the die processing part, the punch processing part includes the lower fixed plate 2, the punch mold 21 fixed on the upper end of the lower fixed plate 2, and the receiving platform of the punch mold 21 is provided with a The limit groove 22 in the limit; the cooling channel I24 for cooling is provided at the end of the punch mold 21 near the top carrying platform, and the end of the punch mold 21 near the limit groove 22 is provided with an auxiliary Cooling water channel I25; the die processing part includes an upper fixed plate 1, a die mold 11 fixed on the lower end of the upper mount plate 1, and the positioning table of the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com