Positioning pressing machine for bi-directionally adjusting clamp position

A two-way adjustment, press-fitting technology, which is applied in workpiece clamping devices, manufacturing tools, metal processing and other directions, can solve the problems of single applicability and lower efficiency of press-fitting machines, and achieves improved applicability and efficiency, simple structure and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

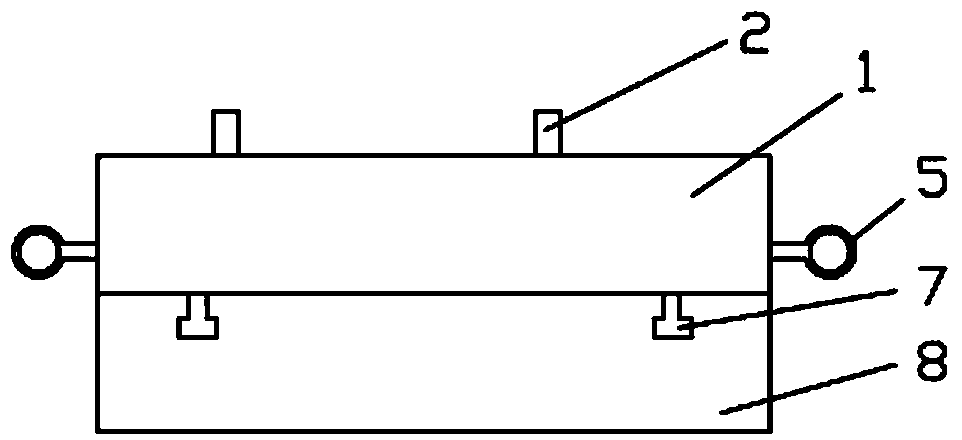

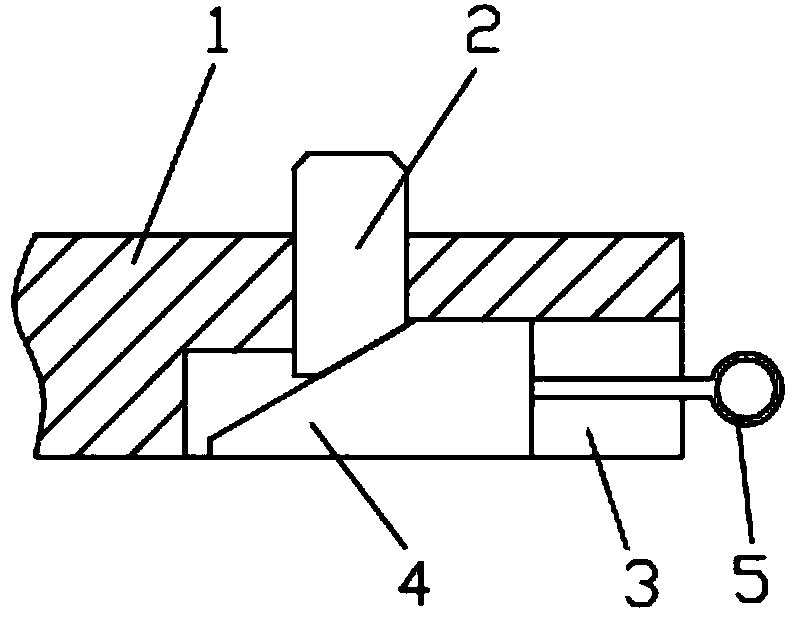

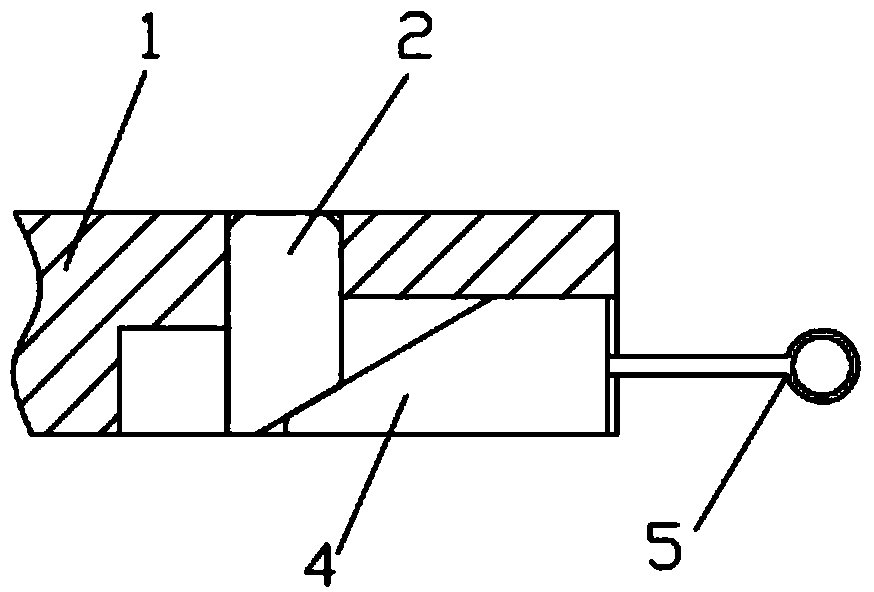

[0015] Figure 1 to Figure 5 It shows the positioning and pressing machine with two-way adjustment of the clamp position provided by the present invention, including a frame and a positioning clamp located on the frame, and the positioning clamp includes a worktable panel 8, a clamp bottom plate 1 located on the worktable panel 8, and positioning pins 2 , the workbench panel 8 is fixed on the frame; the top surface of the fixture bottom plate 1 is provided with a pin hole, the positioning pin 2 is installed in the pin hole, and the side of the fixture bottom plate 1 is provided with a through groove 3 communicating with the pin hole, and the through groove 3 A wedge-shaped block 4 is arranged inside, and the bottom surface of the positioning pin 2 is an inclined surface and is pressed against the wedge-shaped surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com