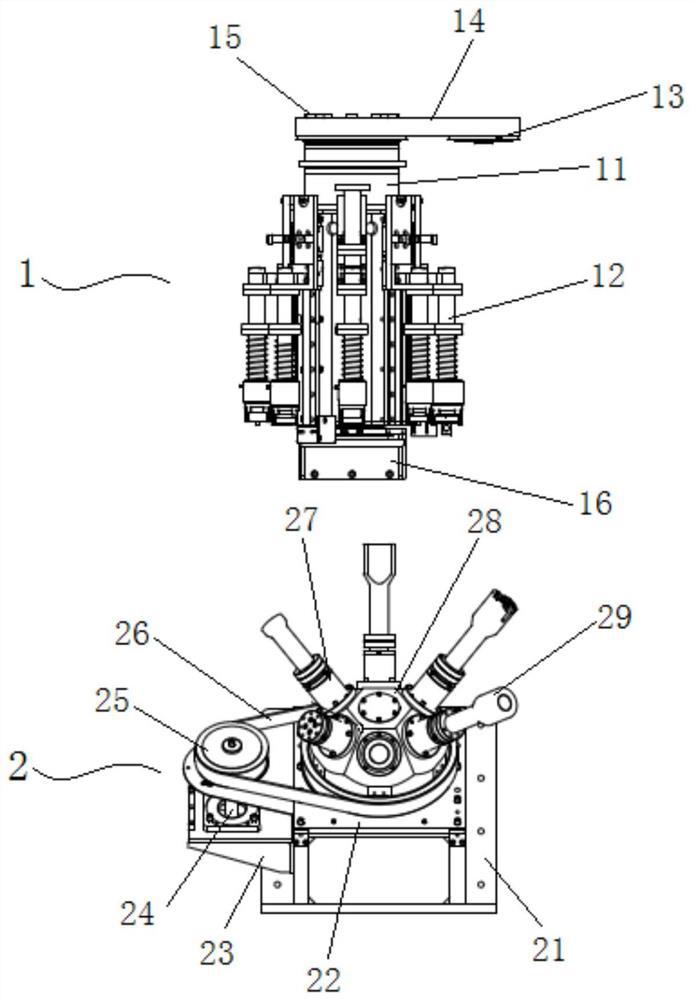

Rotary press-fitting device and press-fitting system

A press-fit device and rotary technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the product variety exceeds the number of indenters and cannot meet the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

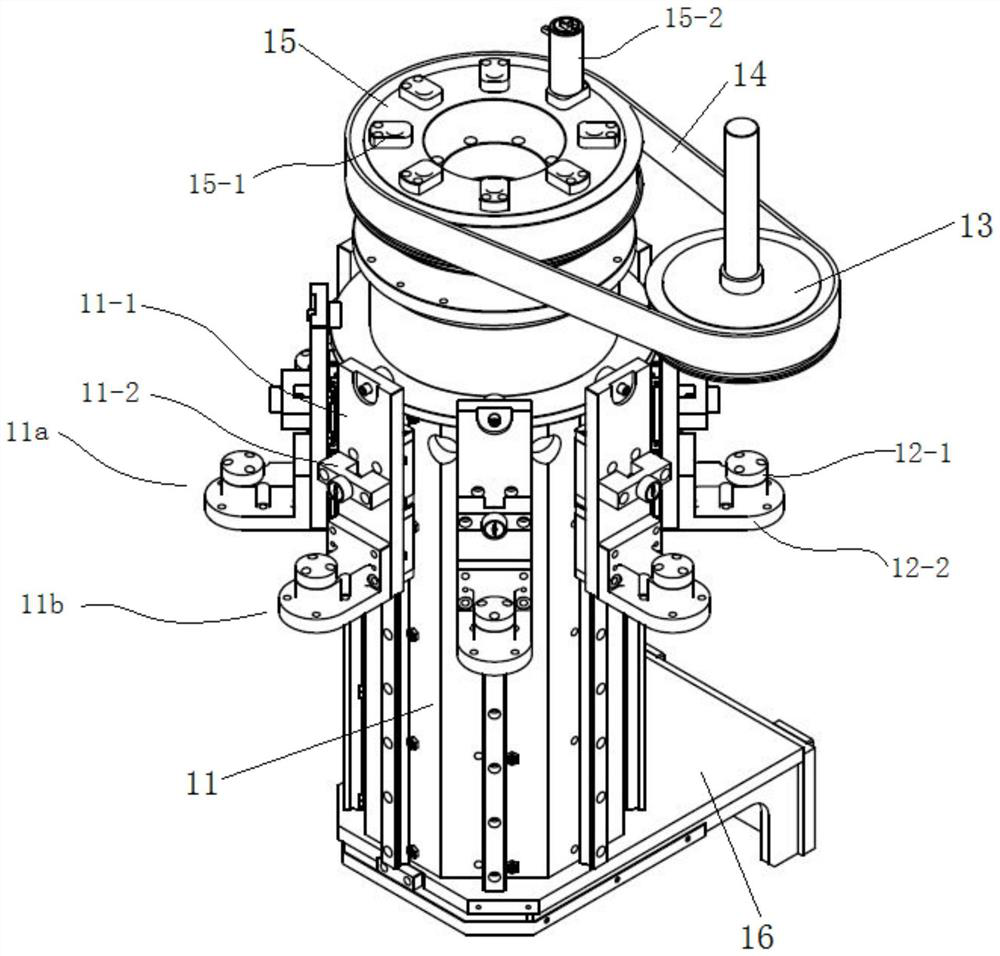

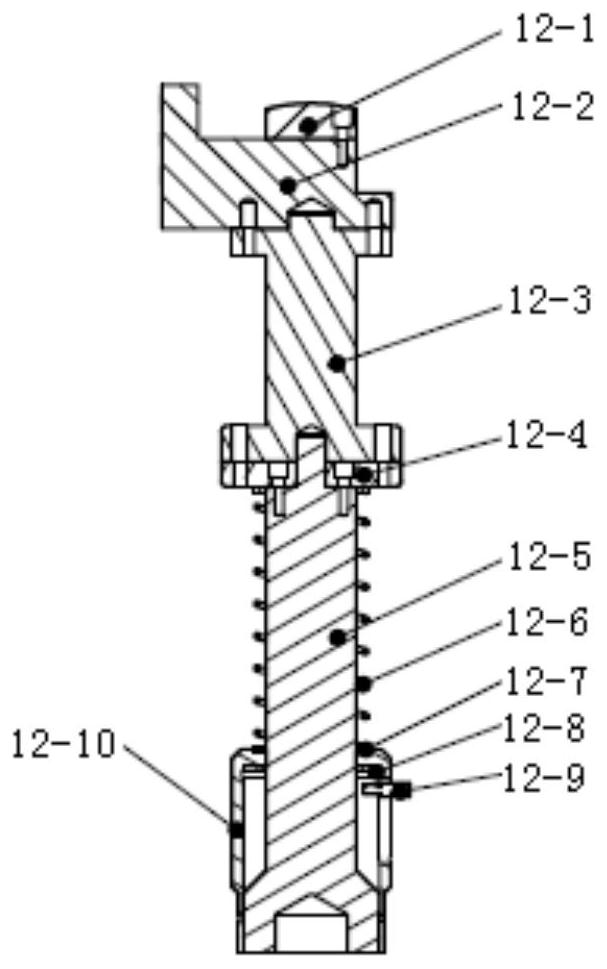

[0029] In order to have a clearer understanding of the disclosed technical features, purposes and effects, the specific implementation manners of the present disclosure will now be described with reference to the accompanying drawings, and the same reference numerals in each drawing represent the same parts.

[0030] For the sake of brevity and intuition in description, the solutions of the present disclosure are described below by describing several representative implementation manners. Numerous details in the embodiments are only used to help the understanding of the solutions of the present disclosure. However, obviously, the technical solutions of the present disclosure may not be limited to these details when implemented. In order to avoid unnecessarily obscuring the solutions of the present disclosure, some embodiments are not described in detail, but only the framework is given. Hereinafter, "including" means "including but not limited to", and "according to..." means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com