Camshaft assembly tooling

A technology for assembling tooling and camshafts, which is applied in the direction of cams, assembly machines, manufacturing tools, etc., can solve problems such as lowering production efficiency, difficulty in meeting high efficiency requirements, single work performance, etc., and achieve the effect of improving press-fitting accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

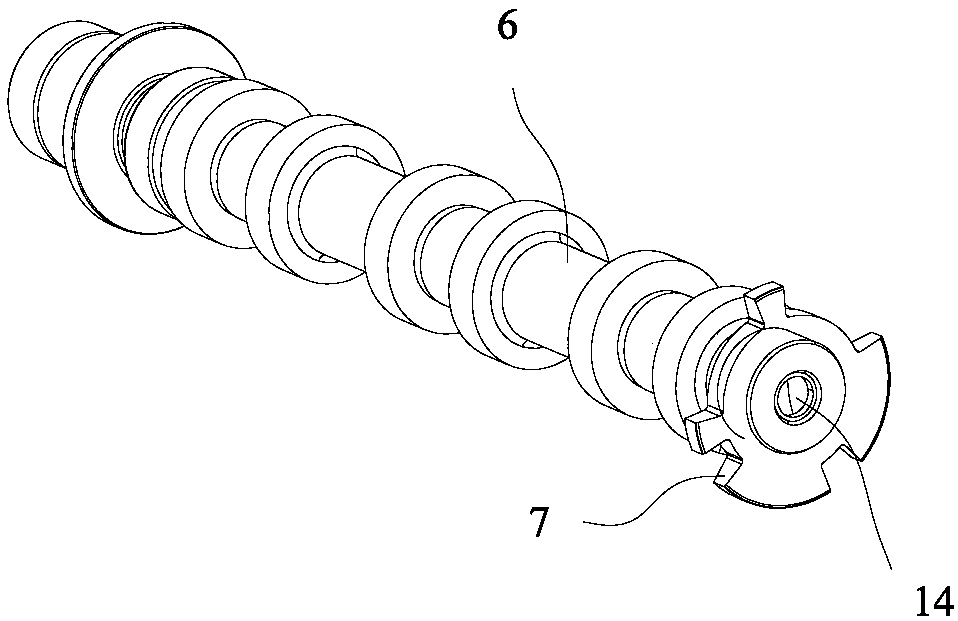

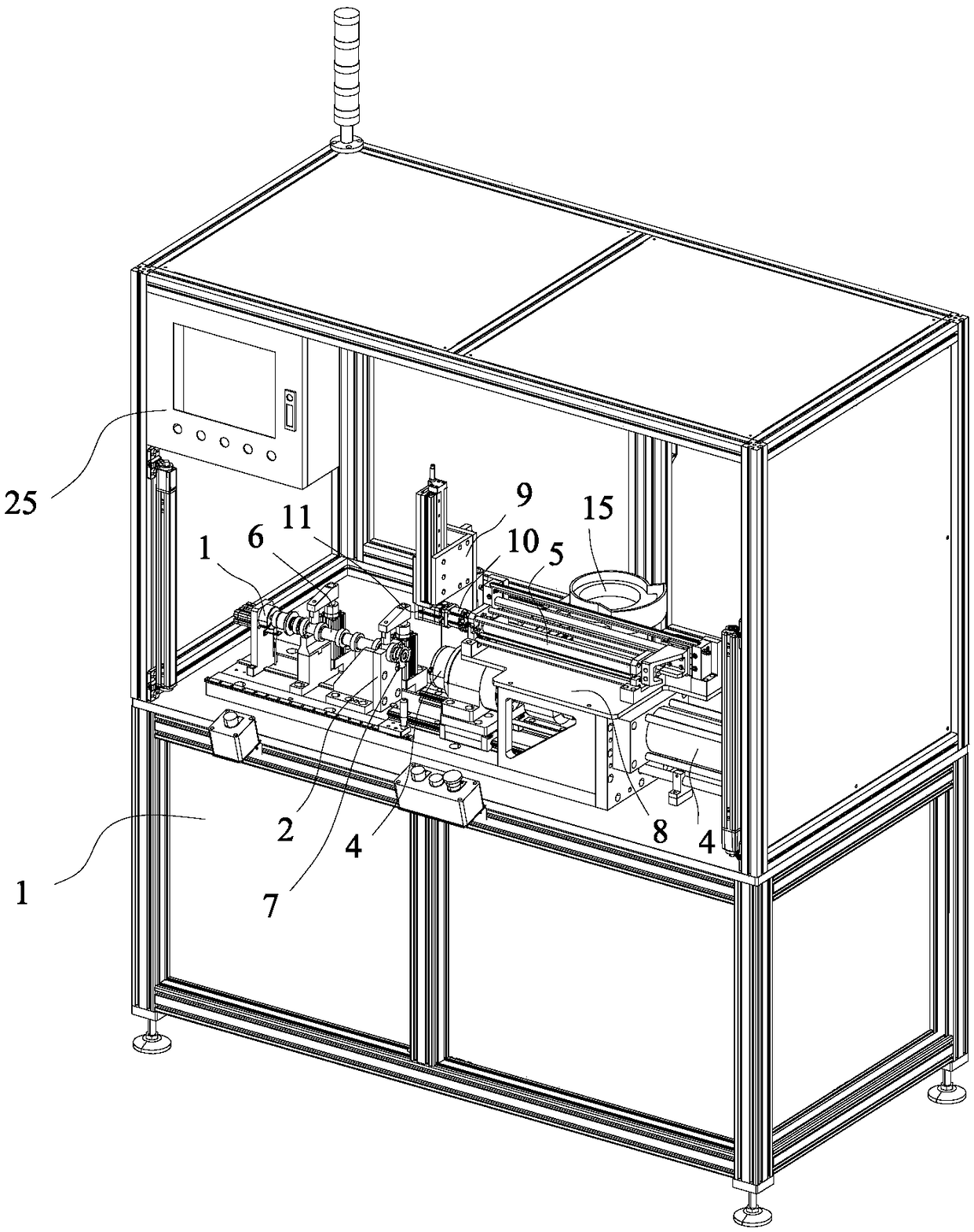

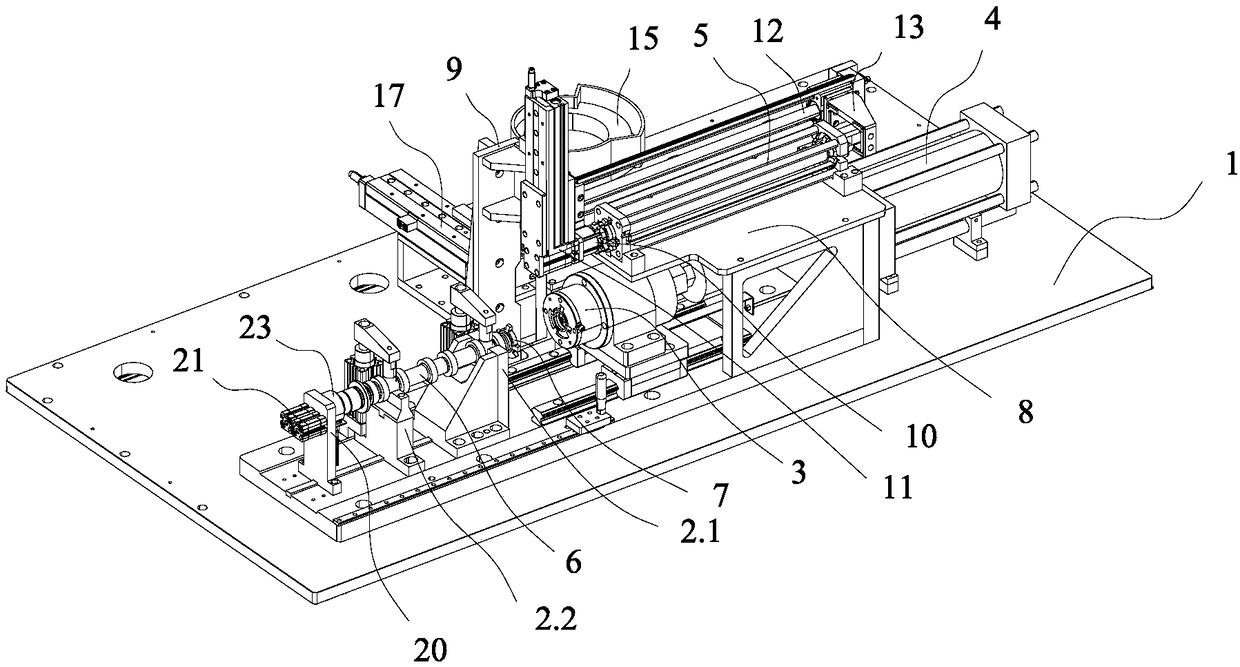

[0044] See attached figure 1 to attach Figure 11 As shown, a camshaft assembly tool includes a base 1; a clamp 2 arranged on the base 1 for fixing the camshaft 6 to be assembled; a signal wheel 7 is placed in advance and the signal wheel 7 is press-fitted on the camshaft 6 The press-fit part 3 is slidably connected to the base 1; the drive press-fit part 3 press-fits the preset signal wheel 7 on the power drive part 4 on the camshaft 6; specifically, the power drive part 4 is a cylinder or an oil cylinder, and the power drive part 4 is fixed on the base 1, and its power output end is connected with the press-fit part 3; the camshaft assembly tool also includes a first mounting frame 8 and a second Two installation racks 9; be located on the first installation rack 8 and be used to place the material rack 5 of a plurality of signal wheels 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com