Thermostat-shell press-fitting device and operating method

A press-fitting device and thermostat technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as uneven stress, reducing the service life of press-fitting device parts, and damage to the thermostat shell, etc. Achieve the effect of improving the precision and effect of pressing, facilitating disassembly and installation, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

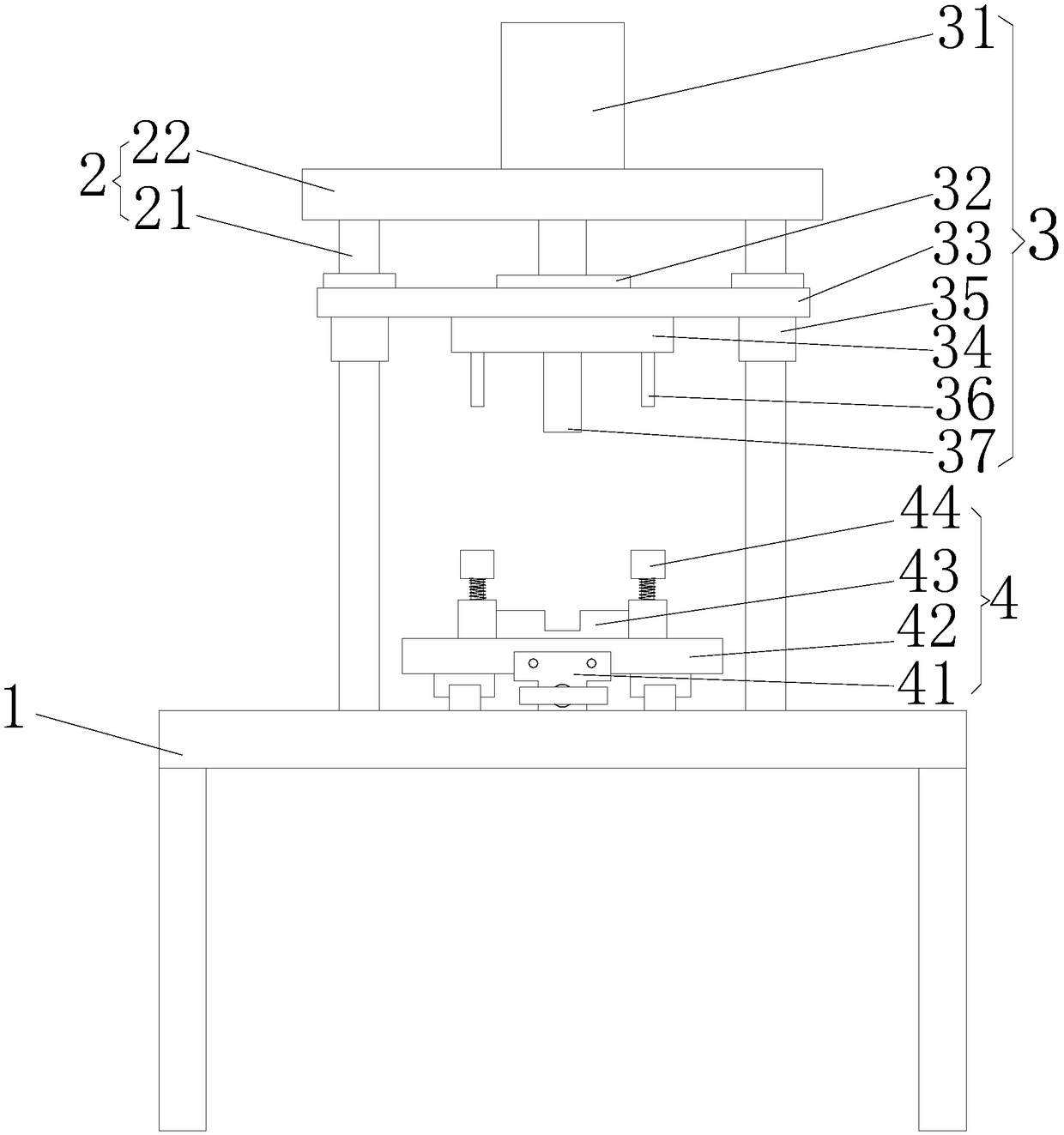

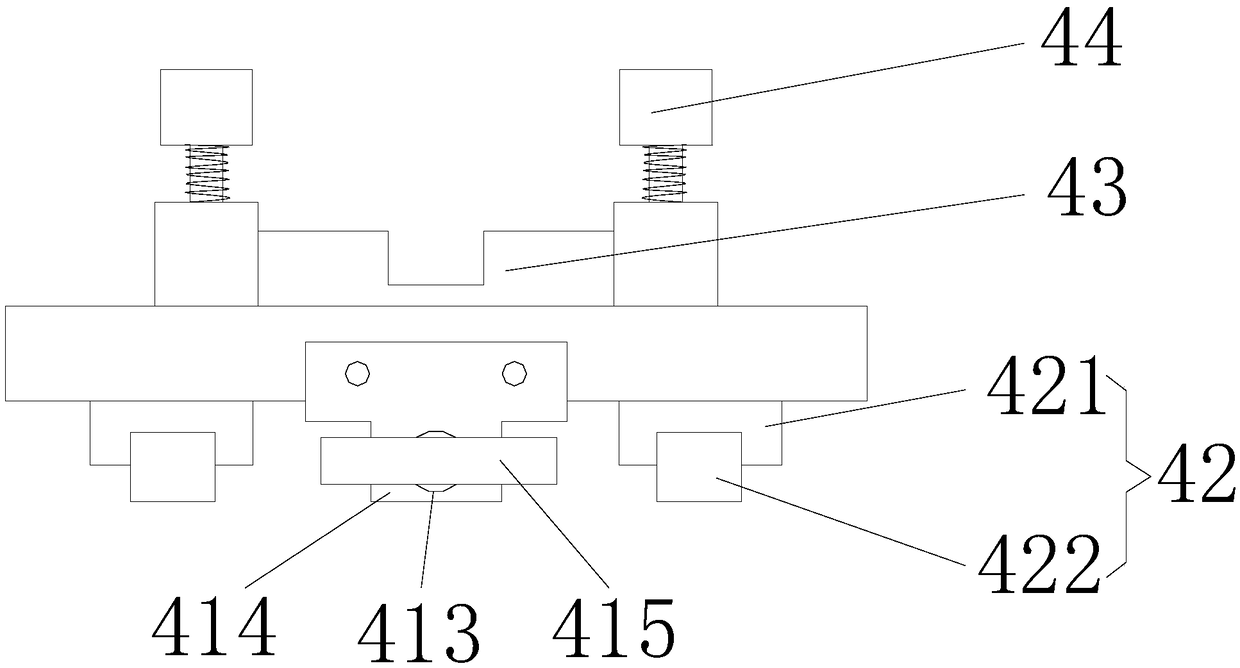

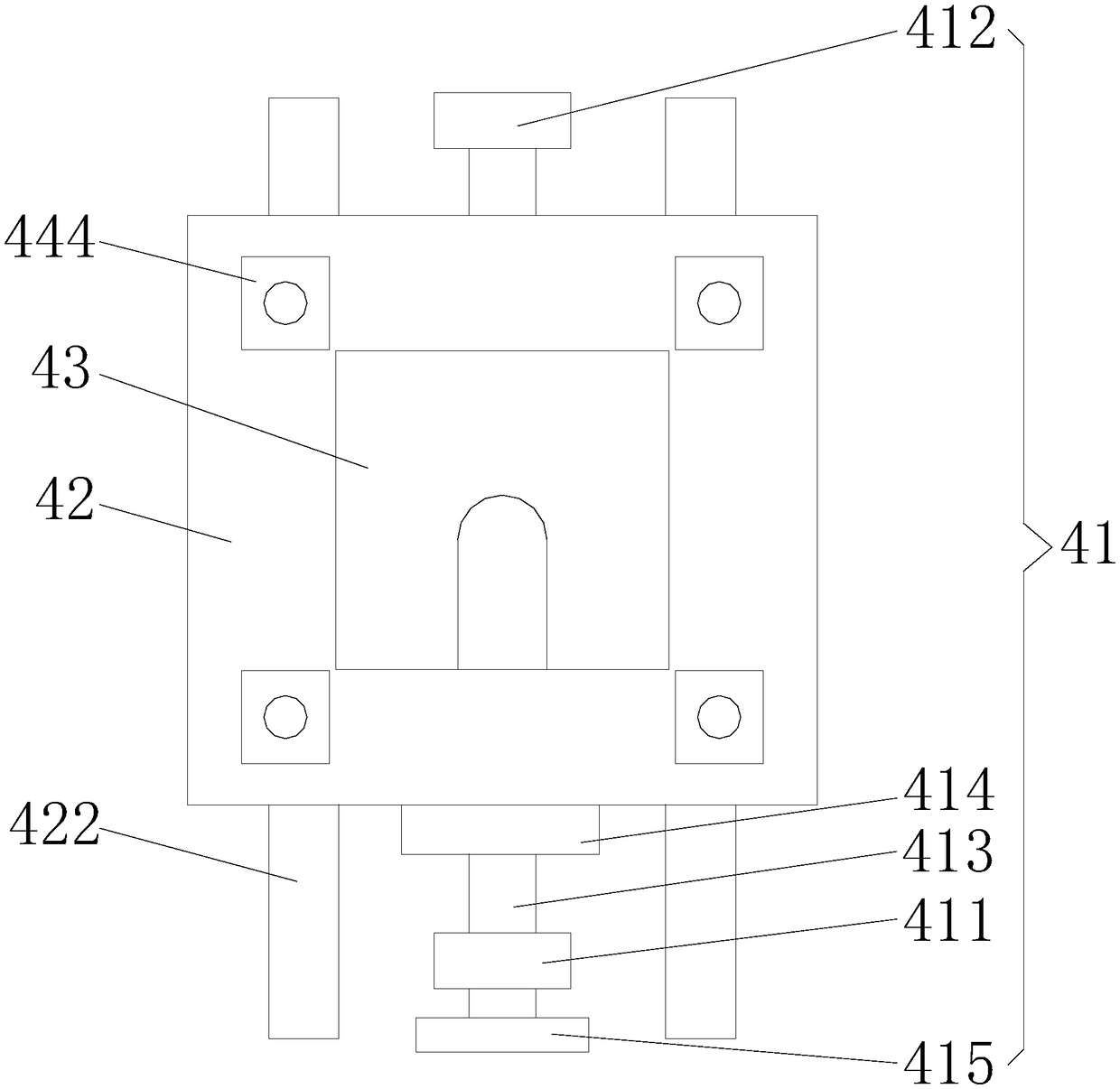

[0033] refer to figure 1 , this embodiment discloses a press-fit device for a thermostat housing, including a support 1, a support mechanism 2, a press-fit mechanism 3 and a fixing mechanism 4, the support mechanism 2 and the fixing mechanism 4 are fixed on the support 1, The pressing mechanism 3 is fixed on the supporting mechanism 2 .

[0034] The support 1 is a flat support with four legs, but it is not limited to this, as long as it can support the structure of the supporting mechanism 2, the pressing mechanism 3 and the fixing mechanism 4.

[0035] The supporting mechanism 2 includes four sliding guide columns 21 and a support plate 22, the sliding guide columns 21 are respectively distributed along the four corners of the support 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com