Drilling, pressing and riveting machine tool

A technology of machine tools and drilling pressure, which is applied to other manufacturing equipment/tools, devices for coating liquid on the surface, manufacturing tools, etc., can solve problems such as high labor intensity, low work efficiency, and difficult quality assurance, and reduce labor intensity , Improve the effect of quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

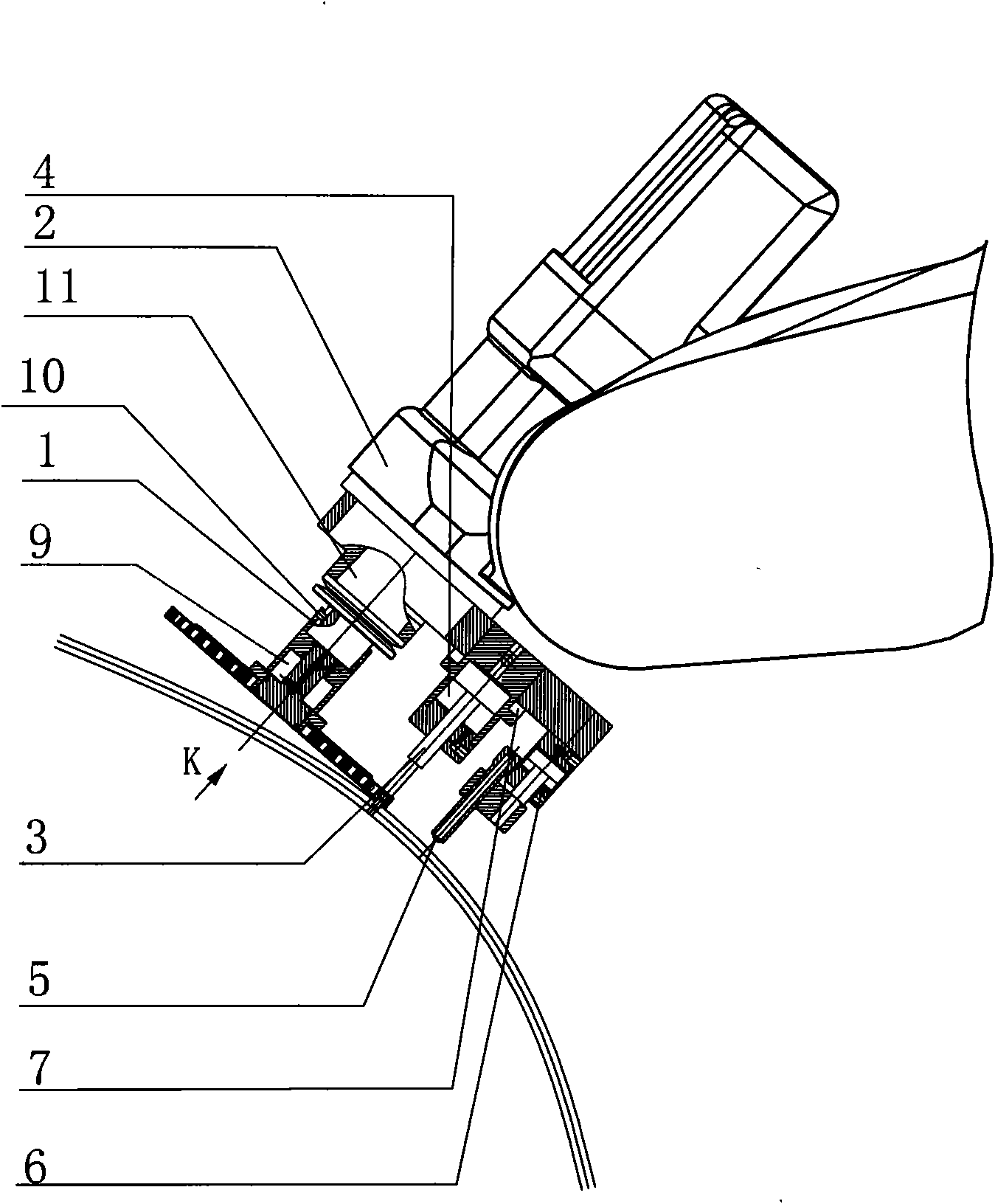

[0025] work process:

[0026] Gluing process: by the attached image 3 As shown, first supply air to the P port 17 of the gluing cylinder, so that the gluing nozzle protrudes, drive the machine tool to align the gluing nozzle with the counterbore position, connect a tube to a device for supplying glue in a small amount, and start the device. The glue will pass through the gluing nozzle and be applied to the position of the counterbore; the 0 port 18 air intake will make the gluing nozzle return to complete the gluing procedure;

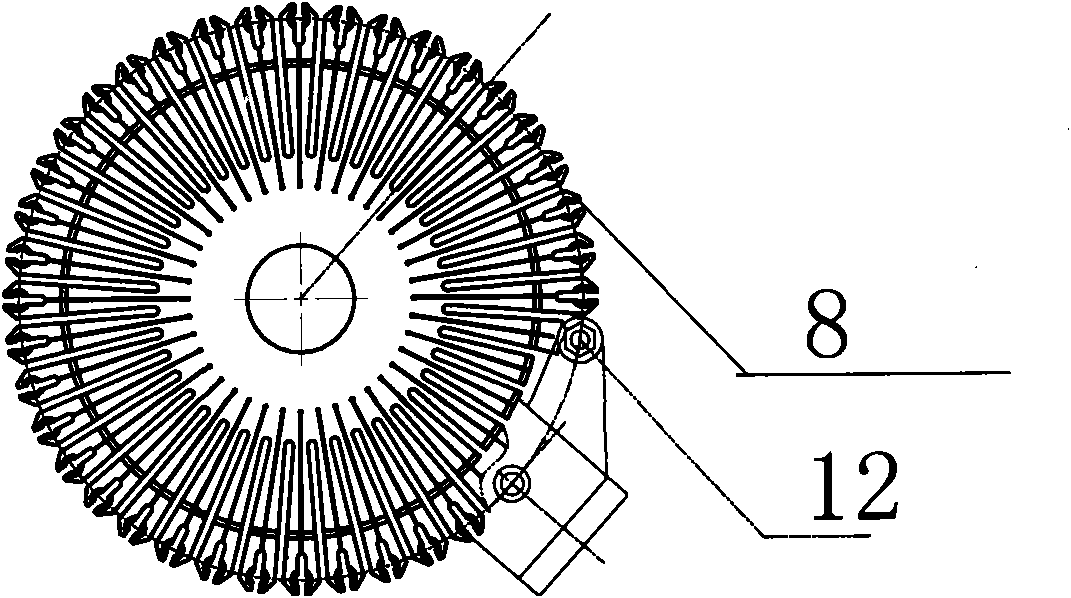

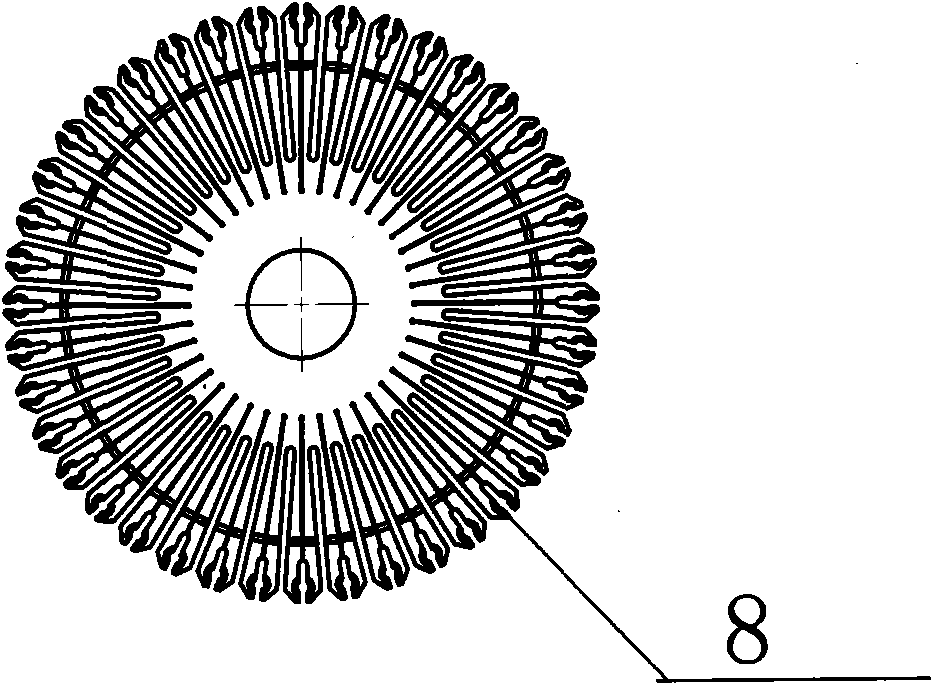

[0027] Nail pressing process: by attached Figure 4 As shown, a clamping disc device that can clamp several rivets or screws is used to provide nail feeding. The clamping disc is made of elastic material, and the clamping hole is slightly smaller than the diameter of the clamped bolt (or rivet) in the natural state. , when the big end of the bolt (or rivet) passes through, it is realized by its elastic deformation, and the clamping disc can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com