Rotary press fit tool and press fit method for plastic exterior trimming part

A technology of exterior decoration and rotary pressing, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low work efficiency, increased equipment cost, and increased occupied area, so as to improve work efficiency and space Utilization rate, the effect of saving manpower and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

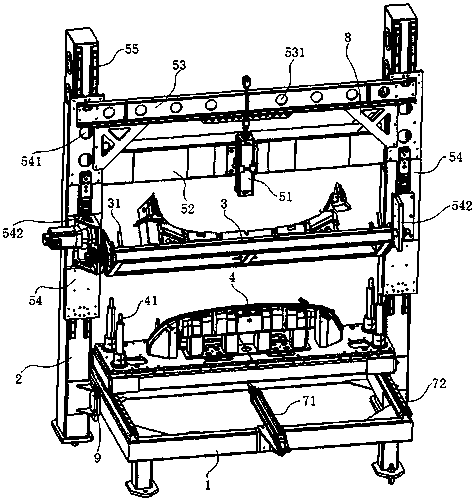

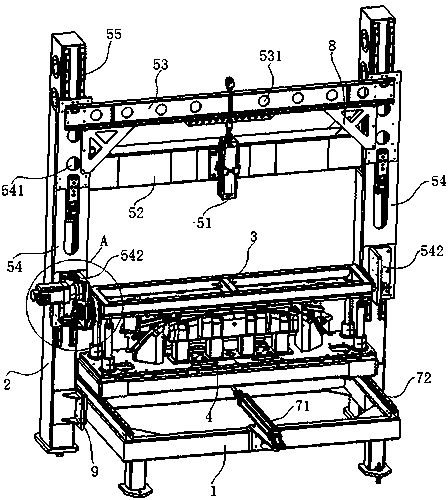

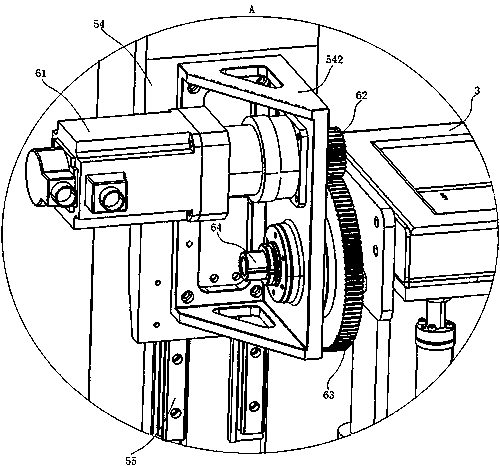

[0030] combine figure 1 , figure 2 and image 3 , a rotary pressing tooling for plastic exterior parts in this embodiment, comprising a base 1, two columns 2 respectively located on the left and right sides of the base 1, an inner panel workbench 4 and an outer panel workbench 3, wherein the inner panel workbench The platform 4 is set on the base 1, the outer panel workbench 3 is located directly above the inner panel workbench 4, and the outer panel workbench 3 is arranged between two upright columns 2 through a lifting mechanism, and the lifting mechanism includes two lifting The sliding plate 54 and the driving mechanism that drives the two lifting sliding plates 54 to move synchronously, the two lifting sliding plates 54 are slidably arranged on the corresponding columns 2 through the lifting slide rails 55 respectively, and the two lifting sliding plates 54 are provided with mounting plates 542 , the two ends of the above-mentioned outer panel workbench 3 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com