Springback prevention bending mold for machining automobile spare parts

An auto parts, anti-springback technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult control of bending plate size, low production efficiency, low bending plate precision, etc., to achieve flexible and reliable pressing Control, use flexible and convenient, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

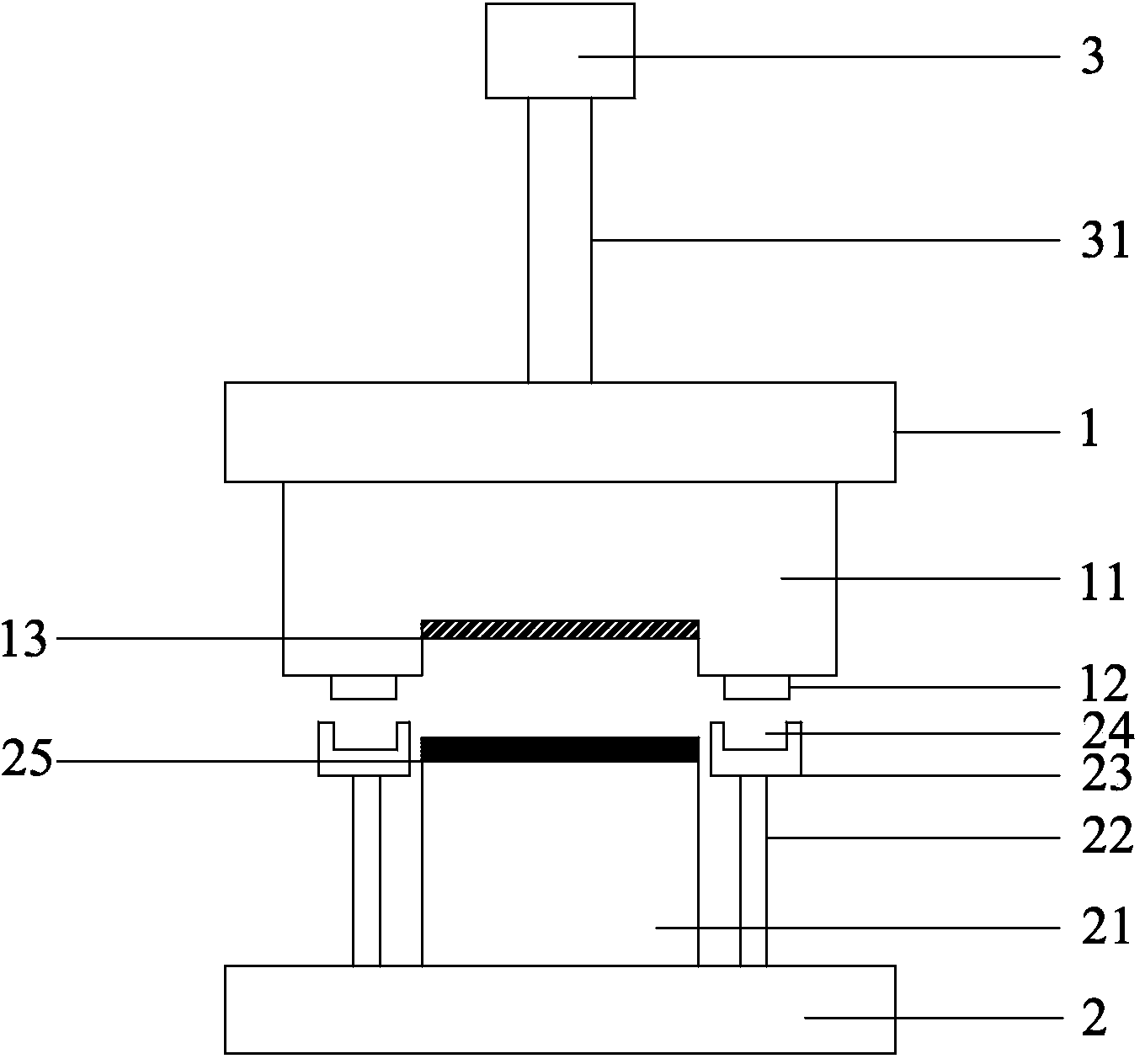

[0017] Such as figure 1 As shown, an anti-rebound bending mold for auto parts processing includes a punch processing part and a concave die processing part that matches the punch processing part placed on the upper end of the punch processing part. The mold processing part includes a lower fixed plate 2, a punch mold 21 fixed on the upper end of the lower fixed plate 2, and a buffer receiving portion is provided on both sides of the punch mold 21, and the buffer receiving portion includes a retractable pillar 22 1. The receiving platform 23 fixed on the upper end of the pillar 22, the receiving platform 23 is provided with a positioning groove 24, and the initial position of the receiving platform 23 is on the same horizontal line as the top platform of the punch mold 21;

[0018] The die processing part includes an upper fixing plate 1, a die 11 fixed on the lower end of the upper fixing plate 1, the positioning table of the die die 11 is provided with a groove for matching w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com