Motor pin shearing and gear press-fitting device and method

A press-fitting device and pin technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to guarantee pin height consistency, unusable pins, low work efficiency, etc., and achieve pin height consistency , the pass rate improvement, the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

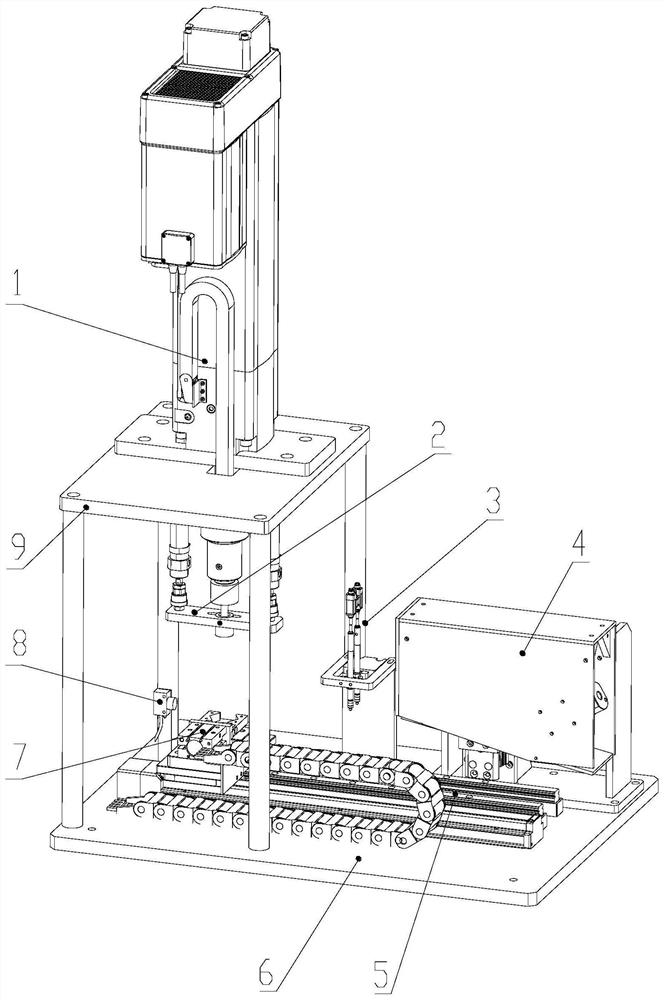

[0040] refer to Figure 1-11 , this embodiment provides a motor pin cutting and gear pressing device, including a servo pressing mechanism 1, a gear placement mechanism 2, a pin height detection mechanism 3, a pin cutting mechanism 4, a transfer mechanism 5, Working platform 6, motor clamping mechanism 7, motor sensor 8 and supporting platform 9.

[0041] The transfer mechanism 5 is installed on the working platform 6, and is used to transfer the motor in the motor clamping mechanism 7 to perform gear press-fitting, pin detection and pin cutting processes. The motor clamping mechanism 7 is provided with a jig for motor positioning 73;

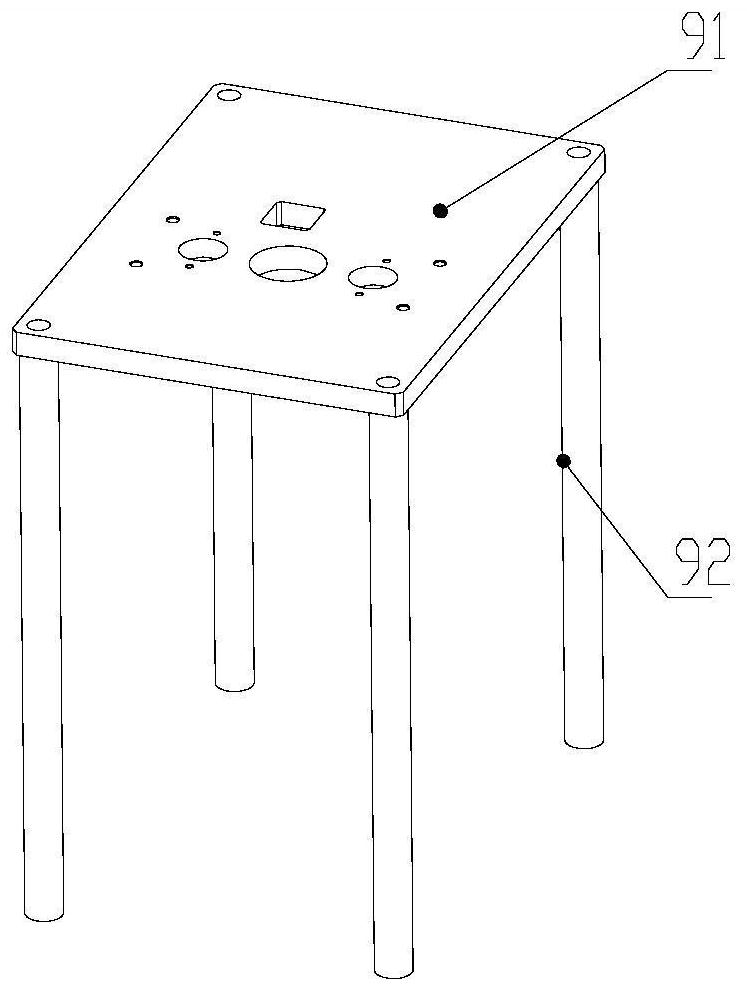

[0042]The support platform 9 is set on the working platform 6, and is used for installing the servo press-fit mechanism 1, the gear placement mechanism 2, the pin height detection mechanism 3 and the motor sensor 8;

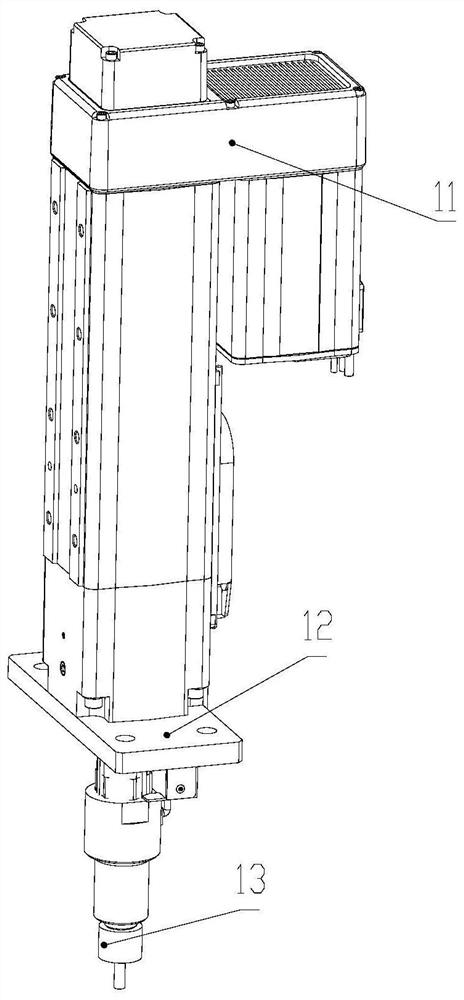

[0043] The gear placement mechanism 2 is arranged below the support platform 9 and facing the motor positioning jig 73, the se...

Embodiment approach 2

[0055] refer to Figure 1 to Figure 11 , the present embodiment provides a motor gear press-fitting and pin cutting method used in embodiment 1, comprising the following steps:

[0056] The first step is to align the motor groove 103 with the limit block in the limit groove 74 and place it in the motor positioning jig 73; the motor sensor 8 detects the motor 10; the air claw 72 is activated to clamp and fix the motor 10 on the motor clamp Hold mechanism 7 on. At this time, the position of the transfer plate 51 where the motor 10 is located is the first station;

[0057] In the second step, the electric push cylinder 54 drives the transfer plate 51 to drive the motor clamping mechanism 7 to enter the pin height detection mechanism 3, the motor shaft of the motor 10 is located in the middle of the two displacement sensors 33, and the measuring heads of the two displacement sensors 33 Stretch out to measure the height of the motor pins and then retract;

[0058] In the third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com