Longitudinal and horizontal two-way adjusting clamp

A two-way adjustment and fixture technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of reducing efficiency and single applicability of fixtures, achieving the effect of simple structure, improving applicability and efficiency, and ensuring press-fitting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

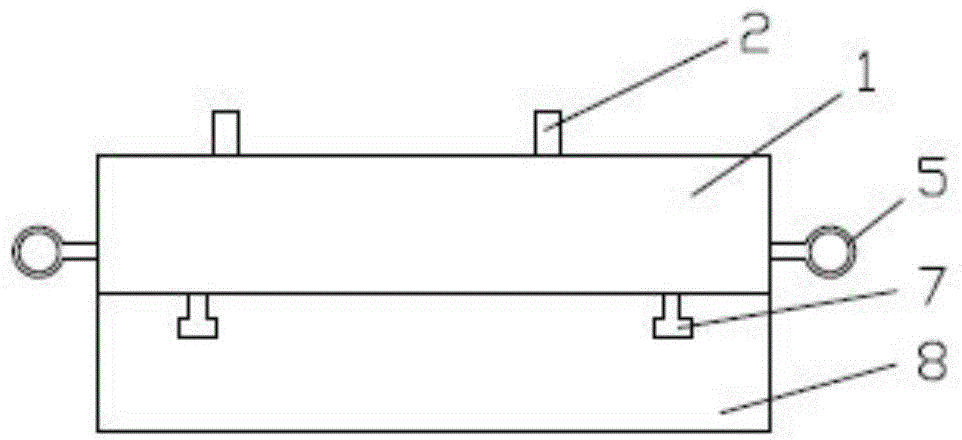

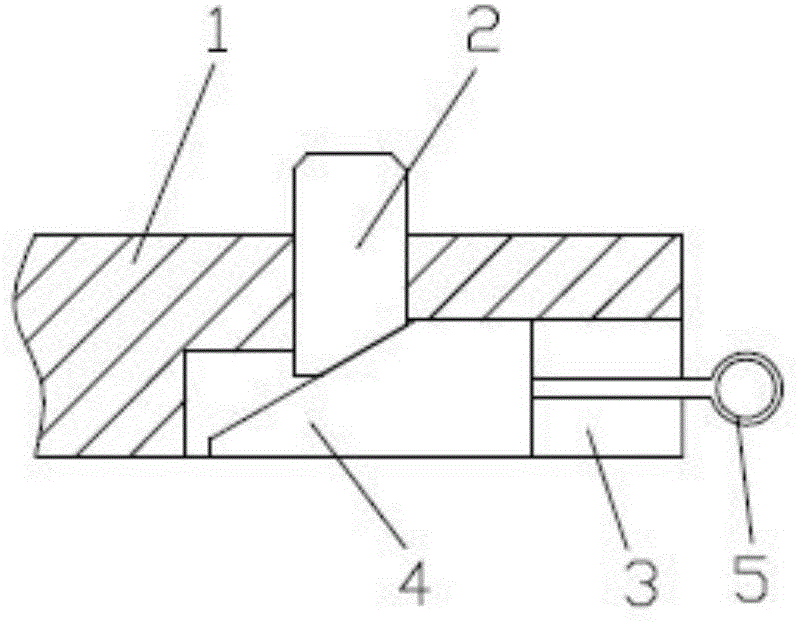

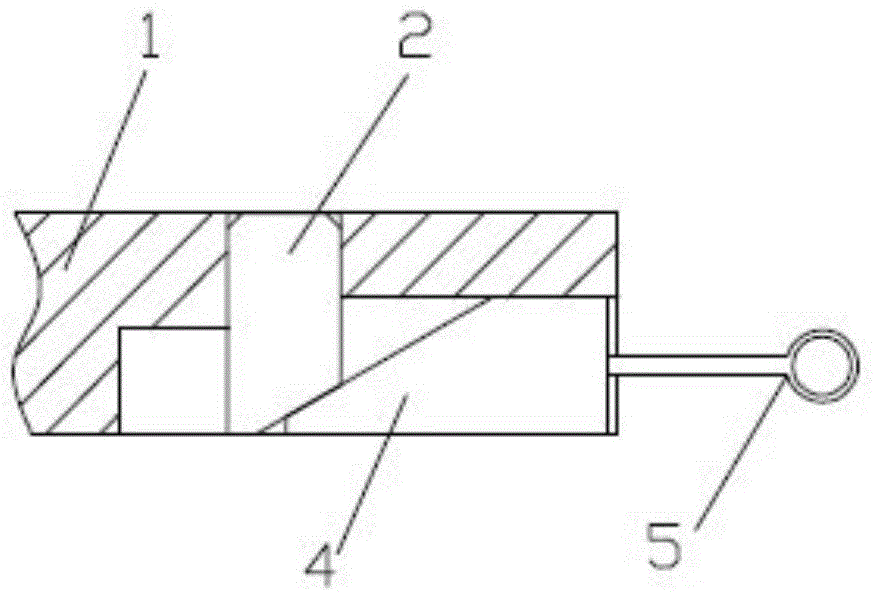

[0015] Figure 1 to Figure 5 It shows the vertical and horizontal two-way adjustable clamp provided by the present invention, including a worktable panel 8, a clamp bottom plate 1 located on the worktable panel 8, and a positioning pin 2. The top surface of the clamp bottom plate 1 is provided with a pin hole, and the positioning pin 2 is installed on the In the pin hole, the side surface of the fixture bottom plate 1 is provided with a through groove 3 communicating with the pin hole, and a wedge block 4 is arranged in the through groove 3. The wedge-shaped surface of the wedge-shaped block 4 matches, the height of the positioning pin 2 is not greater than the thickness of the fixture bottom plate 1, and the end of the wedge-shaped block 4 is provided with a handle 5 protruding from the fixture bottom plate 1; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com