Valve pre-forging constant temperature heating furnace

A constant temperature heating and valve technology, applied in the field of heating furnace, can solve the problems of low thermal efficiency, inaccurate temperature control, etc., and achieve the effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

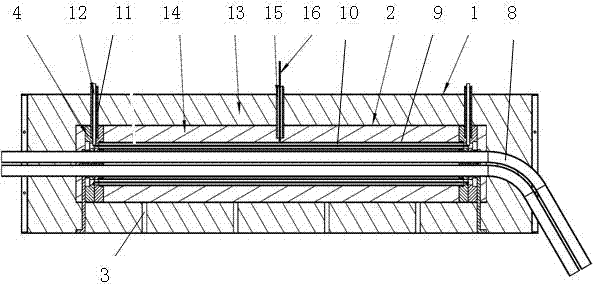

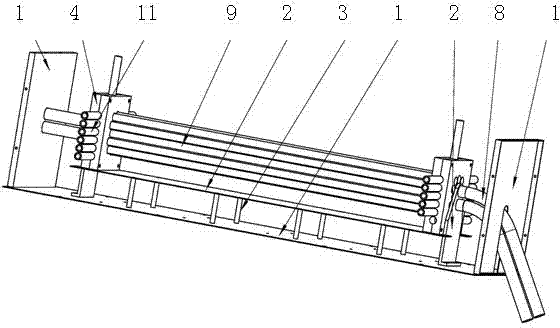

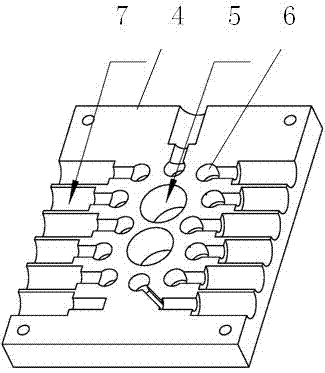

[0018] Such as figure 1 figure 2 image 3 Figure 4 As shown, the valve pre-forging constant temperature heating furnace includes a furnace outer frame 1 and a furnace inner frame 2. The furnace inner frame 2 is set in the furnace outer frame 1 through pillars 3; both ends of the furnace inner frame 2 are provided with a bracket 4 , The center of the bracket 4 is provided with one or more feeding guide holes 5, the periphery of the feeding guide hole 5 is opened with a plurality of furnace wire tube holes 6, and the outside of the furnace wire tube hole 6 is provided with a plurality of cooling rod sleeve grooves 7 (see image 3 Figure 4 ); Through the feed guide hole 5 is provided with a feed guide 8, the two ends of the feed guide 8 respectively extend from the furnace frame 1; through the furnace wire tube hole 6 is provided with a furnace wire tube 9, two of the furnace wire tube 9 The end is embedded in the furnace wire tube installation hole 6, the furnace wire tube 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com