Elevated Temperature Forming Methods for Metallic Materials

a technology of elevated temperature and forming method, which is applied in the direction of metal-working apparatus, electrical apparatus, armour, etc., can solve the problems of difficult formation of certain metals and metal alloys, such as titanium, titanium alloys, nickel-base alloys, etc., and the general difficulty of formation of hard-to-form metallic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

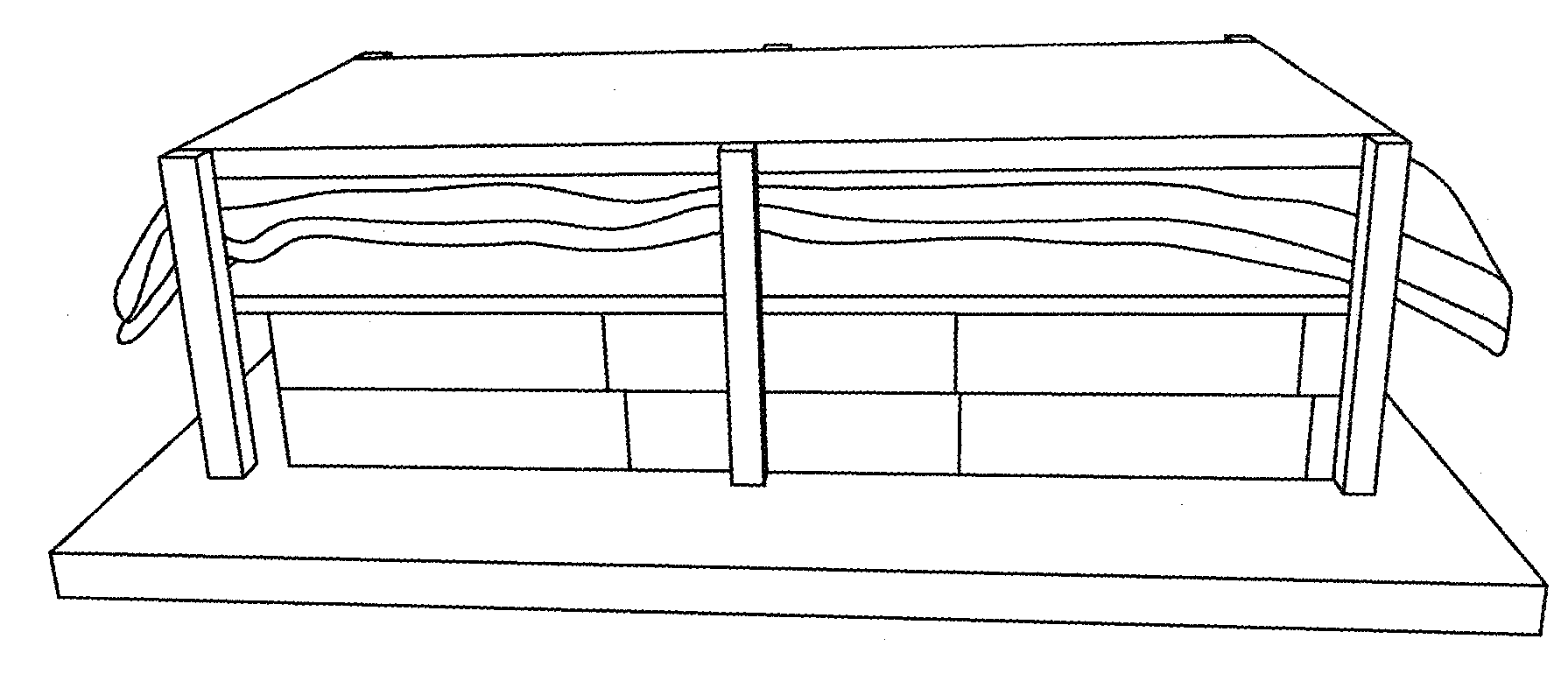

[0097]An induction heating device was constructed in the form of an induction heating table. A photograph of the heating table is provided in FIG. 10. A steel alloy plate having a thickness of 0.5 inch (1.27 cm) was used as the support and the ferrous alloy surface. Legs were welded to the steel plate to support the plate. A copper induction coil was positioned on the underside of the steel alloy plate and adapted to heat a lineal region of the steel alloy plate and thereby heat the ferrous alloy surface of the steel alloy plate. The induction coil was energized with an RF power transformer using a frequency suitable for heating of ferrous alloys such as the steel alloy of the steel alloy plate. The induction heating device may be used to conductively heat localized regions of metallic plates and other articles including hard-to-form metallic materials and other metallic materials. The conductively heated forms may then be bent or otherwise formed, for example, as discussed in conne...

example 2

[0098]A plate of ATI 425 titanium alloy (Ti-4Al-2.5V-1.5Fe-0.25O2 alloy, UNS R54250) having a thickness of 1 inch (2.54 cm) was obtained from ATI Wah Chang, Albany Oreg., an Allegheny Technologies Incorporated company. The plate was hot rolled via conventional mill practices and was received in mill-annealed condition. The plate was sawed into 12 inch by 30 inch samples. The induction heating table described in Example 1 was configured so that a localized lineal region of the ferrous alloy surface was inductively heated to a temperature of 800° F. (428° C.). The titanium alloy plate samples were sequentially positioned on the induction table so that an intended bend line of each sample was positioned over the heated localized region of the induction heating table, and a localized region of each sample was thereby conductively heated. More specifically, a lineal region of each sample, including an intended bend line and an immediately adjacent region, was conductively heated to 800° ...

example 3

[0100]An ATI 425® titanium alloy plate having a thickness of 1 inch (2.54 cm), in the same mill-annealed condition as used in Example 2, was obtained from ATI Wah Chang. The length and width of the plate were 100 inches (2.54 m) by 80 inches (2.032 m). The plate was positioned on the induction heating table described in Example 1, and a lineal region of the plate including an intended bend line and an adjacent region was conductively heated to 800° F. (426° C.) in about 20 minutes. The plate was transferred to a brake press before the heated lineal region of the plate experienced any significant cooling, and the plate was bent to a radius of 2 t along the bend line. The plate was positioned back on the induction heating table and arranged so that a different lineal region including another intended bend line was conductively heated to 850° F. (454.4° C.). The plate was then transferred to a brake press and bent along the bend line to a radius of 2 t before any significant cooling of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com