Automobile hub flange closed type precise die forging method

A technology for precision die forging and automobile hubs, applied in forging furnaces, forging/pressing/hammer devices, furnace types, etc., can solve the problems of poor forming effect, increased material waste, and damaged metal flow lines, etc., to reduce production costs, The product quality is stable and the effect of reducing the trimming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

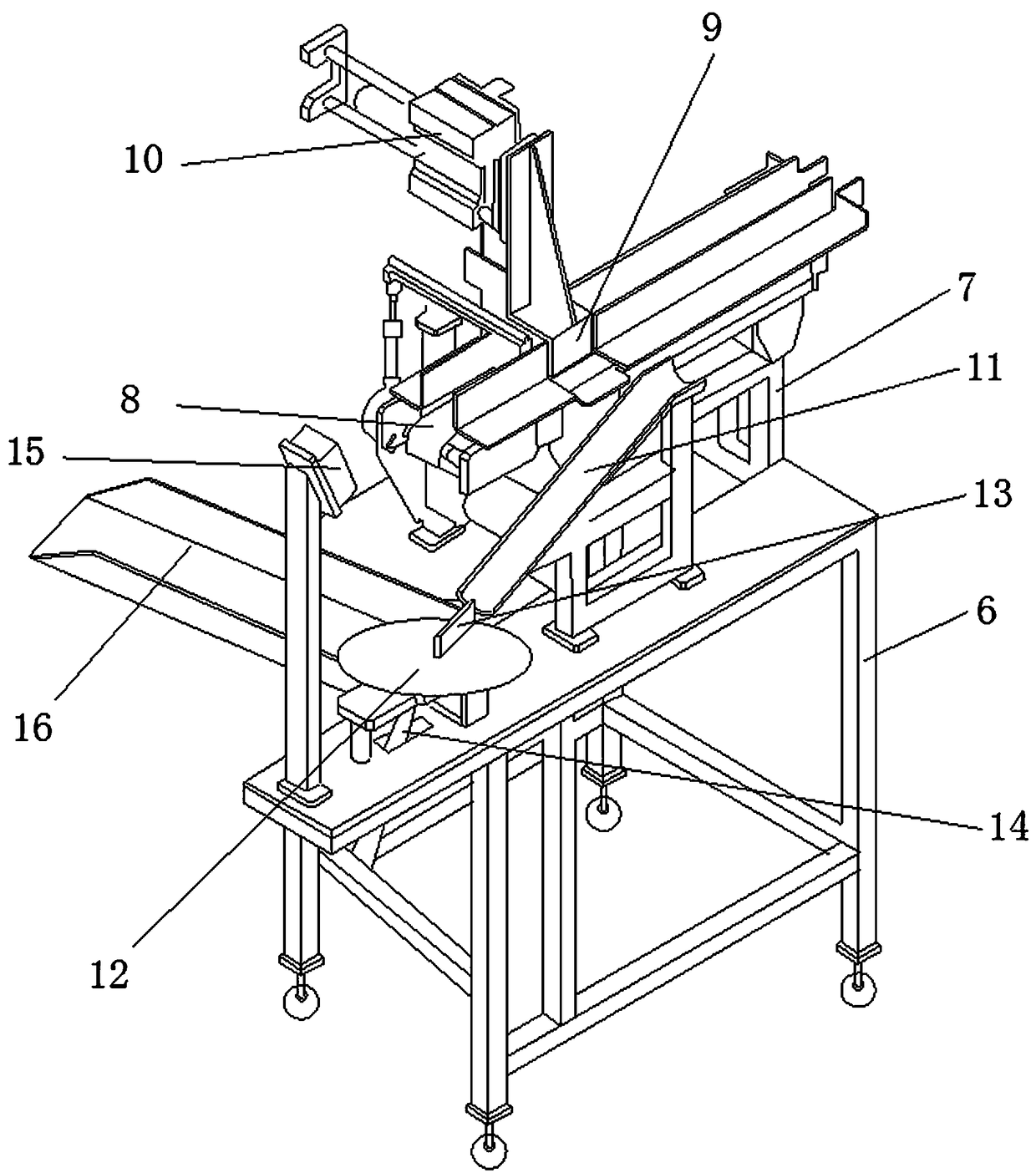

[0034] Embodiment: the automobile hub flange closed precision die forging method of this example is characterized in that described method comprises:

[0035] a. According to the value set on the numerical control mechanism, the metal long bar is cut into suitable specifications such as Figure 9The bar stock 45 shown is transported to the intermediate frequency induction heating furnace by the conveyor;

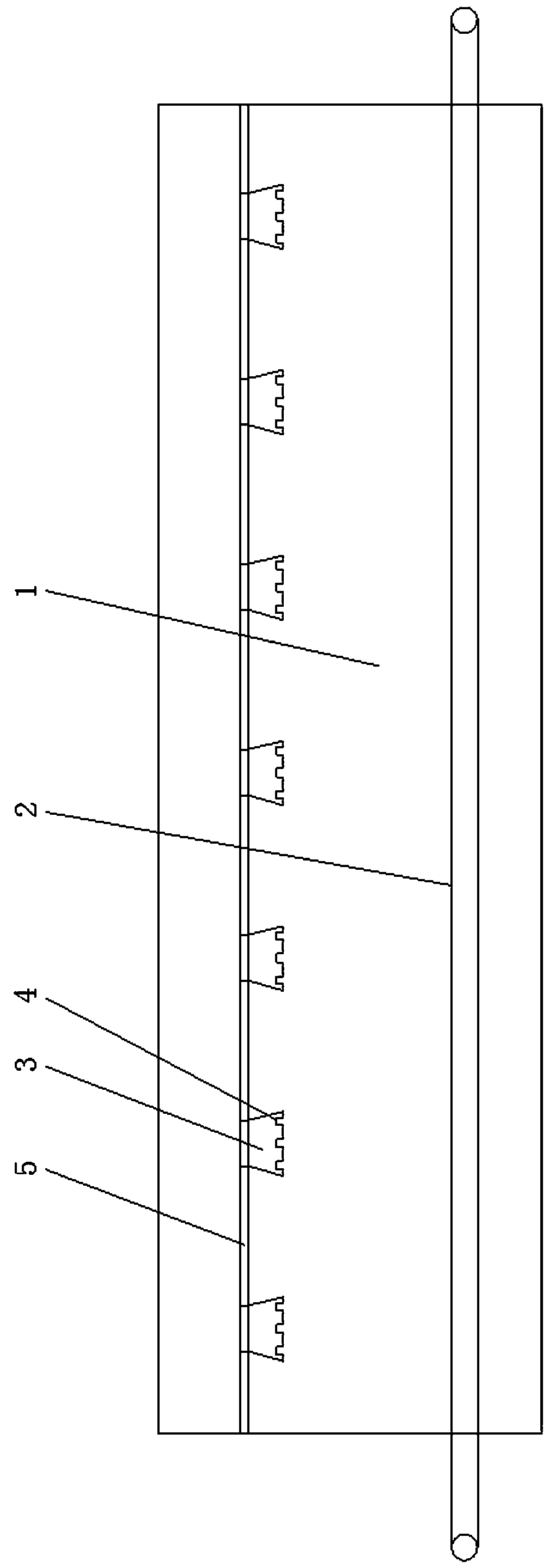

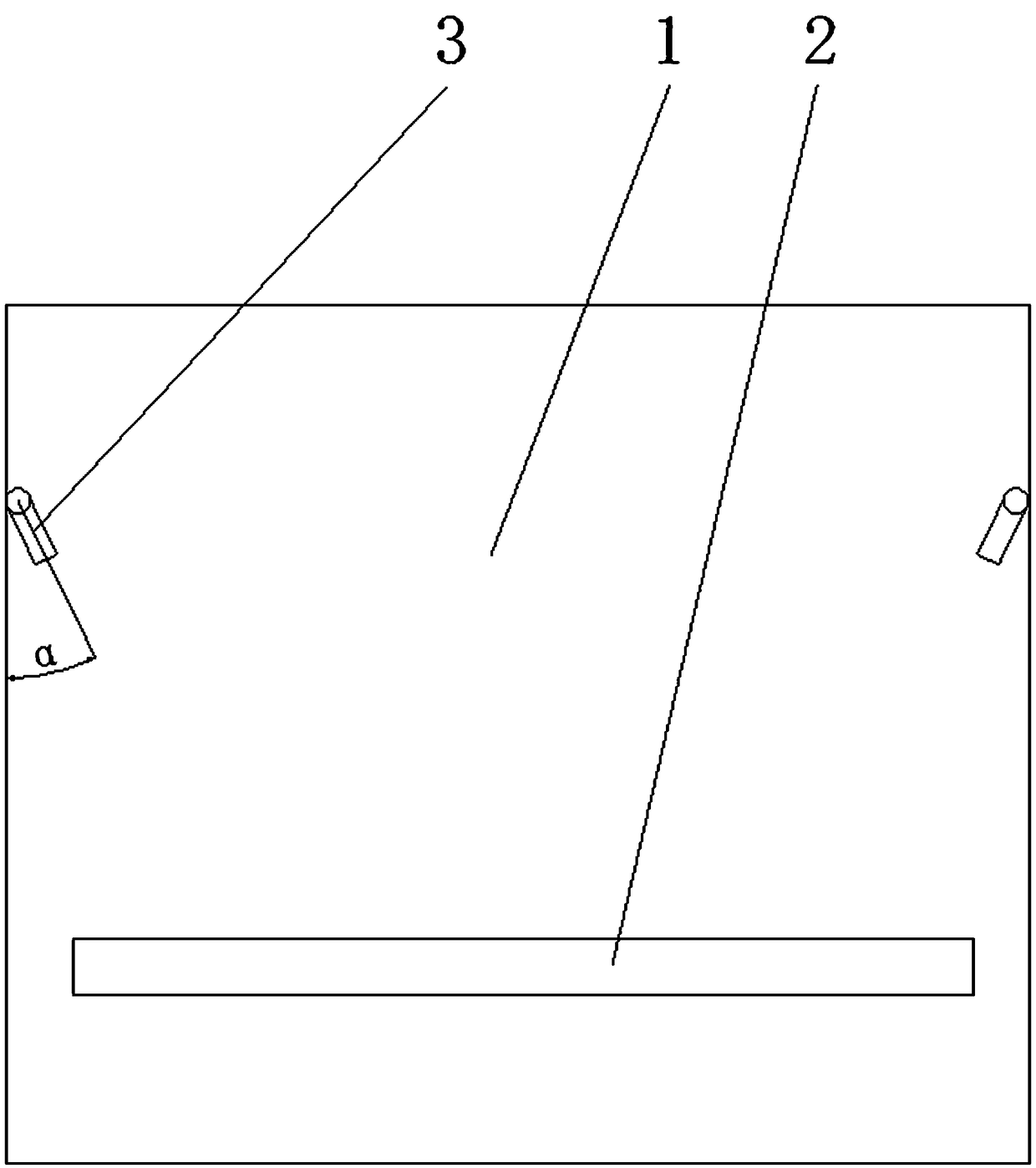

[0036] b. The bar is heated by a medium frequency induction heating furnace, such as figure 1 , figure 2 , the medium frequency induction heating furnace includes a furnace body 1, a heating conveyor belt 2 is arranged in the furnace body, a high temperature resistant fin 3 is hinged on the inner wall of the furnace body, the high temperature resistant fin is inclined downward, and the outer end surface of the high temperature resistant fin is arranged There are several air guide grooves 4, and the high temperature resistant fins are all hinged on an air guide connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com