Automobile control arm forging production line and forging forming technology

A technology for automotive control arms and production lines, applied in the direction of manufacturing tools, forging furnaces, vehicle parts, etc., which can solve the problems of exposure to harmful environments and occupational hazards, energy waste, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

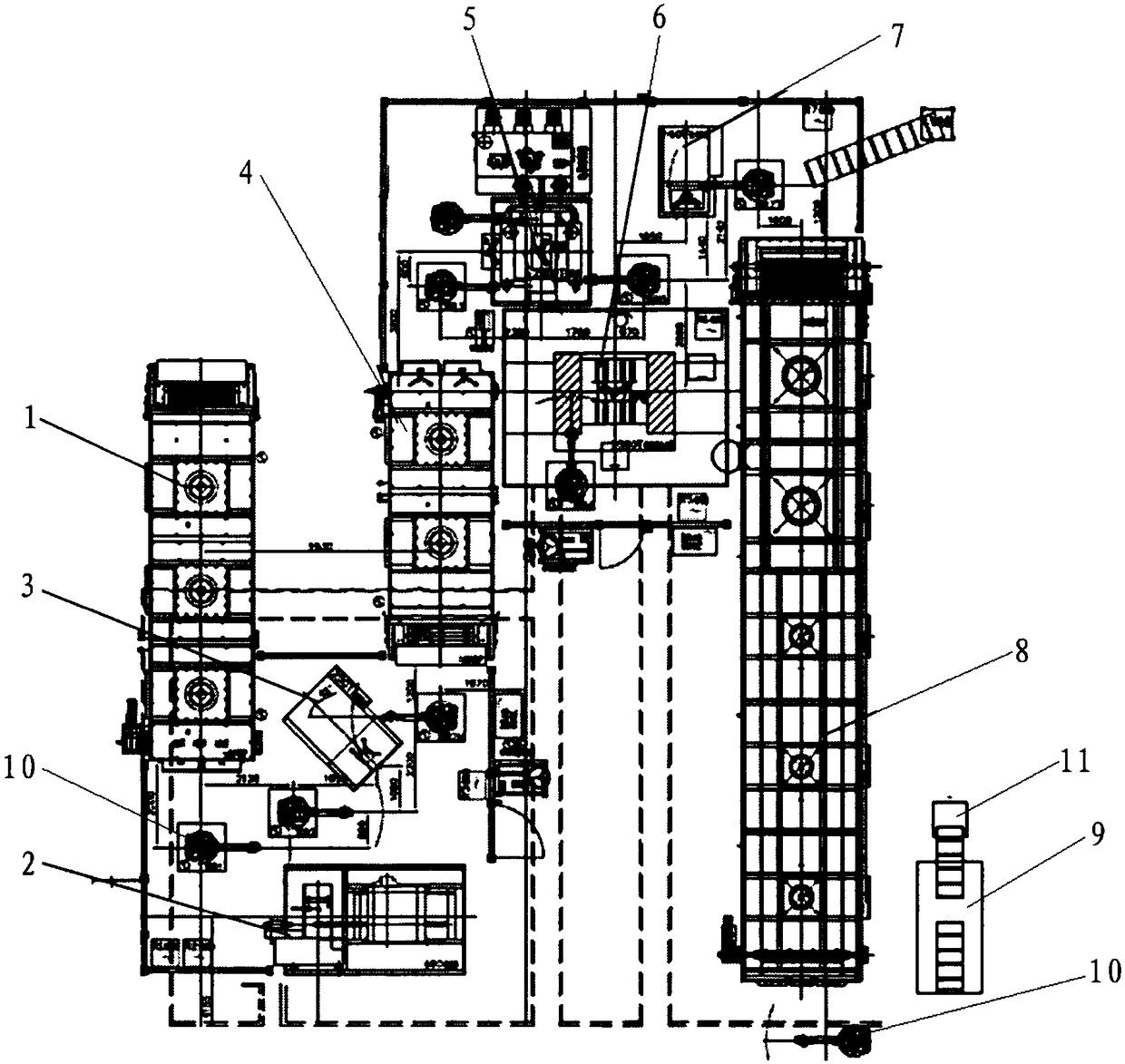

[0088] This embodiment provides a kind of forging production line of automobile control arm, such as figure 1 with figure 2 As shown, the automobile control arm forging production line includes a billet making area, a die forging area and a heat treatment area arranged in sequence according to the production process, and the billet making area, the die forging area and the heat treatment area are arranged in an "S" shape , optimize the layout of the production line according to the production process, save floor space, improve space utilization, and there are multiple manipulators 10 for picking and delivering workpieces between each working area;

[0089] The billet making area includes a first heating furnace 1 and a roll forger 2, the first heating furnace 1 is used to heat the billet, and the billet is transported to the roll forger 2 by the manipulator 10, the The roll forging machine 2 is used for pre-forging and pressing the billet, and transporting the pre-forging an...

Embodiment 2

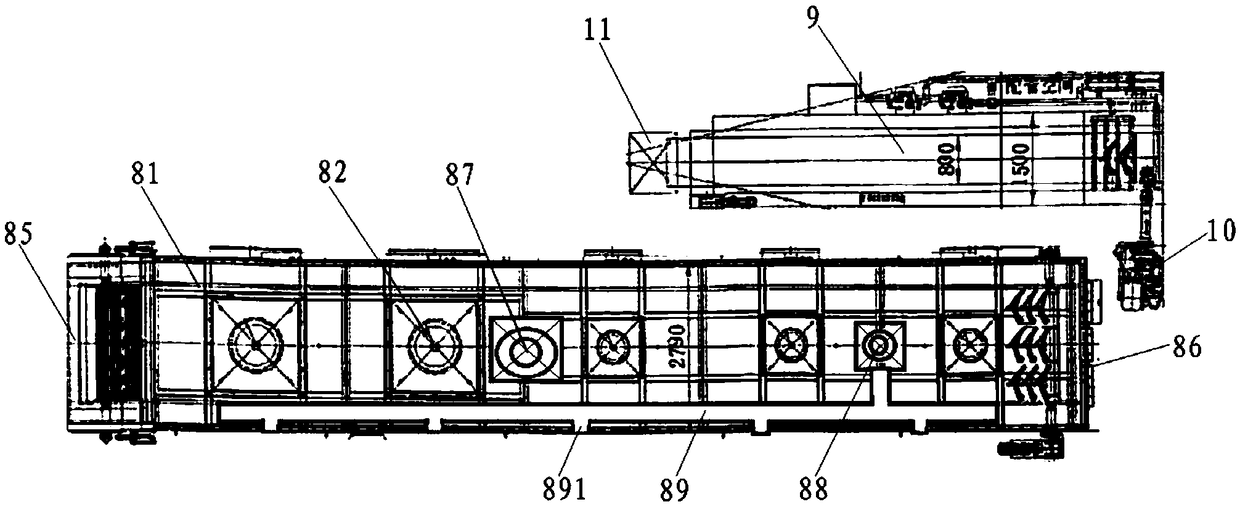

[0129] The structure of the automobile control arm forging production line provided in this embodiment is basically similar to that of the automobile control arm forging production line in Embodiment 1, except for the jet guide structure 83 . Such as Figure 10 with Figure 11 As shown, the jet flow guide structure 83 includes a jet flow plate 831, the jet flow plate 831 is connected to the inner wall of the furnace body 81, and the surface of the jet flow plate 831 is provided with a plurality of elongated jet flow grooves 833, The length direction of the jetting groove 833 is consistent with the conveying direction of the conveying mechanism 84 , a plurality of the jetting grooves 833 are arranged at intervals, and a plurality of the gas ejection ports 8321 are evenly distributed on the bottom of the jetting groove 833 . Adopting the structure of the jet flow groove 833 can effectively increase the amount of gas ejected, further increase the heating speed, and has a simple ...

Embodiment 3

[0132] The structure of the automobile control arm forging production line provided in this embodiment is basically similar to the structure of the automobile control arm forging production line in Embodiment 1, the difference is that the roll forging machine 2, the pre-forging press 5, the final forging Both the press 6 and the shaping punch 7 include an automatic heating system, that is, the above-mentioned equipment can automatically heat its mold when it is working. Preferably, the manipulator includes an automatic lubricating spray system. Before the manipulator grabs the workpiece and puts it into the mold in the next step, the automatic lubricating spray system automatically sprays lubricating spray into the mold, and then The captured workpiece is put into the mold for subsequent demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com