Rotary Dehumidification and Air Conditioning System Using Heat Pipe Heat Recovery and Ultrasonic Enhanced Regeneration

A technology for rotary dehumidification and air conditioning systems, applied in the field of dehumidification systems, can solve the problems of reducing the regeneration temperature of dehumidifiers, energy is not effectively recovered, energy waste, etc., and achieves reduction of heating energy consumption, strong adaptability and operability, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

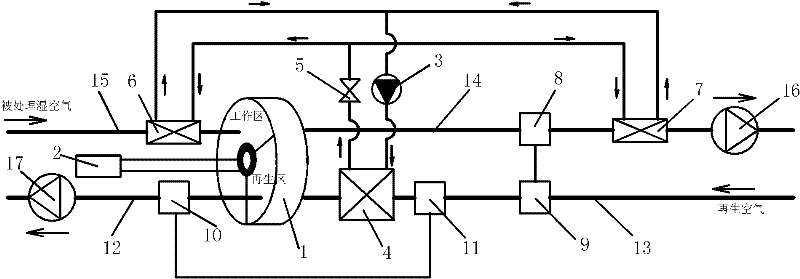

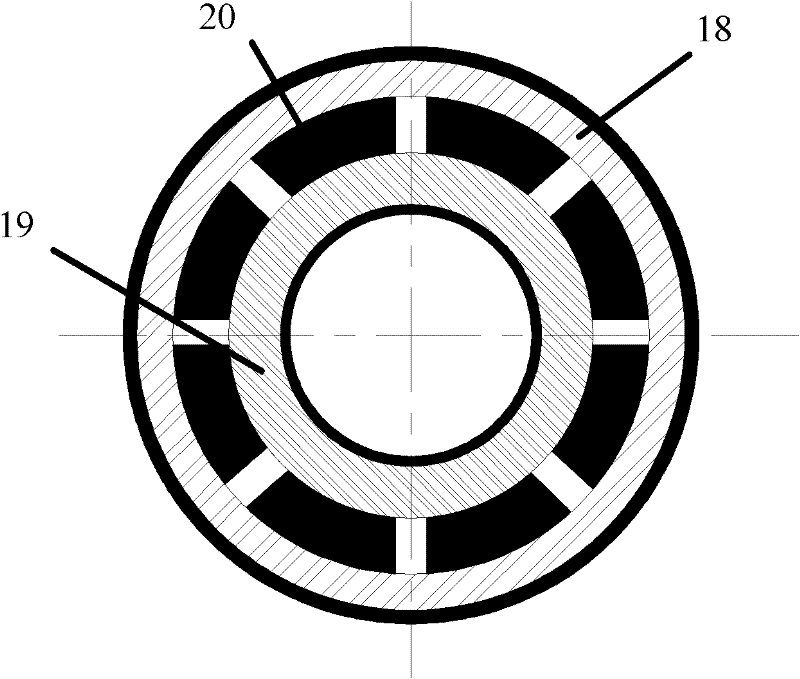

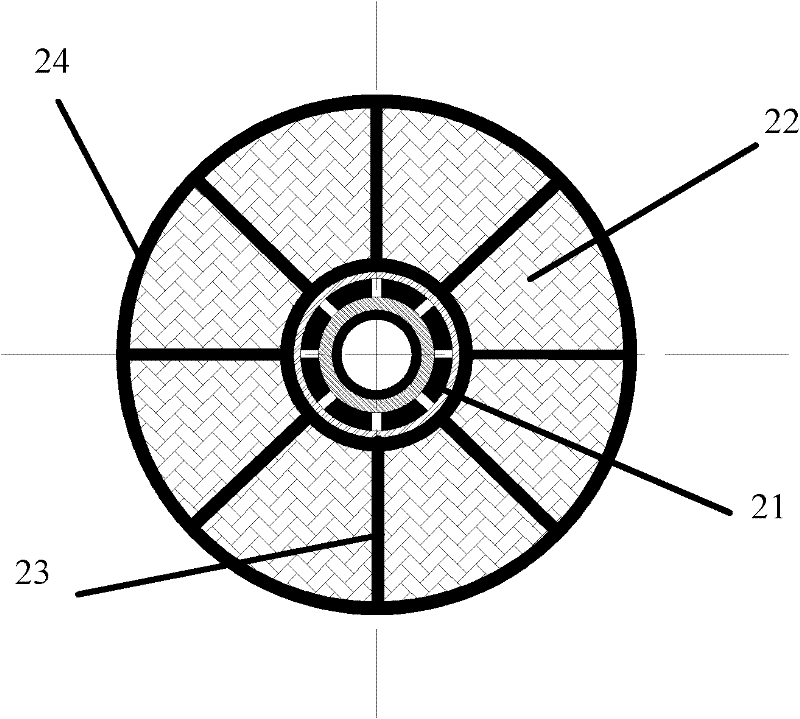

[0017] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the device of the present invention includes an ultrasonic dehumidification wheel 1, an ultrasonic generator 2, a compressor 3, a condenser 4, a throttle valve 5, a first evaporator 6, a second evaporator 7, and the first heat pipe evaporation end 8. The first heat pipe condensing end 9, the second heat pipe evaporating end 10, the second heat pipe condensing end 11, the regeneration air outlet 12, the regeneration air inlet 13, the processing air outlet 14, the processing air inlet 15 , processing air blower 16, regenerative air blower 17, wherein, ultrasonic dehumidification wheel 1 comprises local radiating rod-shaped ultrasonic transducer 21, hygroscopic material 22, partition 23, shell 24, local radiating rod-shaped ultrasonic transducer 21 It includes an outer cover plate 18, an inner cover plate 19, and a piezoelectric ceramic wafer 20.

[0018] Such as figure 1As shown, the air inlet and exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com