Lithium ion flow redox battery

A flow battery, lithium ion technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of hindering the large-scale application of power grid energy storage systems, polluting river water and groundwater, and high operating temperature range, and achieve battery volume energy density and The effect of increased mass energy density, less corrosiveness, and wider operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

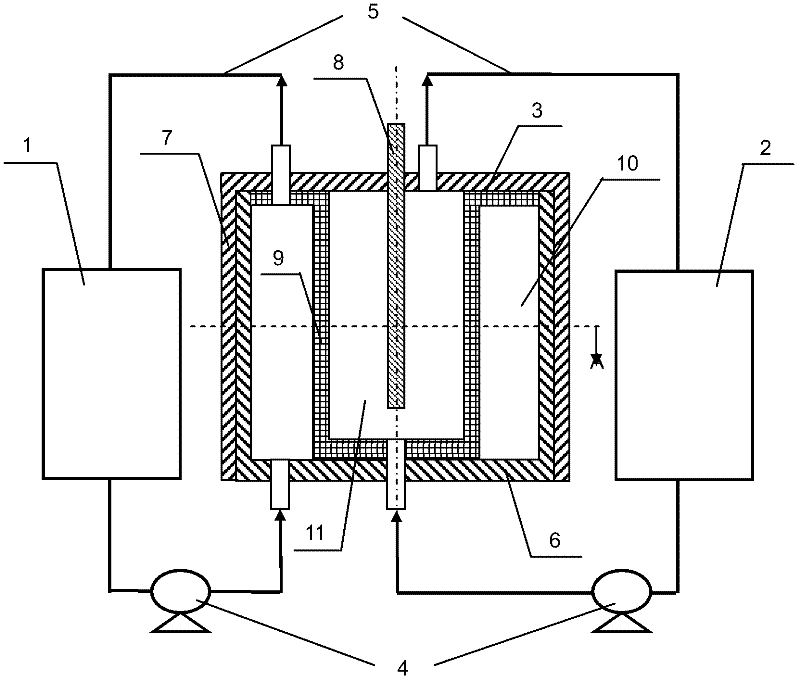

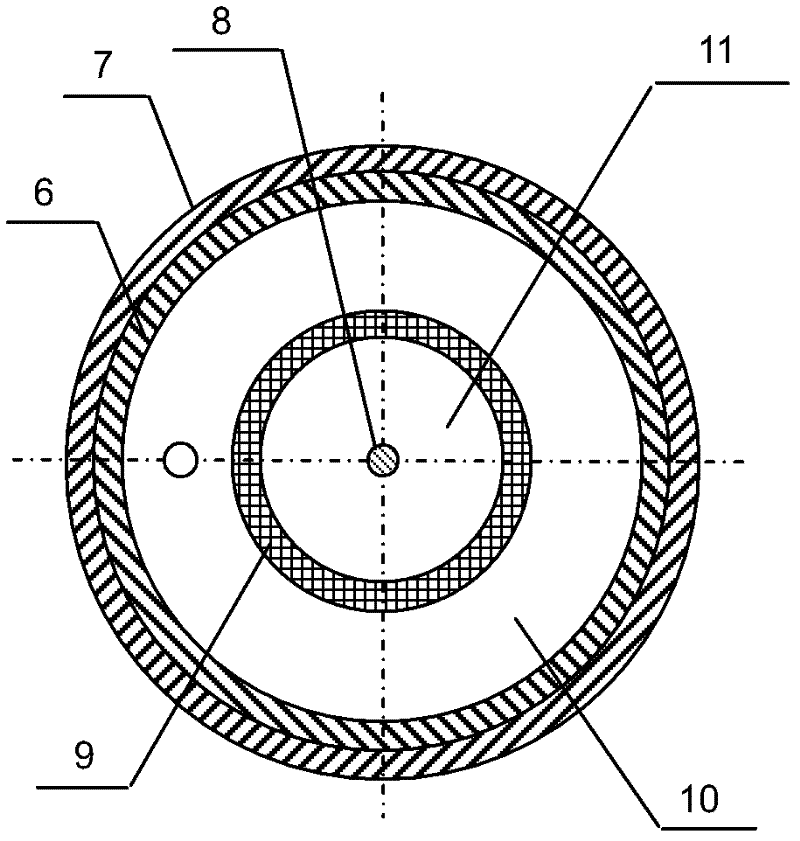

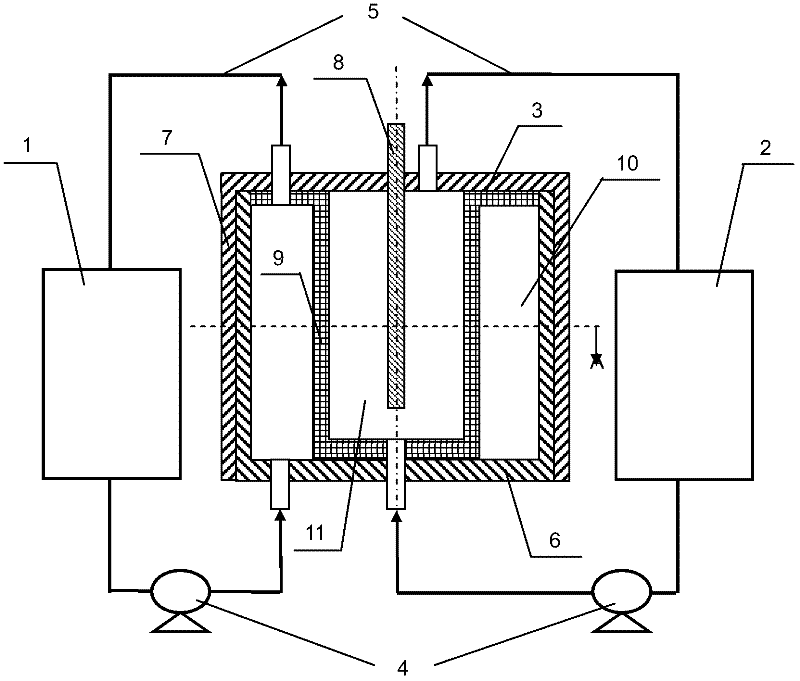

[0022] The lithium ion flow battery of the present invention is composed of a positive electrode suspension pool 1, a negative electrode suspension pool 2, a battery reactor 3, a liquid pump 4 and a sealed pipeline 5, such as figure 1 with figure 2 shown. Wherein, the positive electrode suspension pool 1 holds the mixture of the positive electrode composite material particles and the electrolyte solution, and the negative electrode suspension liquid pool 2 holds the mixture of the negative electrode composite material particles and the electrolyte solution. The mixture flows between the suspension tank and the battery reactor 3 through the sealed pipe 5 driven by the liquid pump 4 . The battery reactor 3 includes a positive electrode current collector 6 of a cylindrical structure, a plastic insulating case 7 placed on the outer layer of the cylindrical structure, a rod-shaped negative electrode current collector 8 placed inside the cylindrical structure, and a positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com