Method for preparing analcite from electrolytic manganese residues

A technology of electrolytic manganese slag and analcime, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of acid and alkali consumption, high requirements for equipment corrosion resistance, high cost, etc., and achieve the goal of saving energy and reducing corrosion resistance Requirements, Effects Favorable for Recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

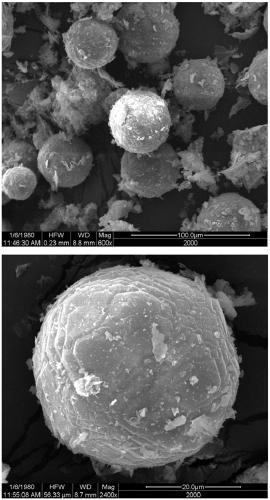

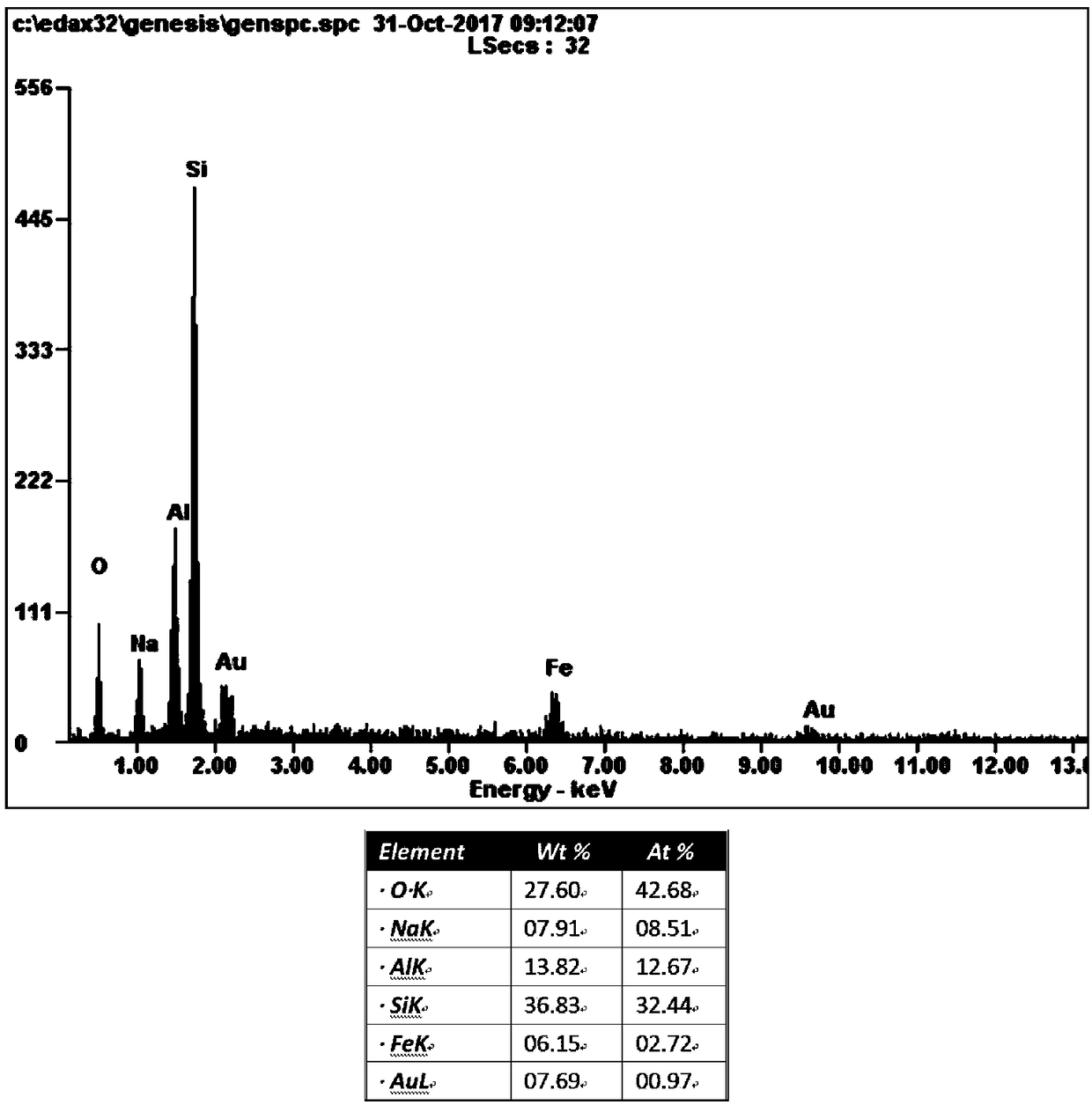

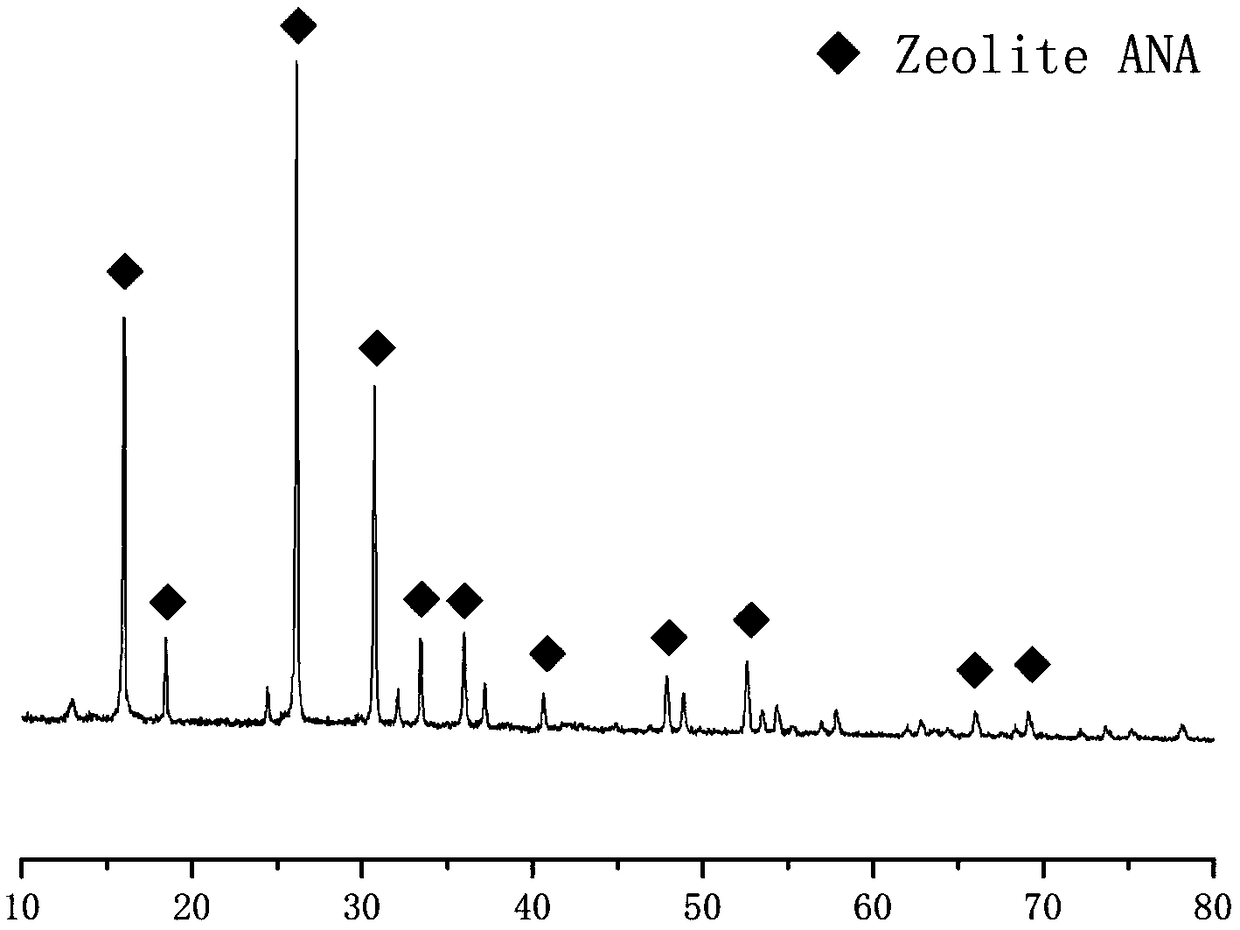

Image

Examples

Embodiment 1

[0041] The electrolytic manganese slag in the following examples all come from the No. 2 Metal Manganese Plant of CITIC Dameng Mining Co., Ltd. The process is to roast manganese dioxide raw ore powder and coal in a rotary kiln at high temperature to convert it into divalent manganese, and then leaching it with sulfuric acid. The electrolytic manganese slag was obtained by plate and frame filter press.

[0042] (1) Dry the electrolytic manganese slag at 105°C, and grind it into powder with a 3000r / min ball mill for 5 minutes;

[0043] (2) Dissolve 100g of powdered manganese slag in 150mL of distilled water, add 12mL of analytically pure hydrogen peroxide with a mass fraction of 30%, stir in a water bath at 90°C for 2 hours, then add 200mL of distilled water and 80g of oxalic acid dihydrate crystals, After reacting for 24 hours under magnetic rotor stirring, filter, and retain the solid residue and supernatant respectively;

[0044] (3) Mix the manganese slag after iron removal...

Embodiment 2

[0055] (1) Dry the electrolytic manganese slag at 105°C, and grind it into powder with a 3000r / min ball mill for 5 minutes;

[0056] (2) Dissolve 100g of powdered manganese slag in 150mL of distilled water, add 12mL of analytically pure hydrogen peroxide with a mass fraction of 30%, stir in a water bath at 90°C for 2 hours, then add 200mL of distilled water and 80g of oxalic acid dihydrate crystals, After reacting for 24 hours under magnetic rotor stirring, filter, and retain the solid residue and supernatant respectively;

[0057] (3) Mix the manganese slag after iron removal with sodium carbonate powder (mass ratio 8g:6.4g), and calcinate at 800°C for 2h;

[0058] (4) Add 100mL of absolute ethanol to the supernatant after step (2) and place it in the dark for crystallization. Suction filter after the crystallization is complete, wash the crystal with 50% ethanol, drain it, and dry it at 60°C to obtain Potassium trioxalate iron (Ⅲ) crystals;

[0059] ⑸Add 0.2049gAl to 10g m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com