Method for preparing aluminum-scandium intermediate alloy by using calciothermy

A technology of master alloy and reduction method, which is applied in the field of preparing aluminum-scandium master alloy by thermal reduction method, can solve problems such as hazards, and achieve the effect of simple operation and stable product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

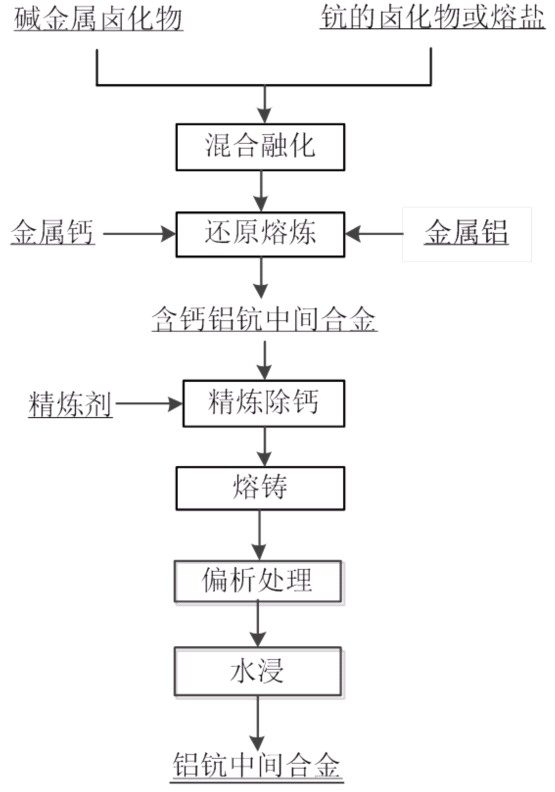

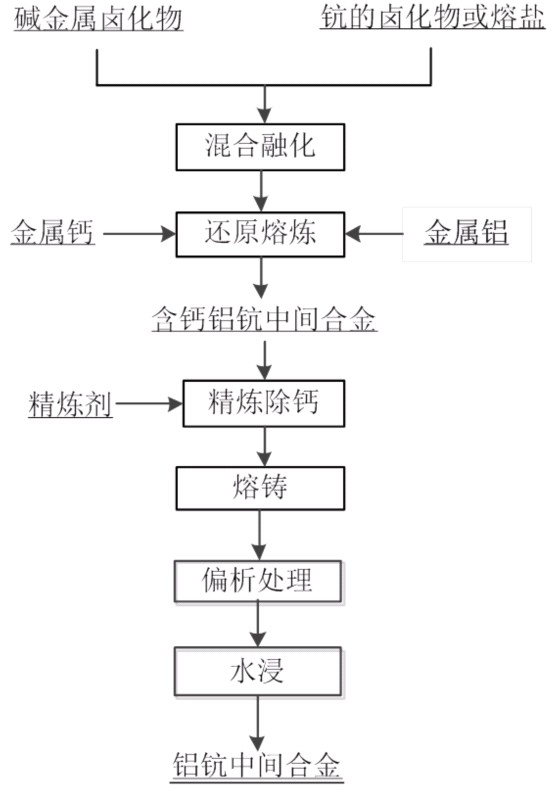

Image

Examples

Embodiment 1

[0029] The invention discloses a method for preparing an aluminum-scandium master alloy by a calcithermal reduction method, comprising:

[0030] 1) Calculate the weight of the raw materials aluminum, calcium metal, scandium halide or its scandium-containing molten salt, anhydrous calcium chloride and alkali metal chloride required for each furnace smelting according to the composition content of the aluminum-scandium master alloy, and weigh them respectively Pick;

[0031] 2) After mixing the flux evenly, add it into the crucible and heat it up to 700°C~1050°C to melt. The solvent is CaCl containing 75%-98% by weight 2 , and 2~25% NaCl or NaCl and KCl uniformly mixed salt, the amount of anhydrous calcium chloride in the flux is calculated according to the solubility of metal calcium in anhydrous calcium chloride molten salt is 1~15g / 100g;

[0032] 3) After the flux is fully melted, add scandium halide and keep warm in a closed protective atmosphere to obtain molten scandium-c...

Embodiment 2

[0038] On the basis of Example 1, the best implementation mode of the present invention is: metal calcium is the reducing agent, the purity of calcium is greater than 99%, and the amount of calcium is calculated according to the stoichiometric reduction reaction, adding 1 to 1.3 times of the theoretical amount. The airtight protective atmosphere is filled with vacuum inert gas protection in the vacuum induction melting furnace, and the inert gas is N 2 He or Ar. Scandium halides are anhydrous scandium halides or scandium-containing molten salts prepared by chemical methods, and the anhydrous scandium halides are anhydrous scandium chloride, anhydrous scandium fluoride, anhydrous scandium bromide or anhydrous scandium iodide , requires complete dehydration, scandium halide content of 1% to 25% of the molten salt. The crucible is a graphite crucible, a corundum crucible, an iron crucible or a tantalum crucible. During the thermal reduction reaction, a large-caliber graphite cr...

Embodiment 3

[0041] Put 68.2g of anhydrous calcium chloride and 16.5g of sodium chloride into a graphite crucible after mixing evenly, put it into a vacuum induction furnace, and after evacuating it, protect it with argon, raise the temperature to 850°C and keep it warm, and add 10.6g of scandium fluoride After the molten salt is melted, add 6.5g of calcium metal and 213.0g of aluminum ingot. After the metal is melted, stir, heat preservation and reduction smelting for 60 minutes, remove slag, add a refining agent with 5% of the weight of the aluminum ingot, heat preservation and decalcification for 30 minutes, take out the crucible, remove The slag is cast and demoulded, and cooled with water at 60~100°C. Water immersion to remove slag and weigh to obtain 203.7g of aluminum-scandium master alloy, analyzed by ICP-AES, the scandium content is 1.87%, and the recovery rate of scandium is 81.17%. The contents of other impurities Ca, Na, F, etc. are all less than 50ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com