Ocean thermal energy conversion power plant

A technology of cold water pipes and recesses, which is applied in the field of marine thermal energy conversion power stations with multi-stage heat engines, can solve problems such as the impact of fish schools and coral reef systems and the impact of marine environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

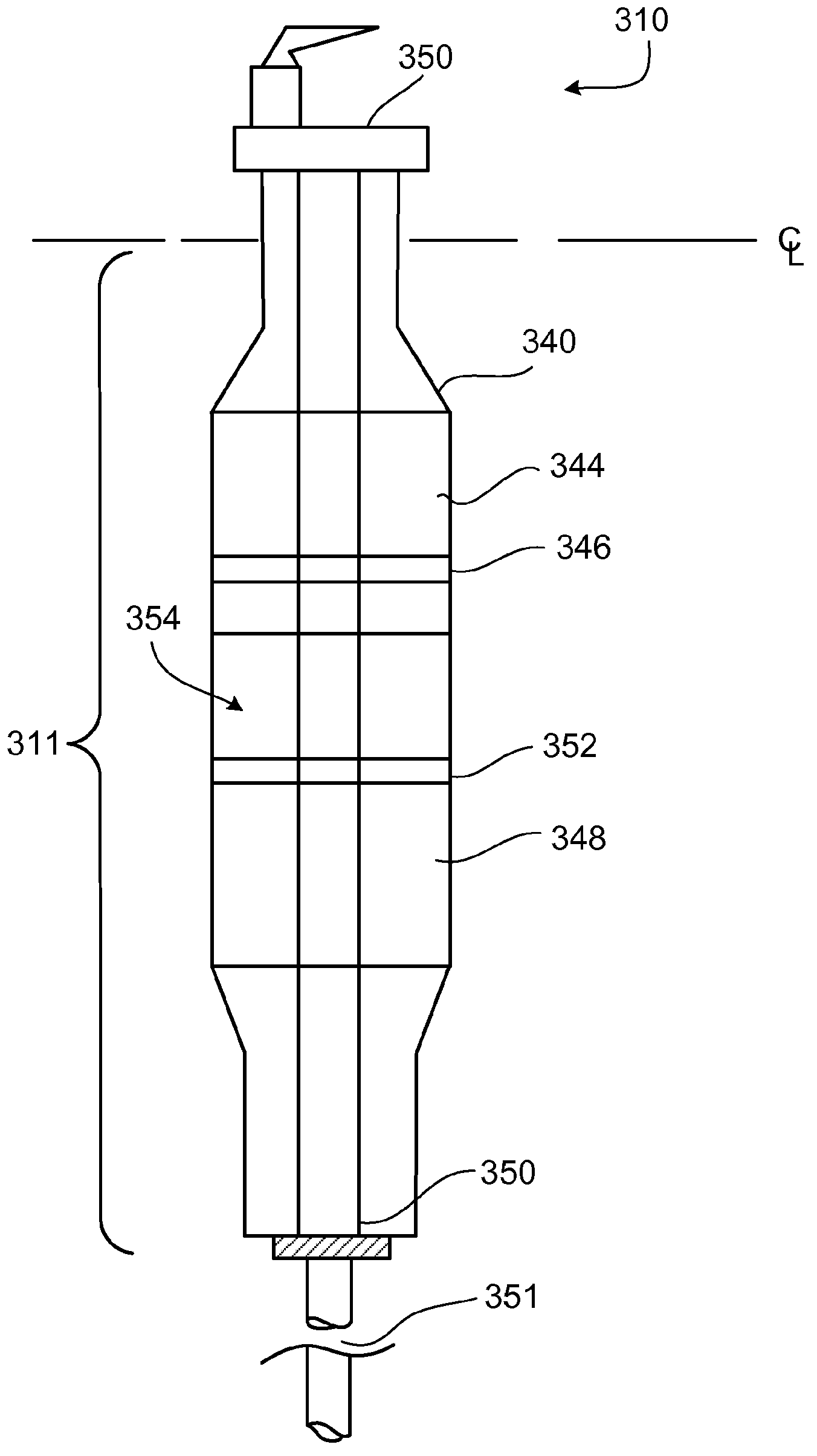

[0143] Cold water pipe assemblies were provided to facilitate on-site construction of approximately 3000 feet of continuous staggered batten pipe. In addition, the slatted design handles the adverse shipping and handling loads customarily experienced with segmented pipe construction. For example, dragging and erecting traditionally constructed segmented cold water pipes can place dangerous loads on the pipes.

[0144] Batten construction allows multiple 40' to 50' long staves to be fabricated off-site. Each plank is approximately 52 inches wide and 4 inches to 12 inches thick. The slats can be shipped in stacks or in containers to an offshore platform where a cold water pipe can then be constructed from multiple slats. This eliminates the need for separate equipment for assembling the pipe sections.

[0145] The battens may be constructed of nylon reinforced vinyl ester having a modulus of elasticity between about 66,000 psi (pounds per square inch) and 165,000 psi. The st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com