Efficient thermodynamic cycle system utilizing vortex tubes

A thermal cycle system and vortex tube technology, applied in lighting and heating equipment, steam engine devices, compressors, etc., can solve the problems of low thermal cycle efficiency, reduced compression work, large compression work, etc., to achieve high cycle efficiency, reduce Small compression work, the effect of improving net efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

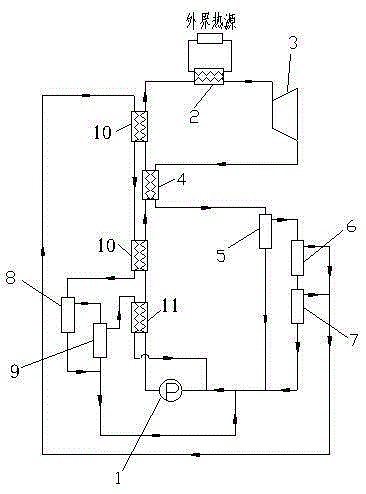

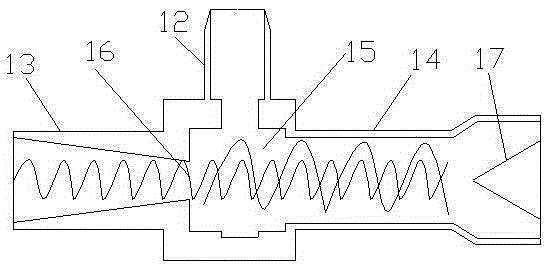

[0013] like figure 1 and figure 2 As shown, a high-efficiency thermodynamic cycle system using a vortex tube is mainly composed of a working medium pump 1, a heat exchanger 2 and an expander 3. The outlet of the working medium pump 1 is connected to the expander 3 through the heat exchanger 2, and the expansion A cooling unit is arranged between the engine 3 and the working medium pump 1, the cooling unit is a vortex tube split flow cooling unit, the vortex tube split flow cooling unit includes a five-stage vortex tube combination, the vortex tube is a very simple energy separation device, and it consists of Nozzle 12, vortex chamber 15, separation orifice 16, low-temperature end pipe 13, high-temperature end pipe 14 and regulating valve 17, the low-temperature liquid working fluid separated by the first-stage vortex tube 5 and the third-stage vortex tube 7 enters the working medium pump The inlet of 1, the high-temperature gaseous working medium separated by the second-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com