Variable pitch spiral compression machine head of spiral compression-expansion refrigerator

A technology of compression expansion and refrigerator, which is applied in the direction of machines/engines, rotary piston machinery, mechanical equipment, etc., and can solve problems such as low efficiency, inapplicability, and increased cylinder diameter of centrifugal compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

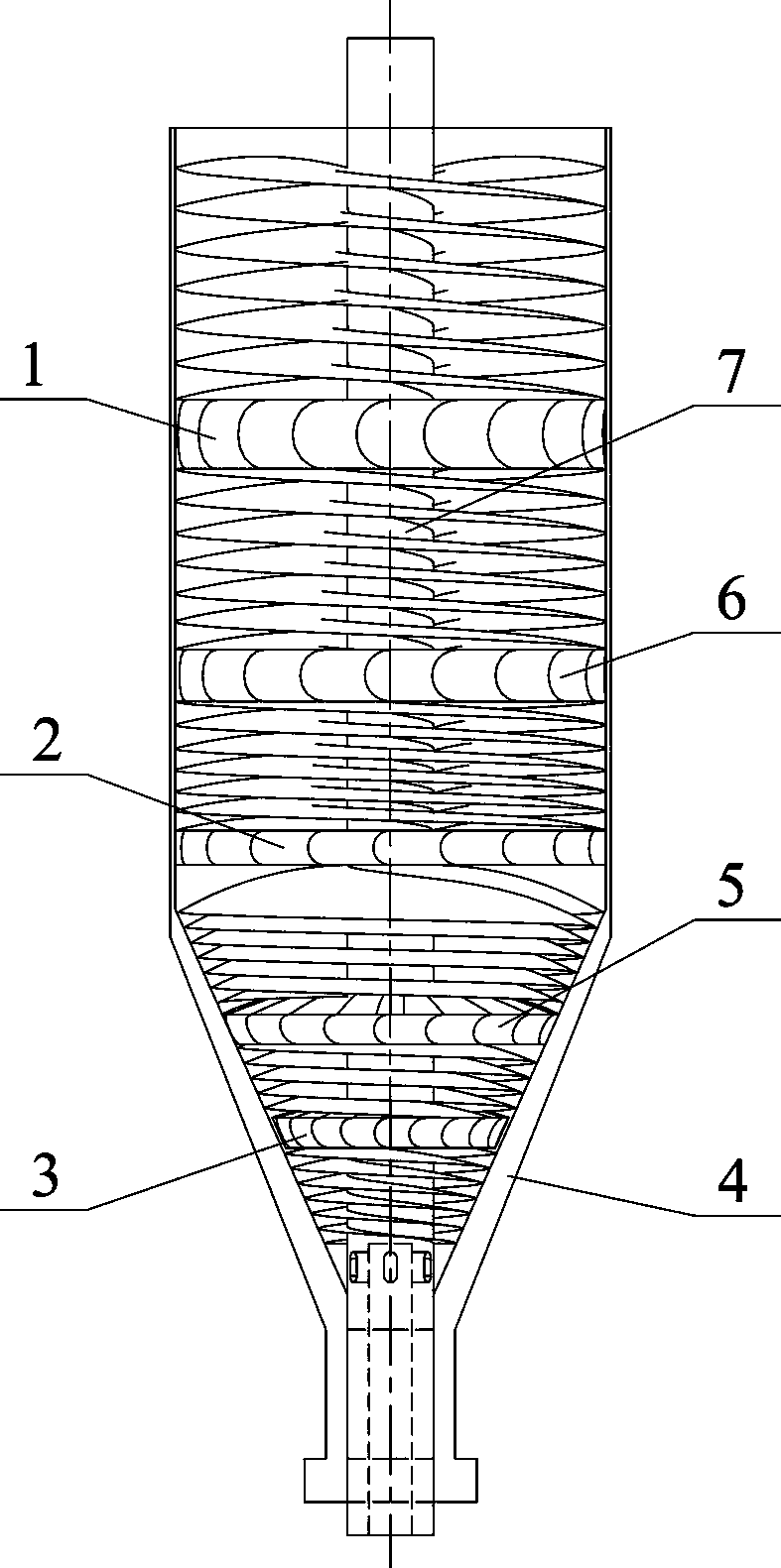

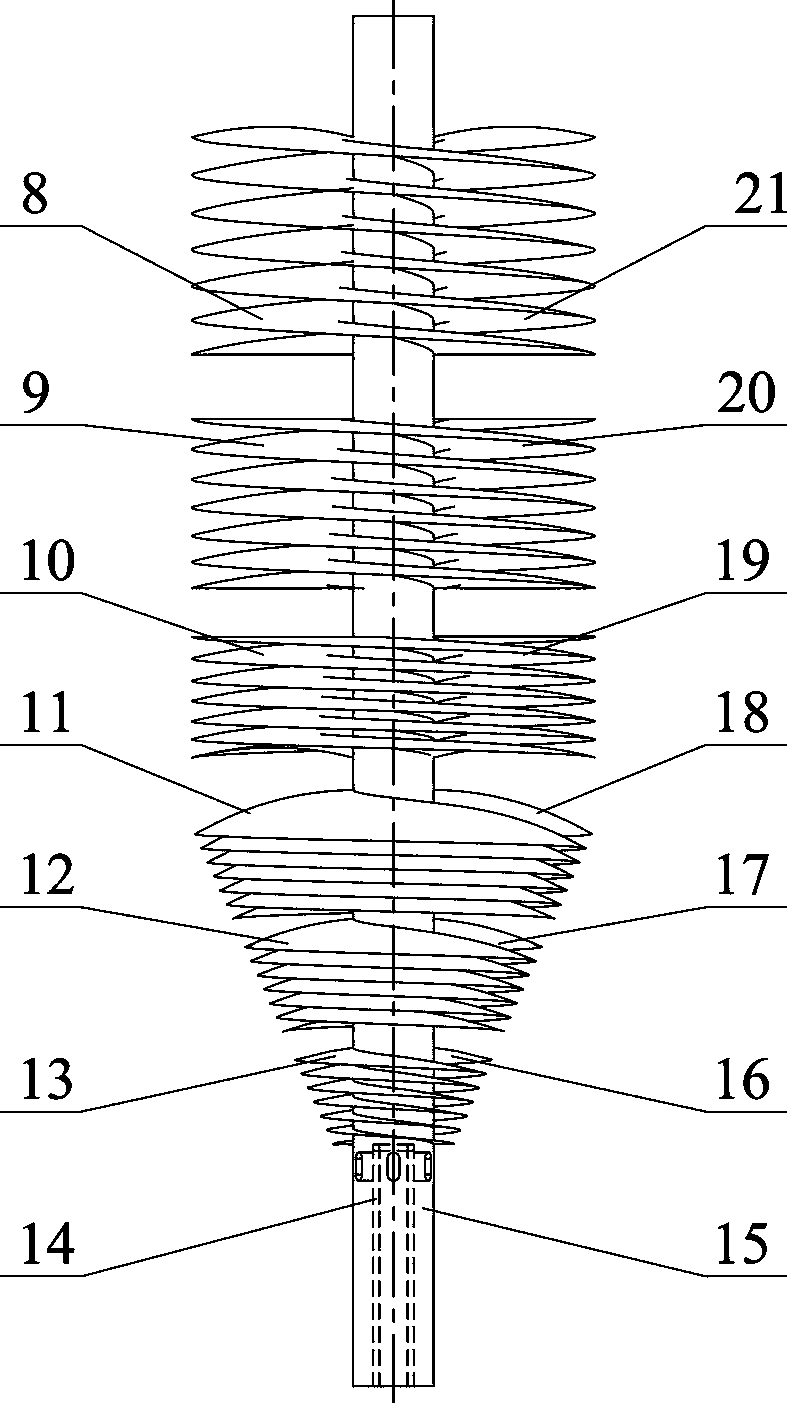

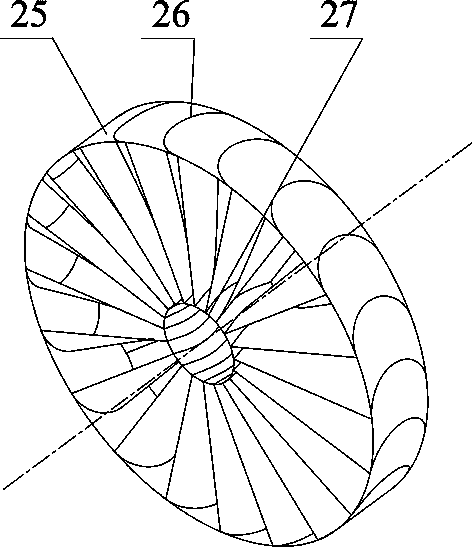

[0020] Manufacture variable-pitch screw compressor heads for screw compression expansion refrigerators, including the first horizontal diffuser ring (1), the third horizontal diffuser ring (2), the second conical diffuser ring (3), and the compression cover ( 4), the first conical diffuser ring (5), the second horizontal diffuser ring (6), the helical rotor (7); the helical rotor (7) includes the first blade of the first stage (8), the first blade of the second stage (9), the first blade of the third stage (10), the first blade of the fourth stage (11), the first blade of the fifth stage (12), the first blade of the sixth stage (13), the heat insulating sleeve (14), the central shaft ( 15), the sixth-level second blade (16), the fifth-level second blade (17), the fourth-level second blade (18), the third-level second blade (19), the second-level second blade (20), the first-level The second blade (21); the first conical diffuser ring (5) and the second conical diffuser ring (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com