Oblique flow re-pressurizing expansion refrigeration device and method

An expansion refrigeration and oblique flow technology, applied in the field of gas expansion refrigeration, can solve the problems of increased flow resistance, pressure energy consumption, and unsolved liquid drainage problems of double-opening oscillating tubes, and achieve the effect of improving refrigeration efficiency and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

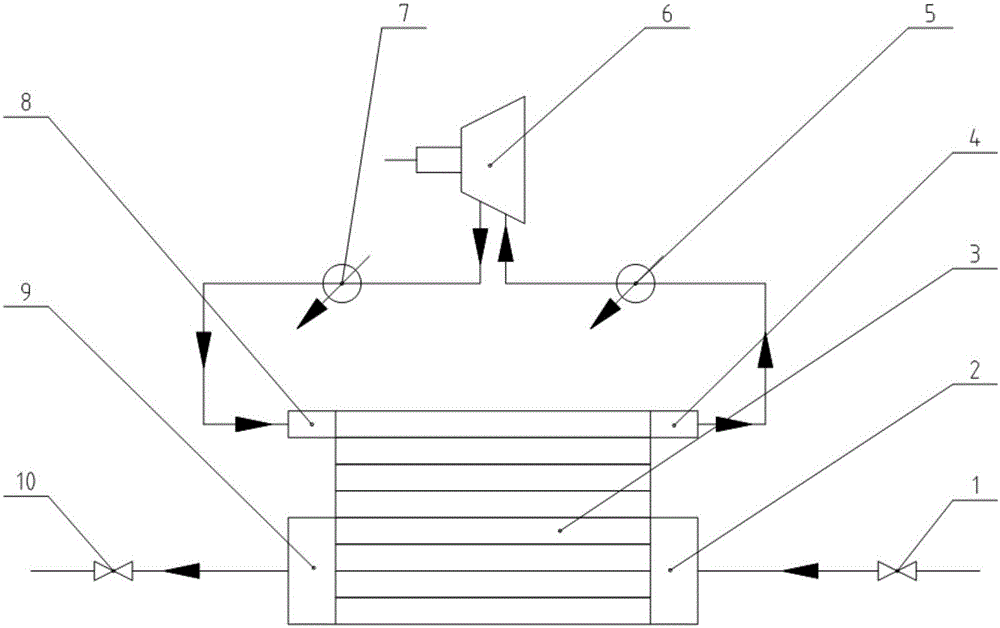

[0025] An oblique flow repressurization expansion refrigeration device and method, the oblique flow repressurization expansion refrigeration device includes an intake valve 1, a double-opening pressure exchange air wave machine 3, a cooler, a compressor 6 and a cold-end exhaust valve 10; The right end of the open pressure exchange air wave machine 3 has two ports, which are the bleed air chamber 2 and the high-temperature exhaust chamber 4, and the left end has two ports, which are the high-pressure intake nozzle 8 and the low-temperature discharge chamber 9; the intake valve 1 It is connected with the bleed air chamber 2, and the high-temperature exhaust chamber 4 is connected with the high-pressure intake nozzle 8 after passing through the first cooler 5, the compressor 6 and the second cooler 7 in sequence; the low-temperature discharge chamber 9 is connected with the cold-end exhaust valve 10 ;

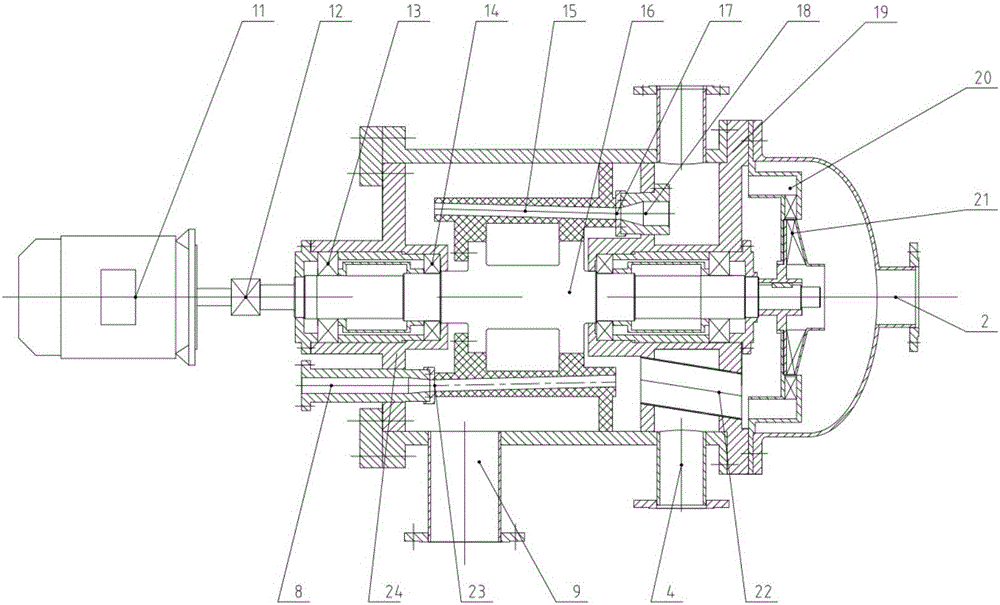

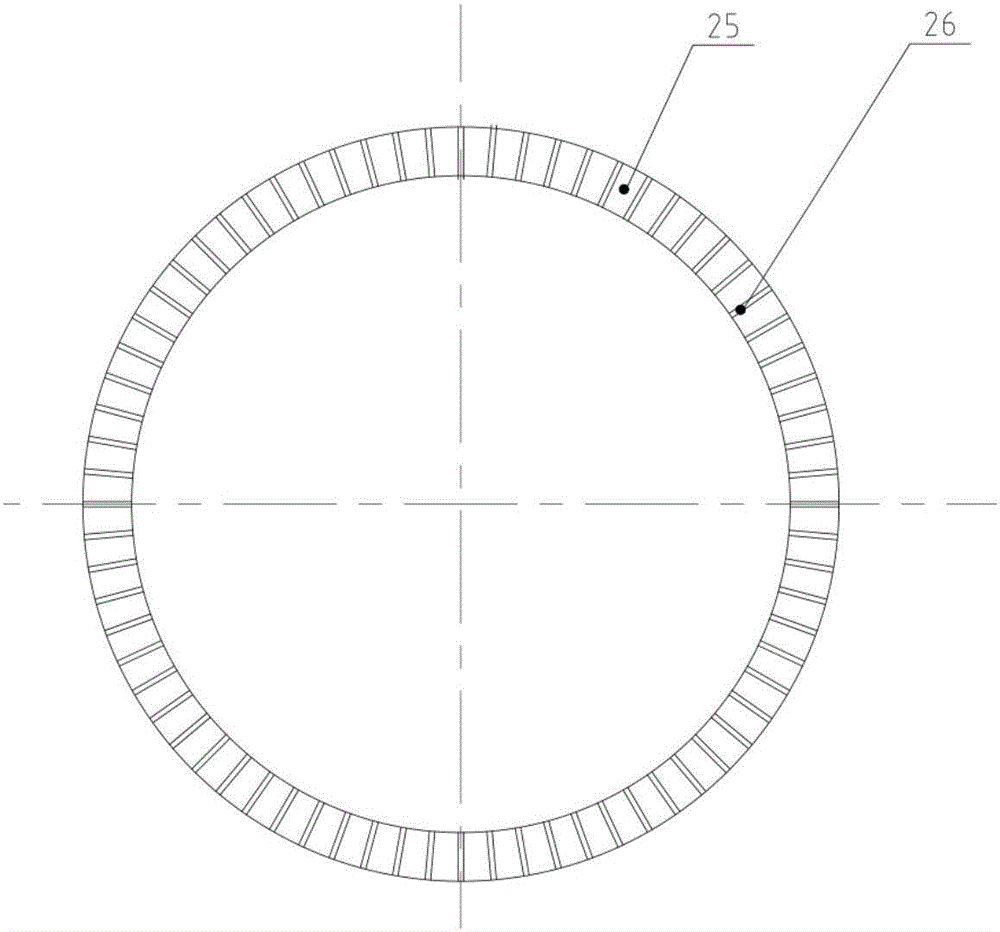

[0026] The double-opening pressure exchange air wave machine 3 is the core co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com