A process for separating a product gas from gaseous mixture

A technology for gaseous mixtures, mixtures, applied in separation methods, removal of gaseous pollutants, gaseous fuels, etc., can solve problems such as increasing operating pressure, increasing reboiler temperature, and amine solvent stability limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

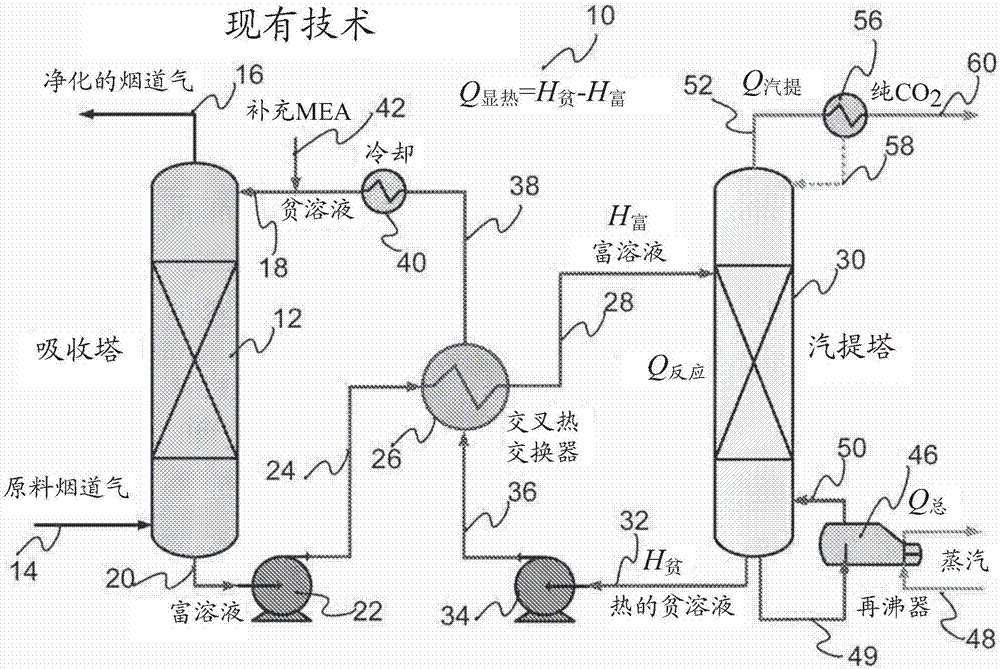

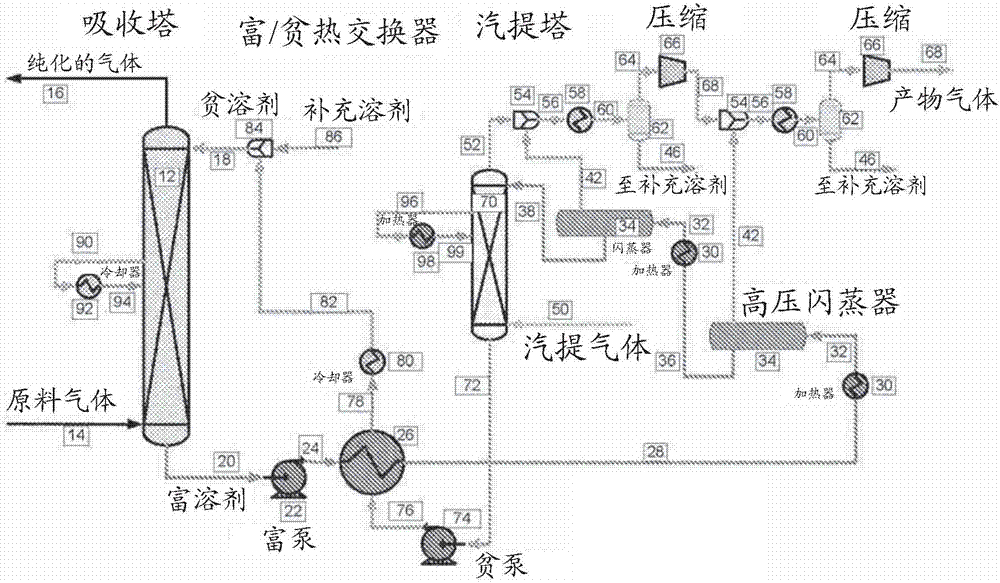

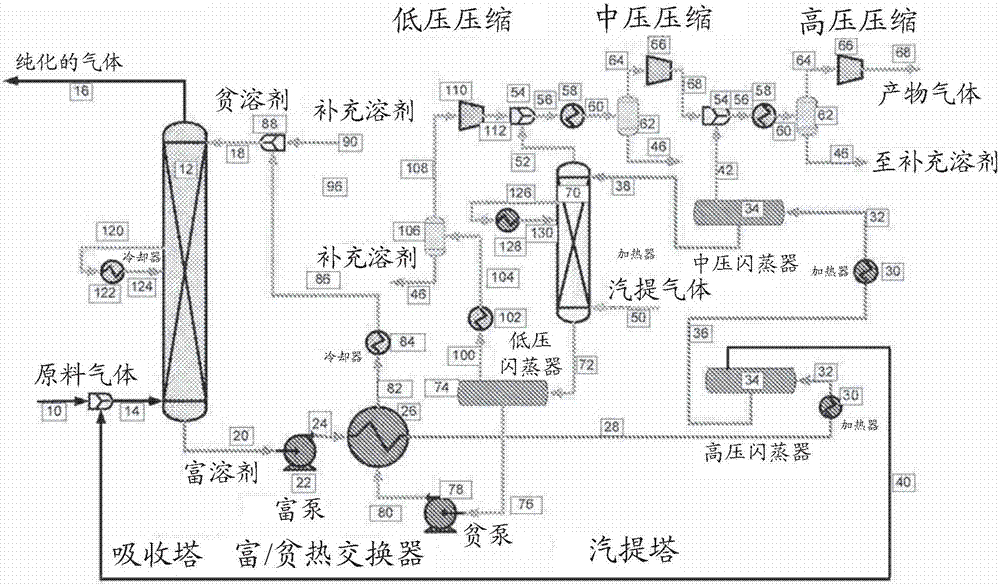

[0058] In related US Patent Publication 2014-0017622, WO 2012-006610 and US Patent 8,425,655 a gas pressure separation (GPS) system and associated methods are disclosed to strip product gas from a liquid stream and produce High pressure gaseous effluents of product gases, these inventions are incorporated herein by reference. The GPS system in the previous related invention, which is a core component in any application, is introduced into this improved invention. Modifications of this embodiment to the settings of the original GPS system include the number of heating devices that need to be integrated into the GPS system. The greater the number of heating units in the column, the better the potential thermodynamic efficiency of the separation process. However, the complexity of the GPS tower and the resulting capital cost of the tower and operating cost of the GPS system increase with the number of heating installations. Thus, instead of using at least two heating means, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com