Integrated oxygen-enriched combustion power system

An oxygen-enriched combustion and fluid technology, which is applied to fluid heaters, gas turbine devices, machines/engines, etc., can solve the problems of increasing the power consumption of the flue gas recirculation fan and the underutilization of the heat energy of the flue gas of the oxygen-enriched combustion boiler. , to reduce energy consumption, improve net efficiency, and improve cycle efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

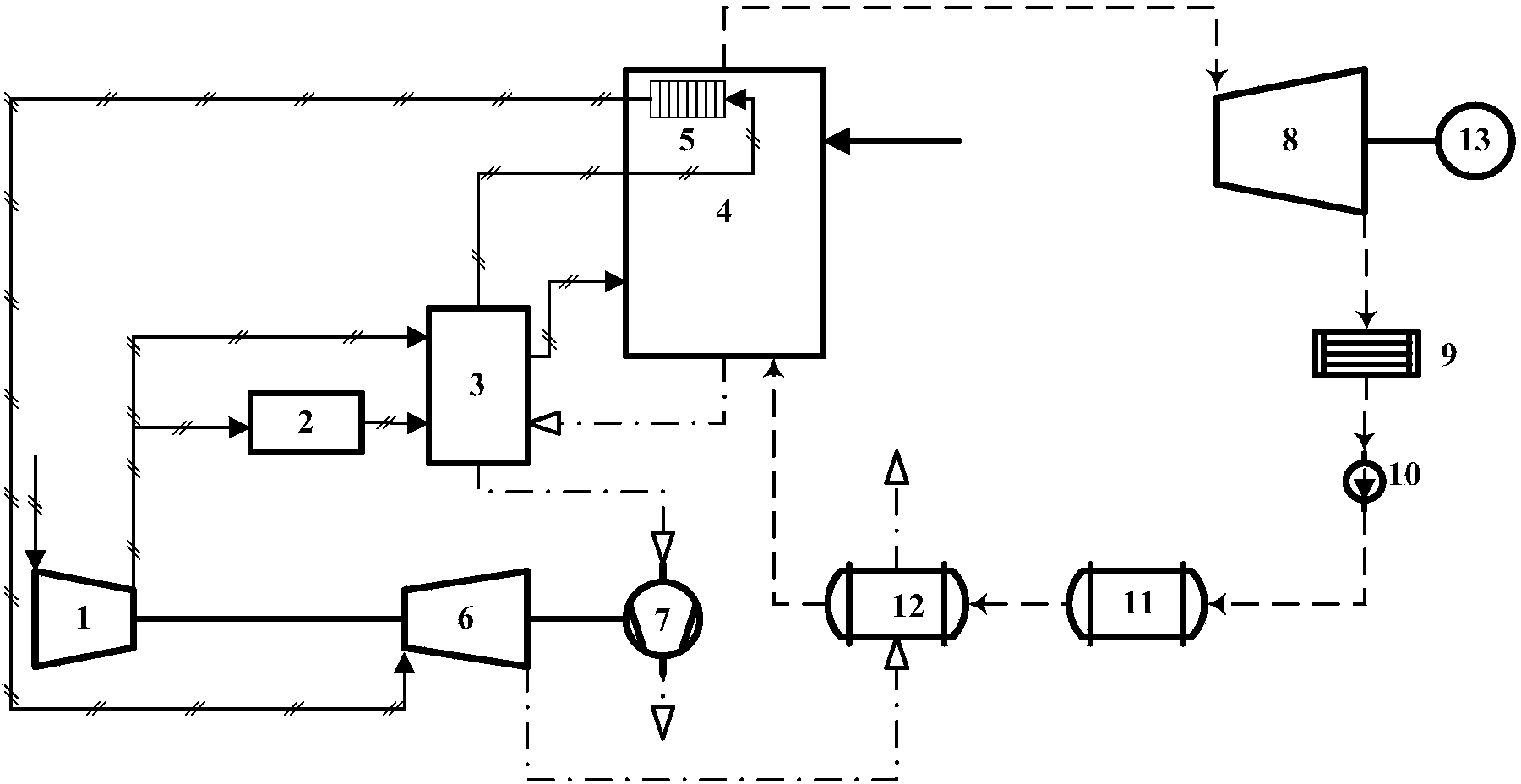

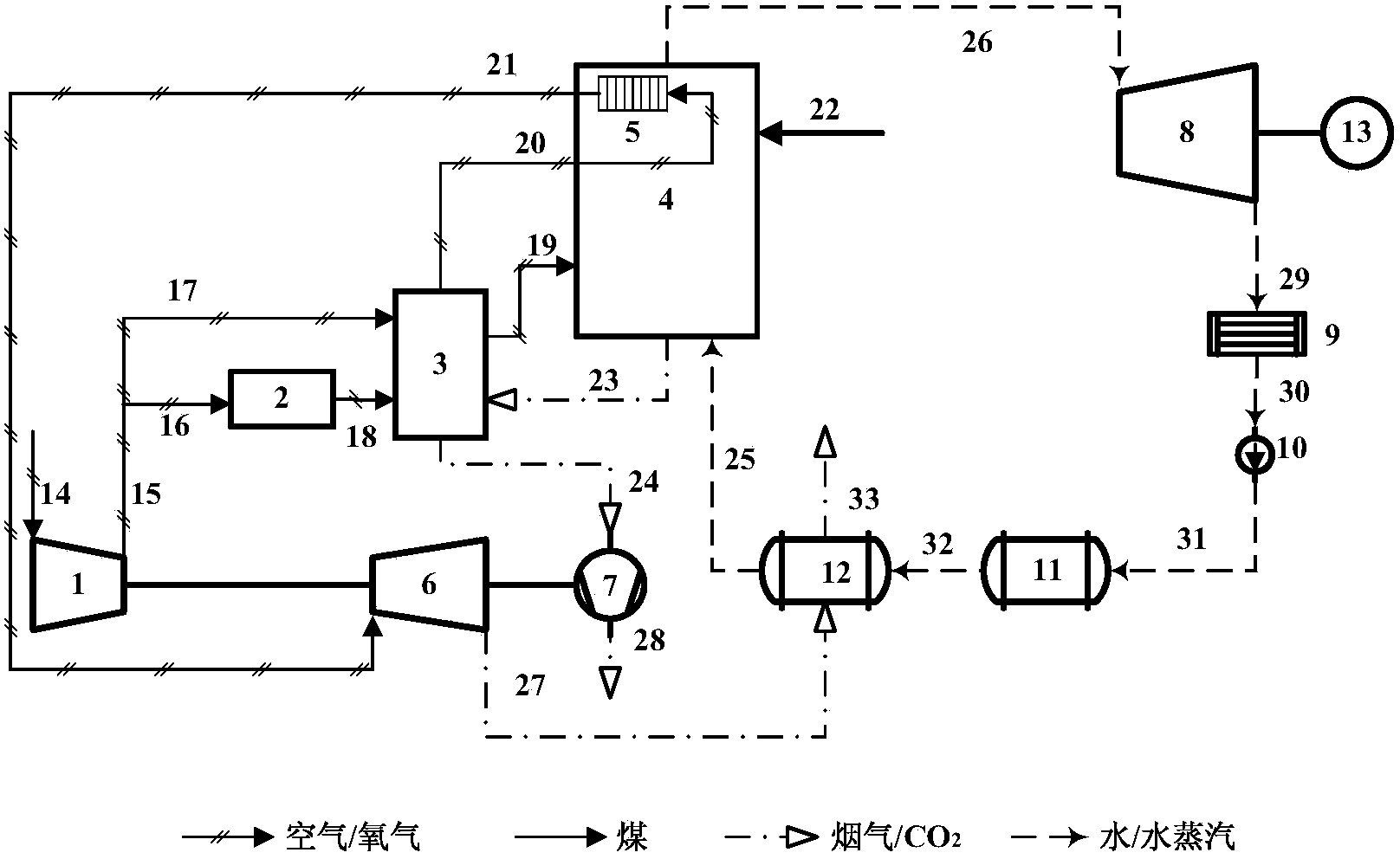

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0020] The core idea of the embodiment of the present invention is to combine the utilization of the flue gas heat of the oxy-fuel combustion boiler with driving the air separation compressor, CO 2 Combined with compressors, the high-temperature air heated by the flue gas of the oxygen-enriched combustion boiler is used as the working medium of the gas turbine, and the gas turbine is used to drive the air separation compressor, CO 2 Compressor, so as to realize the control of combustion temperature in the oxy-fuel combustion boiler furnace; make full use of the high-grade heat energy of the flue gas, achieve the effect of reducing the plant power consumption rate and improving the net efficiency of the system; and make the gas turbine no need to consume additional fuel; the high temperature of the gas turbine The exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com