Laser working method

A laser processing method and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as toxic waste liquid, affecting the surface finish of workpieces, and expensive chemical vapor deposition equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

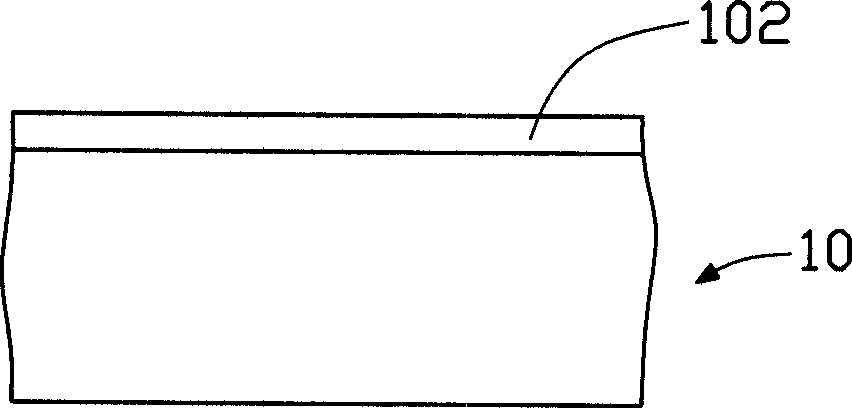

[0014] see figure 2 , first coating a protective layer on the surface of the workpiece 10, the protective layer is a polyimide layer 102, and the polyimide layer 102 can be coated by immersion plating (dip-coating) or spin coating (spin-coating) etc., the polyimide layer 102 has a thickness of 500 angstroms to 500 microns.

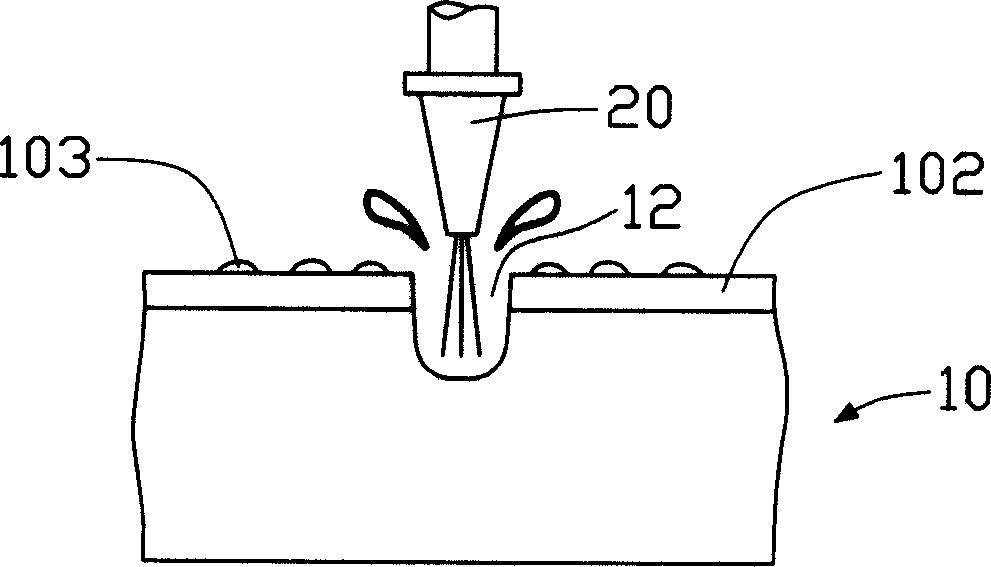

[0015] see image 3 , when using a laser processing machine 20 to perform drilling processing on the workpiece 10, the laser beam first melts and vaporizes the polyimide layer 102, and then melts the workpiece 10 under the polyimide layer 102 to form holes 12, The molten material of the workpiece 10 scatters to the surface of the polyimide layer 102 to form particles 103 .

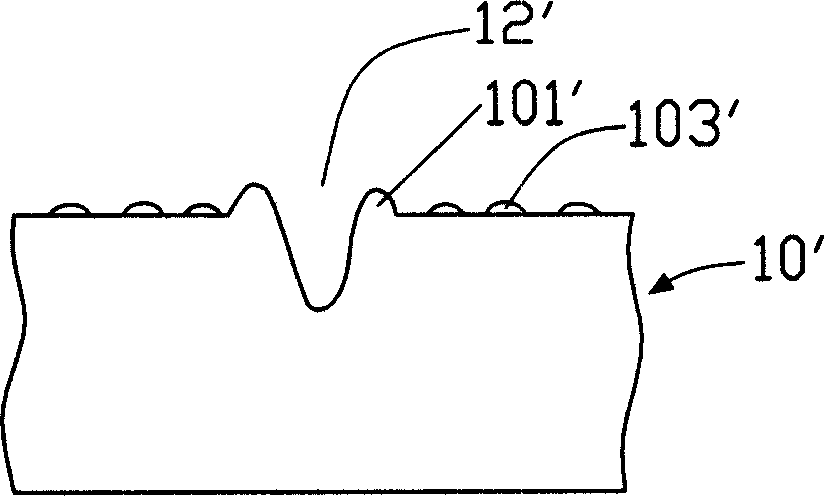

[0016] see Figure 4 After the hole 12 is processed, the polyimide layer 102 on the surface of the workpiece 10 is dissolved and removed by an acetone solvent or a phenolic solvent such as cresol, and the particles 103 on the polyimide layer 102 and (or) external dust, etc. are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com