Method for preparing conductive carbon film-coated calcium or calcium-tin alloy serving as anode material of lithium battery

A technology of conductive carbon film and negative electrode material, used in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as poor cycle performance, achieve uniform thickness, easy preparation, and improve electrochemical kinetic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

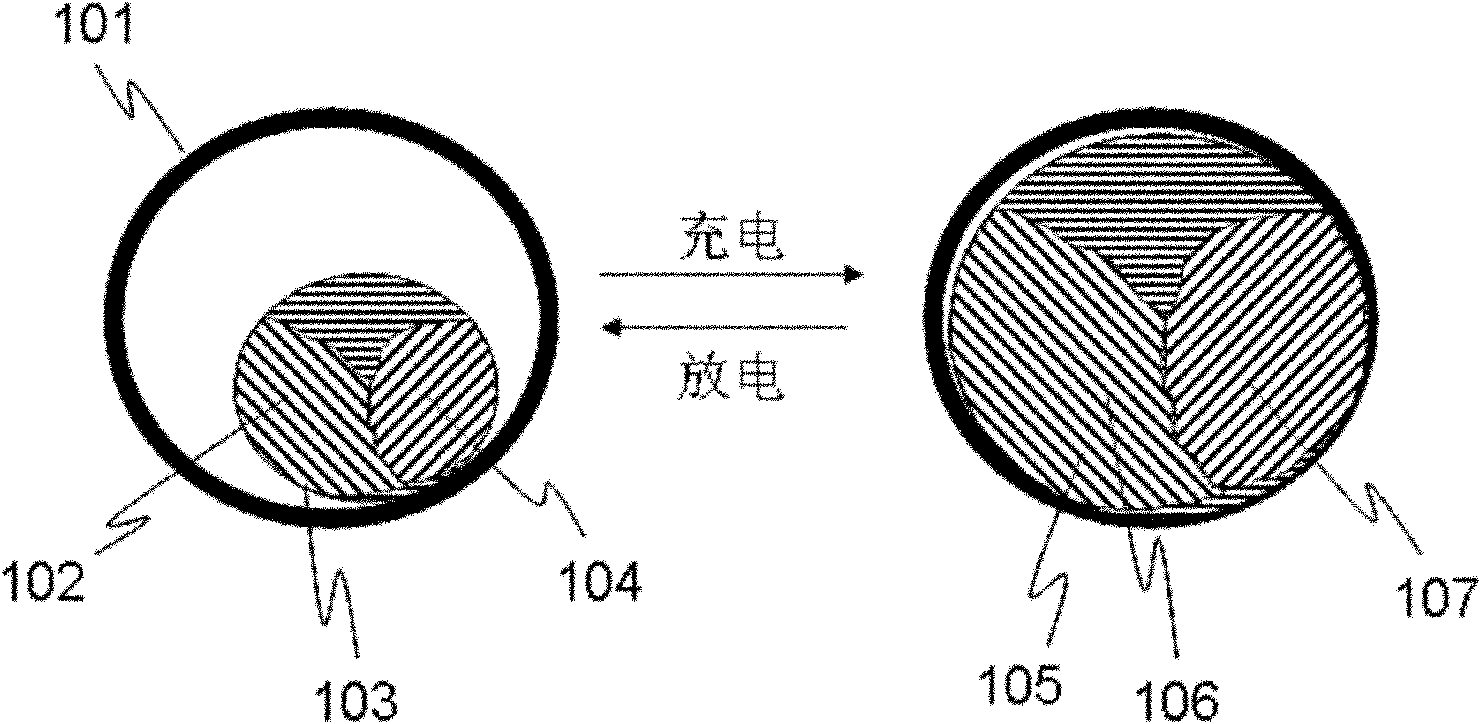

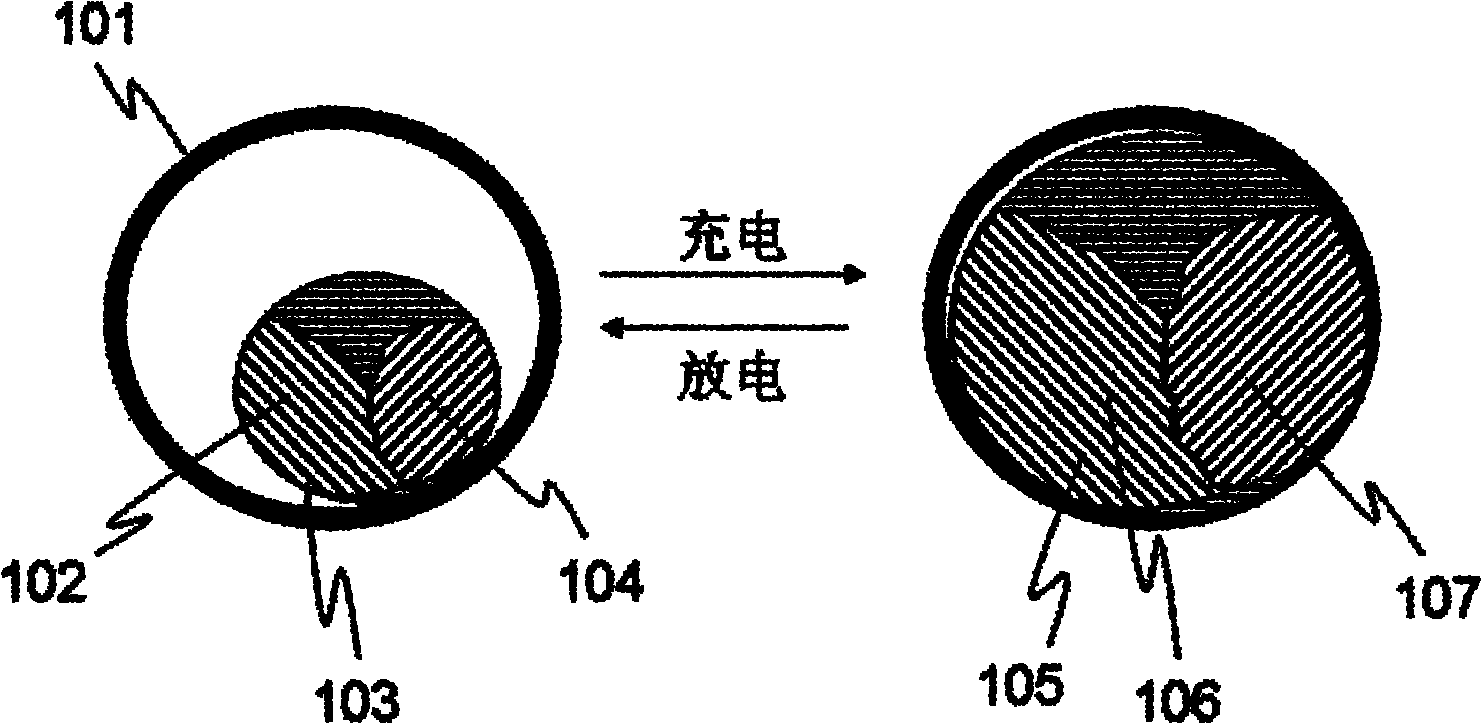

[0033] Example 1: Preparation of carbon-coated calcium material

[0034] Take metal calcium particles with a purity of 99.99% and heat to 850 o After C is melted, it is sprayed with high-purity argon (purity 99.999%) and sprayed into the polyethylene glycol liquid. The calcium droplets are cooled in the polyethylene glycol liquid to form a spherical powder. At the same time, the calcium droplets that are in contact with the calcium droplets The polyethylene glycol is carbonized to form a carbon-coated calcium material. Polyethylene glycol has a molecular weight of 800 and a purity of 99%.

[0035] Filter out the carbon-coated calcium material and calcinate it again in a vacuum atmosphere with the temperature controlled at 600 o C, Further carbonization to remove polyethylene glycol remaining on the carbon-coated calcium material. After cooling, the carbon-coated calcium material is obtained as the negative electrode material for high-capacity lithium-ion batteries.

Embodiment 2

[0036] Example 2: Carbon-coated Ca-Ca 2 Preparation of Sn eutectic alloy

[0037] Take metal calcium and tin particles with a purity of 99.99% in a mass ratio of 58:42, at 900 o After C is melted, it is sprayed with high-purity argon (purity 99.999%) and sprayed into the polyethylene glycol liquid. The calcium-tin alloy droplets form spherical Ca-Ca after cooling in the polyethylene glycol liquid. 2 Sn eutectic powder, at the same time, the polyethylene glycol in contact with Ca-Sn alloy droplets is carbonized to form carbon-coated Ca-Ca 2 Sn eutectic material. Polyethylene glycol has a molecular weight of 600 and a purity of 99%. Filter out carbon-coated Ca-Ca 2 Sn eutectic material, calcined again in the atmosphere of high-purity argon (purity 99.999%), the temperature is controlled at 700 o C, Further carbonization to remove polyethylene glycol remaining on the carbon-coated calcium material. After cooling, carbon-coated Ca-Ca 2 Sn eutectic materials are used as anod...

Embodiment 3

[0038] Example 3: Carbon-coated CaSn-CaSn 3 Eutectic Alloy Preparation

[0039] Take metal calcium and tin particles with a purity of 99.99% according to the mass ratio of 13.5:86.5, at 700 o After C is melted, it is sprayed with high-purity argon (purity 99.999%) and sprayed into the polyethylene glycol liquid. The calcium-tin alloy droplets form spherical CaSn-CaSn after cooling in the polyethylene glycol liquid. 3 Eutectic powder, at the same time, the polyethylene glycol in contact with the calcium-tin alloy droplets is carbonized to form carbon-coated CaSn-CaSn 3 eutectic material. Polyethylene glycol has a molecular weight of 200 and a purity of 99%. Filter out carbon-coated CaSn-CaSn 3 Eutectic material, calcined again in an atmosphere of high-purity argon (purity 99.999%), the temperature is controlled at 550 o C, Further carbonization to remove polyethylene glycol remaining on the carbon-coated calcium material. After cooling, carbon-coated CaSn-CaSn 3 Eutectic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com