Preparation and application of conductive carbon film-coated calcium nitride compound serving as anode material of lithium battery

A technology of negative electrode material and conductive carbon film is applied in the field of preparation and application of negative electrode material of lithium battery coated with nitrogen-calcium compound by conductive carbon film. Achieve the effects of good electrical conductivity, improved electrochemical kinetic performance, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Carbon coated Ca 3 N 2 preparation

[0030] Take metal calcium particles with a purity of 99.99% and heat to 850 o After C is melted, it is sprayed with high-purity nitrogen (purity 99.999%) and sprayed into polyethylene glycol liquid. The calcium mist reacts with nitrogen gas in a nitrogen atmosphere to form calcium nitride (Ca 3 N 2 ) microspheres, which form spherical powder after cooling in a polyethylene glycol liquid with a molecular weight of 200 and a purity of 99%. At the same time, the polyethylene glycol in contact with calcium nitride is carbonized, and the gas generated during the carbonization process makes the carbon The membrane swells, forming a carbon-coated calcium nitride material primary.

[0031] Filter out carbon-coated Ca 3 N 2 The primary product is refined by calcining again in an atmosphere of high-purity nitrogen with a purity of 99.999% for 2 hours, and the temperature is controlled at 700 o Below C, the residual calcium in...

Embodiment 2

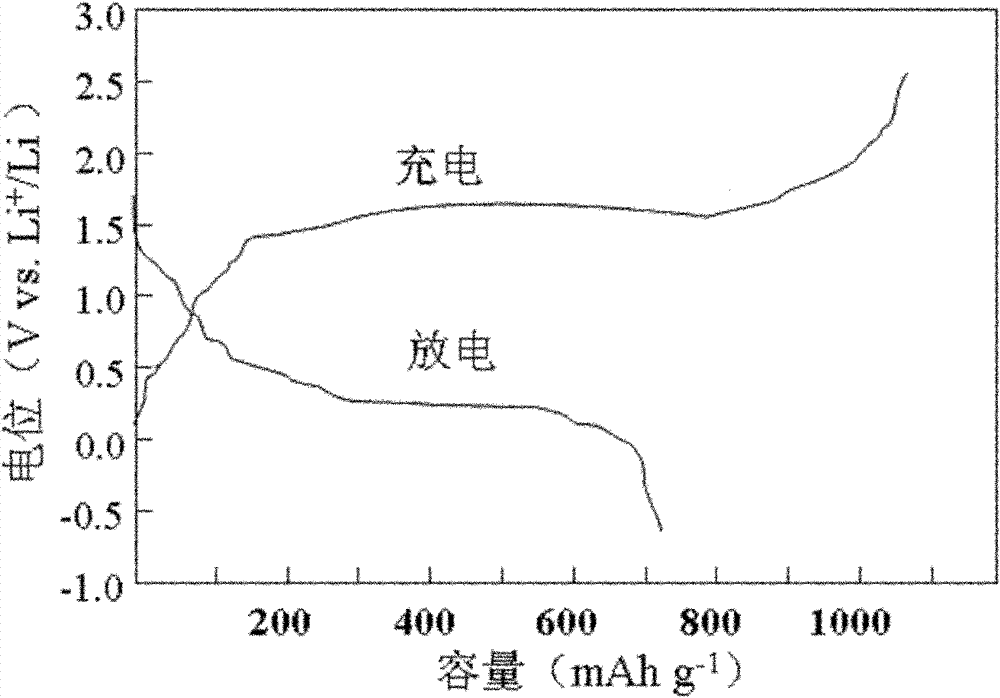

[0032] Example 2: Carbon coated Ca 3 N 2 Lithium battery with negative electrode (1)

[0033] Take calcium metal with a purity of 99.99%, at 850 o After C is melted, it is sprayed with high-purity nitrogen (purity 99.999%) and sprayed into polyethylene glycol liquid. The calcium mist reacts with nitrogen gas in a nitrogen atmosphere to form calcium nitride (Ca 3 N 2 ) Microspheres form spherical powder after cooling in polyethylene glycol liquid with a molecular weight of 600 and a purity of 99%. At the same time, the polyethylene glycol in contact with calcium nitride is carbonized, and the gas generated during the carbonization process makes the carbon The membrane swells, forming a carbon-coated calcium nitride material primary.

[0034] Filter out carbon-coated Ca 3 N 2 The primary product is refined by calcining again in an atmosphere of high-purity nitrogen with a purity of 99.999% for 3 hours, and the temperature is controlled at 650 o Below C, the residual calci...

Embodiment 3

[0038] Example 3: Carbon-coated Ca 3 N 2 Lithium battery with negative electrode (2)

[0039] Take calcium metal with a purity of 99.99%, at 850 o After C is melted, it is sprayed with high-purity nitrogen (purity 99.999%) and sprayed into polyethylene glycol liquid. The calcium mist reacts with nitrogen gas in a nitrogen atmosphere to form calcium nitride (Ca 3 N 2 ) Microspheres form spherical powder after cooling in polyethylene glycol liquid with a molecular weight of 800 and a purity of 99%. At the same time, the polyethylene glycol in contact with calcium nitride is carbonized, and the gas generated during the carbonization process makes the carbon The membrane swells, forming a carbon-coated calcium nitride material primary.

[0040] Filter out carbon-coated Ca 3 N 2 The primary product is refined by calcining again in an atmosphere of high-purity nitrogen with a purity of 99.999% for 3 hours, and the temperature is controlled at 650 o Below C, the residual calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com