Patents

Literature

34results about How to "Improve electrochemical kinetic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Making method of zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode

InactiveCN103594684AAvoid affecting transport performanceInhibition of dissolutionCell electrodesAluminum doped zinc oxideRadio frequency magnetron sputtering

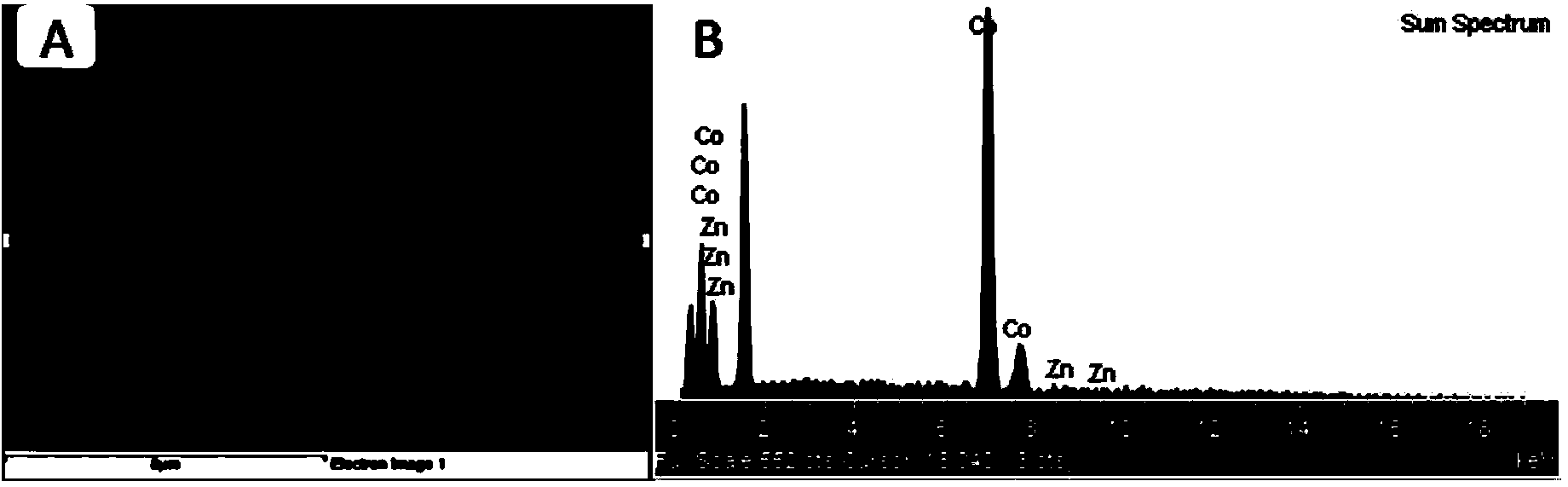

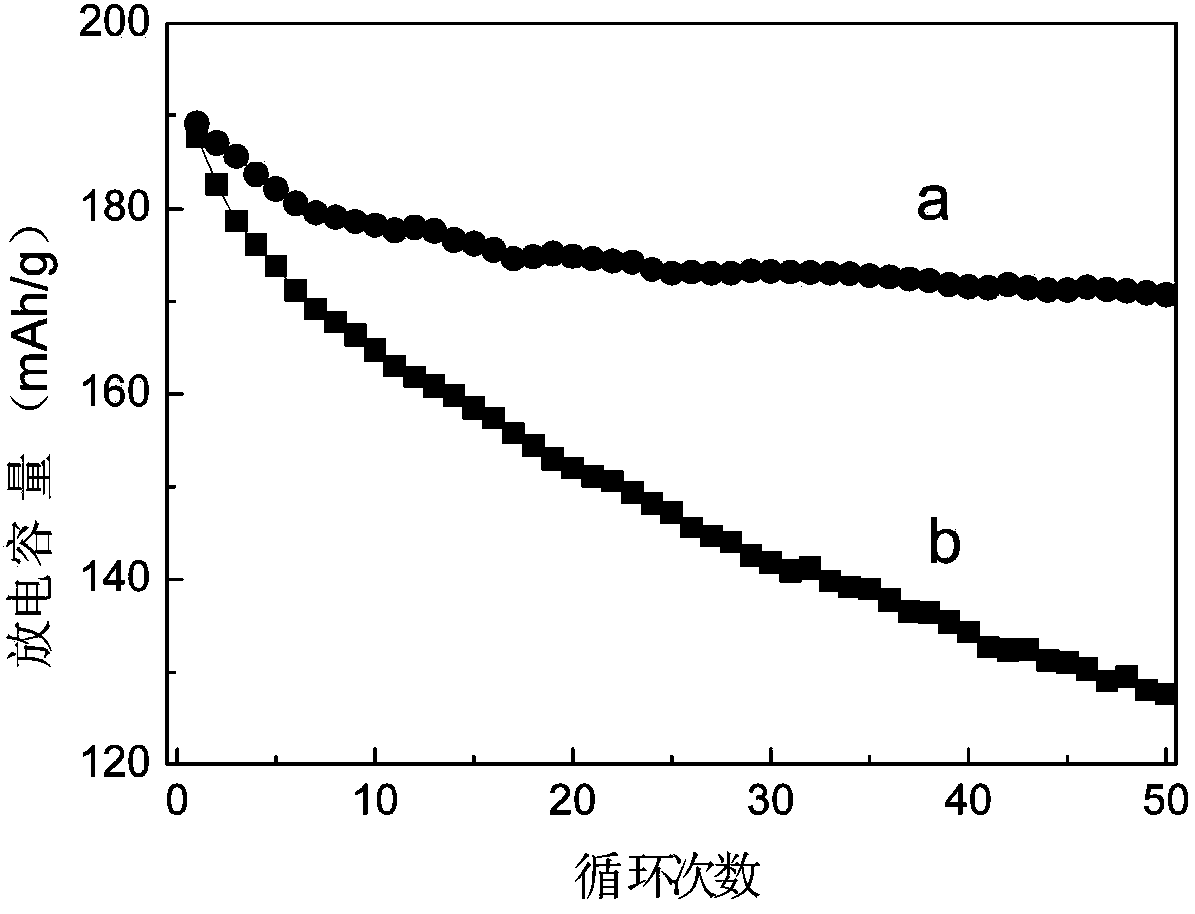

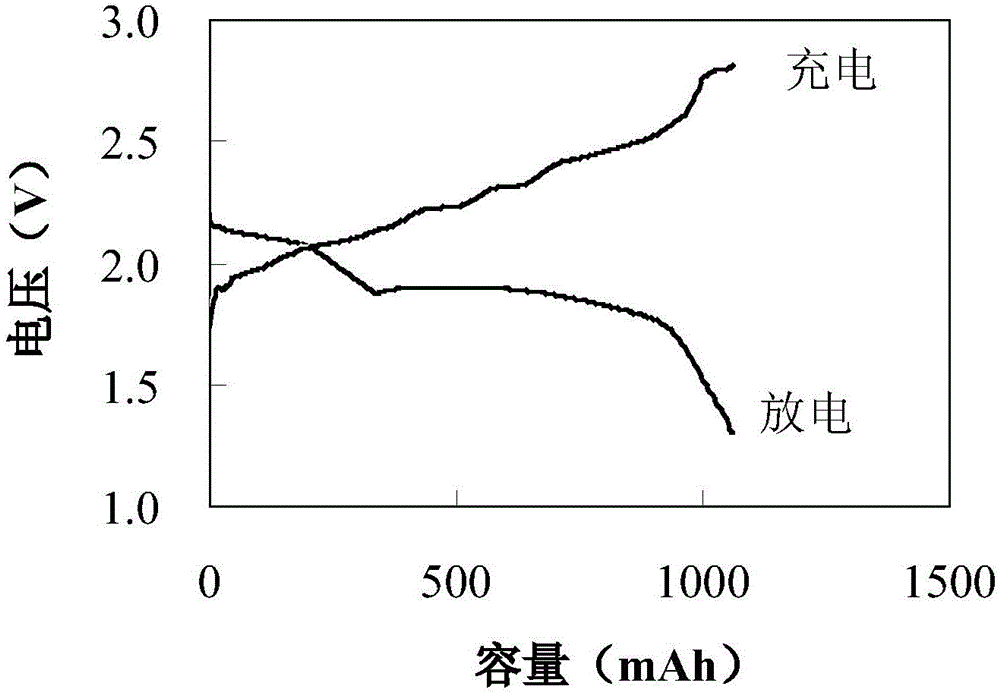

A making method of a zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode belongs to the technical field of batteries. In the invention, zinc oxide or aluminum-doped zinc oxide deposited on a routine lithium cobaltate electrode through a radio frequency magnetron sputtering technology as a coating material to obtain the coated and modified lithium cobaltate electrode. The method concretely comprises the following steps: mixing lithium cobaltate powder with a conductive additive, a binder and a solvent, grinding to prepare a slurry, coating a current collector with the slurry, drying the coated current collector to make the routine sheet lithium cobaltate electrode, and depositing the coating layer of zinc oxide or aluminum-doped zinc oxide by adopting the radio frequency magnetron sputtering technology to realize the coating modification of the lithium cobaltate electrode. The method improves the electrode interface situation, effectively inhibit the secondary reactions on the high-potential interval electrode surface, reduces the capacity loss and improves the structural stability of an active material, so the working voltages of the batteries are widened, and the energy density, the power density and the cycle performance of the batteries are improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Preparation method of lithium sulfur battery membrane electrode

InactiveCN104157909AImprove performanceEliminates the possibility of a reactionFinal product manufactureElectrolyte accumulators manufactureLithium–sulfur batteryInternal resistance

The invention relates to the technical field of a lithium sulfur battery, and aims at providing a preparation method of a lithium sulfur battery membrane electrode. The preparation method of the lithium sulfur battery membrane comprises the following steps: preparing a carbon material with nano ferrous sulfide being dispersed on the surface of a carbon carrier, and then preparing a positive electrode material by utilizing the carbon material; respectively preparing a positive electrode and a negative electrode as well as a lithium ion exchange membrane, and finally pressing the positive electrode, the negative electrode and the lithium ion exchange membrane into the lithium sulfur battery membrane electrode. The prepared lithium sulfur battery membrane electrode is good in conductivity, low in internal resistance, good in electrode reaction reversibility, good in chemical stability and thermal stability, low in price, easy to prepare, pollution-free, simple in battery manufacturing process, favorable for mass production and capable of effectively reducing the production cost.

Owner:ZHEJIANG UNIV

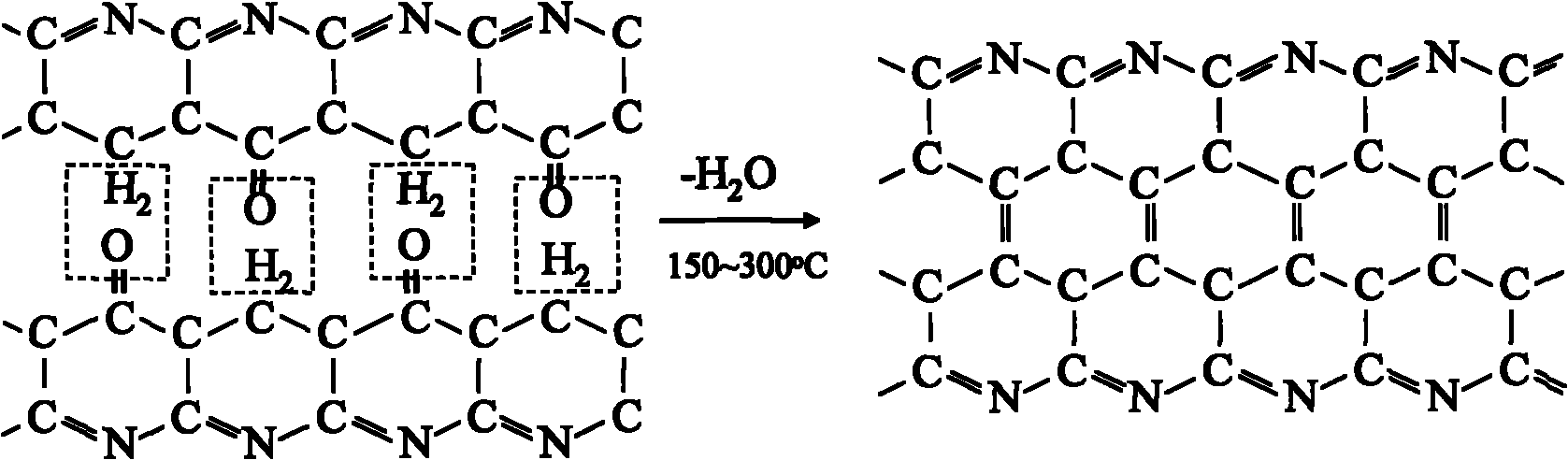

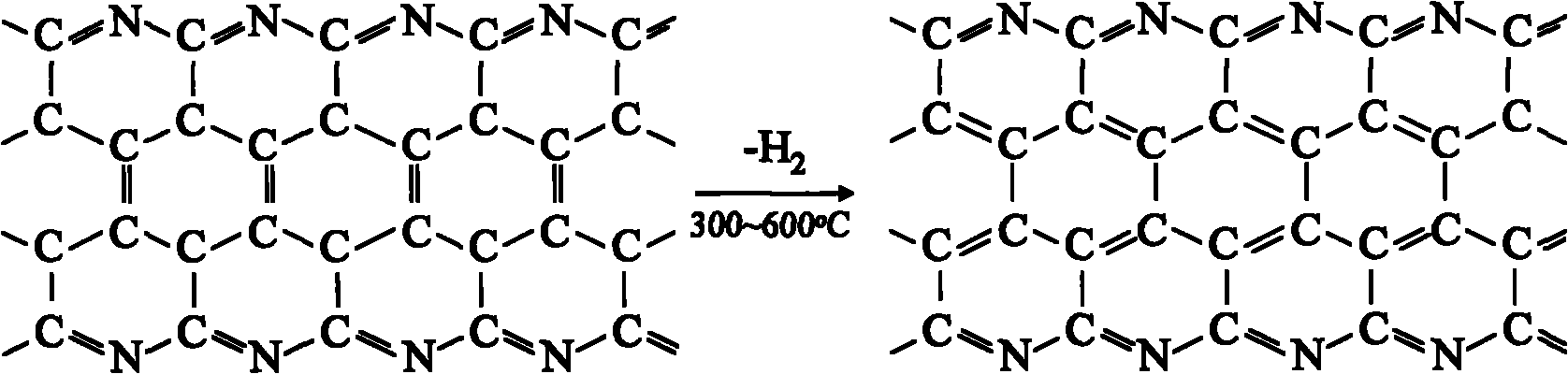

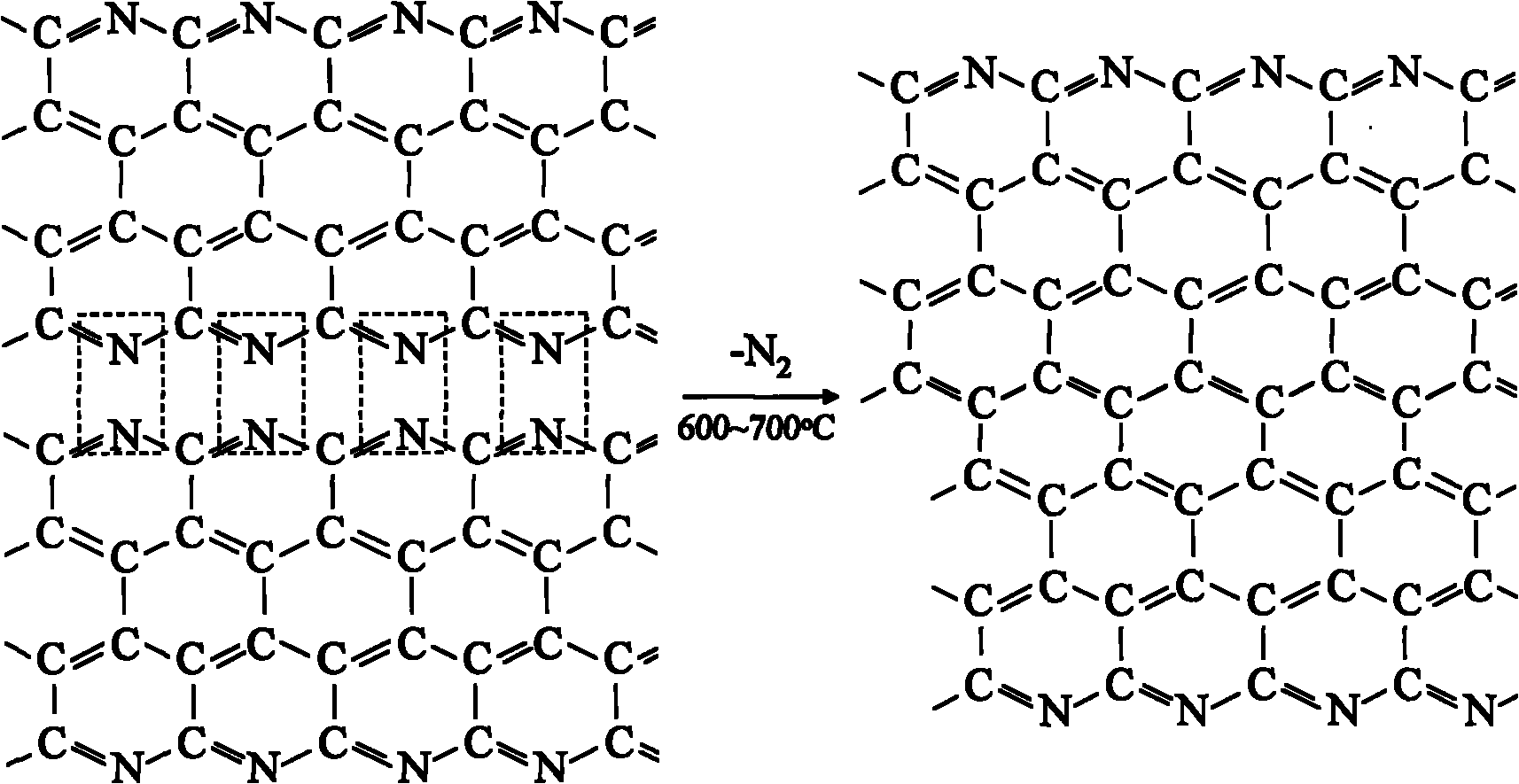

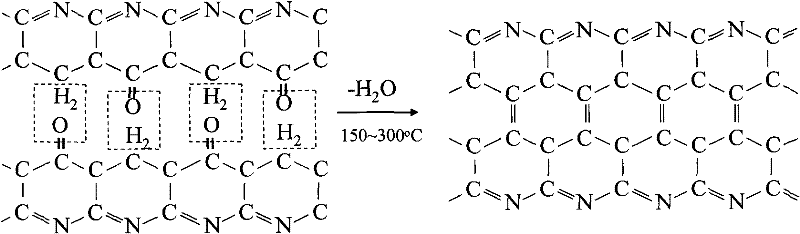

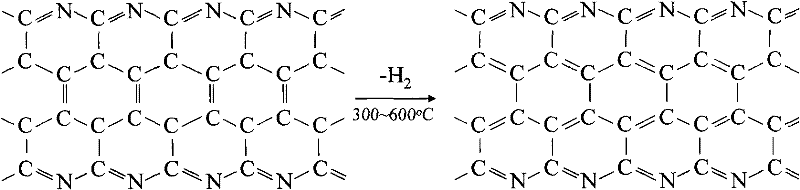

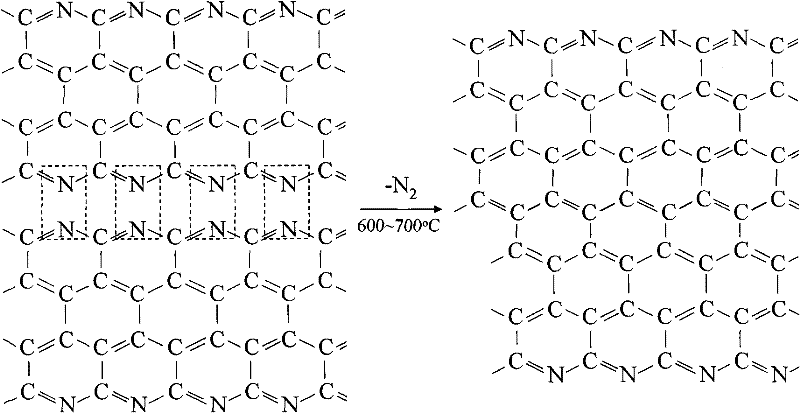

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204AImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmReaction temperature

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

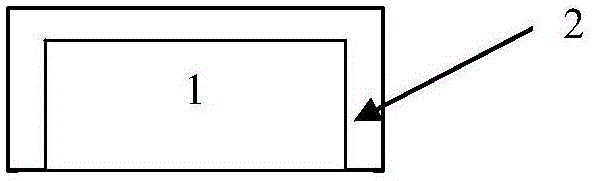

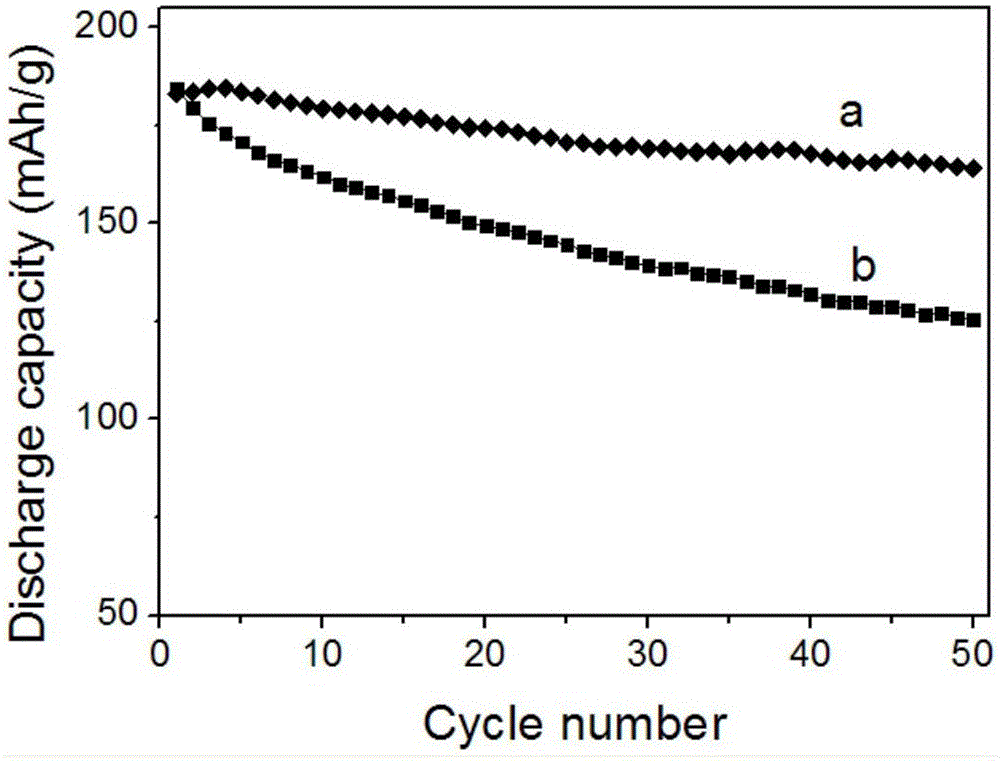

Composite lithium cobalt oxide electrode and fabrication method thereof

InactiveCN105140463AImprove performanceDoes not affect transportationCell electrodesLithium carbonateDecomposition

The invention provides a composite lithium cobalt oxide electrode and a fabrication method thereof, relating to the technology of a battery and aiming at solving the problem of poor performance of a high potential region of a conventional lithium cobalt oxide electrode. According to the summery of the technical scheme, the composite lithium cobalt oxide electrode comprises an ordinary lithium cobalt oxide electrode 1 and a lithium carbonate cladding layer 2, wherein the lithium carbonate cladding layer 2 is coated on the ordinary lithium cobalt oxide electrode 1 and deposited on the surface of the ordinary lithium cobalt oxide electrode 1 by a radio frequency magnetron sputtering process. The composite lithium cobalt oxide electrode has the advantages that the cladding layer is taken as an artificial solid electrolyte interface (SEI) membrane, the dissolution of a transition metal atom in an electrolyte and the decomposition of the electrolyte at a high potential are effectively suppressed, and a side reaction on the surface of the electrode is prevented from being generated, the structure of an active material is stabilized to a certain extent, the generation of a passivation layer on the surface of the electrode is slowed down, and the battery performance is improved. The lithium cobalt oxide electrode is applied to a lithium ion battery.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

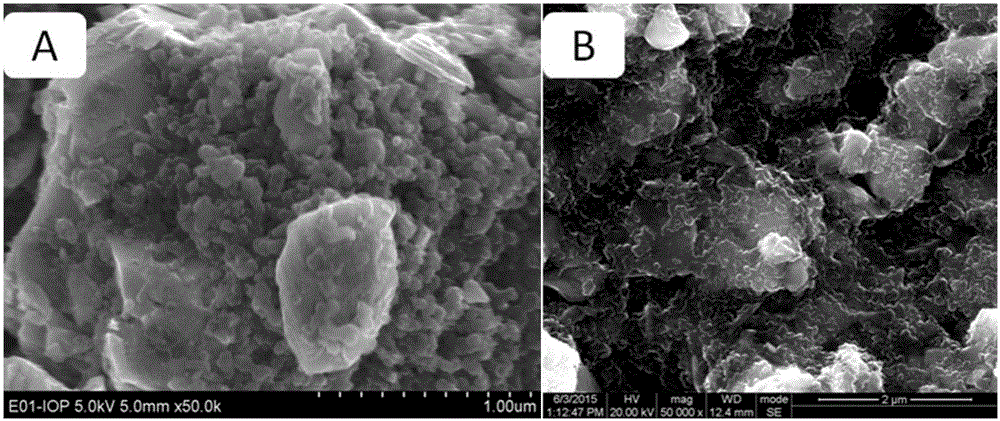

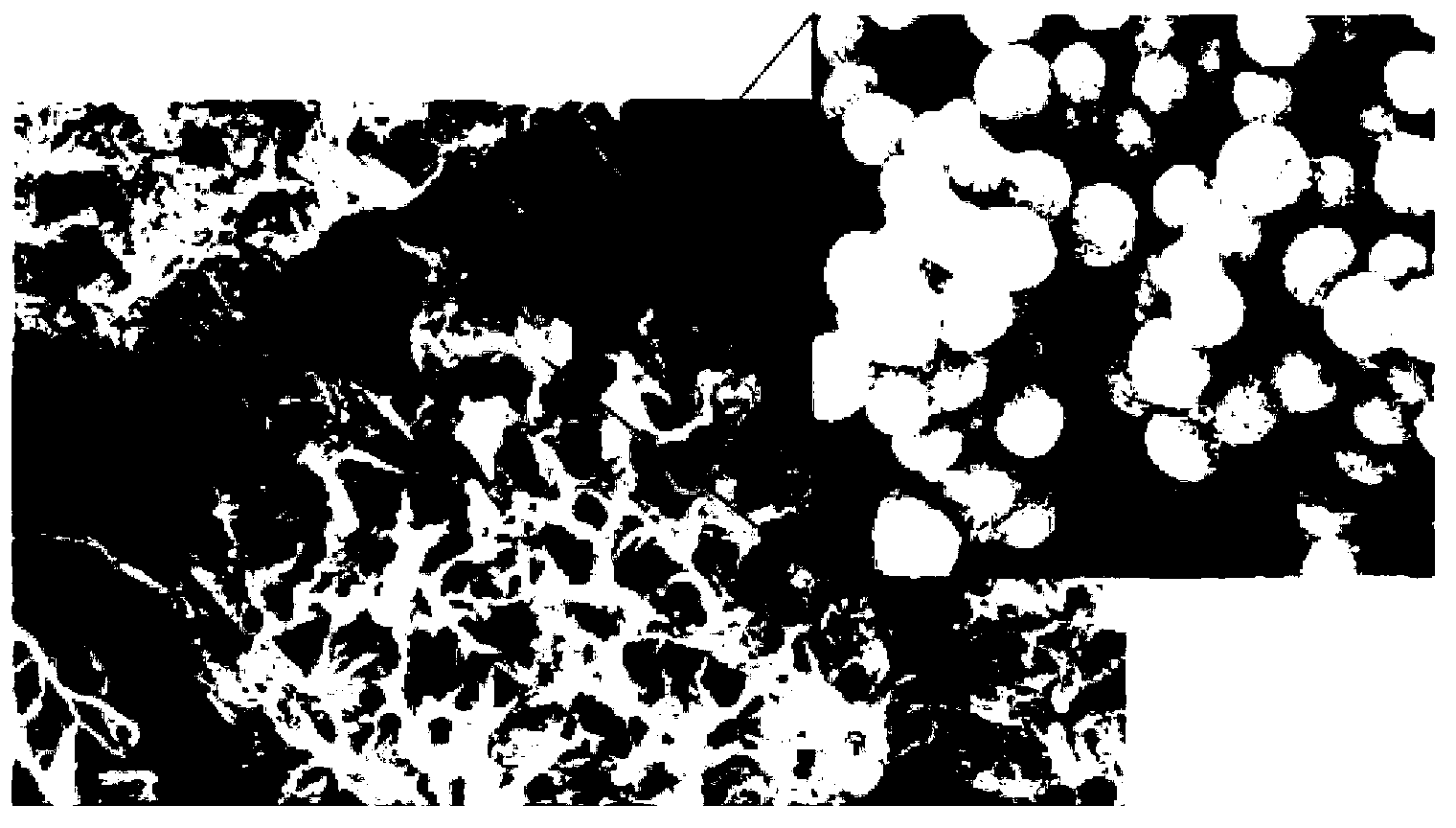

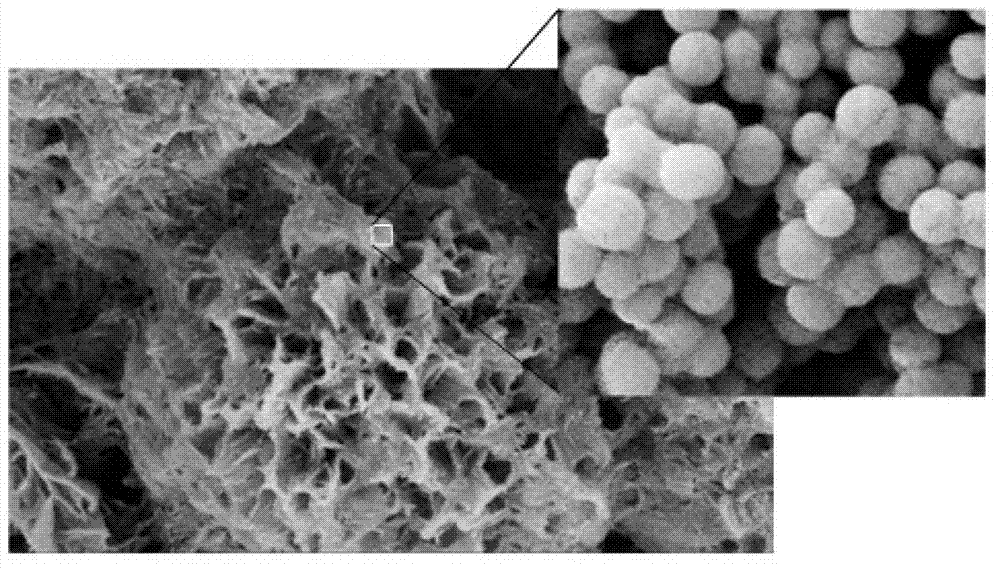

Three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material and preparation method thereof

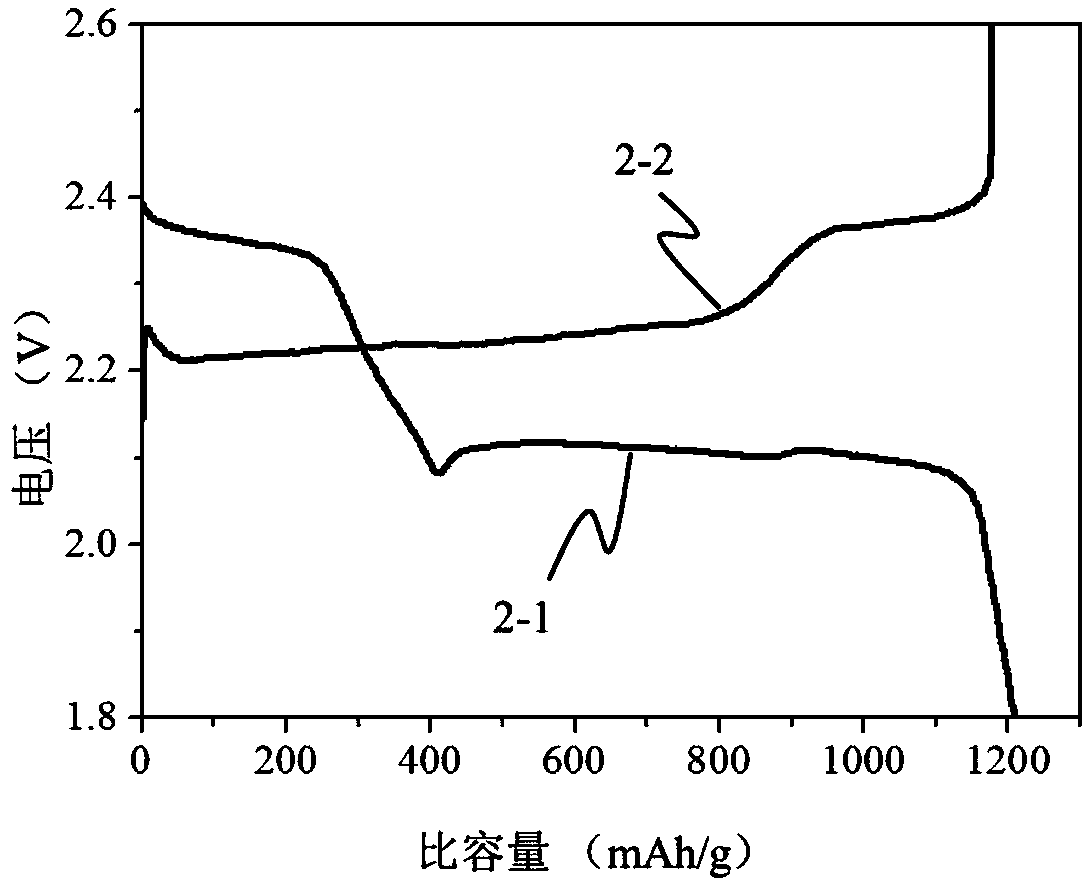

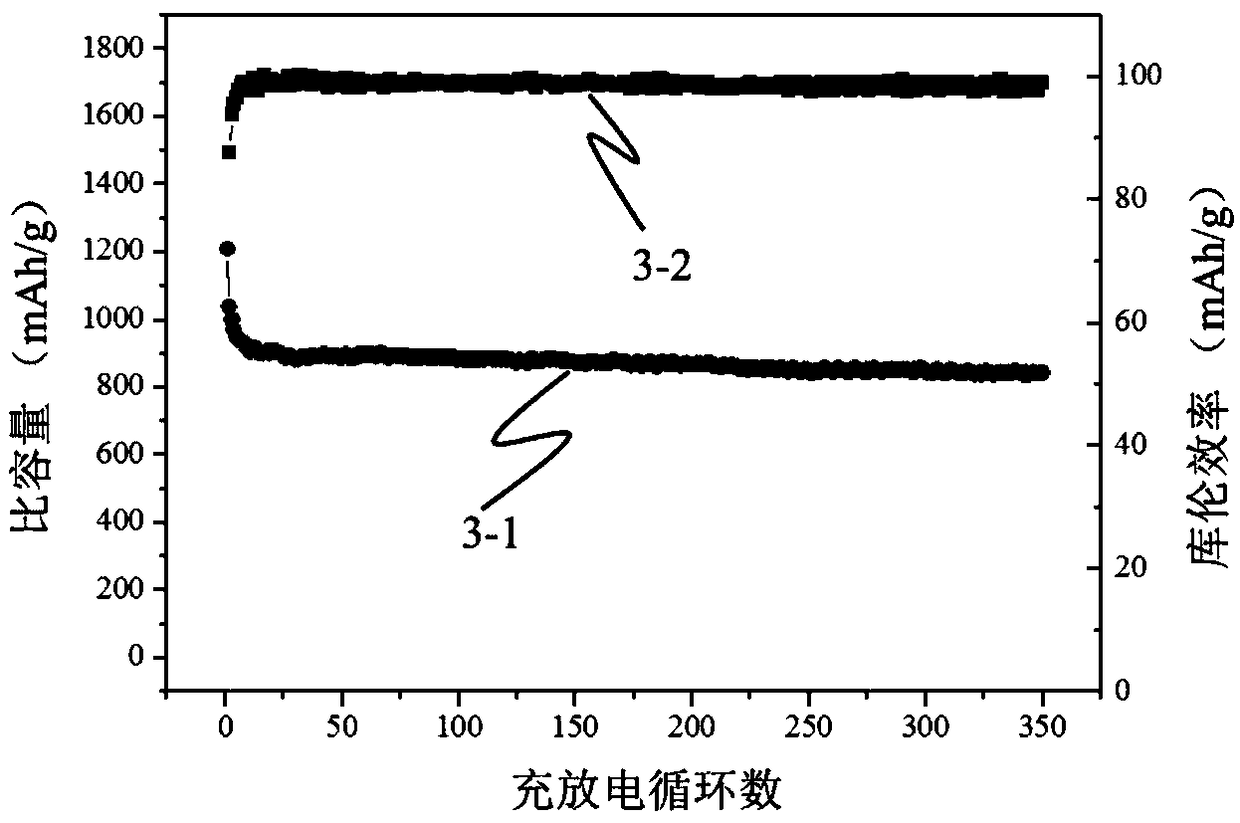

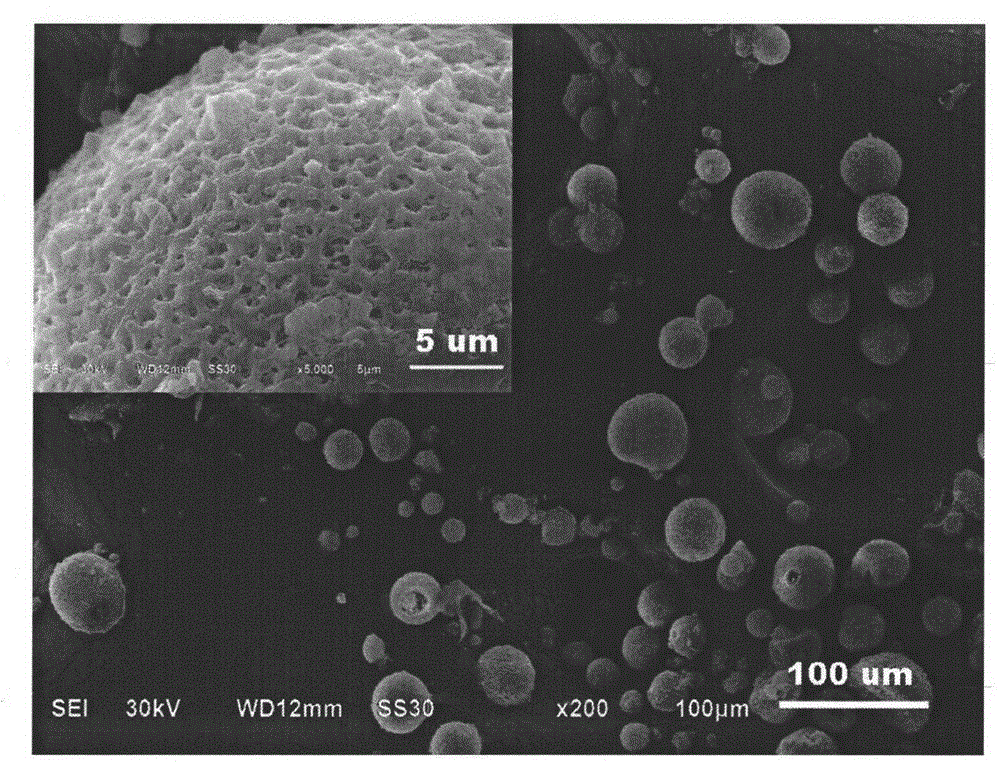

InactiveCN103904322AExcellent high temperature cycle performanceExcellent high rate charge and discharge performanceCell electrodesSecondary cellsMicrosphereManganate

The invention discloses a three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material and a preparation method thereof. The preparation method comprises the following steps of adsorbing Mn<2+> ions onto a carbonyl (-COH-) group in a microgel three-dimensional macromolecular network by adopting poly(acrylamide, acrylic acid) microgel spheres as a template; increasing the pH value of the poly(acrylamide, acrylic acid) microgel spheres so as to in-situ hydrolyze the Mn<2+> ions to generate Mn(OH)2 crystal nucleus, depositing the Mn(OH)2 crystal nucleus into a space formed by the three-dimensional macromolecular network to form nano composite polymer microspheres; placing the obtained nano composite polymer microspheres into a tubular furnace to be calcined at a high temperature in an inert gas atmosphere to prepare the three-dimensional porous nanocarbon composite lithium manganate spherical positive electrode material. The positive electrode material has the advantages of excellent high-temperature cycling performance, large multiplying power charging-discharging performance and the like, and can be widely applied to the production of a lithium battery.

Owner:XIANGTAN UNIV

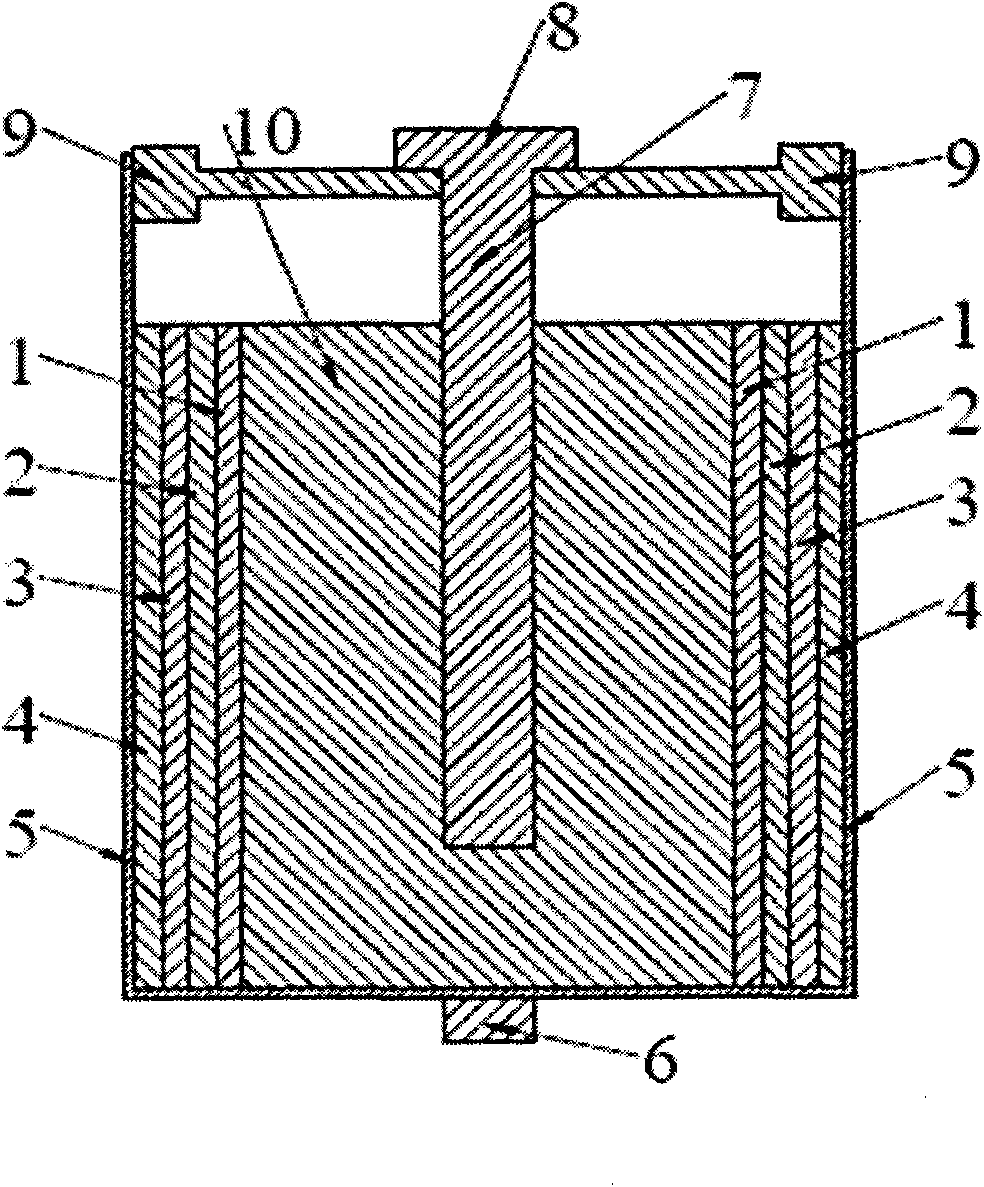

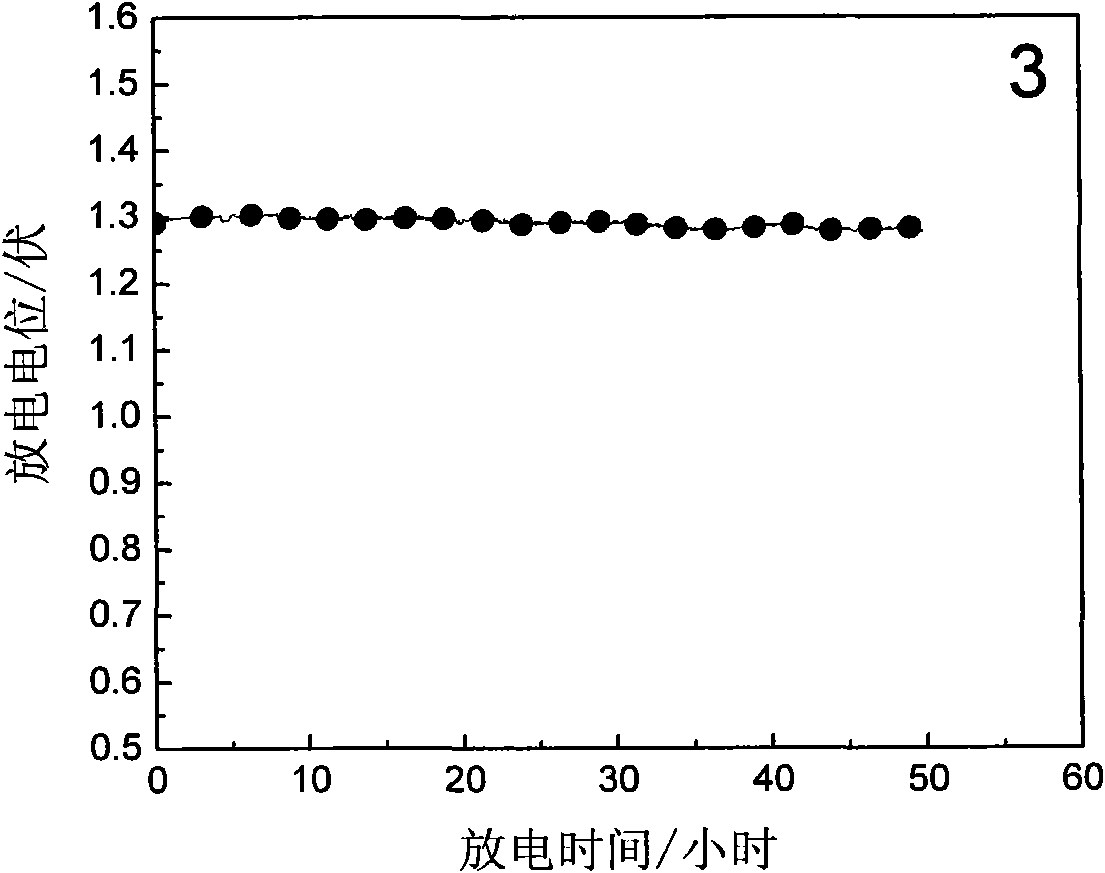

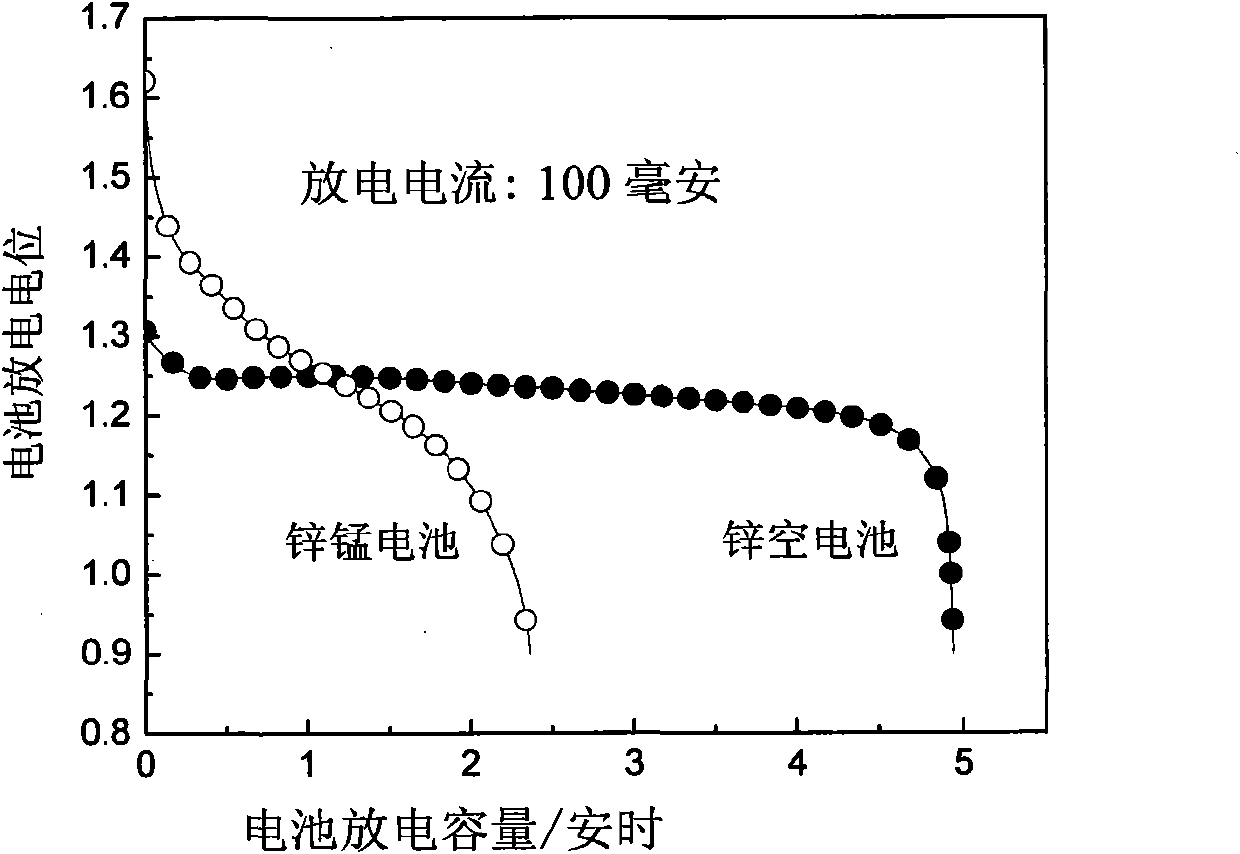

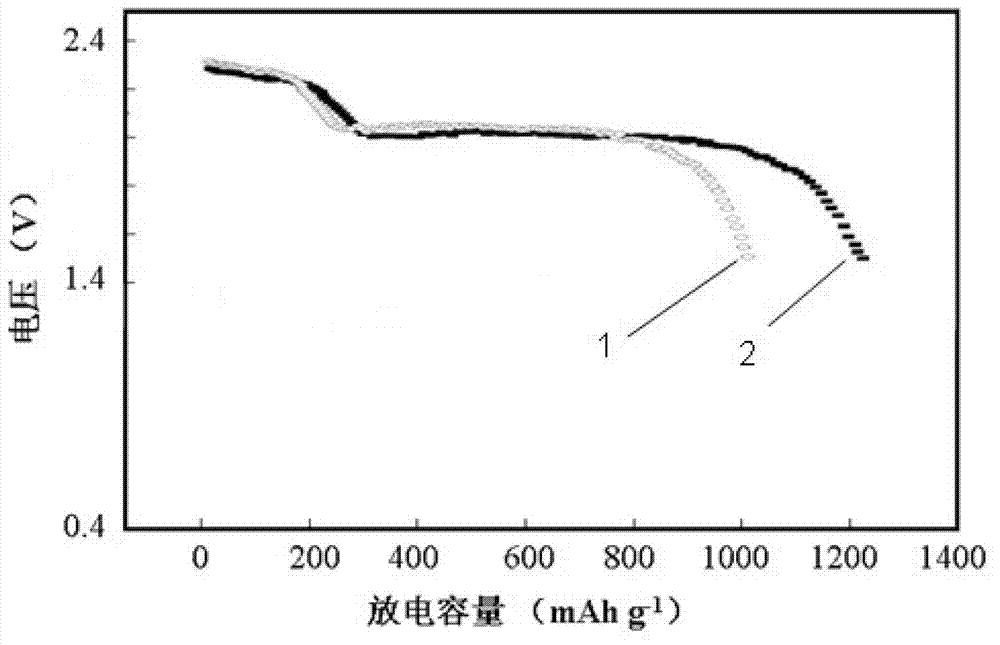

Cylindrical film air electrode and application thereof in zinc-air battery

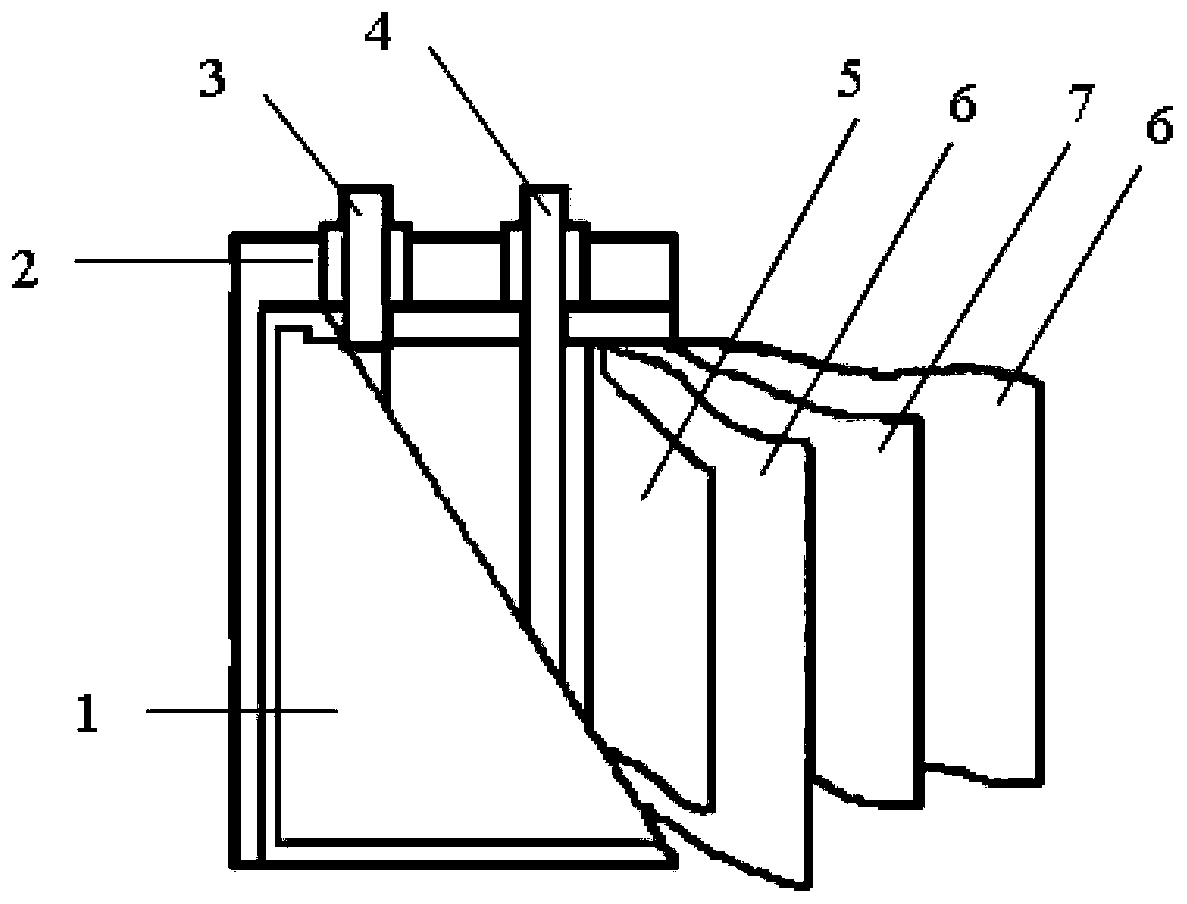

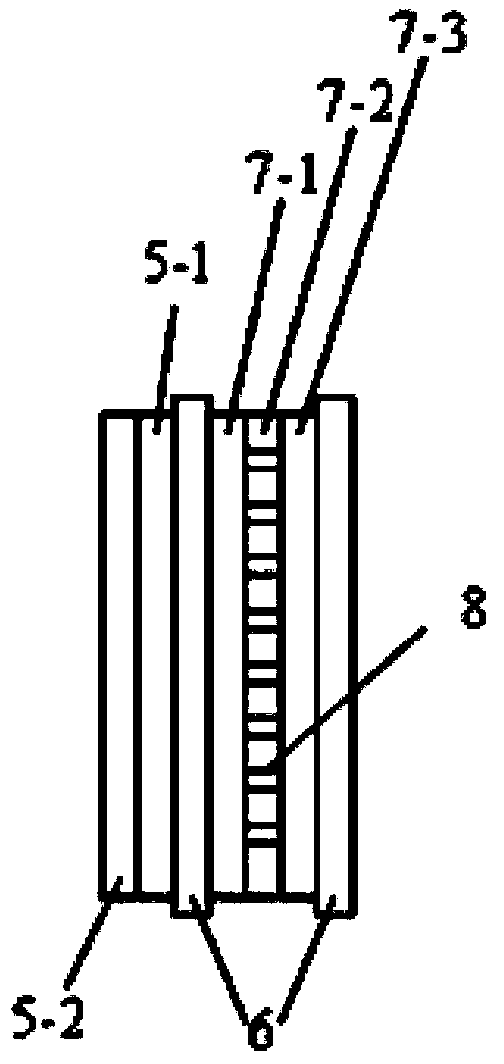

InactiveCN102005578AImprove electrochemical kinetic performanceShorten the diffusion pathFuel and primary cellsCell electrodesHigh energyEngineering

The invention relates to a cylindrical film air electrode comprising a gas diffusion layer, an electric catalyst layer, a current-collecting net and a battery diaphragm, wherein the gas diffusion layer is used as an outer wall of the cylindrical film air electrode, the bottom center of the cylindrical film air electrode is provided with an air electrode joint. A cylindrical zinc-air battery prepared by the cylindrical film air electrode comprises a battery shell, the cylindrical film air electrode, a zinc electrode and a plastic seal ring, wherein the cylindrical film air electrode is arranged into a cylinder used as the battery shell, the zinc electrode comprises zinc alloy cream and an anode current collecting end, and the anode current collecting end is fixed at the upper end of the battery shell cylinder by the plastic seal ring. The cylindrical film air electrode shortens an air diffusion path and improves electrochemic and dynamic performance of the air electrode, therefore, the zinc-air battery manufactured by adopting the cylindrical film air electrode has the advantages of high energy density, good electrochemic and dynamic performance, smooth discharge curve, long work time, and the like.

Owner:NANKAI UNIV

Composite cathode of chromium-pollution-resistant solid oxide fuel battery and preparation method thereof

InactiveCN103346330AQuick and easy to manufactureSmall particle sizeCell electrodesFuel cellsComposite cathode

The invention discloses a composite cathode of a chromium-pollution-resistant solid oxide fuel battery and a preparation method thereof. The composite cathode comprises an active layer and a collector layer. The active layer is arranged on an electrolyte layer, and the active layer is made of LNF-doped CeO2; and the collector layer is arranged on the active layer and made of LNF. The preparation method comprises the following steps of step1. adhering the pulp which is formed by the preparation material of the active layer onto the electrolyte layer to be dried, and preparing an active layer blank body; step 2. adhering the pulp which is formed by the preparation material of the collector layer onto the active layer blank body, and drying the pulp to obtain the collector layer blank body, and compounding the prepared active layer and the prepared collector layer into a cathode blank body; and step 3. sintering the composite cathode blank body. The composite cathode has excellent electrochemical catalytic performance and chromium pollution resistance; the preparation method has the advantages of simplicity in process, short preparation period and low cost, and the chromium-pollution-resistant solid oxide fuel battery is applicable to the industrialized application.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing conductive carbon film-coated calcium or calcium-tin alloy serving as anode material of lithium battery

InactiveCN102082263AIncrease speed capacityUniform thicknessCell electrodesLi-accumulatorsCarbon filmPolyethylene glycol

The invention relates to a method for preparing an anode material of a lithium battery and aims to provide a method for preparing a conductive carbon film-coated calcium or calcium-tin alloy serving as the anode material of the lithium battery. The method comprises the following steps of: melting high-purity calcium metal or calcium metal and tin metal, spraying into polyethylene glycol liquid byusing high purity argon, and cooling fog drops in the polyethylene glycol liquid to obtain spherical powder; carbonizing polyethylene glycol to obtain a carbon coated calcium material; filtering out the carbon coated calcium material; calcining again in vacuum or high purity nitrogen atmosphere at the temperature of below 700 DEG C; further carbonizing to remove residual polyethylene glycol on the carbon coated calcium material; and cooling to obtain the conductive carbon film-coated calcium serving as the anode material for preparing the lithium battery. A conductive carbon film is formed onthe surfaces of the calcium or calcium-tin alloy particles and is favorable for the stability of an electrode structure. A gas spraying method for preparing the carbon coated material is favorable for scale production and cost reduction.

Owner:ZHEJIANG UNIV

Preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material

InactiveCN103311512AIncrease speed capacityImprove reliabilityCell electrodesSecondary cellsModified carbonHeat stability

The invention relates to the technology of batteries, and aims at providing a preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material. The method comprises the following steps: reacting carbon source material, deionized water and spherical aluminum powder at the temperature of 250 DEG C, and performing centrifugal separation to obtain a brown or black solid powder sample; washing, performing centrifugal separation, drying, and then carbonizing at a constant temperature in nitrogen; performing acid treatment or alkaline treatment after cooling; washing and performing vacuum drying after filtering so as to obtain hollow carbon spheres; reacting the hollow carbon spheres, indole and transition metals at the temperature of 100-300 DEG C, performing vacuum drying after filtering and washing so as to obtain hollow carbon spheres modified by indole and transition metals; grinding and mixing with elemental sulfur, placing in a reactor, vacuumizing and heating to complete sulfur storage process through reactions, and cooling to room temperature. Organic electrolytes are safe in the application of battery; the anode material has good electrode reaction reversibility and good chemical stability and heat stability, and is low in cost, easy to prepare and free from pollution.

Owner:ZHEJIANG UNIV

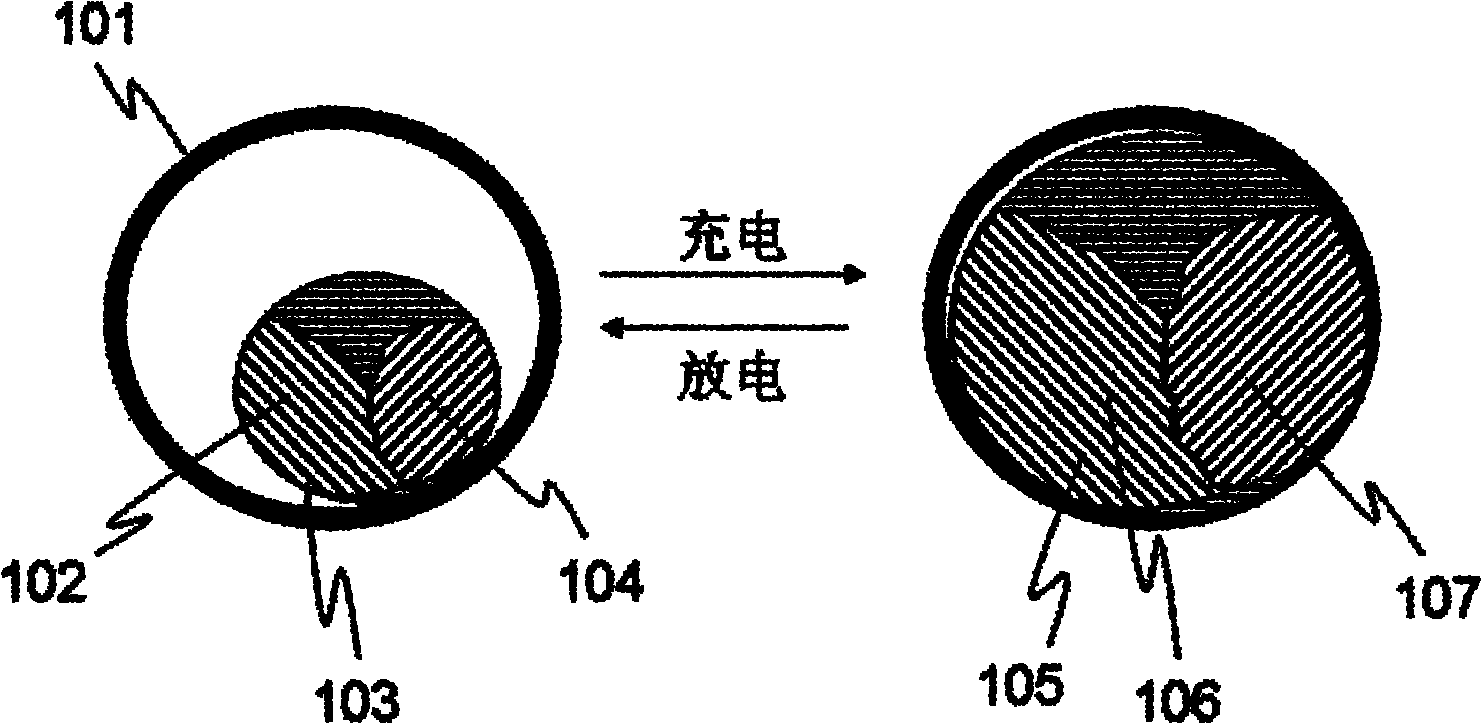

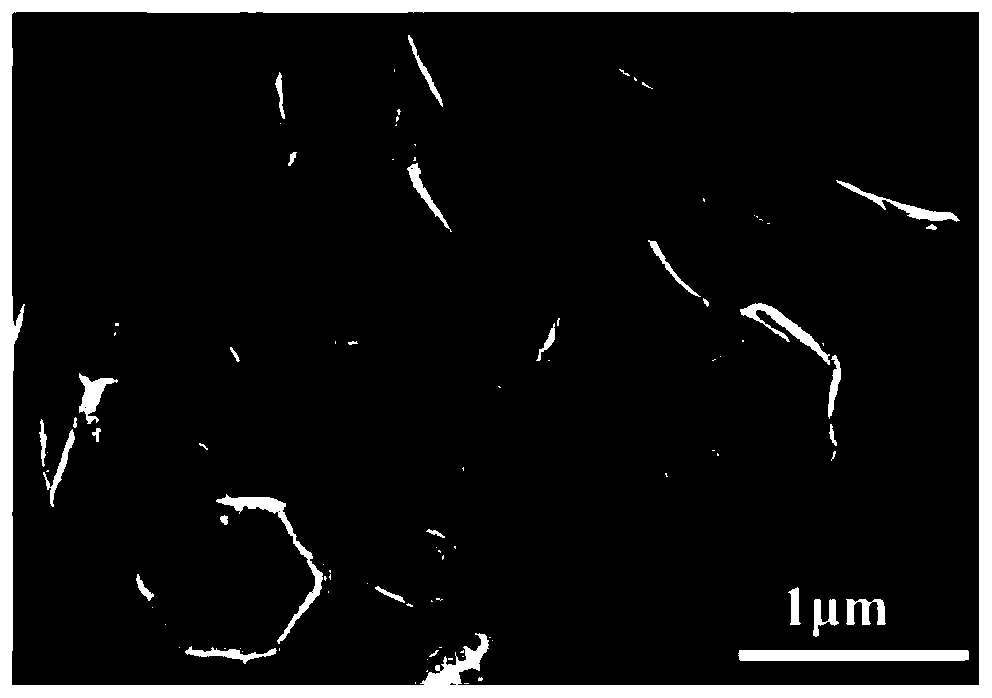

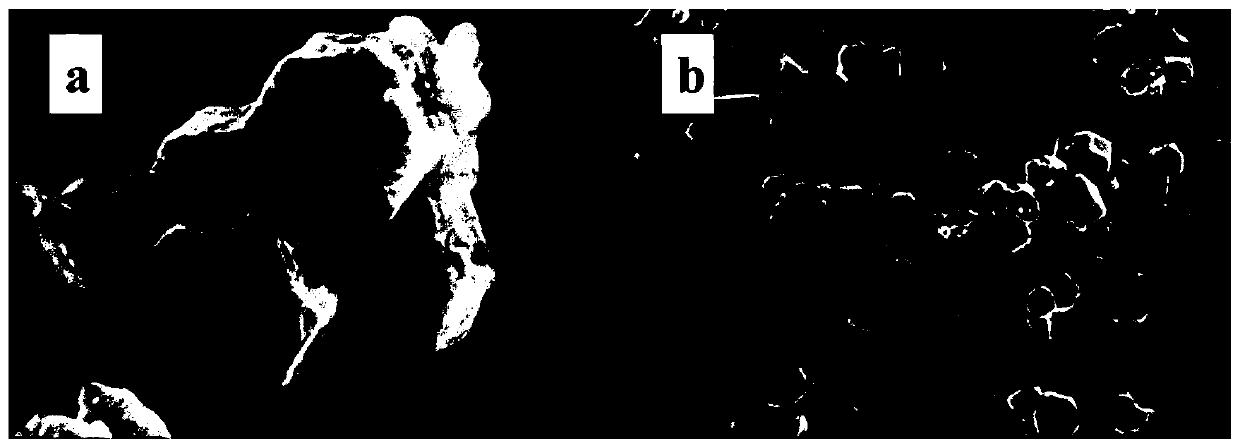

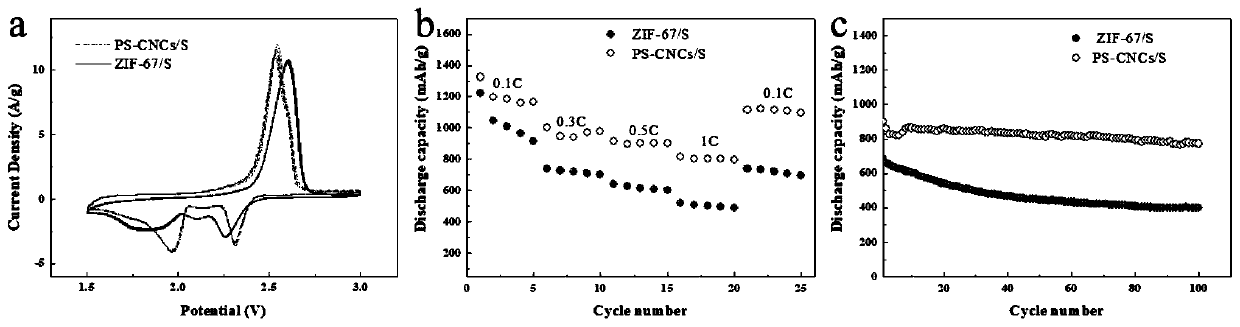

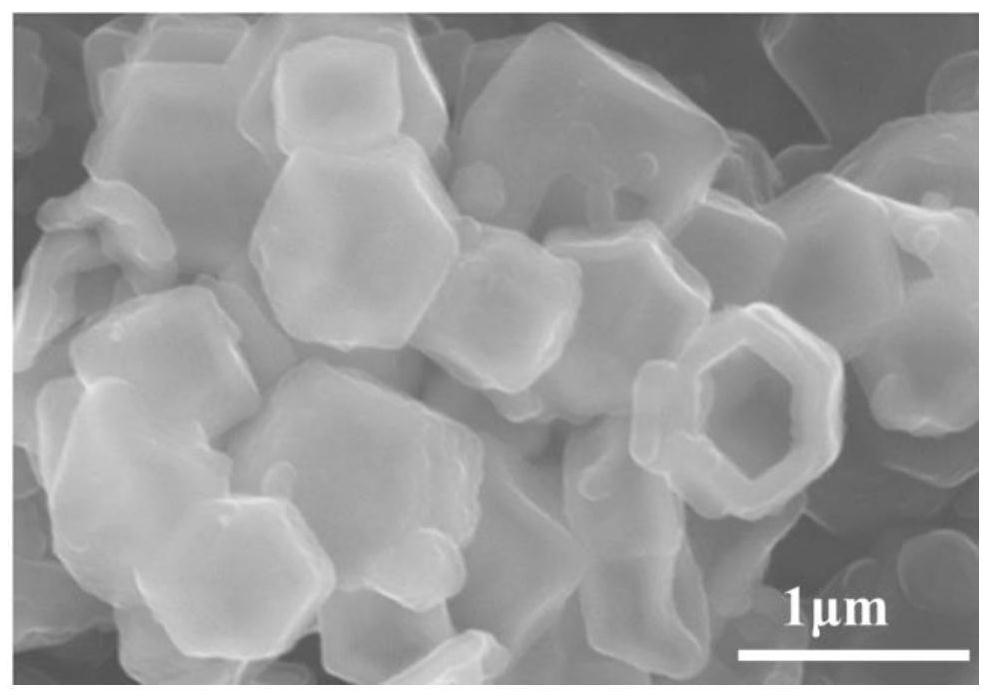

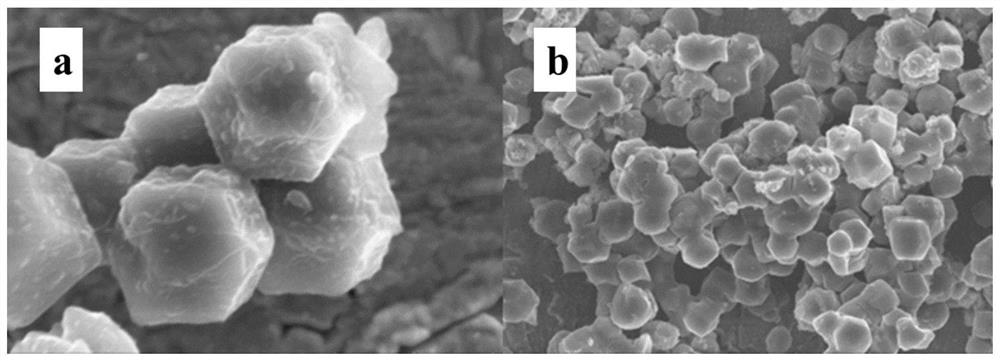

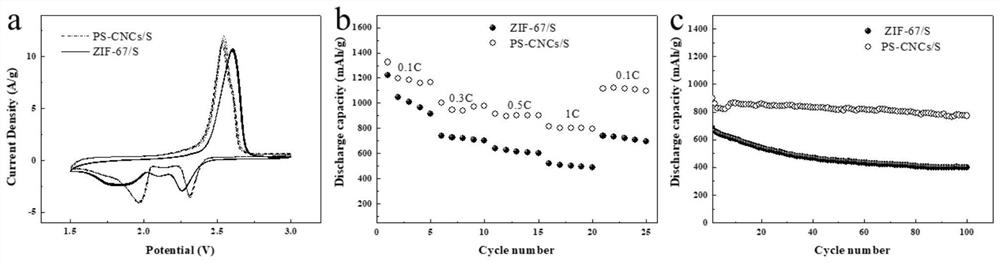

Polypyrrole-coated sulfur-doped cobalt-based carbon nanocage material, preparation method and application thereof

ActiveCN110783549ALimit volume expansionAlleviate volume expansionPositive electrodesLi-accumulatorsLithium–sulfur batteryPolypyrrole

The invention discloses a polypyrrole-coated sulfur-doped cobalt-based carbon nanocage material, a preparation method and application thereof, and belongs to the technical field of lithium-sulfur batteries. The method specifically includes the following steps: preparation of a precursor cobalt-based ZIF-67, preparation of sulfur-doped cobalt-based carbon nanocages, and preparation of polypyrrole-coated sulfur-doped cobalt-based carbon nanocages (PS-CNCs). By forming an internal hollow structure in the carbon nanocages, it is possible to contain more active material sulfur and restrict the volume expansion of sulfur, thereby effectively alleviating the volume expansion during a battery reaction, and extending a service life. The co-doping of sulfur and cobalt can effectively improve the interaction of the PS-CNCs and polar polysulfides in a reaction can effectively inhibit the shuttle effect of the polysulfide and improve the cycle performance of the battery. The use of the polypyrrole-coated carbon nanocages can significantly improve the conductivity of the material, reduce the impedance, inhibit polarization, and improve battery stability. The method of the invention has low cost,simple operation and an obvious effect, and is suitable for popularization.

Owner:JILIN UNIV

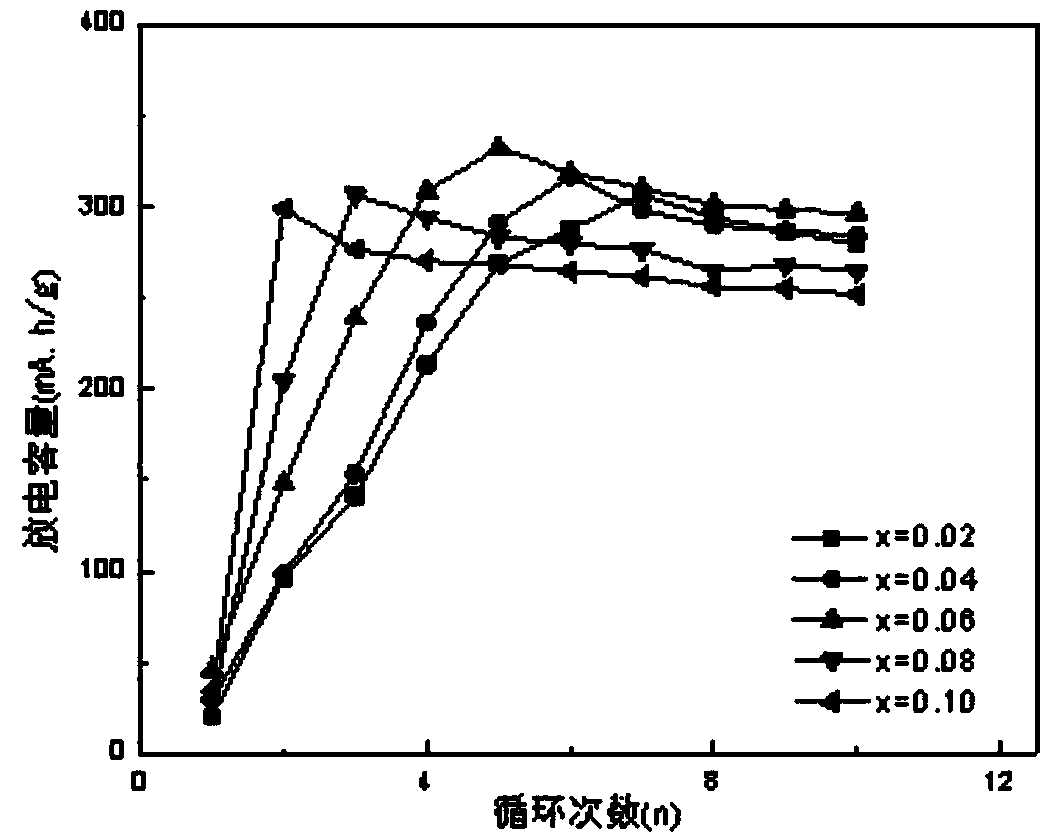

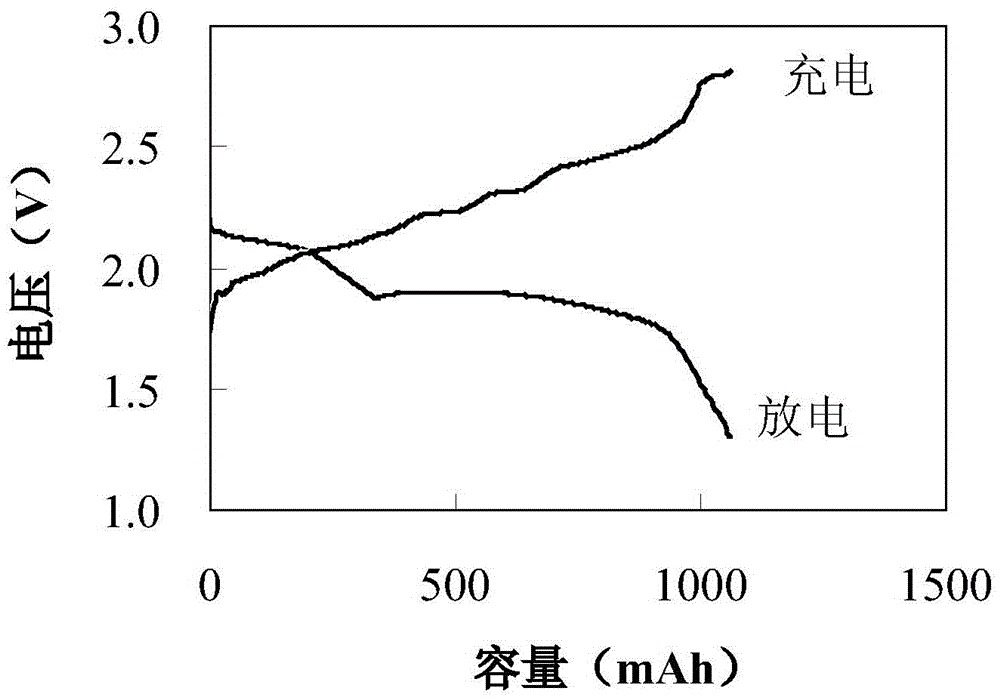

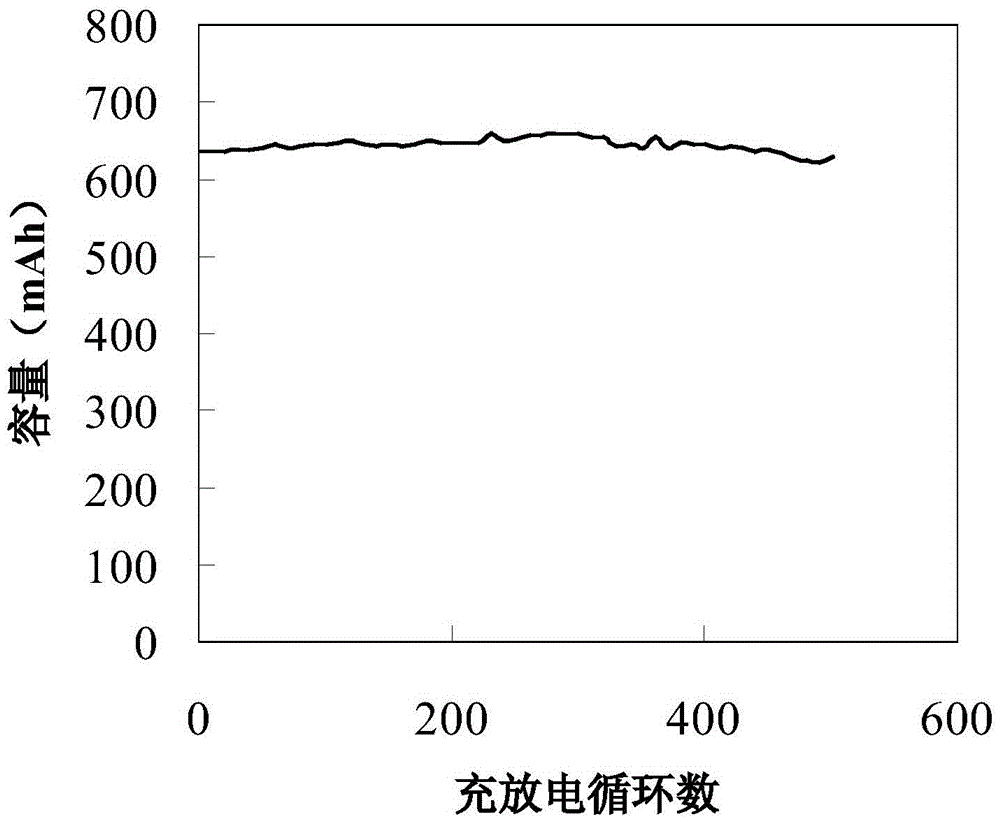

Vanadium-based hydrogen storage alloy as well as preparation method and application thereof

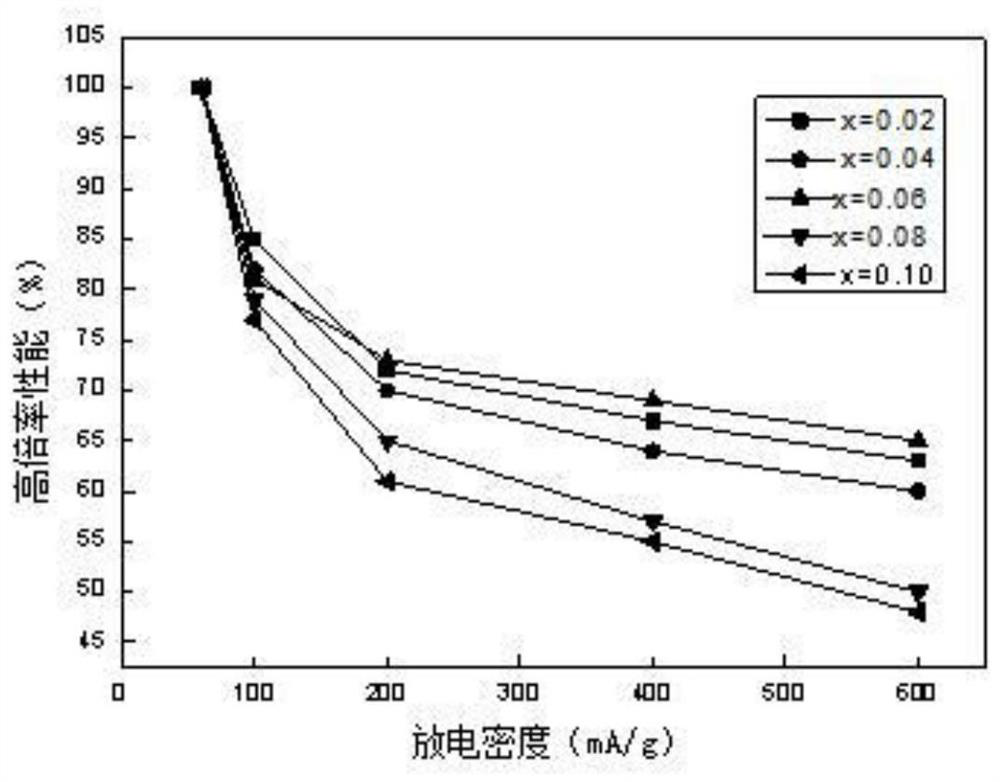

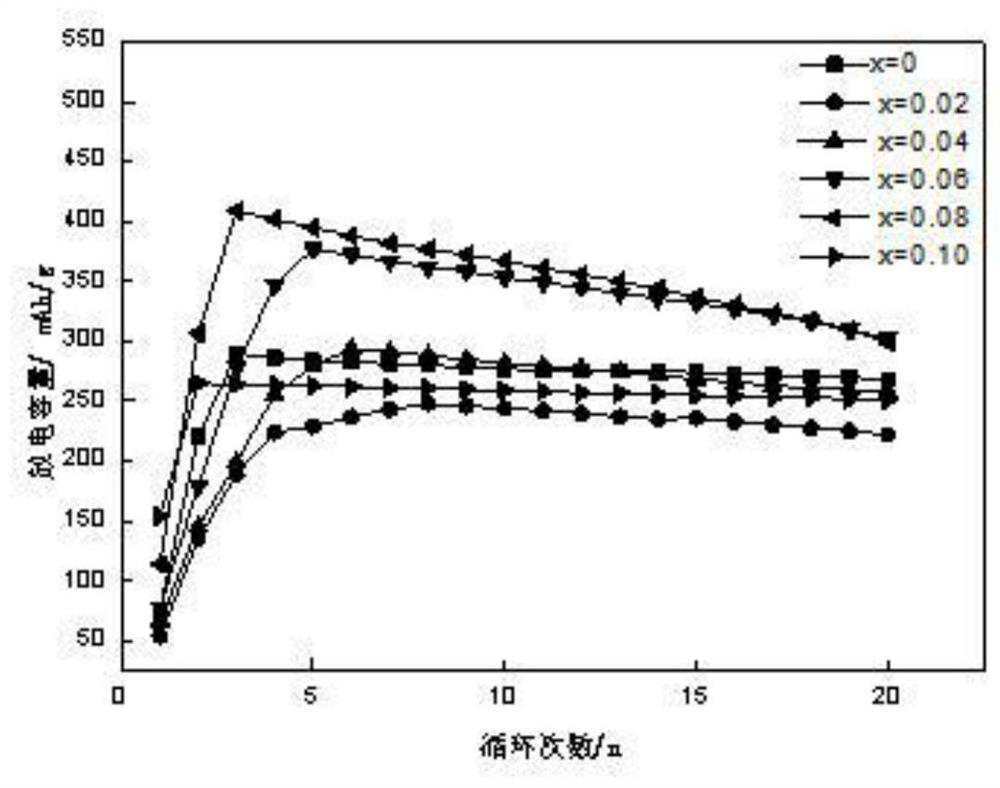

ActiveCN109390580AImprove discharge capacityImprove electrochemical kinetic performanceCell electrodesNickel accumulatorsRare-earth elementElectrochemical kinetics

The invention discloses a vanadium-based hydrogen storage alloy, and belongs to the technical field of nickel-hydrogen battery development. The chemical formula of the alloy is V2TiNi0.5Cr0.5Mx, x islarger than 0 and smaller than or equal to 0.2, and M is at least one of La, Ce, Y, Sc, Nd, Gd, Er, and Yb. According to the alloy, the advantages and disadvantages of rare earth hydrogen storage alloy and vanadium-based hydrogen storage alloy are considered, V, Ti, Cr and Ni are used as matrix alloys, La, Ce, Y, Sc, Nd, Gd, Er and Yb in rare earth are used as modified metals, and after rare earthelements are introduced into the vanadium-based hydrogen storage alloy, on the one hand, the discharge capacity of the hydrogen storage alloy serving as a nickel-hydrogen battery anode material can be improved, and on the other hand, the electrochemical kinetics performance of the alloy electrode can be improved. The technical problems of low actual discharge capacity and insufficient kinetics performance of the existing nickel-hydrogen battery are solved.

Owner:PANZHIHUA UNIV

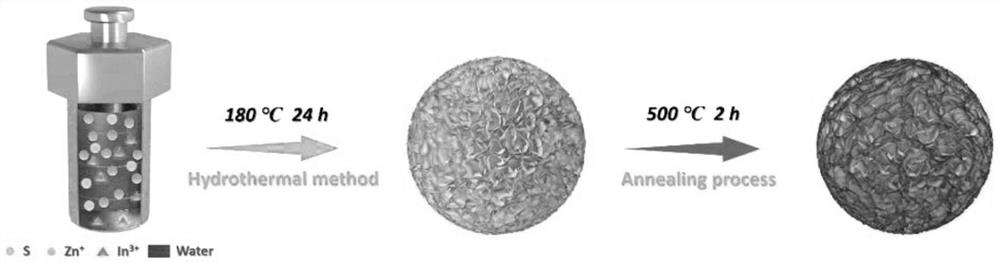

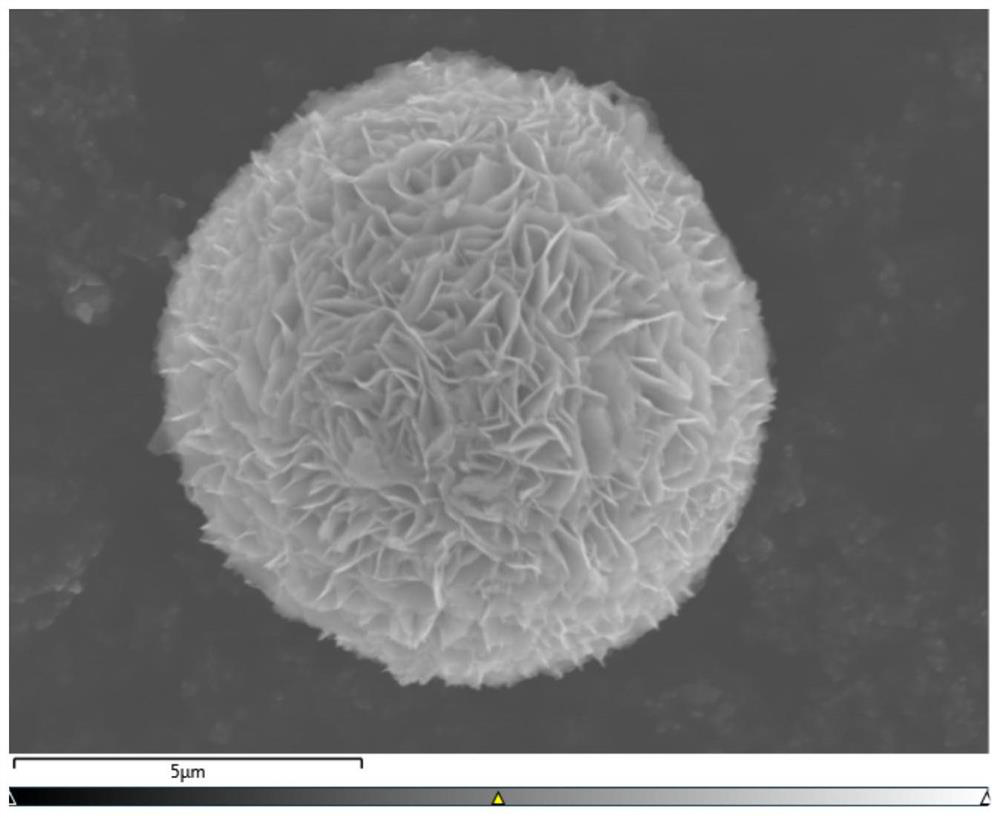

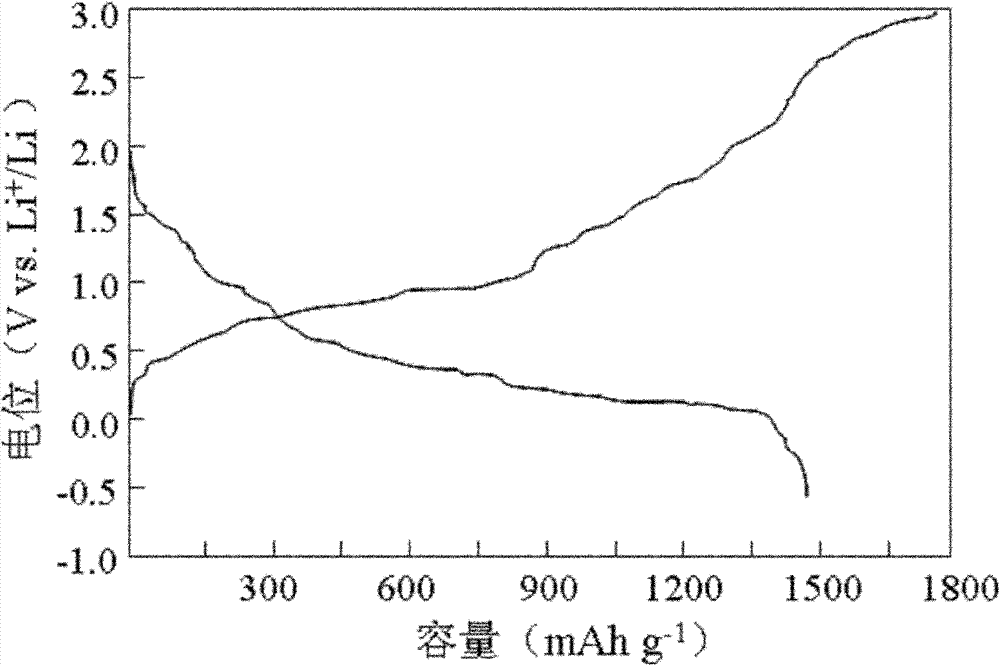

ZnIn2S4 sodium ion battery negative electrode material and preparation method thereof

ActiveCN112960688AUniform microscopic morphologyHigh crystallinityCell electrodesGallium/indium/thallium compoundsPhysical chemistrySodium-ion battery

The invention provides a ZnIn2S4 sodium-ion battery negative electrode material and a preparation method thereof. Specifically, a precursor solution is transferred into a 50 mL polytetrafluoroethylene reaction kettle, the reaction kettle is placed in a container filled with inert gas, the inert gas is introduced into the precursor solution for 10-30 min to drive dissolved oxygen in the precursor solution, the influence of oxygen on Zn is avoided, and large-scale ZnIn2S4 particles with good crystallinity and a uniform microflower spherical microstructure are obtained.

Owner:HENAN UNIVERSITY

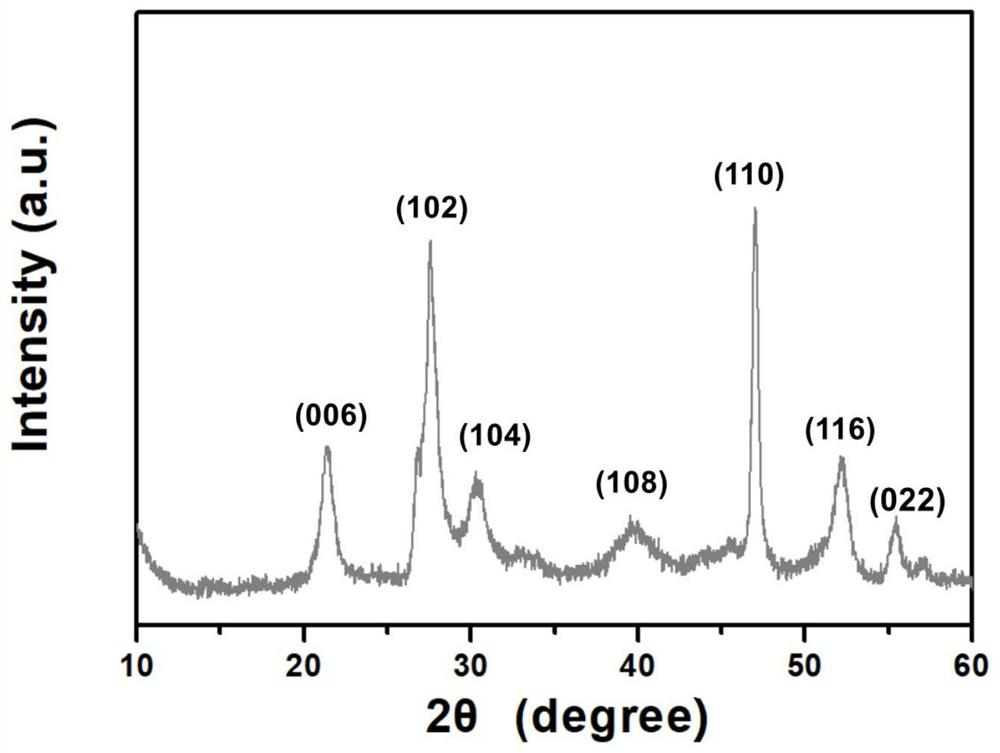

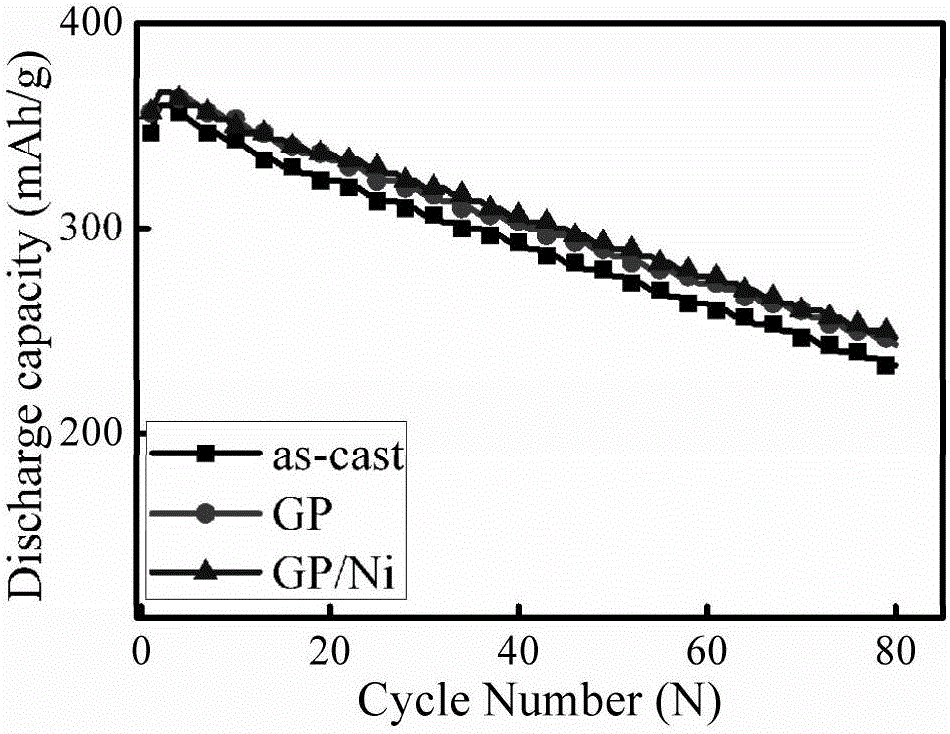

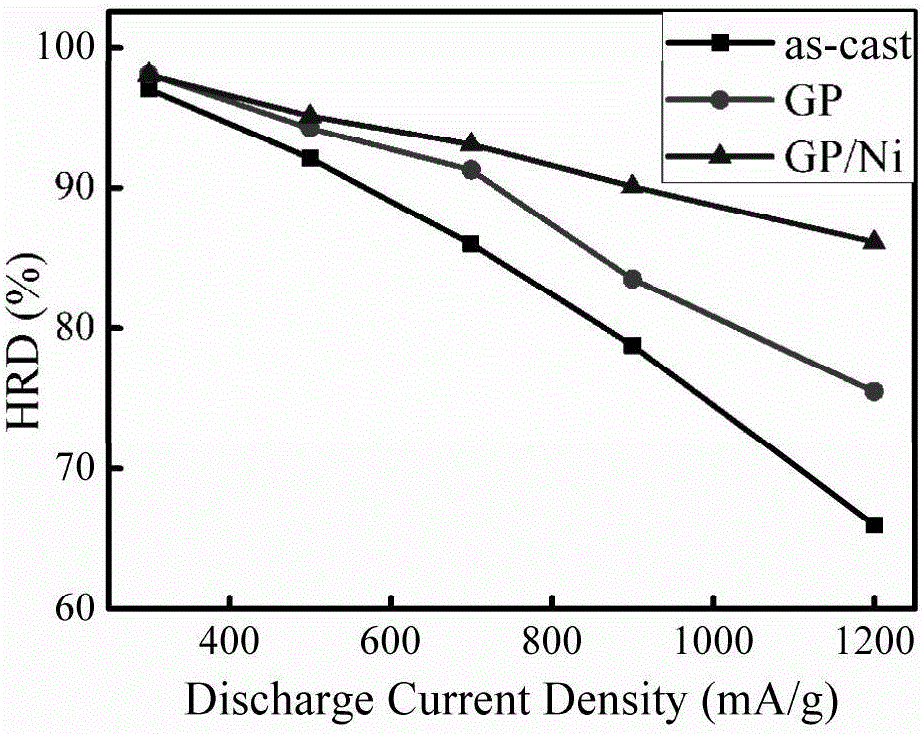

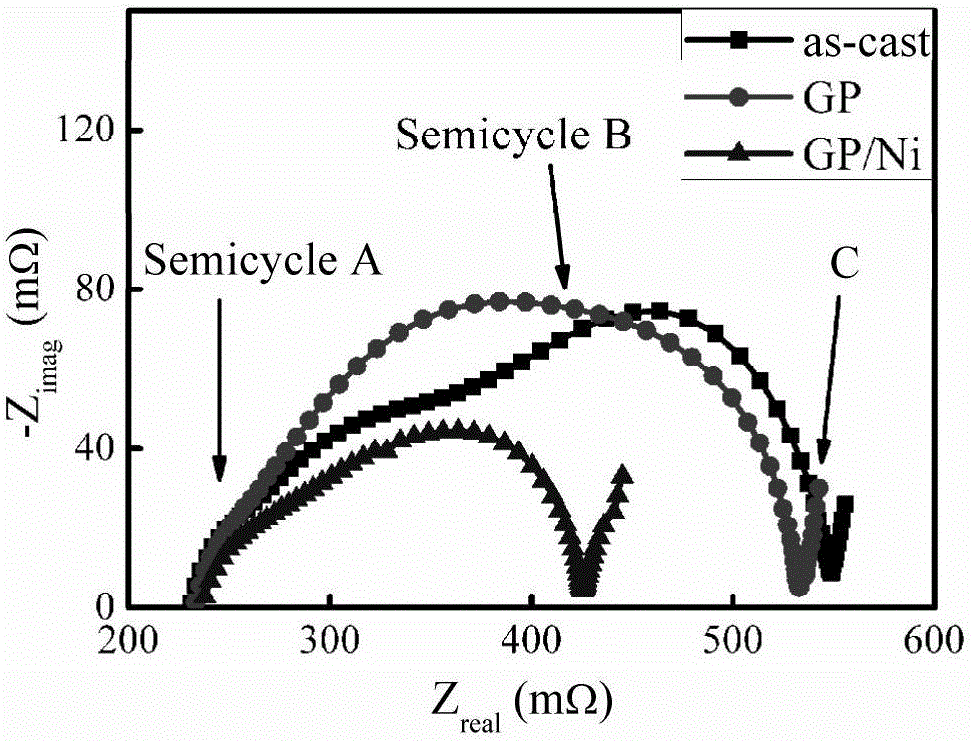

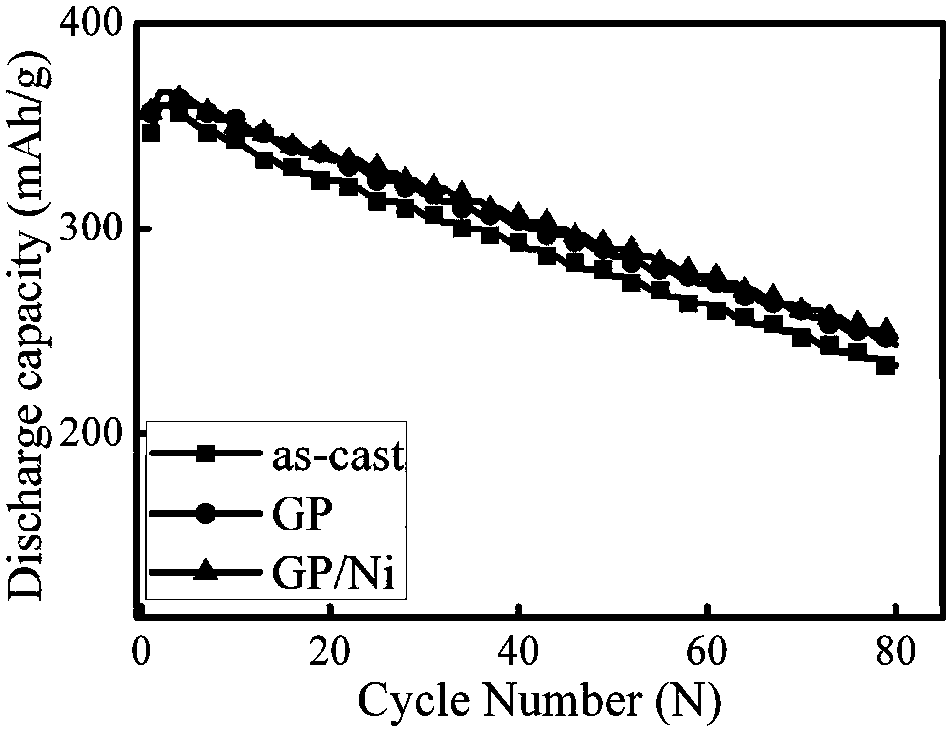

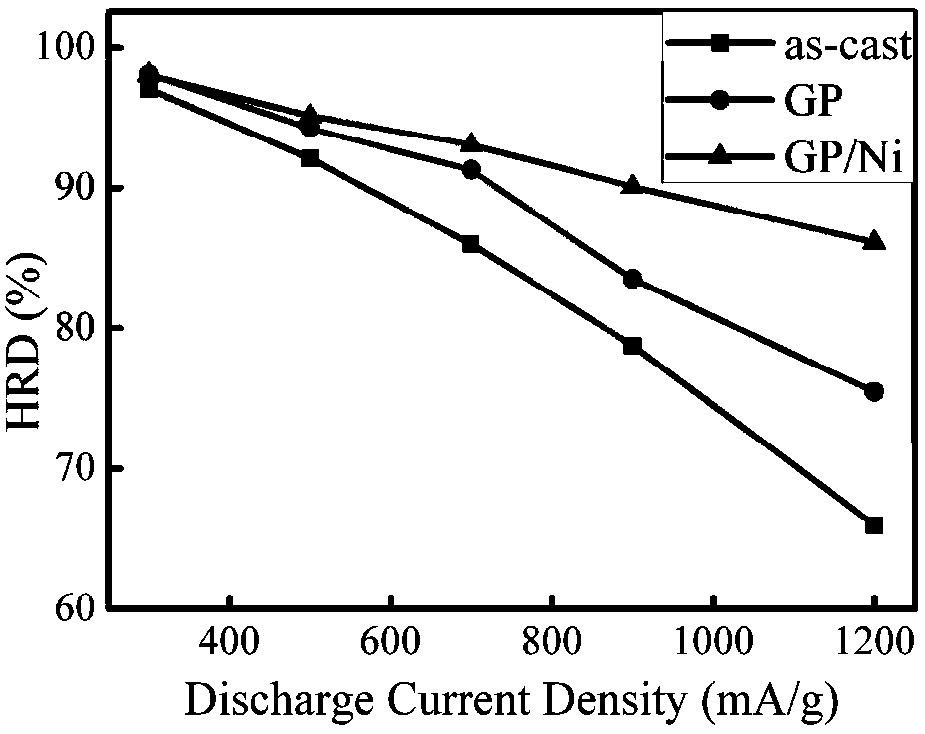

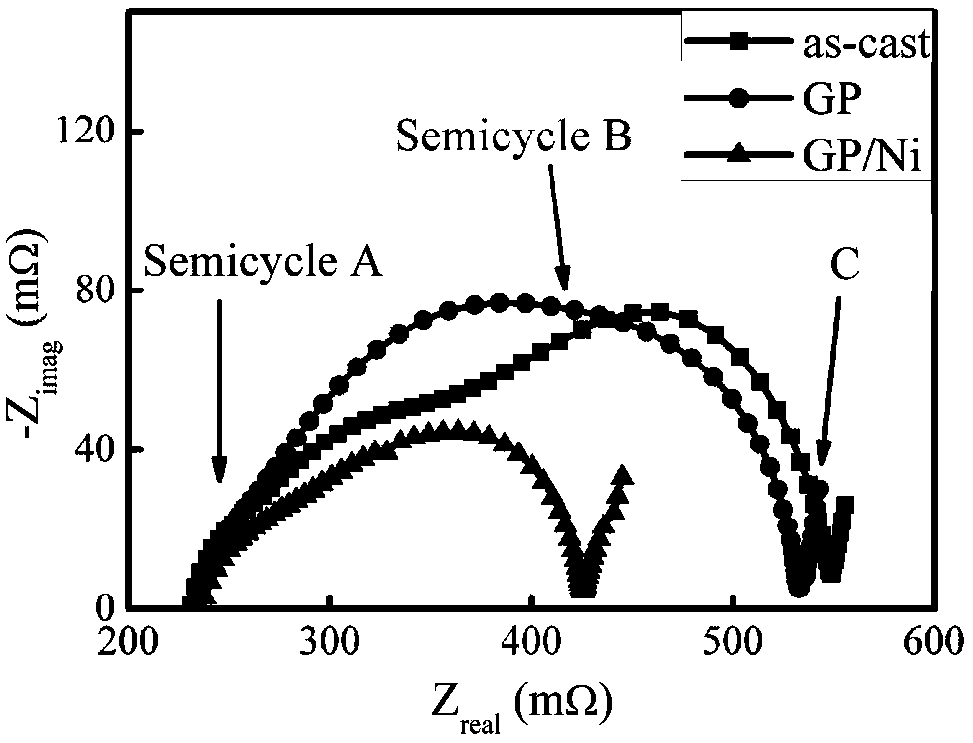

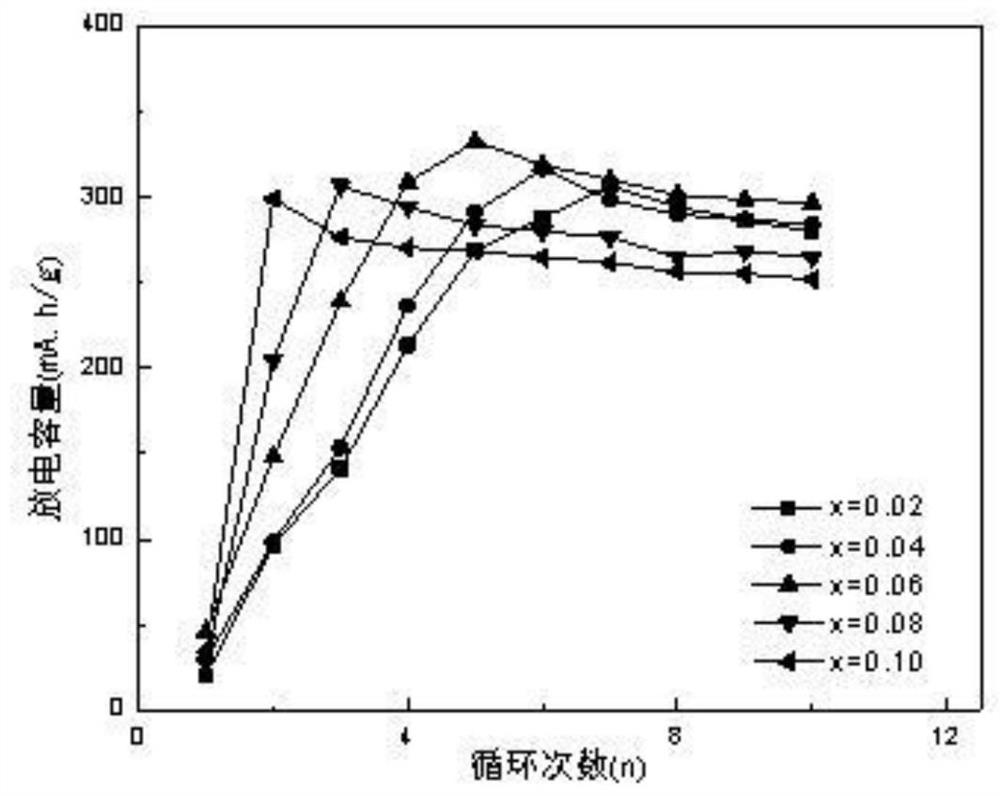

Method for improving electrochemical and dynamic properties of La-Mg-Ni-based alloy electrode

ActiveCN106025213ALower electrochemical impedanceImprove electrochemical kinetic performanceCell electrodesNickel accumulatorsNickel compoundsGraphene

The invention discloses a method for improving the electrochemical and dynamic properties of an La-Mg-Ni-based alloy electrode. The method comprises the steps of: smelting raw materials of La, Mg, Ni and Co into a cast alloy; crushing the cast alloy; and adding graphene and a graphene / nickel compound for mixing and ball-milling to prepare an La-Mg-Ni / graphene and La-Mg-Ni / graphene compound Ni-MH battery material. The method has the advantages that the electrochemical and dynamic properties of the material are obviously improved after the graphene and the graphene / nickel compound are added to La-Mg-Ni alloy powder for mixing and ball-milling; and a solid foundation is laid for later research of the Ni-MH battery material.

Owner:GUANGXI UNIV

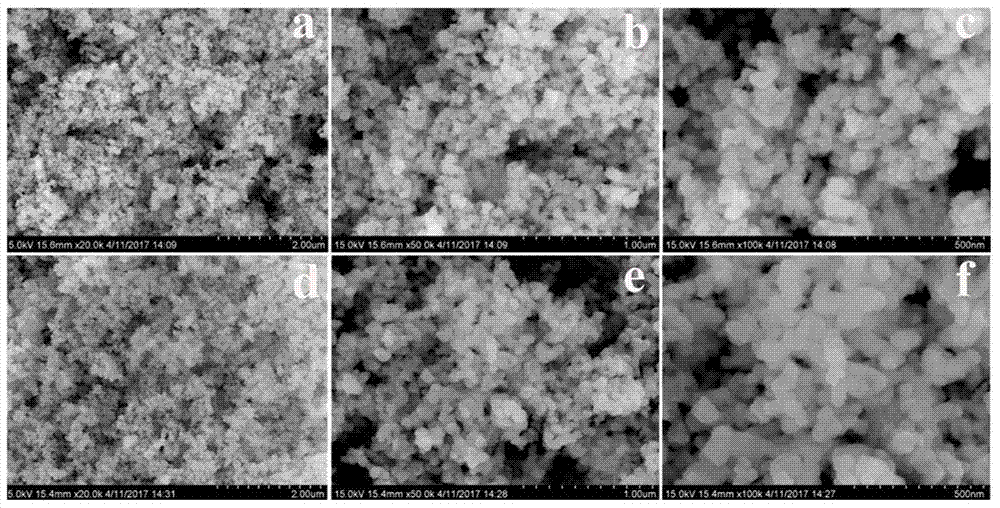

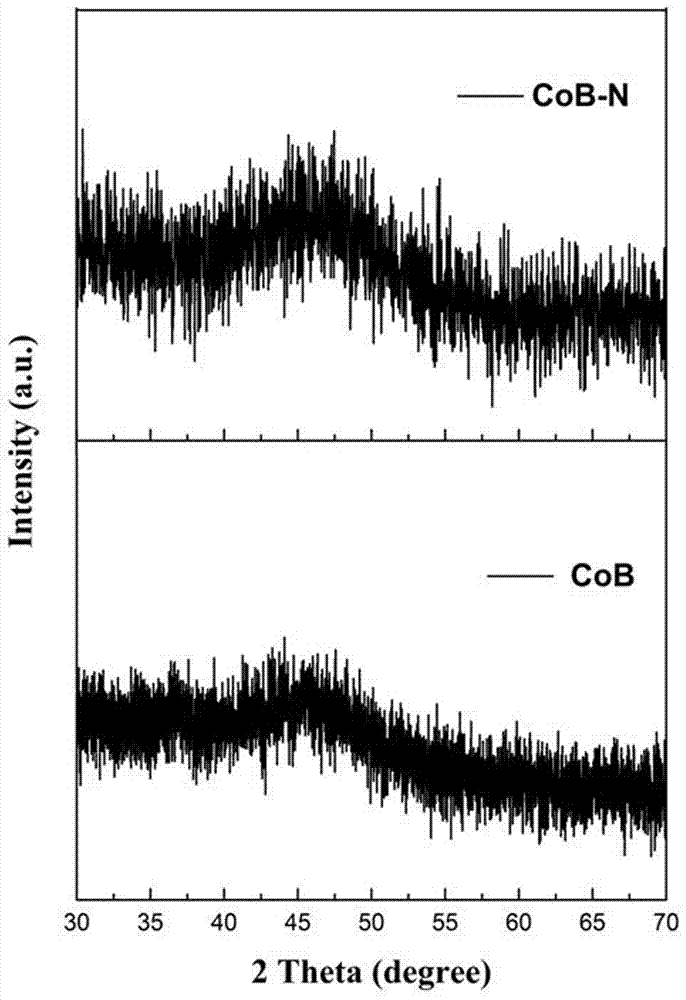

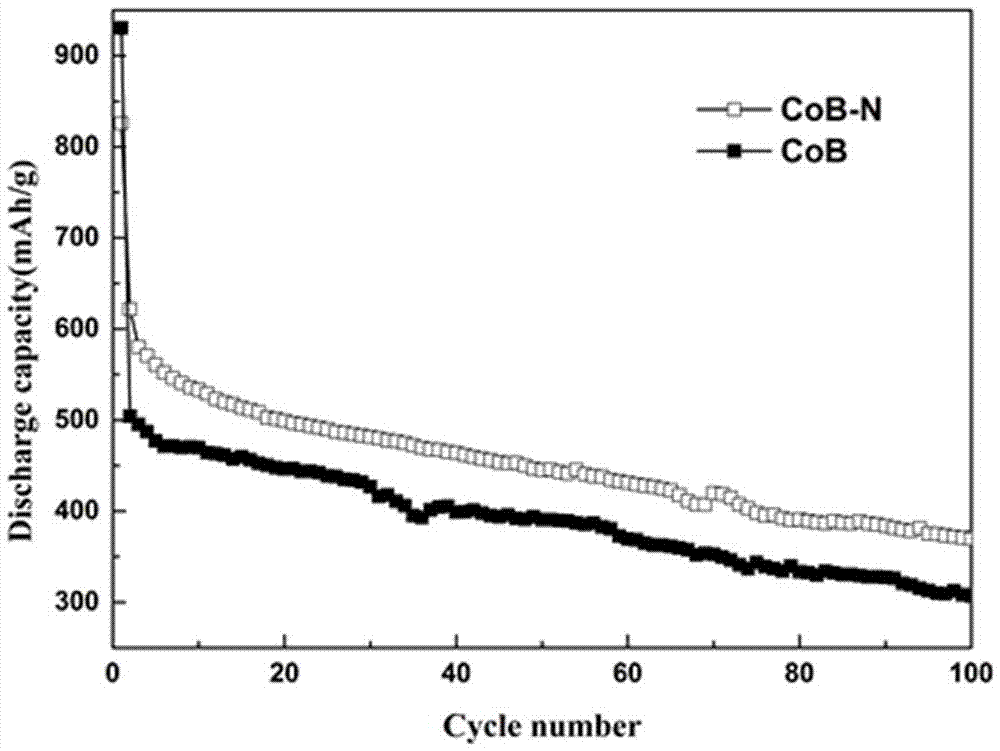

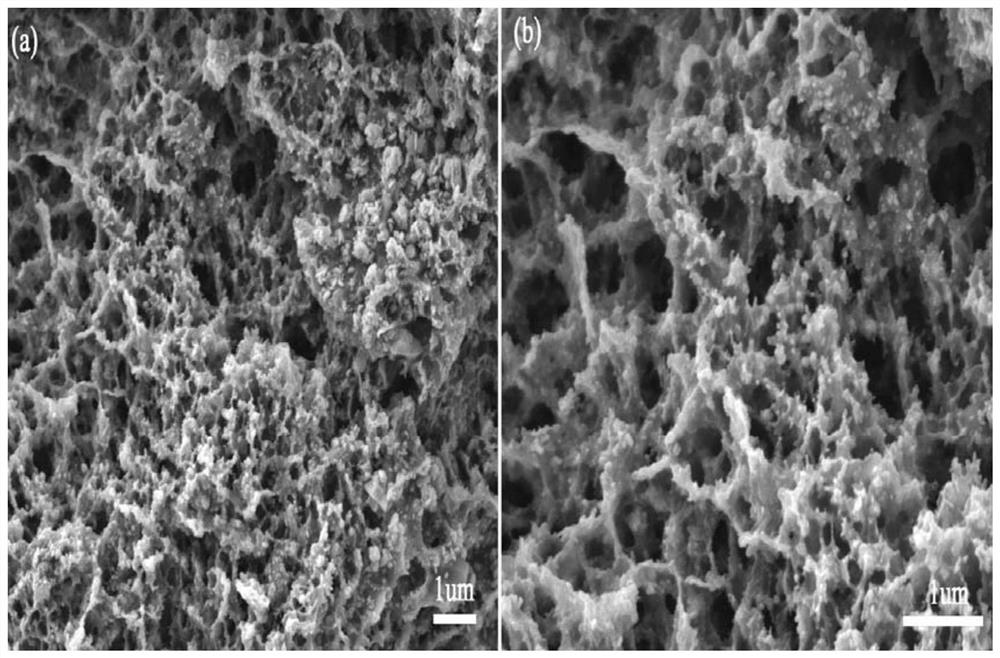

Preparation method and application of nitrogen-doped CoB alloy

ActiveCN107170972AImprove electrochemical kinetic performanceSmall particle sizeAlkaline accumulatorsHybrid capacitor electrodesCharge currentSpecific discharge

The invention discloses nitrogen-doped CoB alloy. The nitrogen-doped CoB alloy is prepared by the steps of reducing a mixed solution of cobalt chloride and a nitrogen-containing alkali compound by virtue of a sodium borohydride solution under an ultrasonic condition, and carrying out washing and vacuum drying; and the specific surface area is 20m<2> / g-50m<2> / g, and the diameter range of particles is 300nm-600nm. When the nitrogen-doped CoB alloy is used as a battery cathode material, a primary specific discharge capacity value reaches 500mAh / g-1000mAh / g under the charging current density of electrochemistry capacity of 100mA / g; and after 100 times of circulation, the specific discharge capacity value is 300mAh / g-500mAh / g, the capacity retention ratio is 30%-50%, and the limiting diffusion current density is 1000mA / g-6000mA / g. A preparation method of the nitrogen-doped CoB alloy comprises the following steps: (1) dissolving cobalt chloride and the nitrogen-containing alkali compound into water, so as to obtain a mixed solution; (2) preparing a sodium borohydride solution, and dropwise adding the sodium borohydride solution into the mixed solution in the step (1) at a certain speed, so as to obtain black turbid liquid; and (3) filtering the black turbid liquid, washing, and drying. The nitrogen-doped CoB alloy is uniform in particle distribution, has excellent electrochemical and kinetic properties and further has wide application prospects in the fields of secondary cells, super-capacitors and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

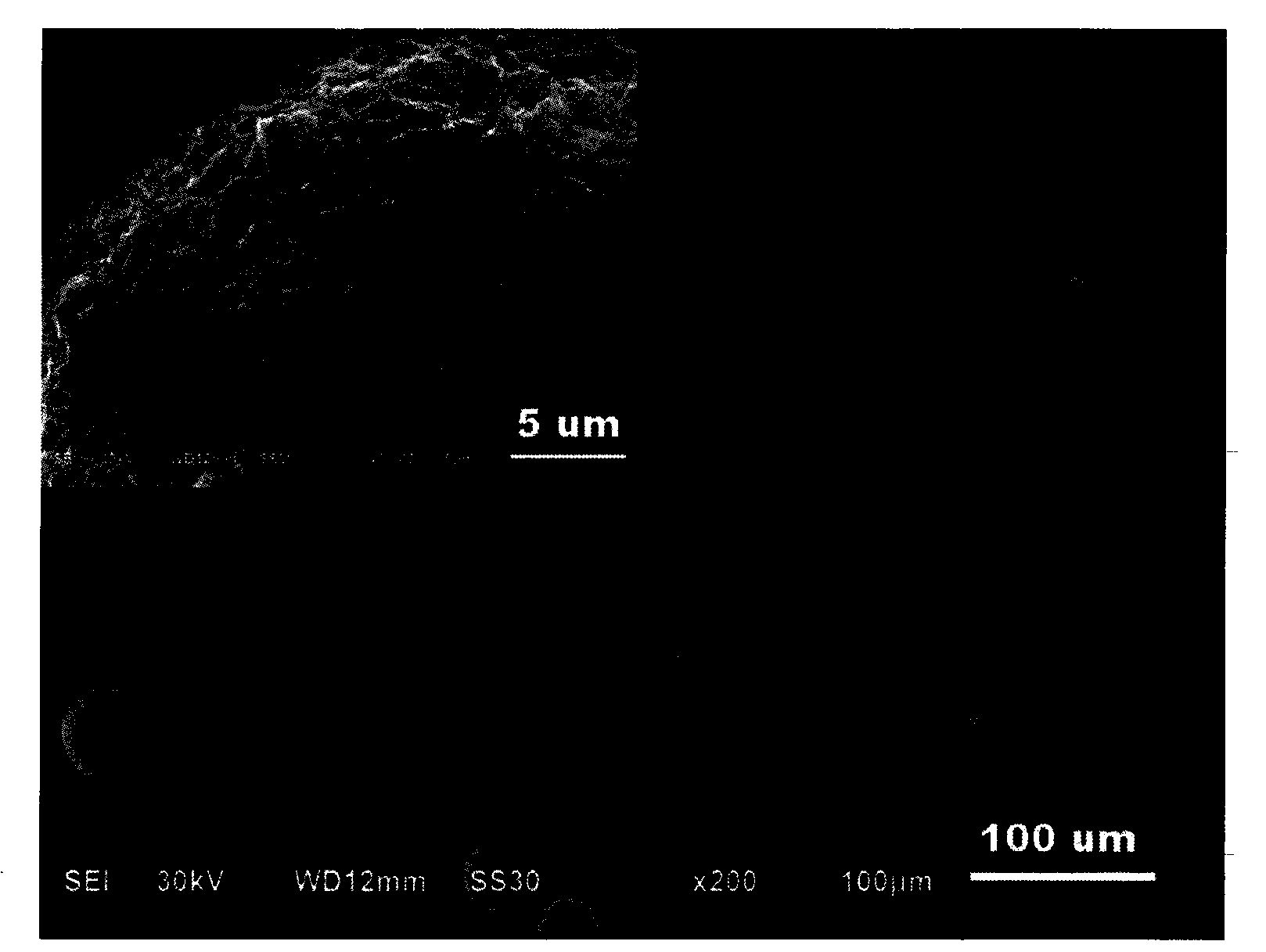

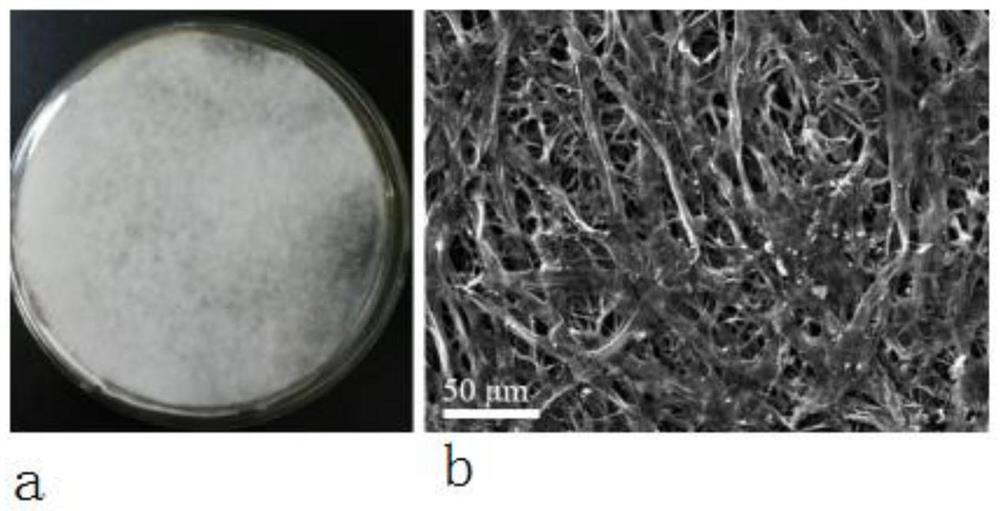

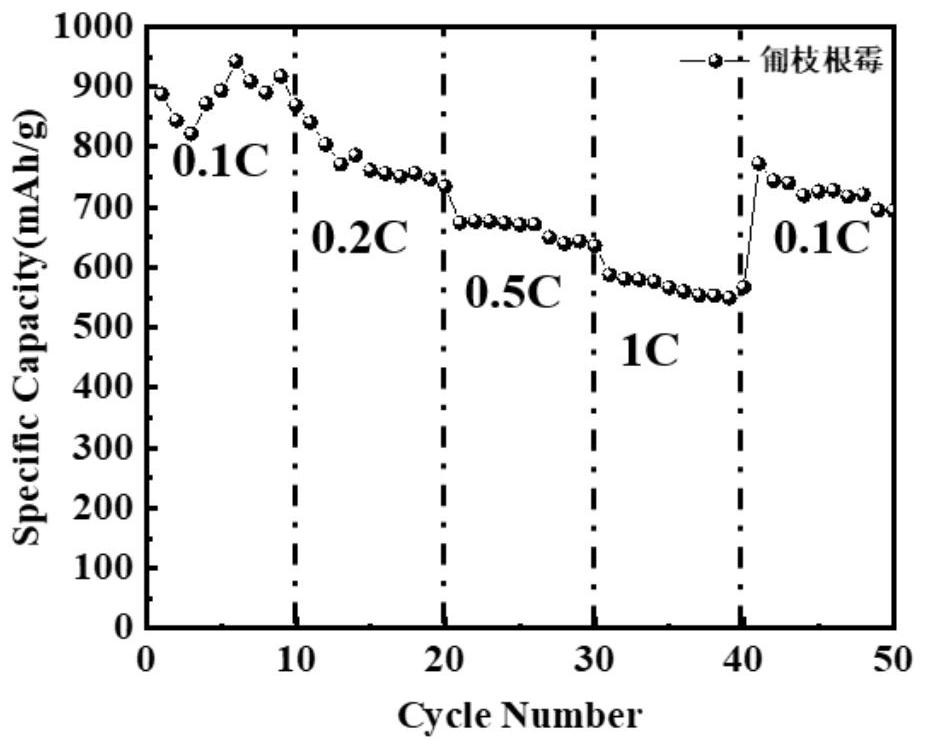

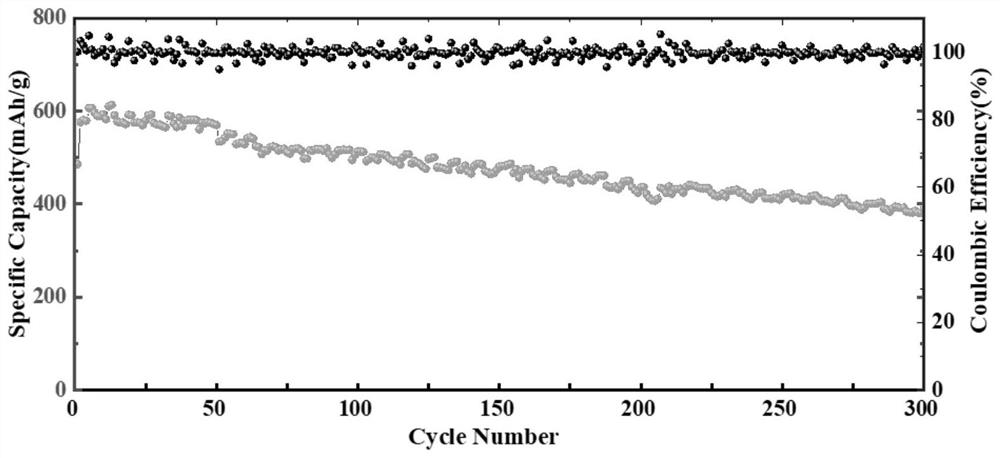

Preparation method and application of mycelium-based carbon film conductive skeleton and method for preparing battery

ActiveCN114188540ARapid cultivationShort cyclePositive electrodesLi-accumulatorsCarbon filmTest battery

The invention discloses a preparation method and application of a hypha-based carbon film conductive skeleton and a method for preparing a battery, biomass hypha is used as a raw material, and a hypha fiber film is prepared by mechanical crushing, stirring, dispersion by an ultrasonic-assisted method, suction filtration and film formation and then by a freeze drying method. The preparation method comprises the following steps: clamping a freeze-dried mycelium membrane between two graphite plates, placing the graphite plates in a tubular furnace, taking nitrogen as protective gas, carrying out stepped heating to obtain a mycelium-based carbon membrane conductive skeleton, and further adsorbing a high-concentration lithium octasulfide solution through rotary dispensing to obtain the self-supporting positive electrode material of the lithium-sulfur battery. According to the invention, the hypha fibers are interwoven with one another, so that the self-supporting positive plate has excellent adsorption capacity and relatively good supporting property, the loading density and uniformity of active substances in the self-supporting positive plate are effectively improved, and the tested battery has relatively good cycle life and rate capability. The self-supporting positive plate prepared by the invention adopts a laminated assembled large-size battery cell, and is expected to be used in a high-capacity and high-power commodity soft package lithium-sulfur battery.

Owner:XIAN UNIV OF TECH

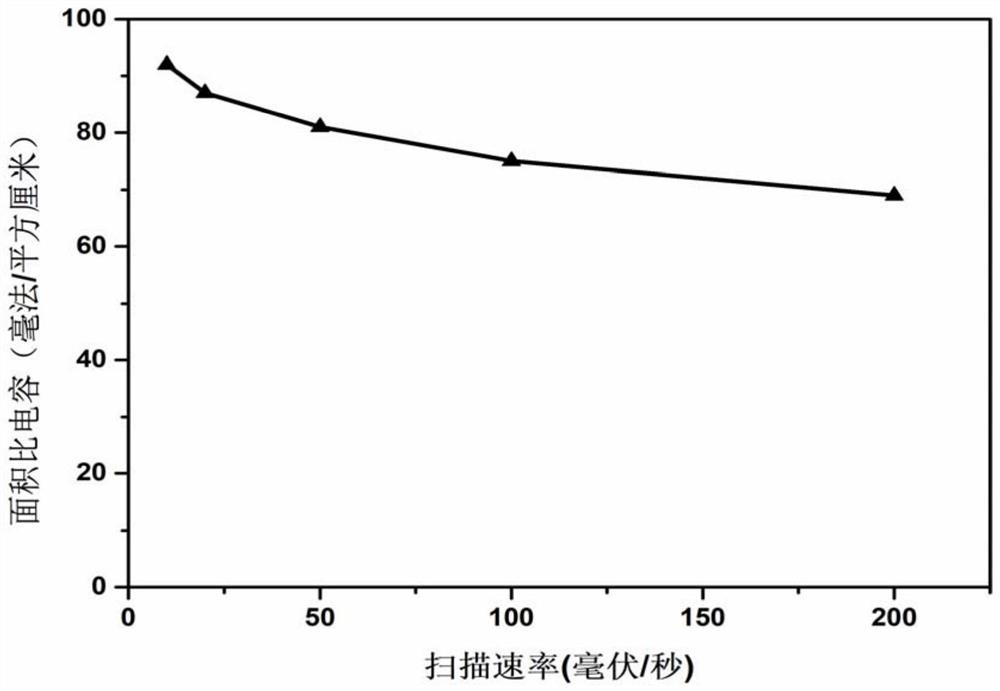

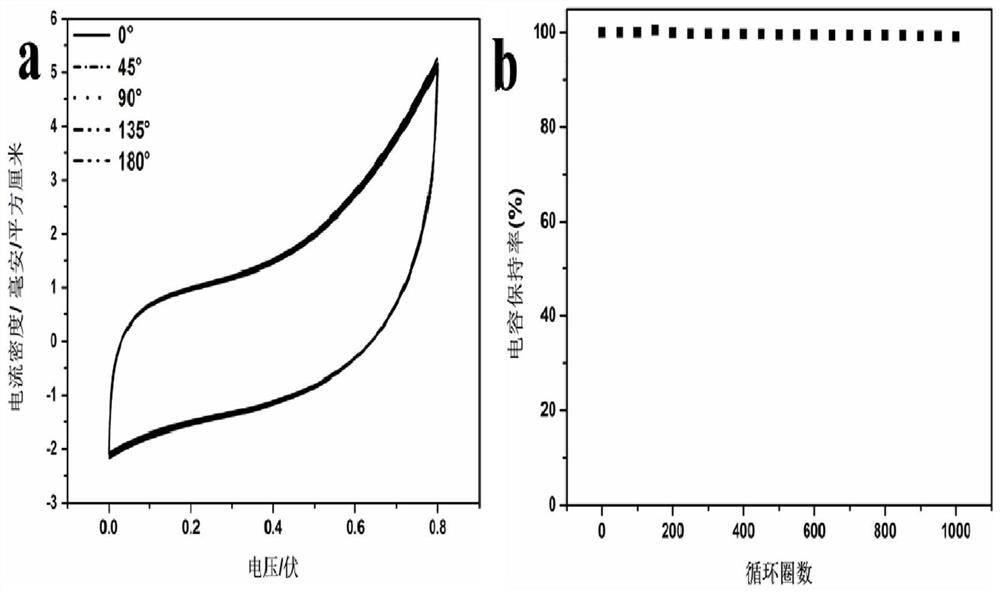

A kind of preparation method of self-healing flexible solid supercapacitor

ActiveCN110415997BReduce interface resistanceImprove performanceHybrid capacitor electrolytesHybrid/EDL manufactureConductive polymerElectrochemical kinetics

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

A polypyrrole-coated sulfur-doped cobalt-based carbon nanocage material, preparation method and application thereof

ActiveCN110783549BLimit volume expansionAlleviate volume expansionPositive electrodesLi-accumulatorsLithium–sulfur batteryPolypyrrole

Owner:JILIN UNIV

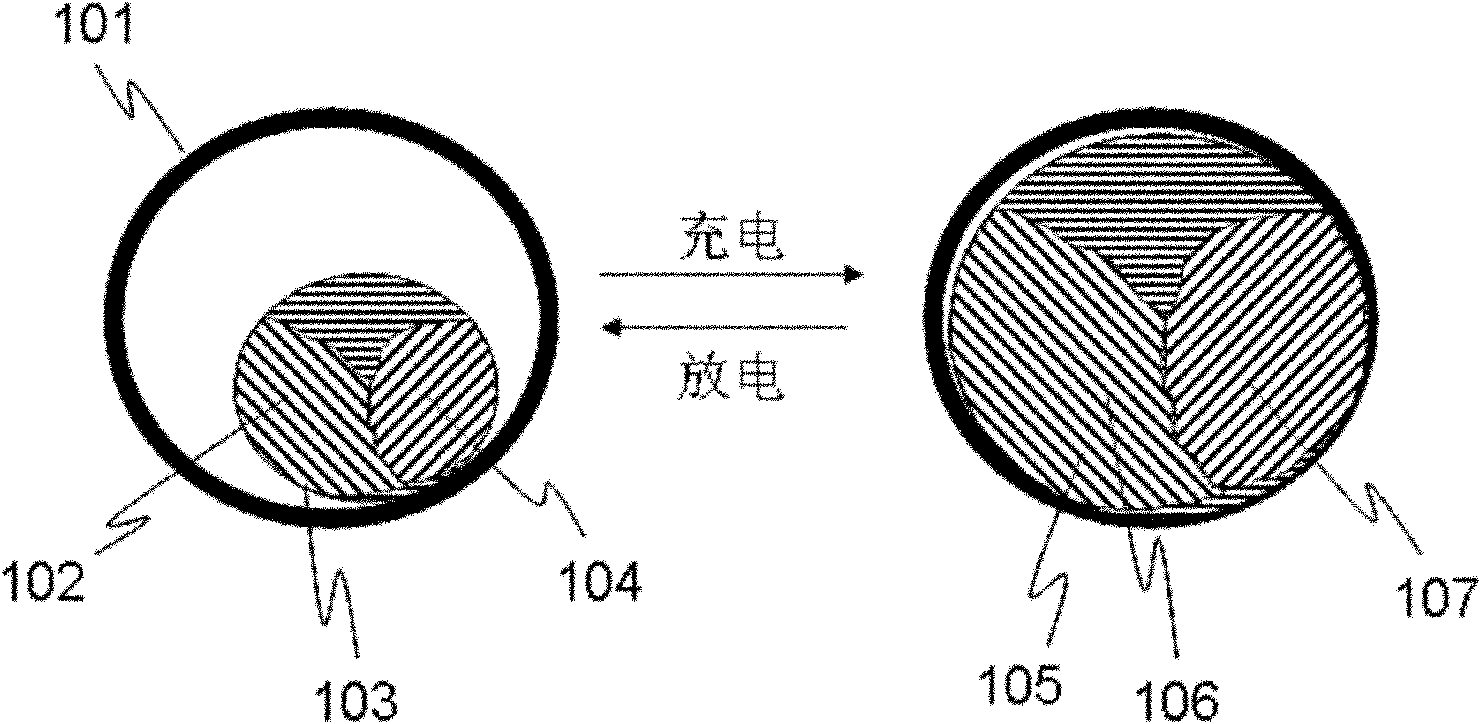

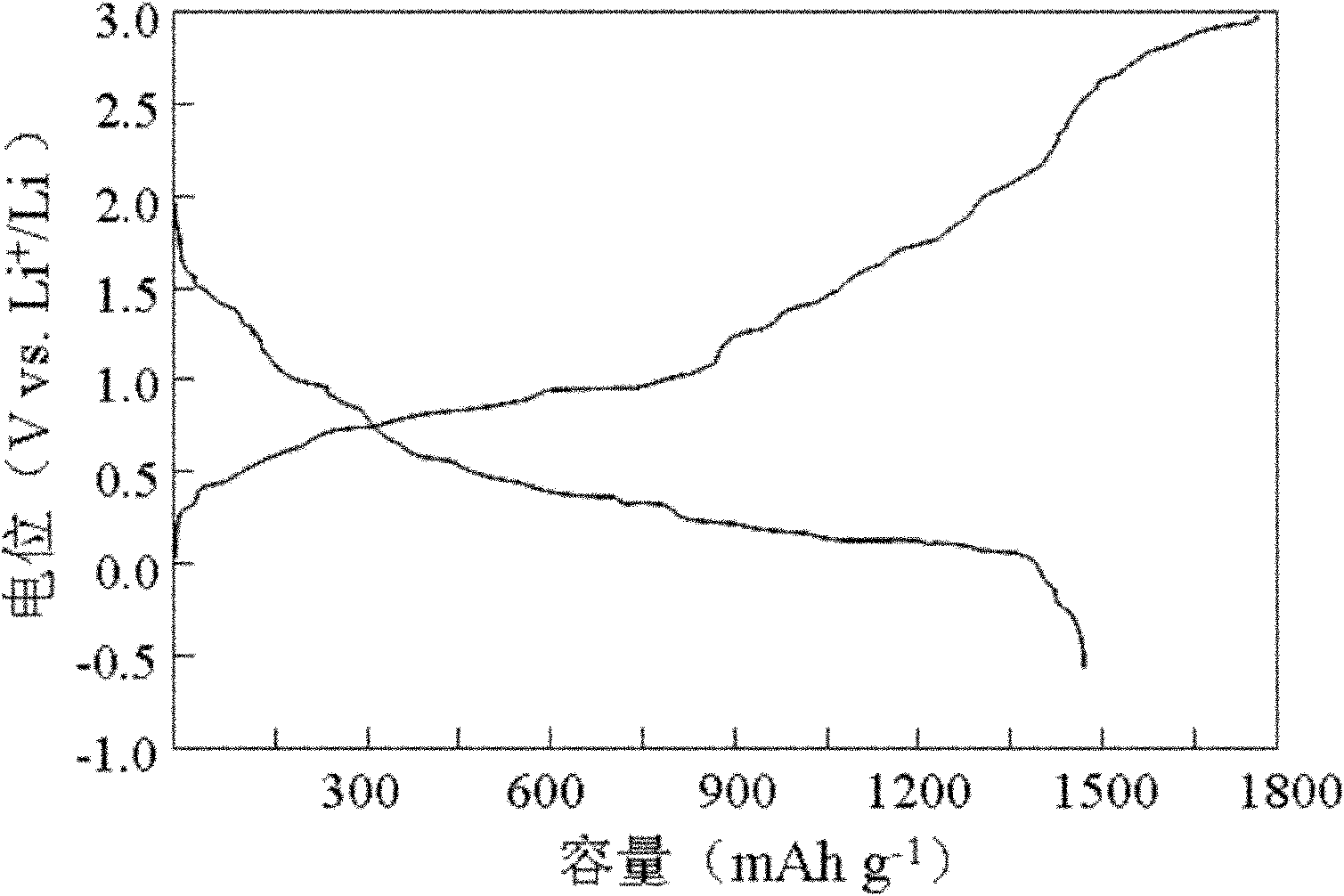

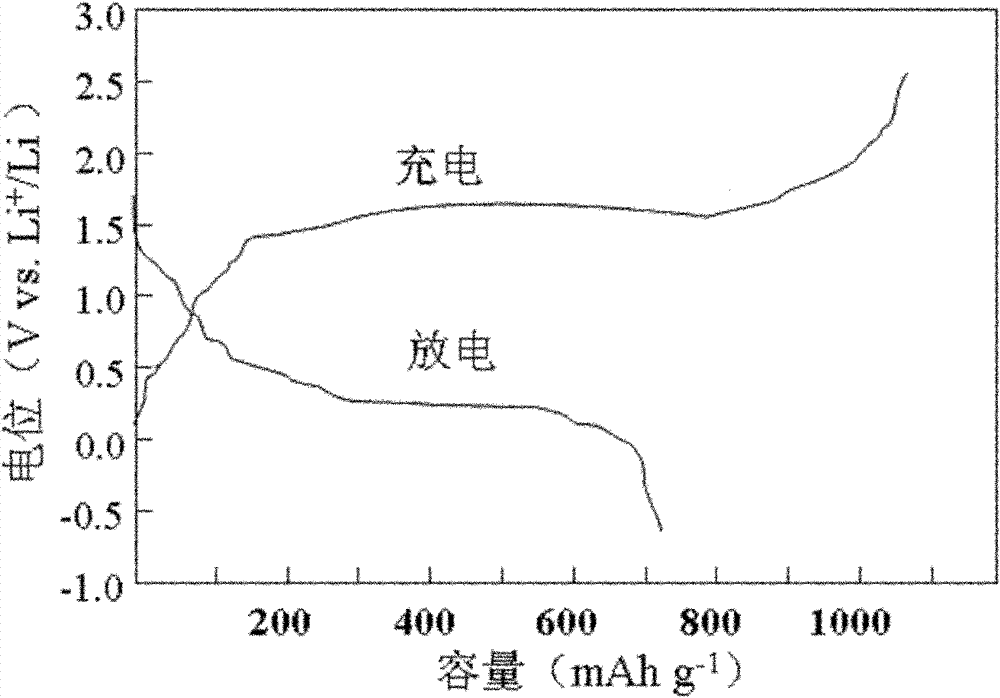

Preparation method of lithium-sulfur battery using carbon-supported boron-lithium alloy as negative electrode material

InactiveCN106602049BImprove conductivityHigh delithiation specific capacityFinal product manufactureNegative electrodesAlloyLithium.free

The invention relates to the preparation of a lithium-sulfur battery, and aims to provide a preparation method of a lithium-sulfur battery using a carbon-supported boron-lithium alloy as a negative electrode material. Including: adding silicone glue into N-methylpyrrolidone and stirring and heating to obtain NMP solution of silicone glue; mixing elemental sulfur and conductive carbon black evenly, heating and insulating in vacuum, and obtaining carbon-loaded sulfur material after cooling; carbon-loaded sulfur Materials, acetylene black and NMP solution of silicone glue are mixed and ground, prepared into a paste and coated on the aluminum film; dried in the shade and then pressed to form a positive electrode sheet; the positive electrode sheet microporous polypropylene diaphragm negative electrode sheet is installed in the battery case In the process, electrolyte solution is added, and a lithium-sulfur battery is obtained after sealing. The invention utilizes the characteristic of extremely high delithiation specific capacity of the boron-lithium alloy, improves the speed capacity of the lithium-sulfur battery, and can be used as a power battery of an electric vehicle. The synthesis method is simple in process, does not contain toxic substances, only emits CO2 and water in the whole synthesis process, is green and environmentally friendly, and has the ability of large-scale production.

Owner:ZHEJIANG UNIV

A kind of three-dimensional porous nano-carbon composite lithium manganese oxide spherical positive electrode material and preparation method thereof

InactiveCN103904322BShorten migration distanceImprove electrochemical kinetic performanceCell electrodesSecondary cellsCarbon compositesMicrosphere

Owner:XIANGTAN UNIV

A method for improving electrochemical kinetics of la-mg-ni based alloy electrodes

ActiveCN106025213BGuaranteed cycle stabilityImprove electrochemical kinetic performanceCell electrodesNickel accumulatorsElectrochemical kineticsNickel compounds

The invention discloses a method for improving the electrochemical and dynamic properties of an La-Mg-Ni-based alloy electrode. The method comprises the steps of: smelting raw materials of La, Mg, Ni and Co into a cast alloy; crushing the cast alloy; and adding graphene and a graphene / nickel compound for mixing and ball-milling to prepare an La-Mg-Ni / graphene and La-Mg-Ni / graphene compound Ni-MH battery material. The method has the advantages that the electrochemical and dynamic properties of the material are obviously improved after the graphene and the graphene / nickel compound are added to La-Mg-Ni alloy powder for mixing and ball-milling; and a solid foundation is laid for later research of the Ni-MH battery material.

Owner:GUANGXI UNIV

A kind of preparation method of lithium-sulfur battery membrane electrode

InactiveCN104157909BImprove performanceEliminates the possibility of a reactionFinal product manufactureElectrolyte accumulators manufactureInternal resistanceLithium–sulfur battery

The invention relates to the technical field of lithium-sulfur batteries, and aims to provide a method for preparing membrane electrodes of lithium-sulfur batteries. The preparation method of the membrane electrode of the lithium-sulfur battery comprises the steps of: preparing a carbon material with nanometer ferrous sulfide dispersed on the surface of the carbon carrier, and then using the carbon material to prepare a positive electrode material; then preparing the positive electrode and the negative electrode, and the lithium ion exchange membrane respectively, Finally, the positive electrode, negative electrode and lithium ion exchange membrane are pressed into a lithium-sulfur battery membrane electrode. The lithium-sulfur battery membrane electrode prepared by the invention has: good electrical conductivity, very low internal resistance; good electrode reaction reversibility; good chemical stability and thermal stability; cheap and easy to prepare; pollution-free; battery manufacturing The process is simple, conducive to large-scale production, and can effectively reduce production costs.

Owner:ZHEJIANG UNIV

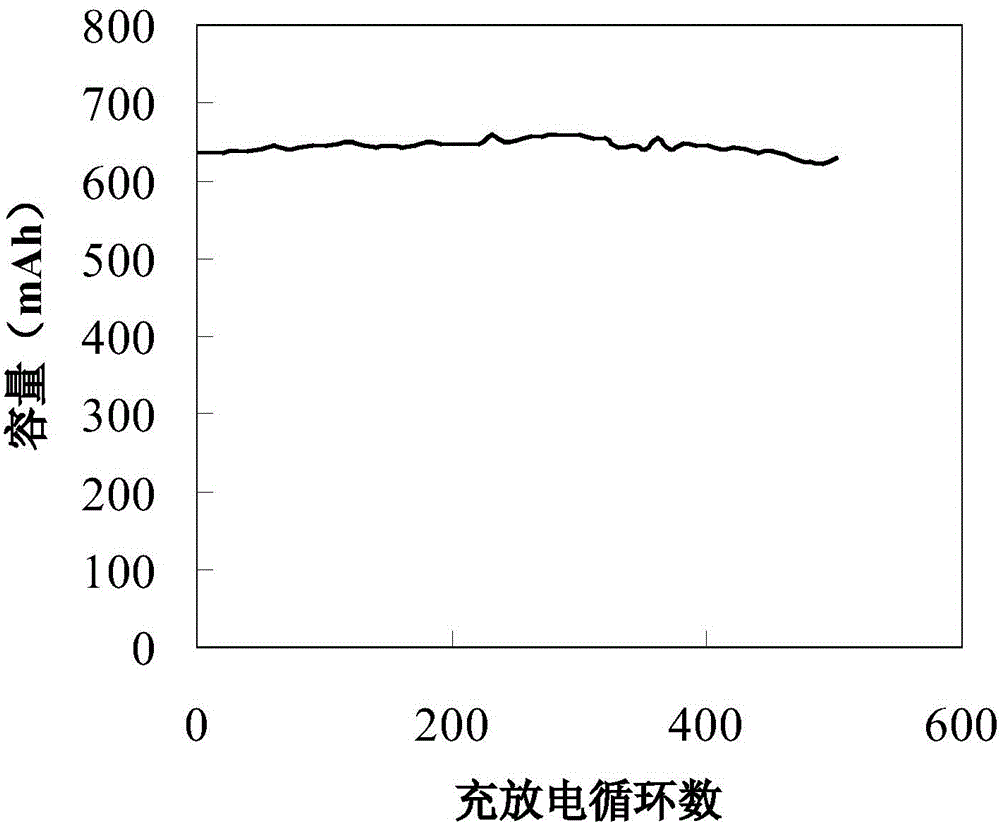

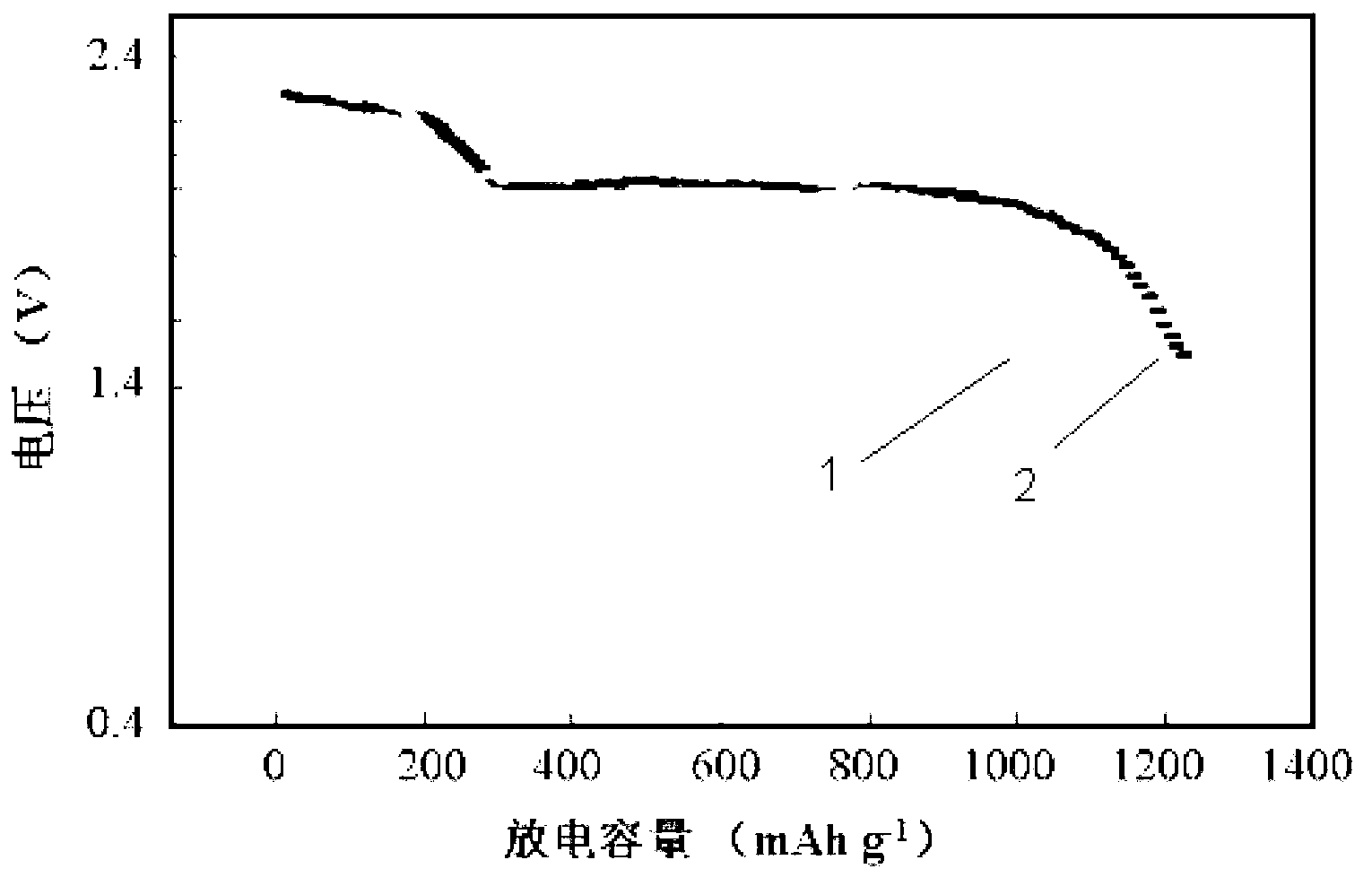

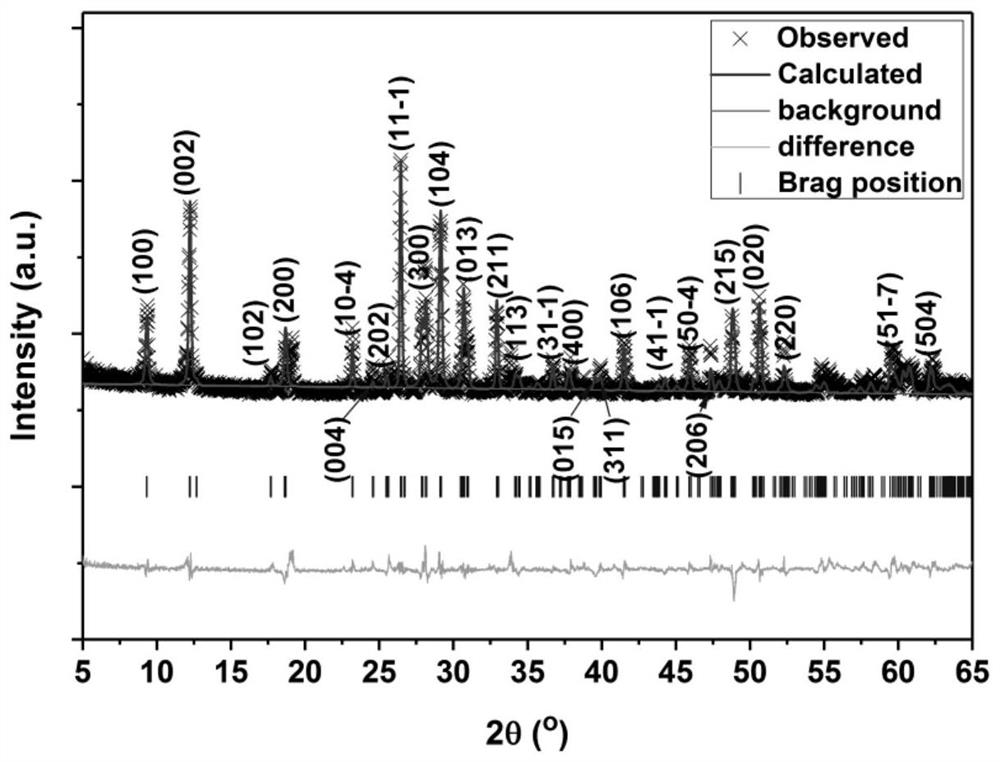

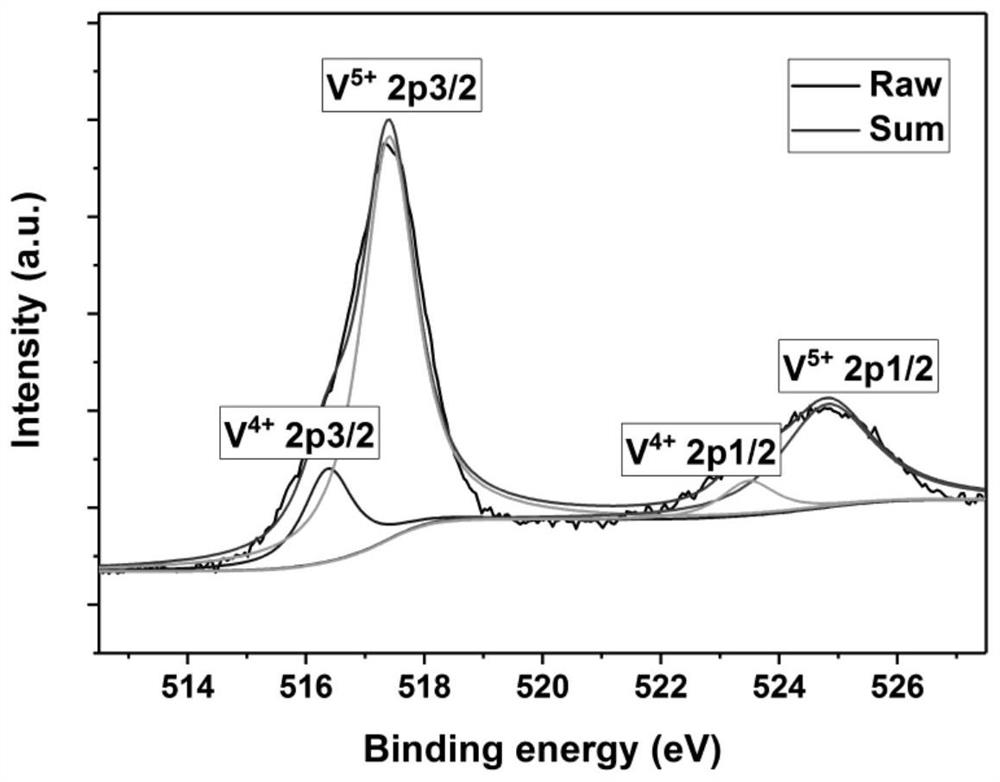

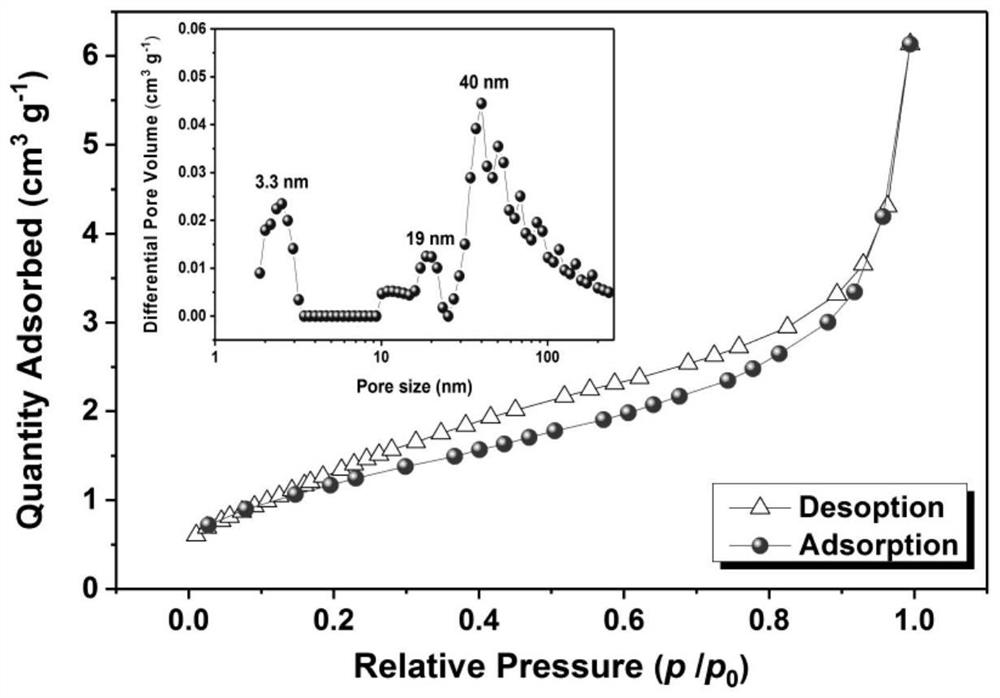

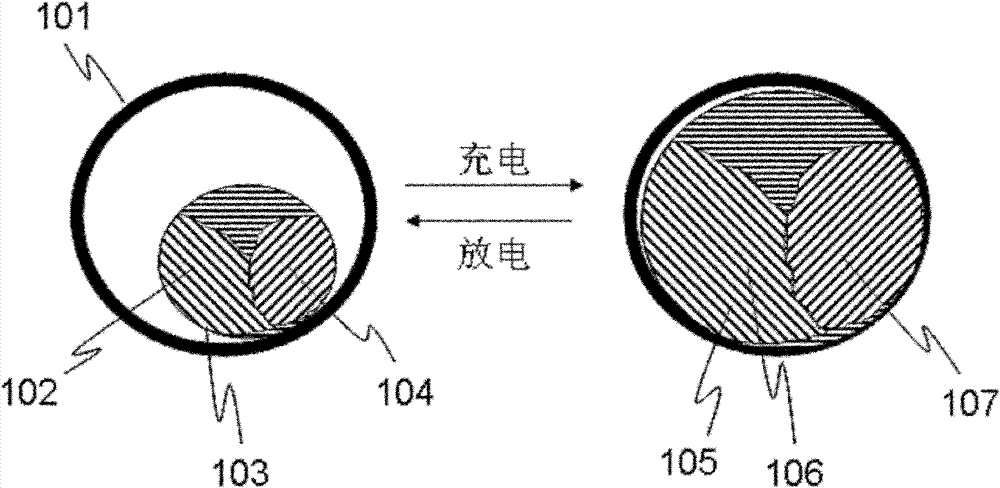

A kind of spherical vanadium bronze coil sodium ion battery cathode material and preparation method thereof

ActiveCN108675350BAvoid decompositionFast and timely deliverySecondary cellsPositive electrodesElectrical batterySodium-ion battery

The invention discloses a sodium ion battery positive electrode material. The sodium ion battery positive electrode material consists of a vanadium bronze wire ball; the vanadium bronze wire ball adopts a hierarchical porous spheroid structure, has the diameter of 1 to 5 um and is formed by interweaving nanotubes; due to the unique hierarchical porous structure, the sodium ion diffusion coefficient of the vanadium bronze material is increased and the rate performance of the vanadium bronze material is greatly improved; furthermore, expansion and shrinkage of the material volume can be retardedand the integrity of the electrode is maintained; and the stability of the battery capacity is guaranteed, so that the cycle performance is improved. Meanwhile, the preparation method provided by theinvention is simple and efficient; a vanadium oxide precursor is prepared by an organic template method, and the spheroid vanadium bronze wire ball with the hierarchical porous structure can be obtained through hydrothermal reaction and calcination reaction; and the integral preparation method is high in repeatability and has actual application value.

Owner:XIANGTAN UNIV

Method for preparing conductive carbon film-coated calcium or calcium-tin alloy serving as anode material of lithium battery

InactiveCN102082263BIncrease speed capacityUniform thicknessCell electrodesLi-accumulatorsCarbon filmPolyethylene glycol

Owner:ZHEJIANG UNIV

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204BImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmElectrical battery

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

Lithium-sulfur battery with stannous sulfide as anchor center and preparation method of positive electrode thereof

InactiveCN104157851BImprove performanceDissolution inhibitionCell electrodesLi-accumulatorsInternal resistanceLithium-ion battery

The invention relates to the field of a lithium sulfur battery, and aims at providing a lithium sulfur battery adopting stannous sulfide as an anchoring center and a preparation method of a positive electrode of the lithium sulfur battery. The preparation method of the lithium sulfur battery adopting the stannous sulfide as the anchoring center specifically comprises the following steps: preparing a macroporous carbon material with nano stannous sulfide being dispersed on the inner wall and a macroporous carbon material with supported sulfur, preparing an anode material of the lithium sulfur battery by utilizing the macroporous carbon material with supported sulfur, preparing the positive electrode by utilizing the positive electrode material, and assembling the positive electrode, a diaphragm, a negative electrode and electrolyte to form the lithium sulfur battery. The prepared high-capacity lithium ion battery positive electrode material is good in conductivity, low in internal resistance, good in electrode reaction reversibility, good in chemical stability and thermal stability, low in price, easy to prepare and pollution-free, so that the electrochemical dynamics performance of the lithium sulfur battery positive electrode can be improved, the electrode polarization can be alleviated, and the speed capacity of the lithium battery can be improved.

Owner:ZHEJIANG UNIV

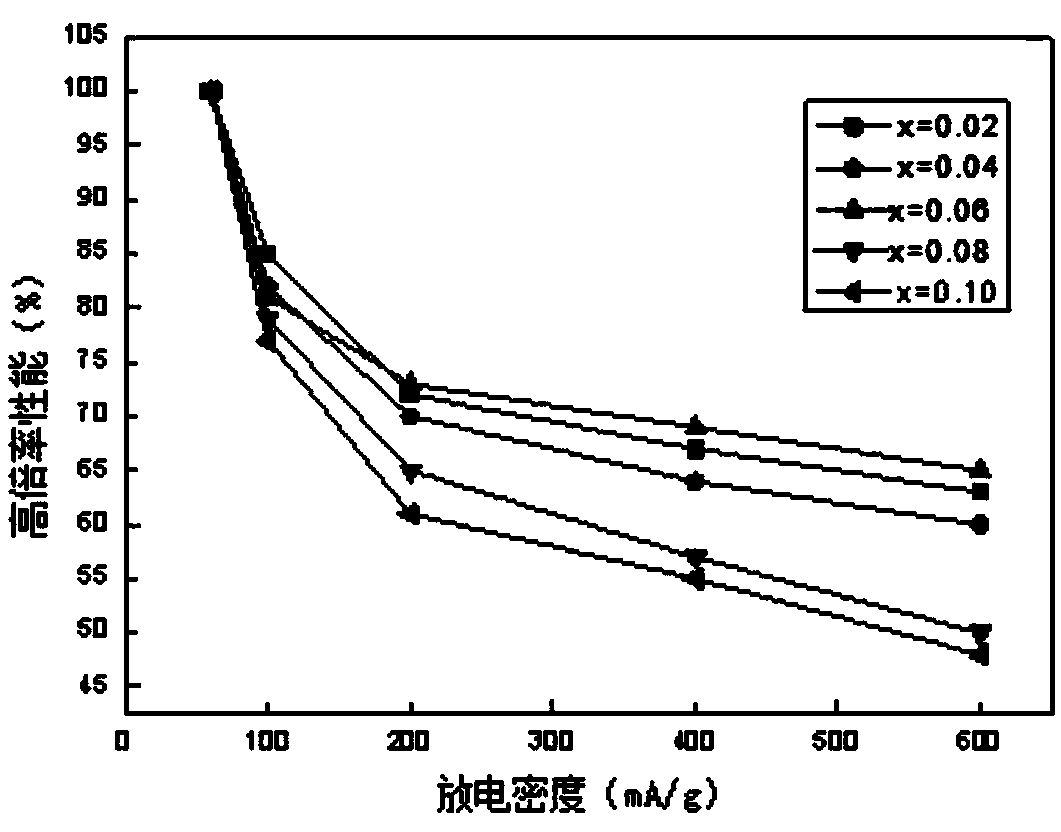

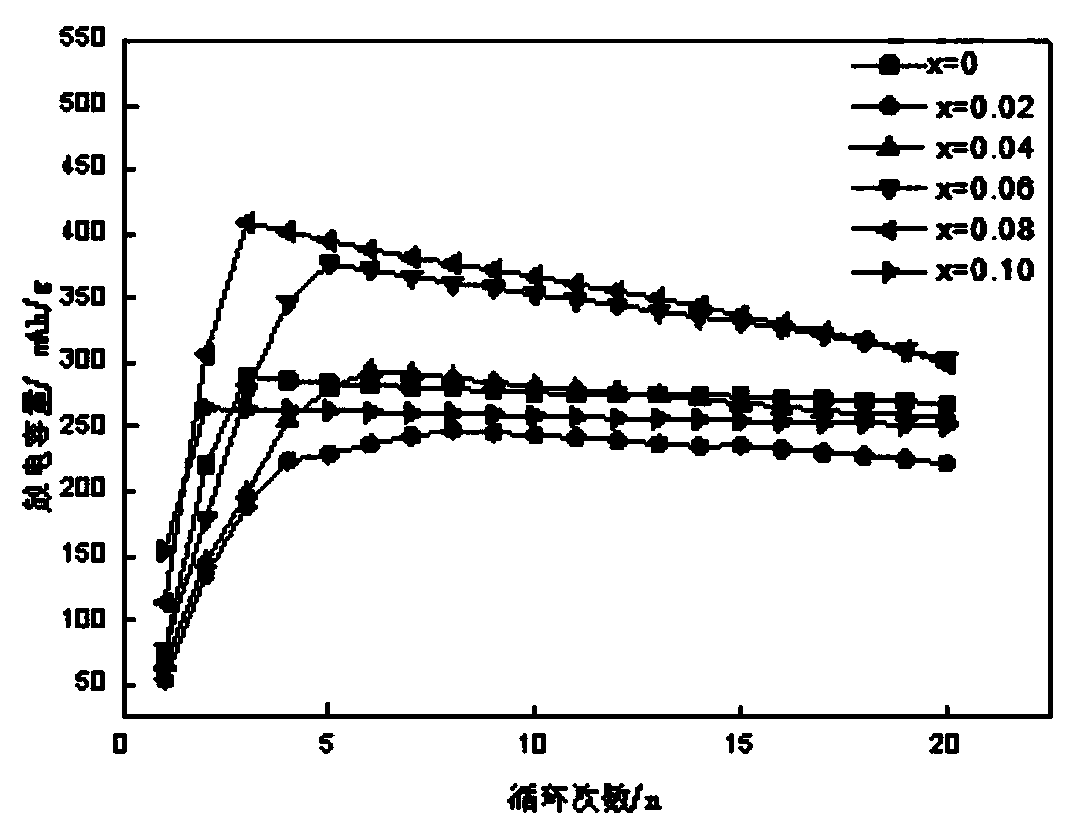

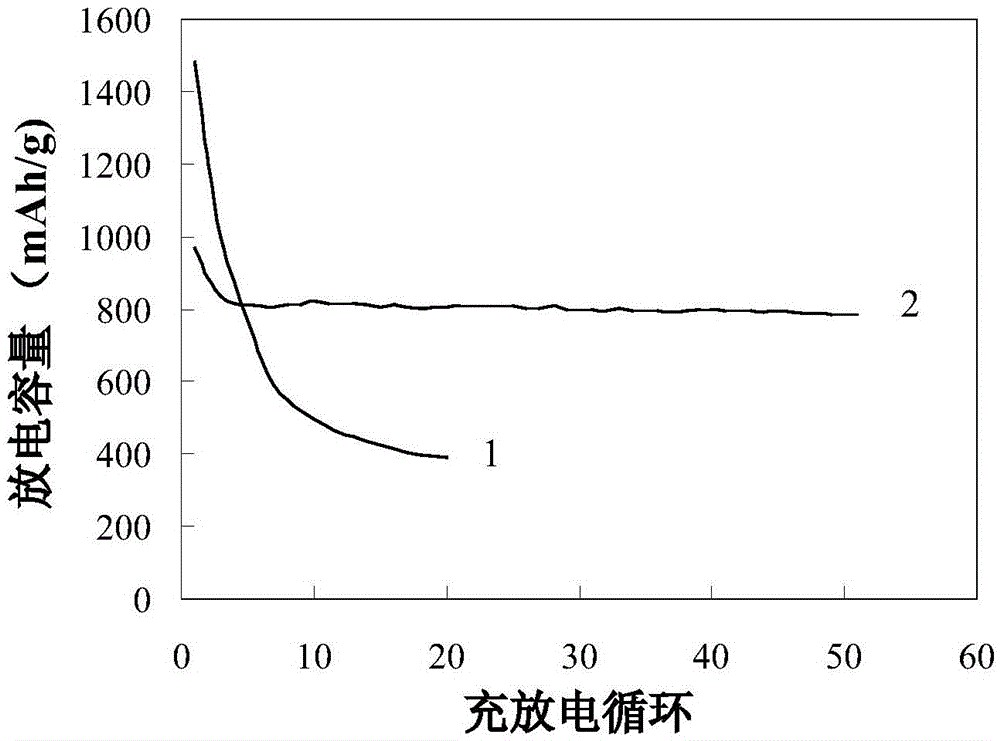

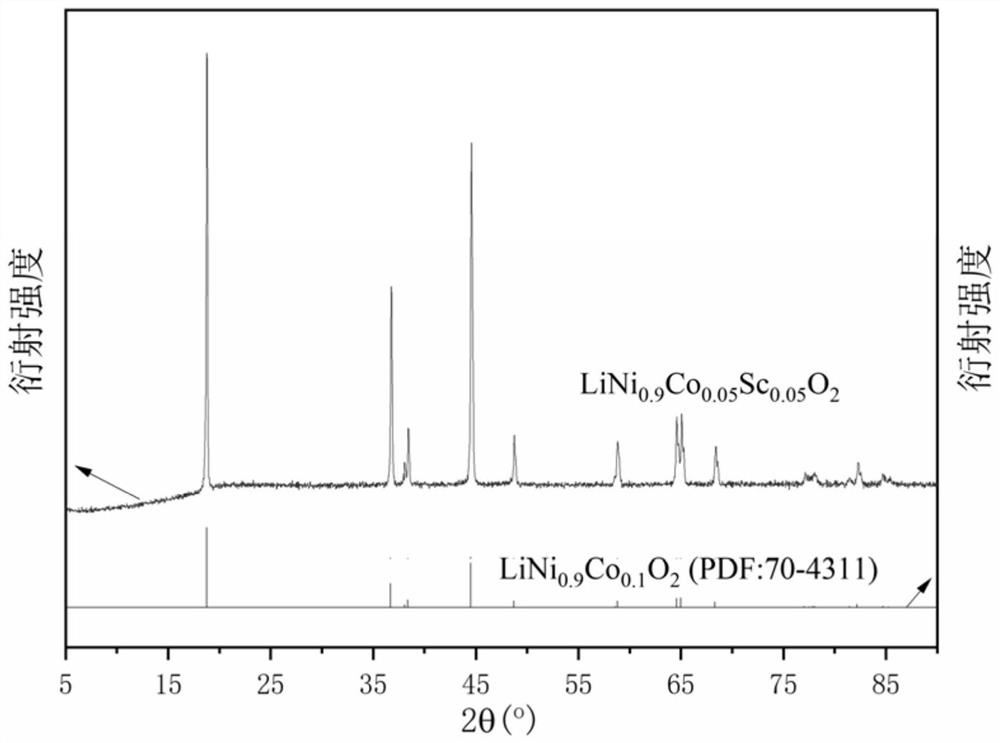

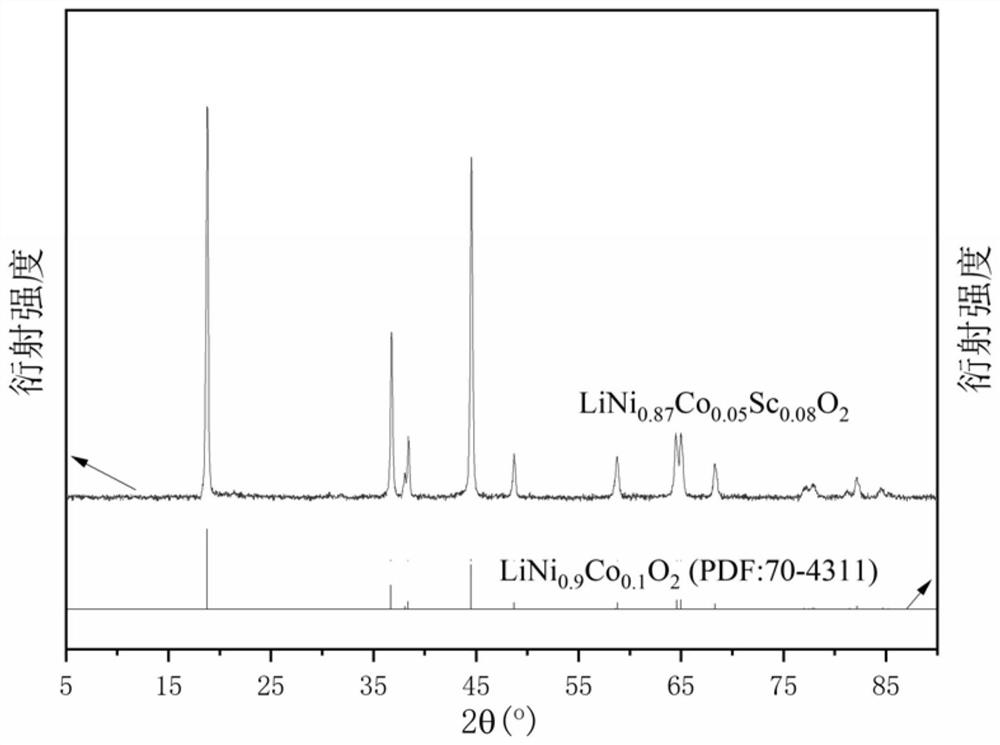

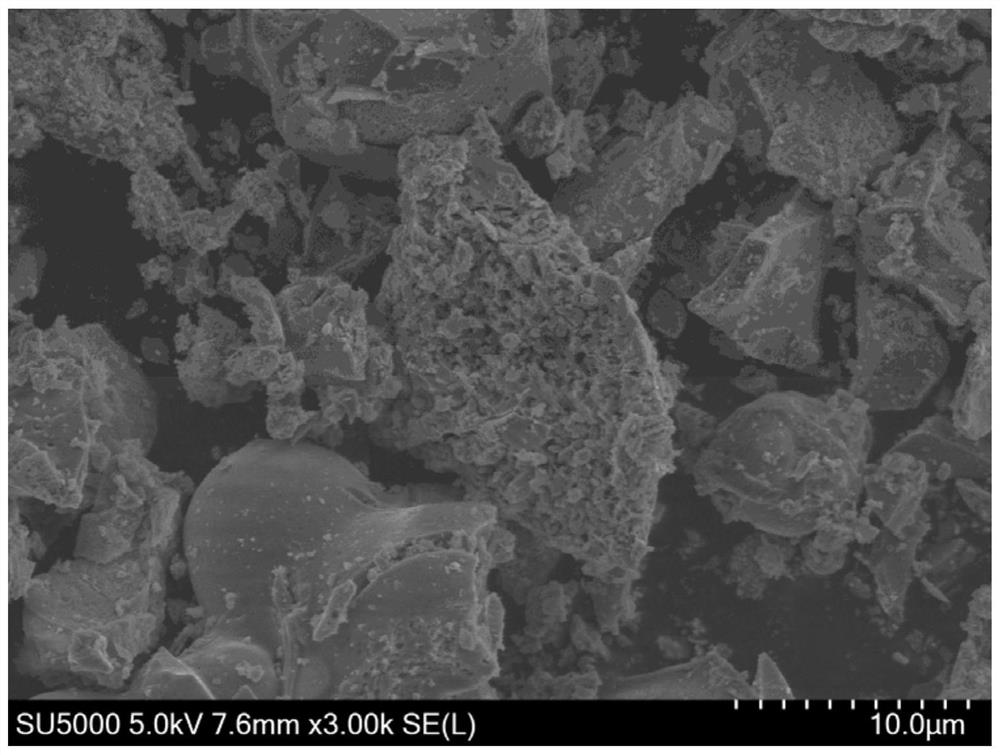

A kind of high nickel ternary lithium ion battery positive electrode material and preparation method thereof

ActiveCN113314711BIncrease capacityImproved magnification performanceCell electrodesSecondary cellsElectrical batteryReaction temperature

The invention discloses a high-nickel ternary lithium ion battery positive electrode material and a preparation method thereof. Adopt Sc 3+ Doping strategy to prepare high-nickel ternary lithium-ion battery cathode material LiNi by sol-gel method x Co y Sc z O 2 (0.85≤x≤0.90, y≤0.1, z≤0.1 and x+y+z=1), Sc doping reduces the degree of lithium-nickel ion mixing and enhances the stability of the crystal structure, improving LiNi x Co y Sc z O 2 The cycle performance is excellent; the chelating agent is used to achieve uniform mixing of the reaction raw materials at the molecular level, reducing the reaction temperature and shortening the reaction time, which is beneficial to obtain LiNi with fine particles. x Co y Sc z O 2 , significantly shortening Li ions in LiNi x Co y Sc z O 2 The diffusion path inside the solid particles improves the electrochemical kinetic properties of lithium ions and improves the rate performance of the material, which has the advantages of high capacity, long life and excellent rate performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material

InactiveCN103311512BIncrease speed capacityImprove reliabilityCell electrodesSecondary cellsModified carbonHeat stability

The invention relates to the technology of batteries, and aims at providing a preparation method of indole-modified carbon sulfur-coated and compound lithium sulfur battery anode material. The method comprises the following steps: reacting carbon source material, deionized water and spherical aluminum powder at the temperature of 250 DEG C, and performing centrifugal separation to obtain a brown or black solid powder sample; washing, performing centrifugal separation, drying, and then carbonizing at a constant temperature in nitrogen; performing acid treatment or alkaline treatment after cooling; washing and performing vacuum drying after filtering so as to obtain hollow carbon spheres; reacting the hollow carbon spheres, indole and transition metals at the temperature of 100-300 DEG C, performing vacuum drying after filtering and washing so as to obtain hollow carbon spheres modified by indole and transition metals; grinding and mixing with elemental sulfur, placing in a reactor, vacuumizing and heating to complete sulfur storage process through reactions, and cooling to room temperature. Organic electrolytes are safe in the application of battery; the anode material has good electrode reaction reversibility and good chemical stability and heat stability, and is low in cost, easy to prepare and free from pollution.

Owner:ZHEJIANG UNIV

Preparation and application of conductive carbon film-coated calcium nitride compound serving as anode material of lithium battery

InactiveCN102082267BGood speed capacityIncrease speed capacityCell electrodesSecondary cellsCarbon filmMicrosphere

The invention relates to preparation and application of an anode material of a lithium battery and aims to provide preparation and the application of a conductive carbon film-coated calcium nitride compound serving as the anode material of the lithium battery. The preparation method comprises the following steps of: after calcium metal is molten, spraying into polyethylene glycol liquid by using high purity nitrogen, and performing a reaction of the calcium fog drops and nitrogen in an nitriding atmosphere to obtain Ca3N2 microspheres so as to obtain a carbon-coated calcium nitride material primary product; and after filtering out a carbon-coated calcium nitride material, calcining for 2 to 3 hours again in the high purity nitrogen atmosphere and carrying out refining to obtain carbon-coated Ca3N2, or calcining for 2 to 3 hours again in vacuum to obtain a carbon-coated Ca3N2-Ca2N mixture. In the invention, a conductive carbon film is formed on the surface of Ca3N2 or Ca3N2-Ca2N, is favorable for stability of an electrode structure, has high heat stability and low cost, is easy to prepare and has no pollution. The conductive carbon film prepared by a spraying method has the advantages of uniform thickness and high conductivity. The electrode polarization is reduced. The speed and the capacity of the lithium battery are improved.

Owner:ZHEJIANG UNIV

A vanadium-based hydrogen storage alloy and its preparation method and application

ActiveCN109390580BImprove discharge capacityImprove electrochemical kinetic performanceCell electrodesNickel accumulatorsRare-earth elementElectrochemical kinetics

The invention discloses a vanadium-based hydrogen storage alloy, which belongs to the technical field of nickel-hydrogen battery development. The chemical formula of this alloy is V 2 TiNi 0.5 Cr 0.5 m x , wherein 0<x≤0.2, M is at least one of La, Ce, Y, Sc, Nd, Gd, Er and Yb. The present invention considers the advantages and disadvantages of rare-earth hydrogen storage alloys and vanadium-based hydrogen storage alloys, adopts V, Ti, Cr, and Ni as matrix alloys, and La, Ce, Y, Sc, Nd, Gd, Er, and Yb in rare earths are After introducing rare earth elements into modified metals and vanadium-based hydrogen storage alloys, on the one hand, the discharge capacity of the hydrogen storage alloy as the negative electrode material of the nickel-hydrogen battery can be improved, and on the other hand, the electrochemical kinetic performance of the alloy electrode can be improved. The technical problems of low actual discharge capacity and insufficient kinetic performance of the existing nickel-hydrogen battery are solved.

Owner:PANZHIHUA UNIV

Method for manufacturing lithium-sulfur battery

InactiveCN103280601BImprove securityIncrease speed capacityCell electrodesFinal product manufactureCharge dischargePolypropylene

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com