A vanadium-based hydrogen storage alloy and its preparation method and application

A hydrogen storage alloy, vanadium-based technology, applied in nickel batteries, structural parts, alkaline batteries, etc., can solve the problems of low discharge capacity, poor kinetic performance, and high cost, and achieve increased discharge capacity and improved electrochemical kinetics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

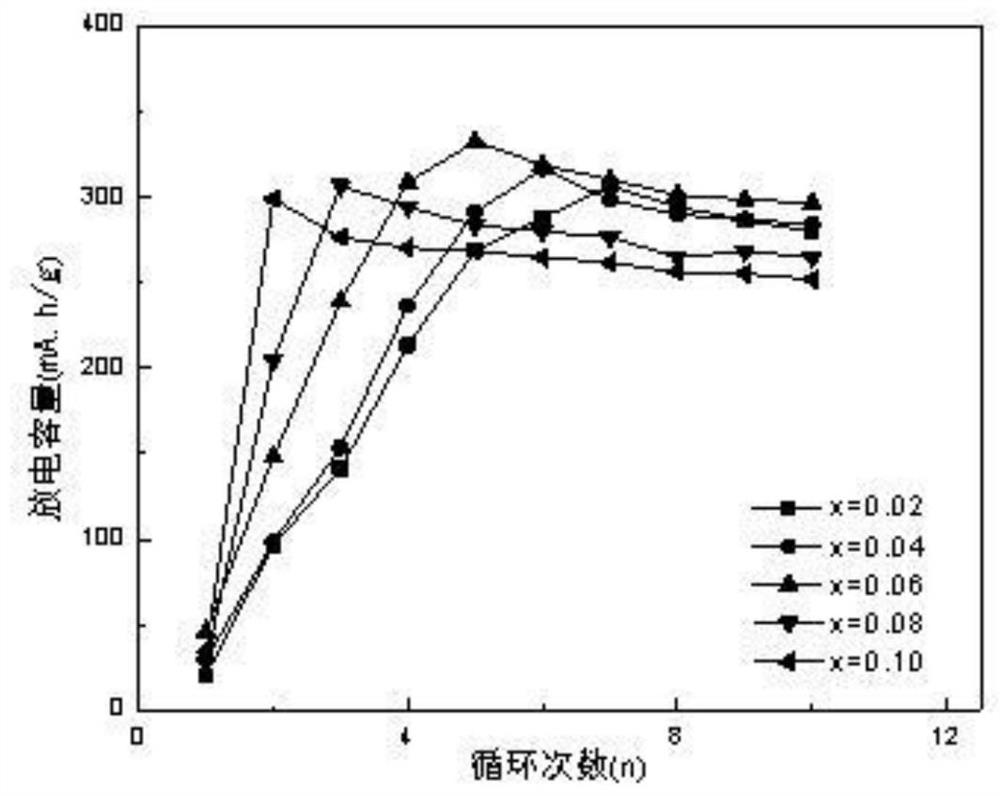

[0026] The chemical formula of rare earth modified vanadium-based hydrogen storage alloy is V 2 TiNi 0.5 Cr 0.5 Mx, where M is La, and x=0.02 to 0.15.

[0027] The specific manufacturing method is to weigh V, Ti, Ni, Cr and La particles or powders according to the stoichiometric ratio, put them into a vacuum non-consumable arc melting furnace, and vacuum to 10 -3 After Pa, the alloy is smelted and taken out after water cooling. The smelted alloy is loaded into a hydrogenation device, and hydrogen is absorbed and released repeatedly to prepare alloy powder for battery assembly.

[0028] Charge-discharge performance test: After the hydrogen storage alloy powder and the nickel hydroxide powder are mixed uniformly in a ratio of 1:4, they are pressed on a nickel foam sheet under a pressure of 20MPa. The diameter of the pressed sample is 10mm. ) 2 / NiOOH, Hg / HgO electrodes were used as reference electrodes. The electrolyte adopts 7mol / L KOH solution, and the test environment t...

Embodiment 2

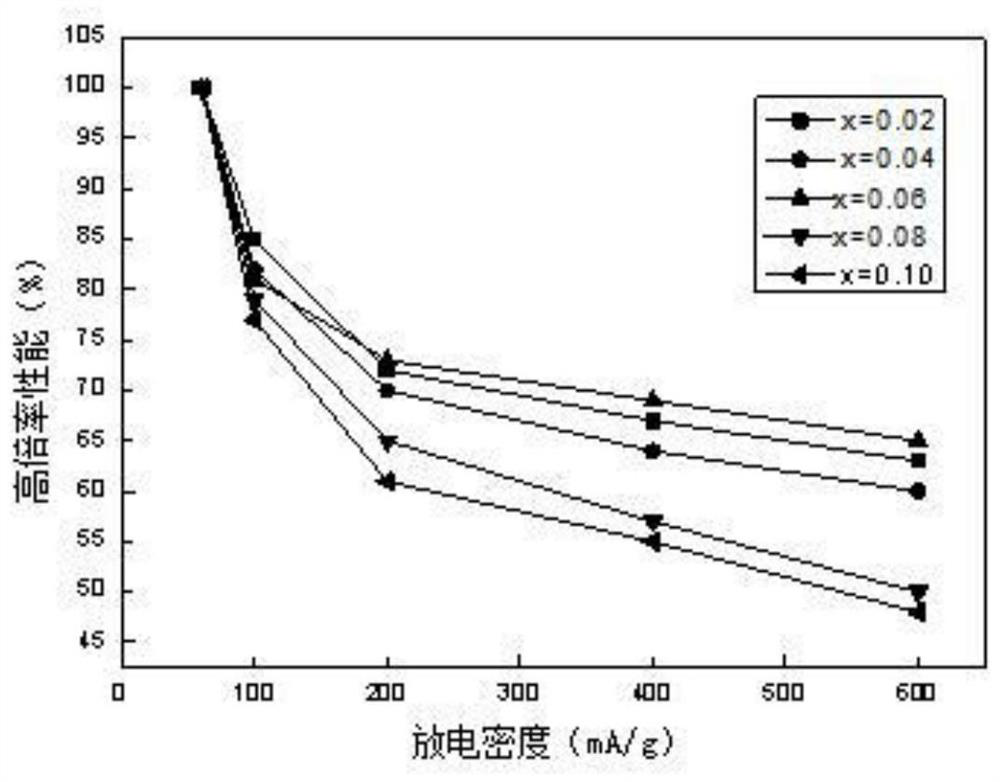

[0030] The chemical formula of the rare earth-modified vanadium-based hydrogen storage alloy is V2TiNi0.5Cr0.5Mx, wherein M is Ce, and x=0-0.1.

[0031] The specific manufacturing method is to weigh V, Ti, Ni, Cr and Ce particles or powders according to the stoichiometric ratio, put them into a vacuum non-consumable arc melting furnace, and vacuumize to 10 -3 After Pa, the alloy is smelted and taken out after water cooling. The smelted alloy is loaded into a hydrogenation device, and hydrogen is absorbed and released repeatedly to prepare alloy powder for battery assembly.

[0032] Charge-discharge performance test: After the hydrogen storage alloy powder and the nickel hydroxide powder are mixed uniformly in a ratio of 1:4, they are pressed on a nickel foam sheet under a pressure of 20MPa. The diameter of the pressed sample is 10mm. ) 2 / NiOOH, Hg / HgO electrodes were used as reference electrodes. The electrolyte adopts 7mol / L KOH solution, and the test environment temperat...

Embodiment 3

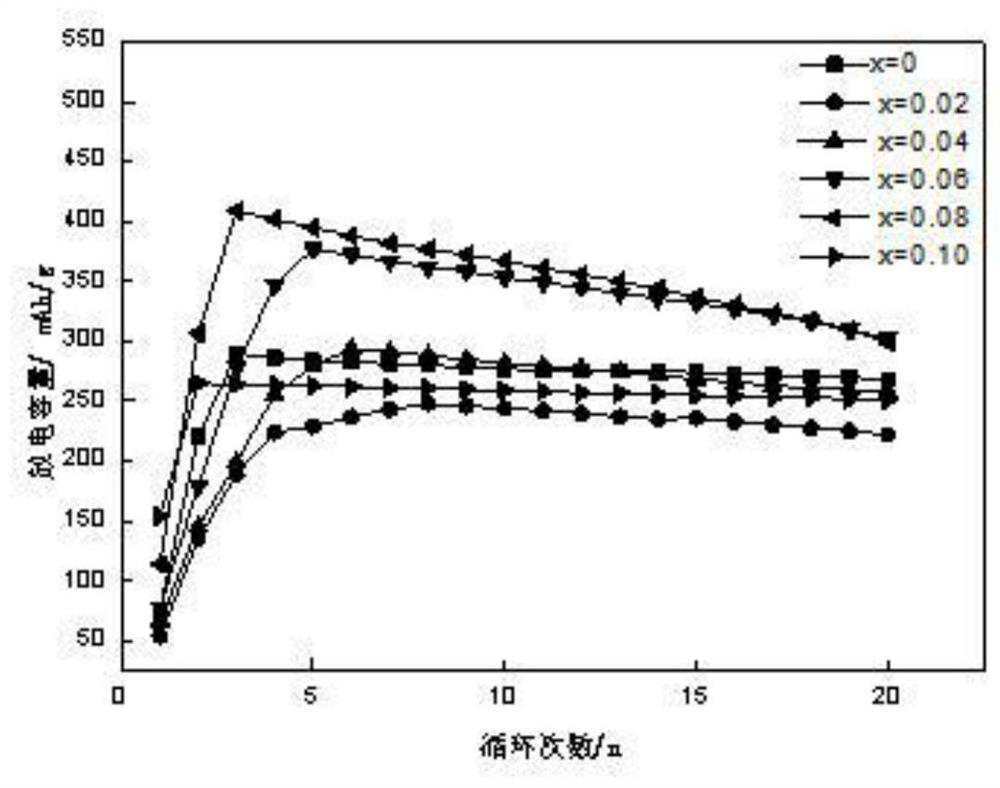

[0034] The chemical formula of the rare earth-modified vanadium-based hydrogen storage alloy is V2TiNi0.5Cr0.5Mx, wherein M is Y, and x=0.02-0.08.

[0035] The specific manufacturing method is to weigh V, Ti, Ni, Cr and Y particles or powders according to the stoichiometric ratio, put them into a vacuum non-consumable arc melting furnace, and vacuum to 10 -3 After Pa, the alloy is smelted and taken out after water cooling. The smelted alloy is loaded into a hydrogenation device, and hydrogen is absorbed and released repeatedly to prepare alloy powder for battery assembly.

[0036] Charge-discharge performance test: After the hydrogen storage alloy powder and the nickel hydroxide powder are mixed uniformly in a ratio of 1:4, they are pressed on a nickel foam sheet under a pressure of 20MPa. The diameter of the pressed sample is 10mm. ) 2 / NiOOH, Hg / HgO electrodes were used as reference electrodes. The electrolyte adopts 7mol / L KOH solution, and the test environment temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com