A kind of spherical vanadium bronze coil sodium ion battery cathode material and preparation method thereof

A technology for sodium ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of rate performance and cycle performance that cannot meet the requirements of use, short cycle life, poor rate performance, etc. The effect of migration distance, increased stability, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

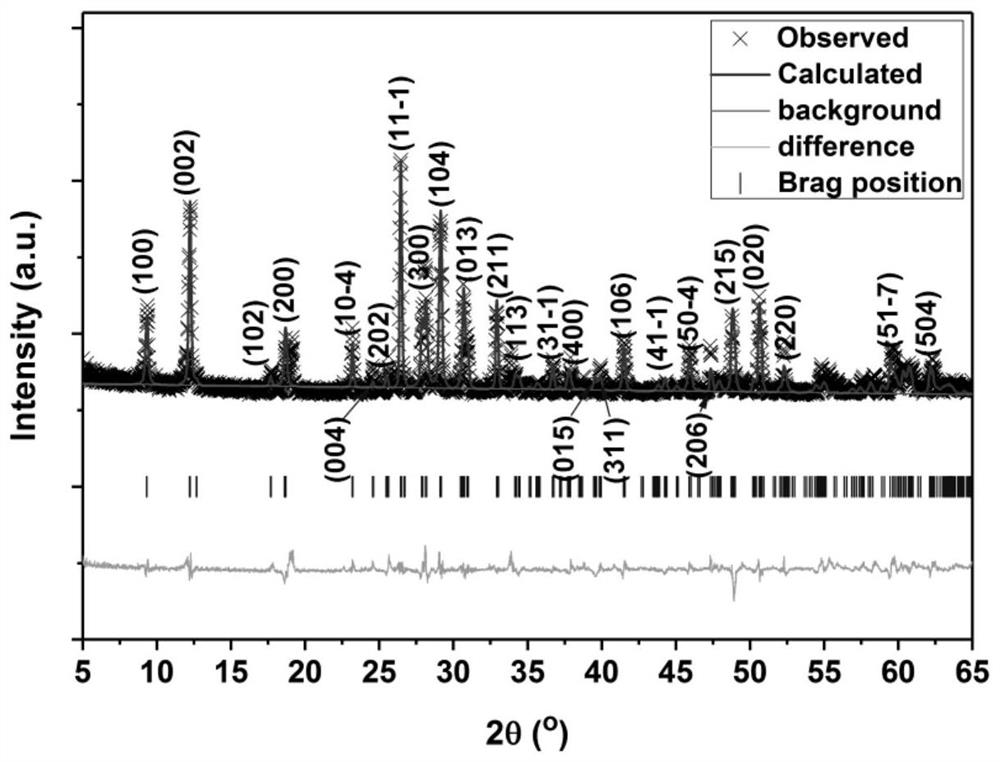

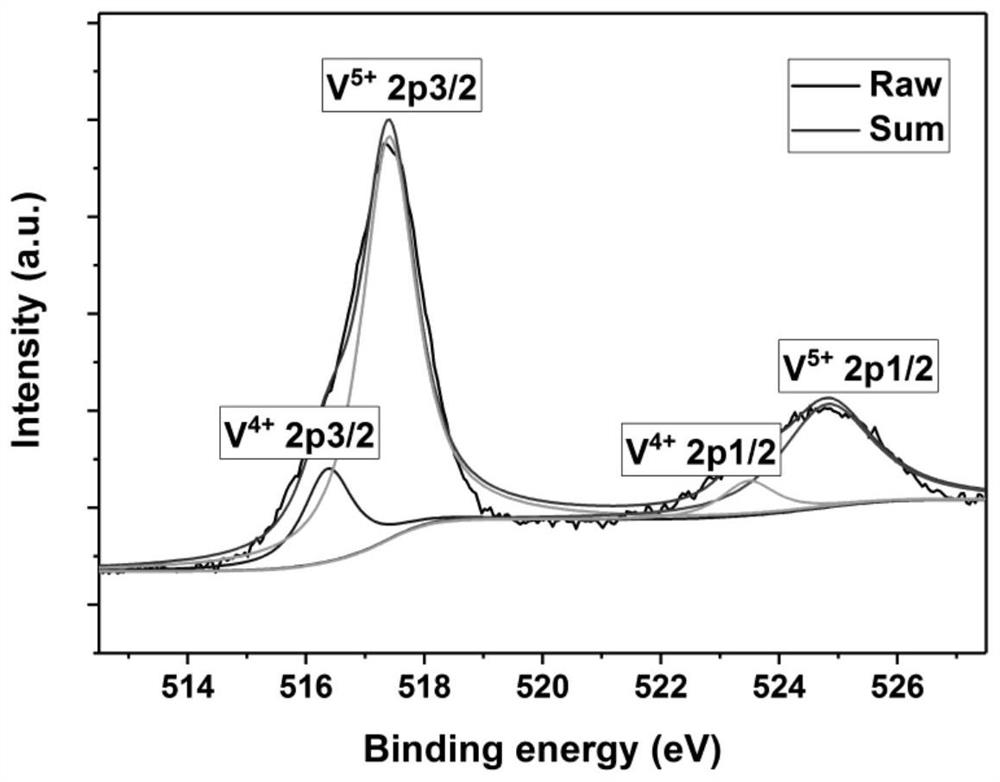

[0050] A positive electrode material for a sodium ion battery is composed of vanadium bronze coils, the vanadium bronze coils have a hierarchical porous spherical structure, the diameter of the vanadium bronze coils is 1-5 μm, and the vanadium bronze coils are composed of interwoven nanotubes.

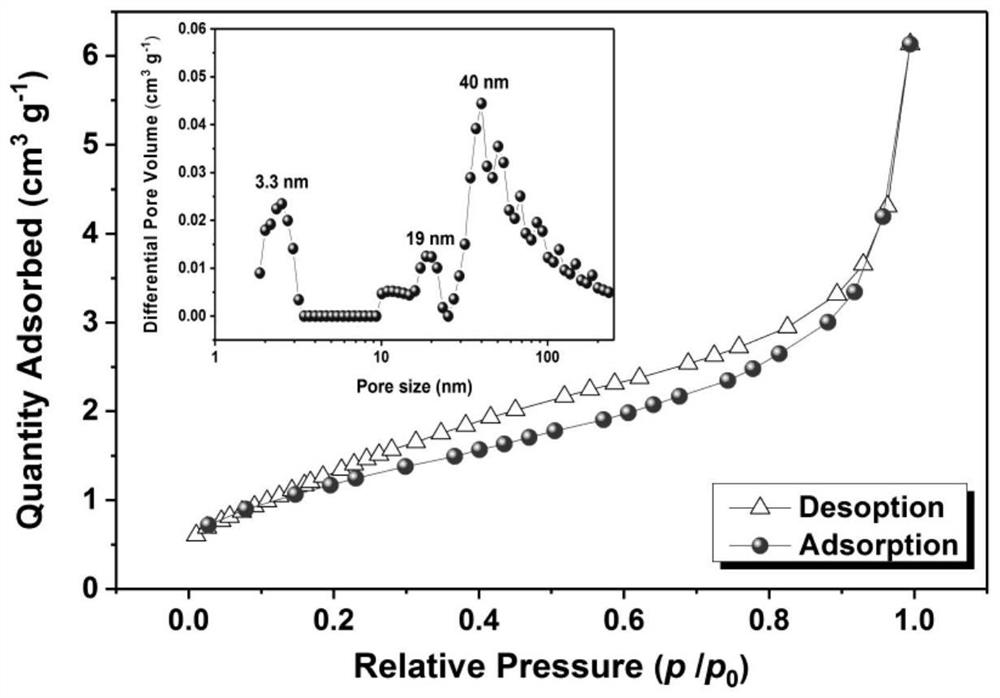

[0051] In order to further optimize the technical scheme, the pore size distribution of the vanadium bronze coils is 3.3nm, 19nm and 40nm, and the specific surface area of the vanadium bronze coils is 12.5m 2 / g.

[0052] In order to further optimize the technical solution, the length of the nanotube is 0.3-2 μm.

[0053] In order to further optimize the technical solution, the length of the nanotube is 0.3-2 μm.

[0054] In order to further optimize the technical solution, the inner diameter of the nanotube is 3nm, and the thickness of the tube wall is 7nm.

Embodiment 2

[0056] A preparation method of a sodium ion battery cathode material, specifically comprising the steps of:

[0057] (1) Preparation of vanadium oxide precursor:

[0058] (a) Weigh vanadium pentoxide and straight-chain organic amine respectively according to the molar ratio of 1: (3~5), and weigh vanadium pentoxide and H 2 o 2 The mass ratio of the solution is 1:(18~43) Weigh the H 2 o 2 solution, set aside; then slowly drop H into the vanadium pentoxide 2 o 2 solution, stir evenly, and then slowly add linear organic amine;

[0059] (b) After fully stirring for 5 hours, put the obtained solution into a reaction kettle lined with polytetrafluoroethylene, and react at 160-250°C for 3-7d;

[0060] (c) Centrifuge the reacted product first, then wash with deionized water and alcohol three times in sequence, and finally vacuum-dry at 60-120° C. for 10-12 hours to obtain a vanadium oxide precursor containing organic amine molecular intercalation.

[0061] (2) Preparation of so...

Embodiment 3

[0076] A preparation method of a sodium ion battery cathode material, specifically comprising the steps of:

[0077] (1) Preparation of vanadium oxide precursor:

[0078] (a) take by weighing 1.82g of vanadium pentoxide in a beaker, then weigh 55.50g of 30% H 2 o 2 The solution was dripped into a beaker filled with alum pentoxide, stirred for 2 hours to form a uniform solution; then slowly added 7.42g of dodecylamine;

[0079] (b) After fully stirring for 5 hours, put the obtained solution into a reaction kettle lined with polytetrafluoroethylene, and react at 200° C. for 5 days;

[0080] (c) Centrifuge the reacted product first, then wash with deionized water and alcohol three times in sequence, and finally vacuum-dry at 80° C. for 10-12 hours to obtain a vanadium oxide precursor containing organic amine molecular intercalation.

[0081] (2) Preparation of sodium-doped vanadium bronze precursor:

[0082] (A) Weigh 2.13g of sodium sulfate and 0.91g of vanadium oxide precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com