Composite lithium cobalt oxide electrode and fabrication method thereof

A technology of composite lithium cobaltate and its production method, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient performance of lithium cobaltate electrodes, and achieve the purpose of suppressing side reactions on the electrode surface, inhibiting decomposition, and stabilizing the electrode surface structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

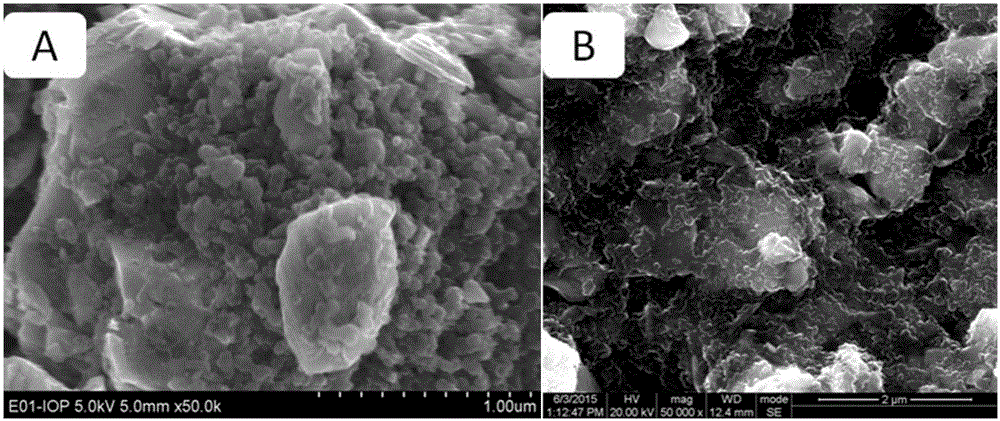

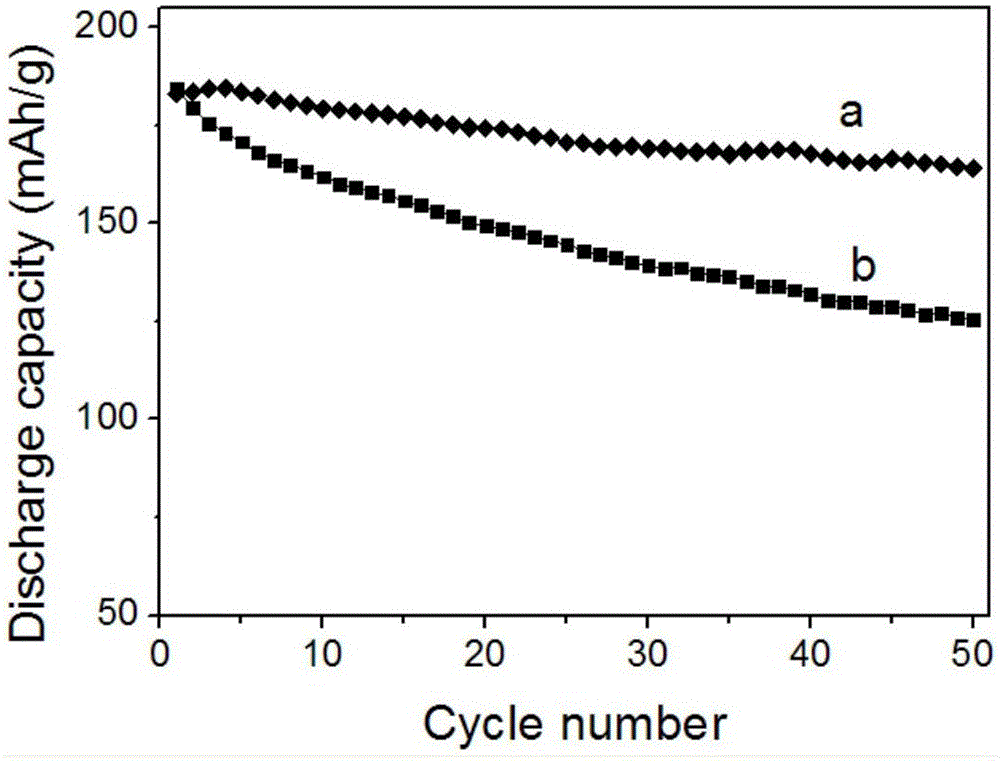

Embodiment 1

[0030] This embodiment is used to illustrate the preparation method of lithium cobaltate electrode and the method for coating it with radio frequency magnetron sputtering to make composite lithium cobaltate electrode. The specific steps are as follows:

[0031] A. Preparation of conventional lithium cobalt oxide electrode

[0032] Weigh 80 parts by weight of lithium cobaltate and 10 parts by weight of acetylene black, mix evenly, add 10 parts by weight of polyvinylidene fluoride (PVDF) and use N-methylpyrrolidone (NMP) as a solvent, mix and grind to form a slurry and uniform Coated on aluminum foil and dried at 110°C to make a conventional lithium cobalt oxide electrode. That is to say, in this example, the ratio of lithium cobaltate powder, the positive electrode active material, conductive additive, and binder is 8:1:1. Here, the ratio range is generally 7:2:1 to 8.5:1:0.5, and 8:1 is commonly used. :1, so this example uses 8:1:1 as an example.

[0033] B. Install the target...

Embodiment 2

[0047] This embodiment is used to illustrate the preparation method of lithium cobaltate electrode and the method for coating it with radio frequency magnetron sputtering to make composite lithium cobaltate electrode. The specific steps are as follows:

[0048] A. Preparation of conventional lithium cobalt oxide electrode

[0049] Weigh 80 parts by weight of lithium cobaltate and 10 parts by weight of acetylene black, mix evenly, add 10 parts by weight of polyvinylidene fluoride (PVDF) and use N-methylpyrrolidone (NMP) as a solvent, mix and grind to form a slurry and uniform Coated on aluminum foil and dried at 110°C to make a conventional lithium cobalt oxide electrode. That is to say, in this example, the ratio of lithium cobaltate powder, the positive electrode active material, conductive additive, and binder is 8:1:1. Here, the ratio range is generally 7:2:1 to 8.5:1:0.5, and 8:1 is commonly used. :1, so this example uses 8:1:1 as an example.

[0050] B. Install the targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com