Cylindrical film air electrode and application thereof in zinc-air battery

An air electrode and air battery technology, which is applied to the fuel cell type half cell and the primary cell type half cell, etc., can solve the problems that do not involve the cylindrical zinc-air cell structure and its manufacturing method, small current discharge, and influence on oxygen diffusion. Path and diffusion speed and other issues, to achieve the effect of improving electrochemical kinetics, smooth discharge curve, and good electrochemical kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

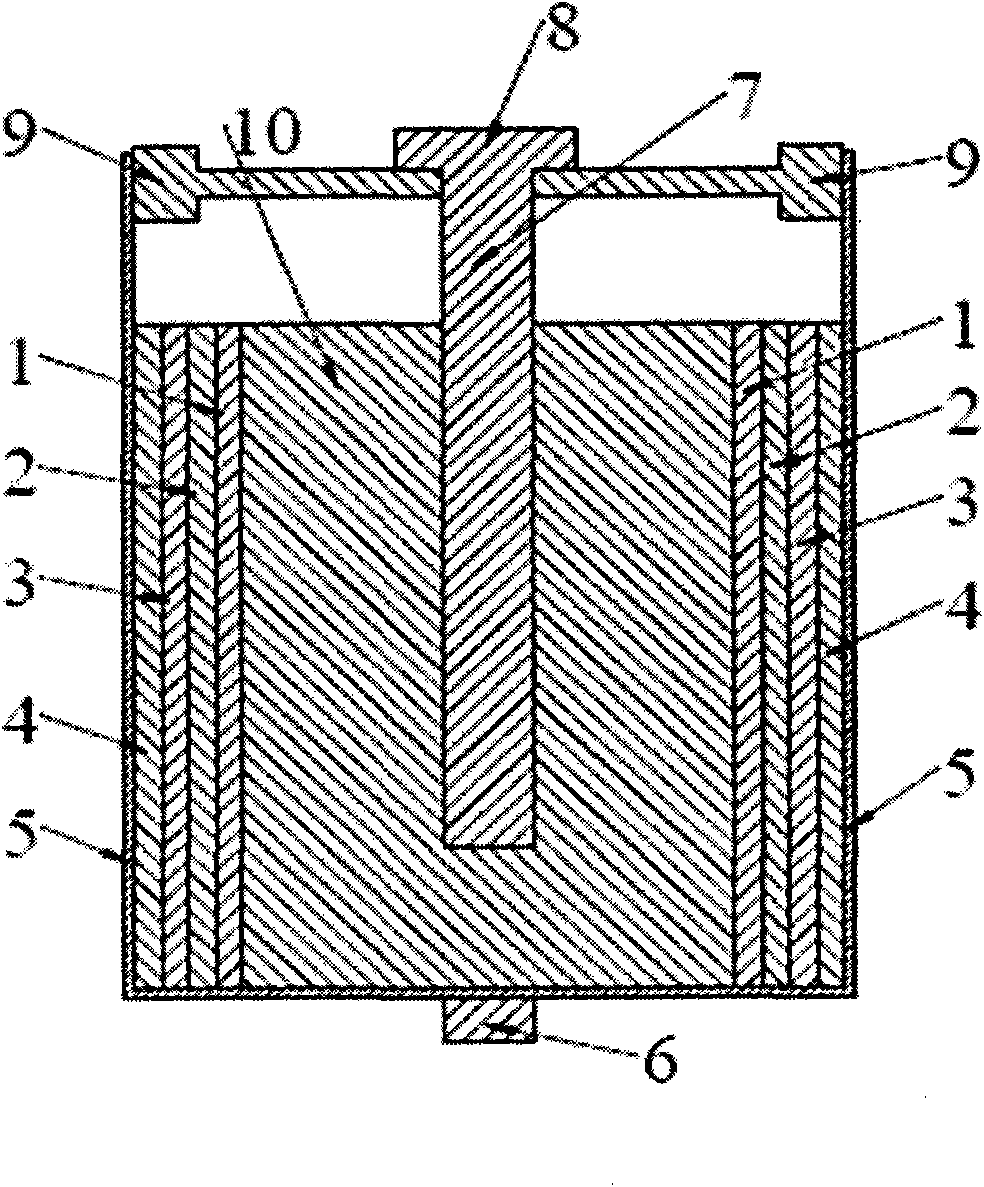

[0025]A cylindrical zinc-air battery prepared by a cylindrical thin-film air electrode is composed of a battery casing 5, a cylindrical thin-film air electrode, a zinc electrode 7 and a plastic sealing ring 9, and the battery casing 5 is made of nickel-plated stainless steel The formed cylinder is provided with ventilation holes; the cylindrical thin film air electrode 2 is composed of a gas diffusion layer 4, an electrocatalytic layer 3, a current collecting net 2 and a battery separator 1, and the gas diffusion layer 4, the electrocatalytic layer 3. The current collecting net 2 and the battery separator 1 are set in sequence and pressed into sheets, then rolled into a cylinder to form an inner cavity, the gas diffusion layer 4 is the outer wall of the cylindrical thin film air electrode and the bottom of the cylinder is closed, and the center of the bottom is set The air electrode electrode joint 6, the annular end surface formed between the gas diffusion layer 4 on the top o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com