Preparation method and application of mycelium-based carbon film conductive skeleton and method for preparing battery

A mycelium-based carbon film, mycelium technology, applied in non-aqueous electrolyte batteries, battery electrodes, lithium batteries, etc., can solve the limitations of lithium-sulfur battery energy storage capacity, cycle life and charging speed, weak electrochemical kinetic performance , it is difficult to achieve commercial application and other problems, to achieve the effect of improving electrochemical kinetic performance, conducive to uniform loading, and high industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

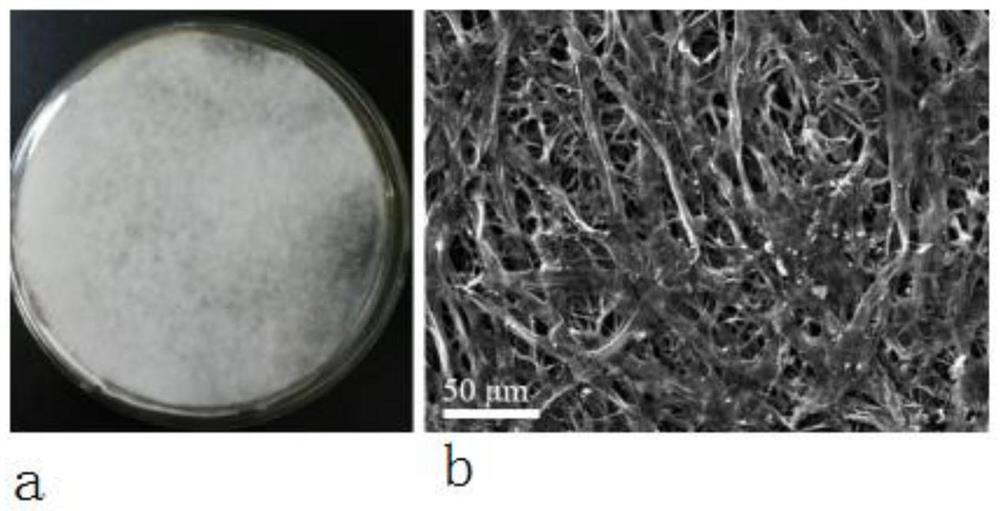

[0040] (1) select the fungal bacterial classification with filamentous form, obtain the mycelia fiber based on microbial culture technology, be specifically: configure PDA culture medium in proportion, sub-pack in multiple test tubes, expand and cultivate the purchased Rhizopus stolonifer, and then transfer Connected in PDB culture medium, under the condition of 25 ℃, keep the constant temperature for a period of time, collect the mycelia fibers, then rinse with deionized water repeatedly, and then immerse in 0.1-1mol / L NaOH solution at 70-80 ℃ Put it into a water bath for 2 hours, and then rinse it with deionized water until the pH value is about 7.0 to obtain a mycelium precursor.

[0041] (2) The mycelium precursor was treated in a crusher for 3 minutes, then dispersed by magnetic stirring for 36 hours, and then ultrasonically crushed for 30 minutes to obtain a clear and transparent mycelium fiber dispersion.

[0042] (3) Vacuum filter 100 mL of mycelial fiber dispersion on...

Embodiment 2

[0047] The difference from Example 1 is that the suction filtration volume of the mycelia fiber dispersion is 200 mL, and the others are the same as in Example 1.

Embodiment 3

[0049] The difference from Example 1 is that the suction filtration volume of the mycelia fiber dispersion is 300 mL, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com