Patents

Literature

103results about How to "Easy for industrial implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof

InactiveCN106867945AIncrease resistanceImprove enrichment capacityBacteriaContaminated soil reclamationMicroorganismResource utilization

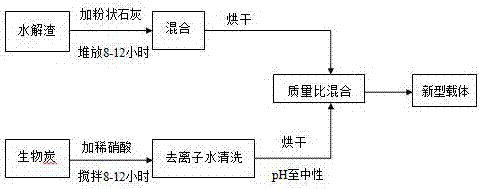

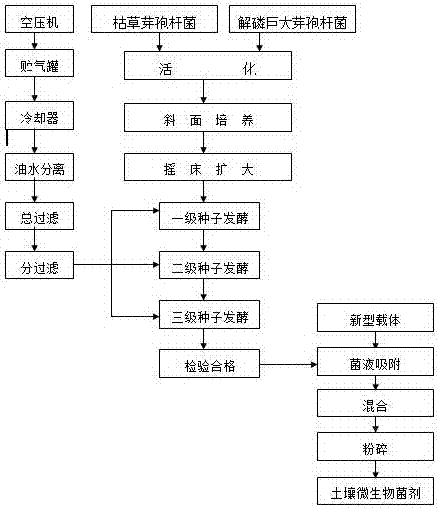

The invention discloses a microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof. A preparing method comprises the steps of fermentation and adsorption of strains. Specifically, bacteria solutions obtained after fermentation of bacillus megateriumvar.phosphaticum and bacillus subtilis LVLE-14 are mixed in proportion, then adsorption is conducted by means of a special adsorption carrier, and then mixing and smashing are conducted to obtain the microorganism passivator. The adsorption carrier comprises hydrolysis residues and biochar which are mixed and smashed according to a certain mass ratio. By the adoption of the microorganism passivator for repairing heavy metal pollution of soil, the content of available heavy metals in soil can be effectively reduced, and the number of microbial populations and plant yield are increased greatly. The method for repairing heavy metal pollution of soil by means of the microorganism passivator is in-situ repair, operation is easy, the cost is low, and industrialized implementation can be easily achieved; furthermore, the repairing effect is good, soil fertility can not be damaged, and the utilization rate of resources can be increased.

Owner:SHANGHAI LVLE BIO TECH

Enzyme preparation for removing pesticide residual on surfaces of vegetables and fruits and preparation method thereof

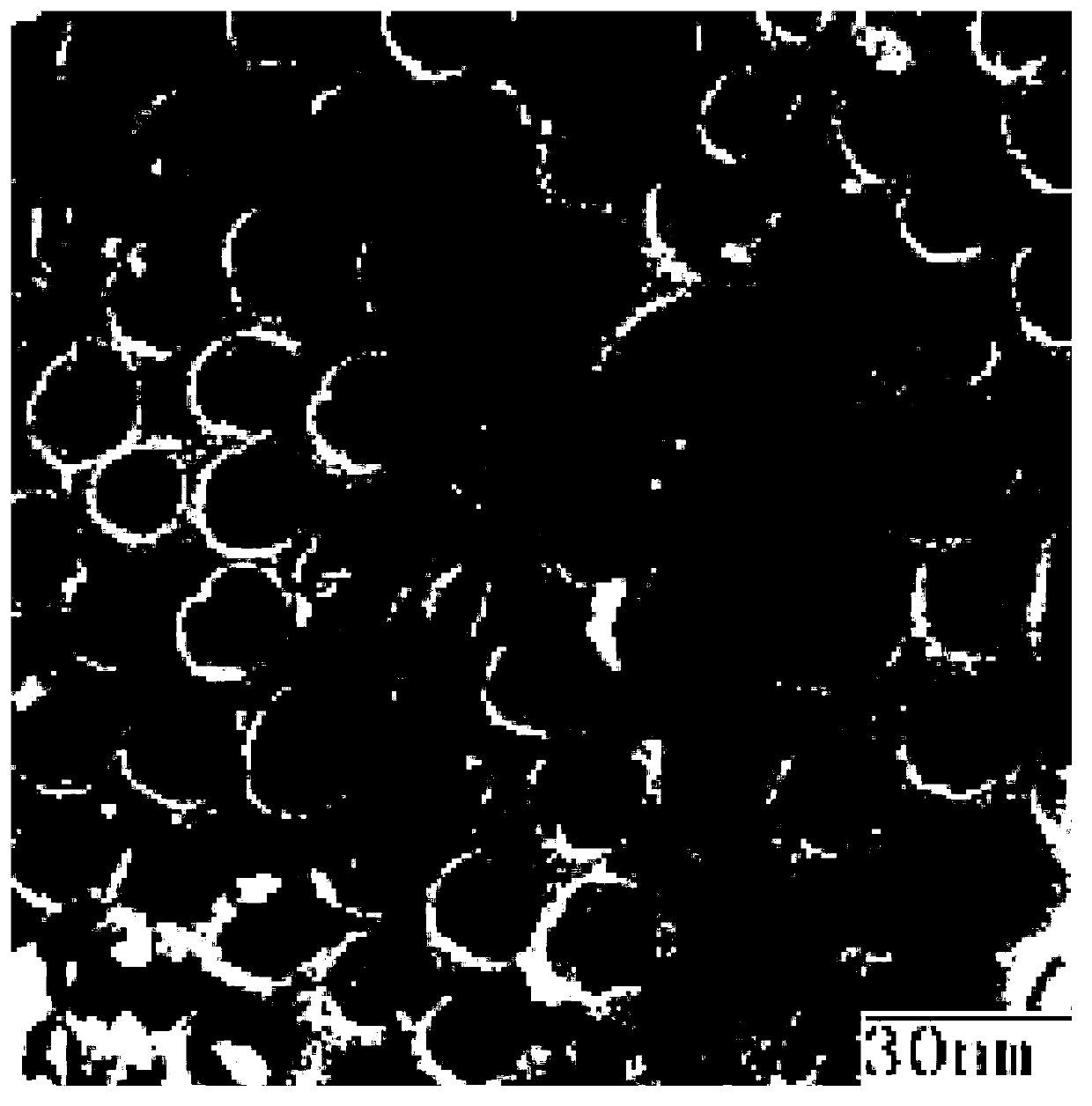

ActiveCN102827709AAffect qualityAffect the tasteNon-surface-active detergent compositionsDetergent powders/flakes/sheetsMicroorganismFluidized bed

The invention provides an enzyme preparation for removing pesticide residual on the surfaces of vegetables and fruits and a preparation method of the enzyme preparation. The enzyme preparation comprises one or more enzymes and alkaline buffer salts, wherein each enzyme preparation is the particular preparation with aperture distributed from 50 to 500 nanometers. The enzyme preparation further comprises fillers with porous structures; and the enzyme preparation is prepared by the method comprising the following steps: pelletizing the mixing materials of one or more enzymes and fillers to obtain the enzyme particle mixture; embedding 45wt% to 55wt% of enzyme in the enzyme particle mixture into the filler; and then mixing the enzyme particle mixture and the water solution of the alkaline buffer salt through a fluidized bed. With the adoption of the enzyme preparation provided by the invention, the pesticide residual on the surfaces of the vegetables and the fruits can be completely and effectively removed; harmful microorganism on the surfaces of the vegetable and fruit can be removed; and the quality of the vegetable and fruit can be further improved.

Owner:山东淳和万生环境技术有限公司

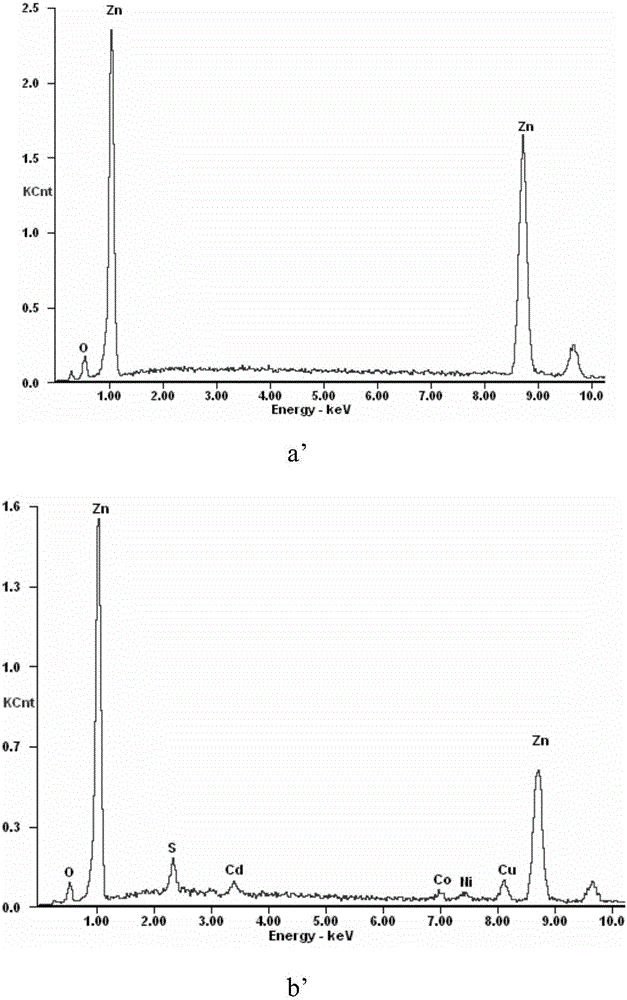

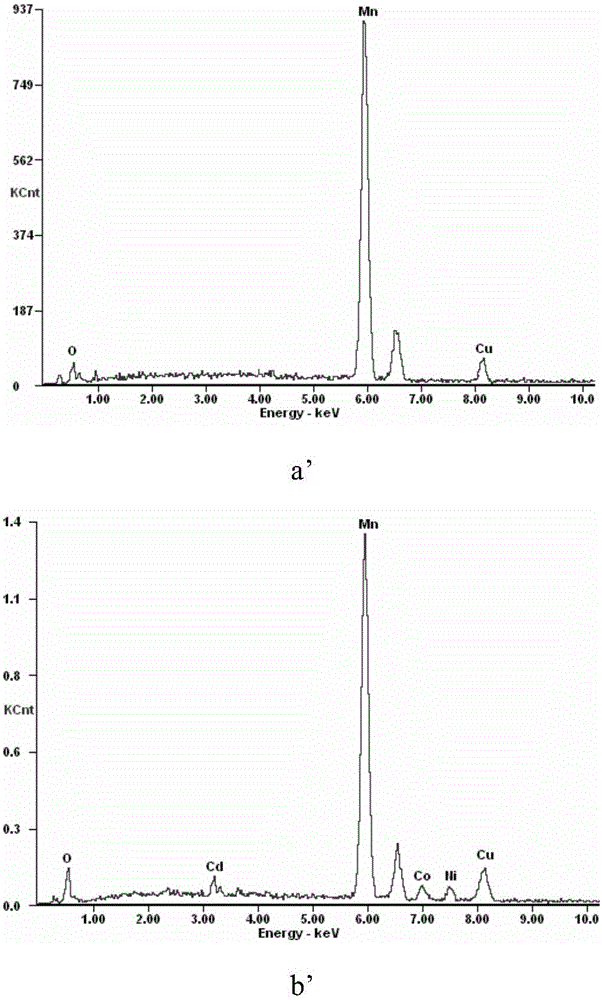

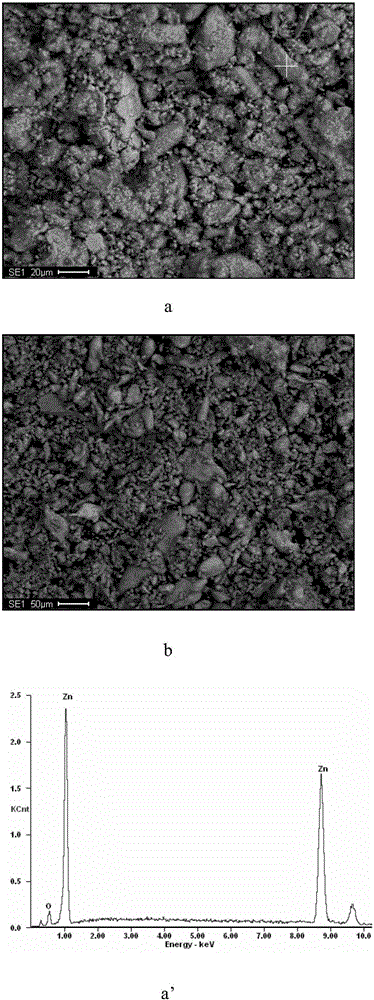

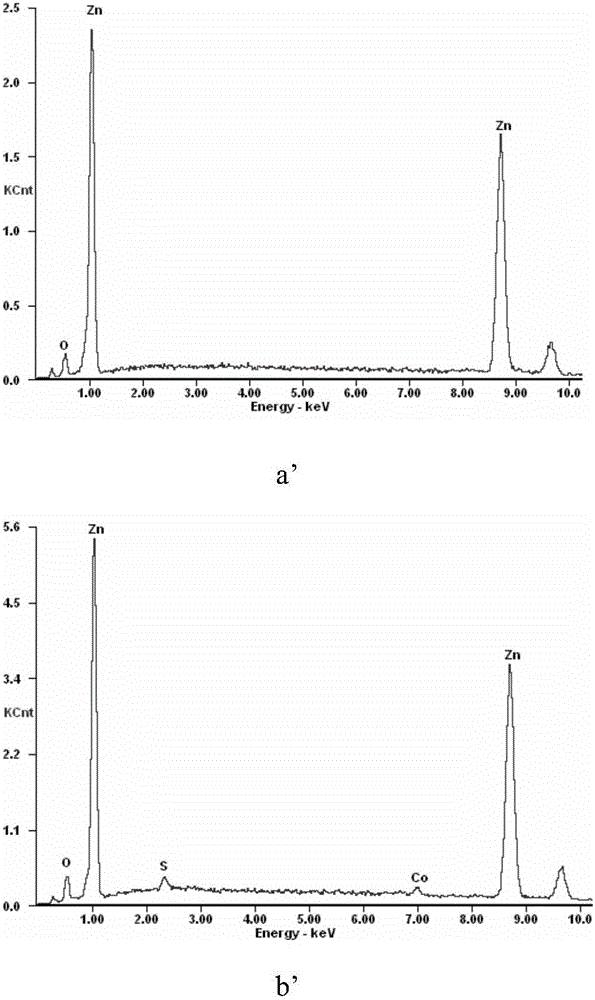

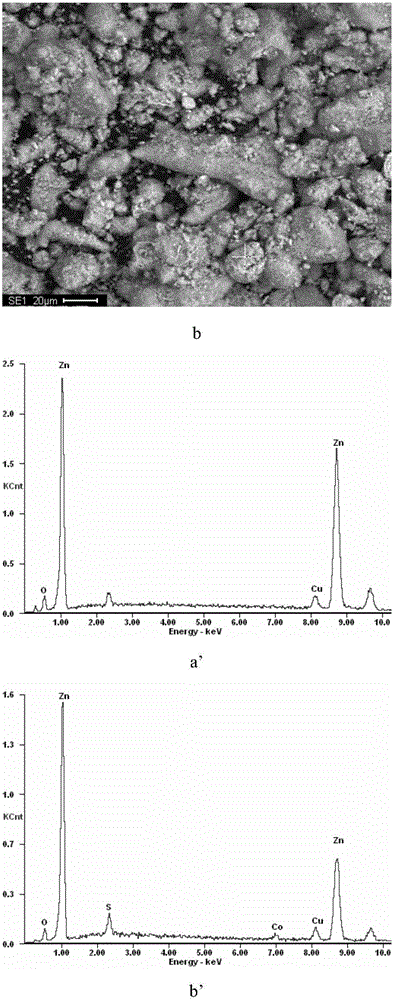

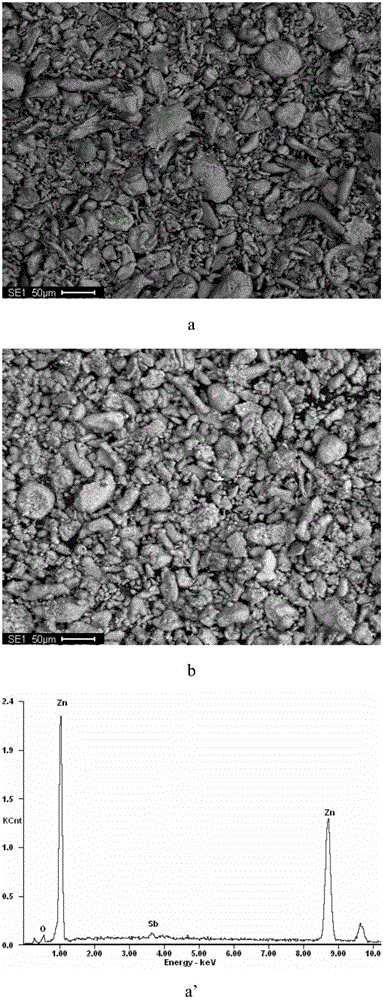

Method for deeply cleaning and removing cobalt by wet hydrometallurgy

ActiveCN106893872AExcellent cobalt removal efficiencyReduce consumptionProcess efficiency improvementManganeseHydrometallurgy

The invention relates to a method for deeply cleaning and removing cobalt by wet hydrometallurgy. The method is characterized in that neutrally-leached supernate in wet hydrometallurgy is sequentially treated by a first-stage cleaning process, a second-stage cleaning process and a third-stage cleaning process to obtain new liquid containing not greater than 0.5mg / l cobalt, wherein the neutrally-leached supernate in wet hydrometallurgy is deeply purified through a cleaning agent and an activating agent in the second-stage cleaning process; the cleaning agent is alloy powder prepared through 50-65% by weight of zinc, 30-49% by weight of manganese, 0.05-2% by weight of aluminum, 0.05-2% by weight of magnesium, and 0.9-3% by weight of lead; the activating agent is one or two of antimonic salt and antimony white. The method has the advantages that the cobalt removing efficiency is outstanding, and particularly the zinc consumption is low and the purpose of deep cleaning can be achieved while the method is used for processing a high-cobalt zinc sulfate solution; meanwhile, impurities which damage the wet hydrometallurgy are not introduced; the operation is simple; the industrial implementation is easily carried out; and the economic benefit is obvious.

Owner:HENAN YUGUANG ZINC IND

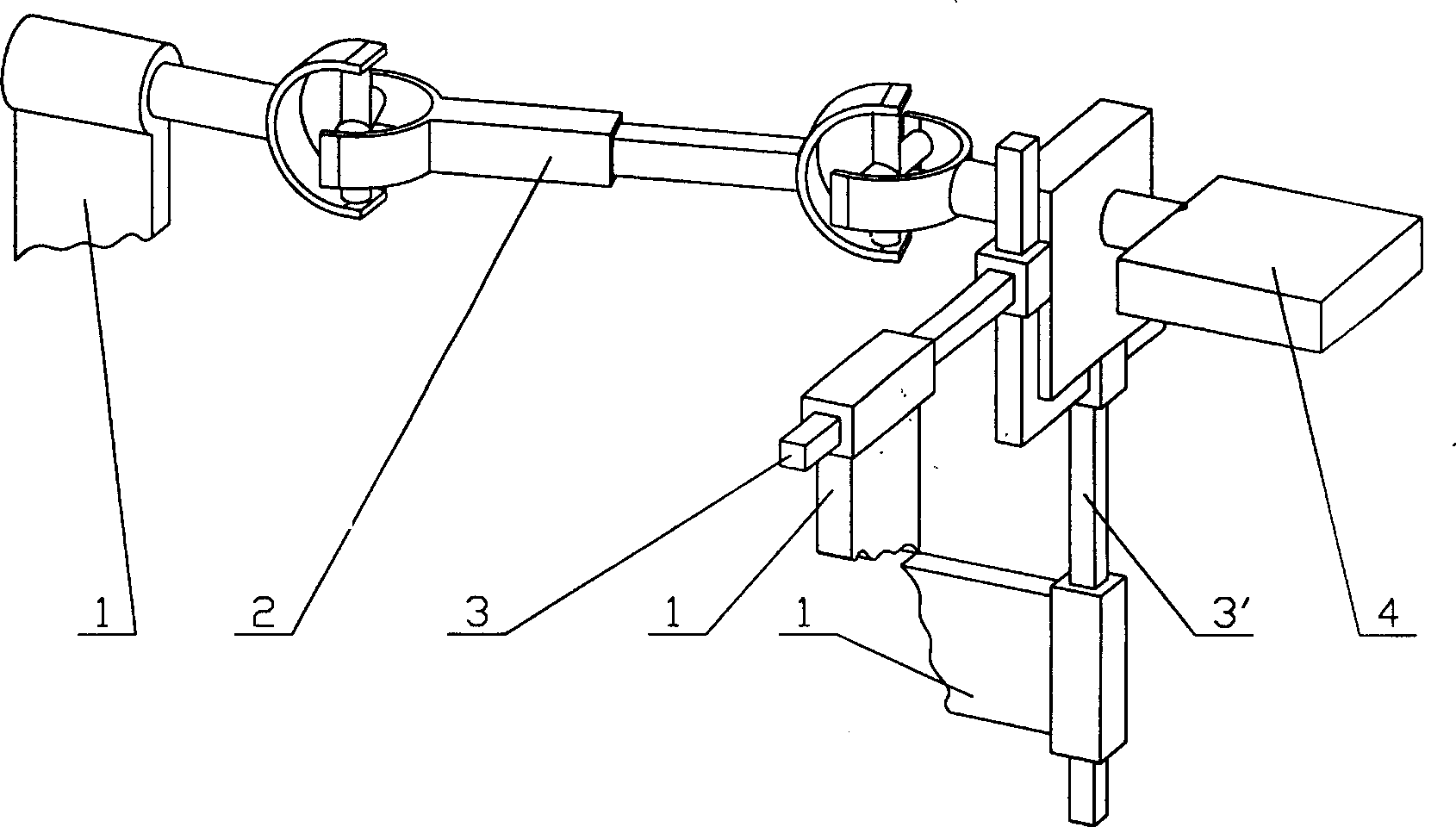

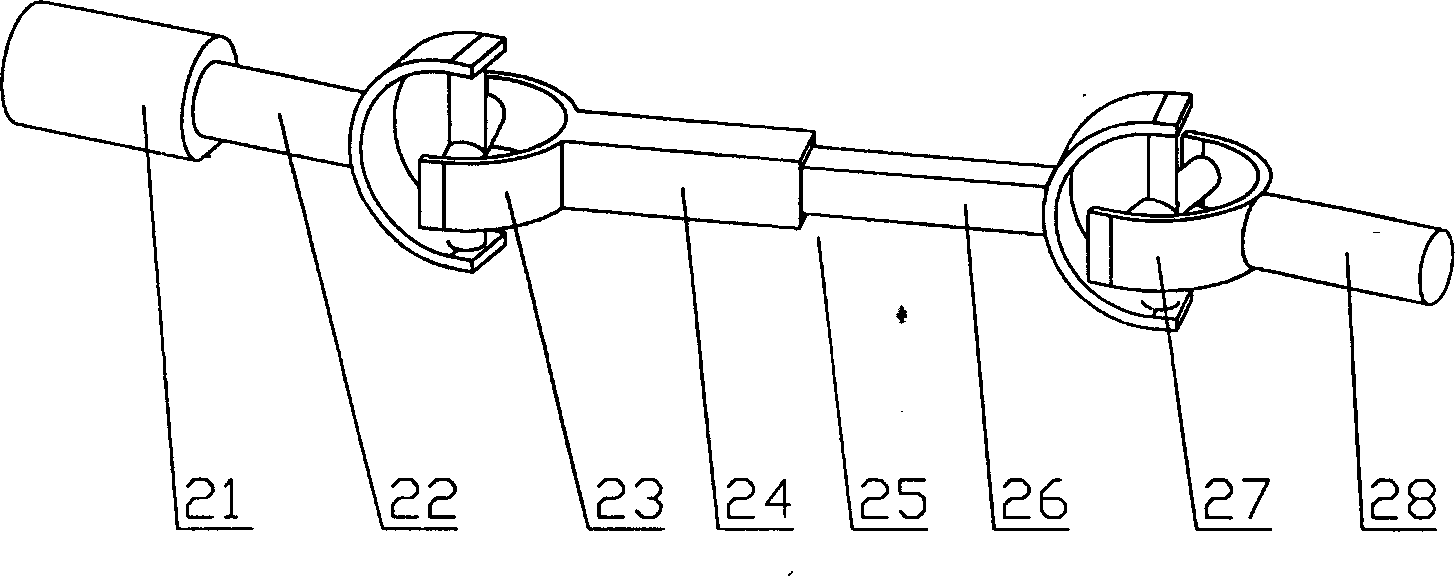

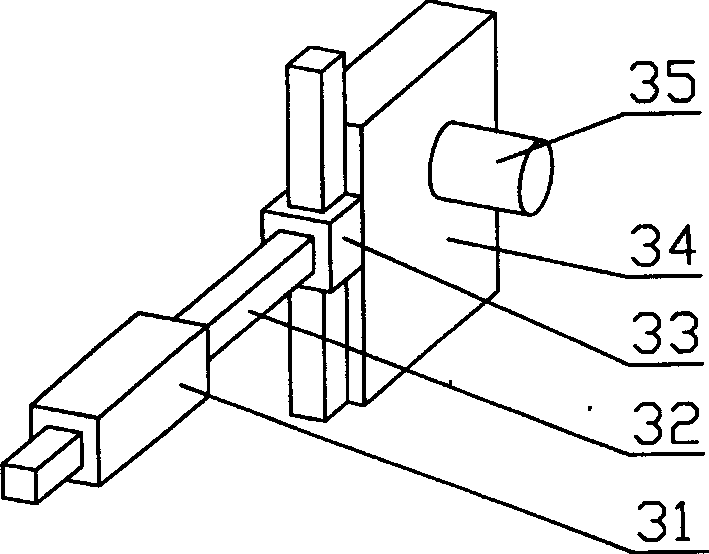

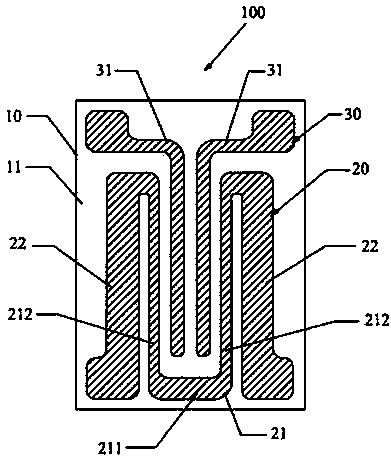

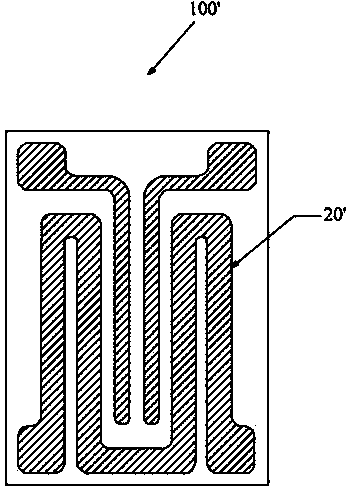

Three freedom degrees decoupling sphere parallel mechanism

InactiveCN1803411ADegenerate parallel kinematics modelEasy to controlProgramme-controlled manipulatorControl theoryHinge angle

Owner:HEBEI UNIV OF TECH

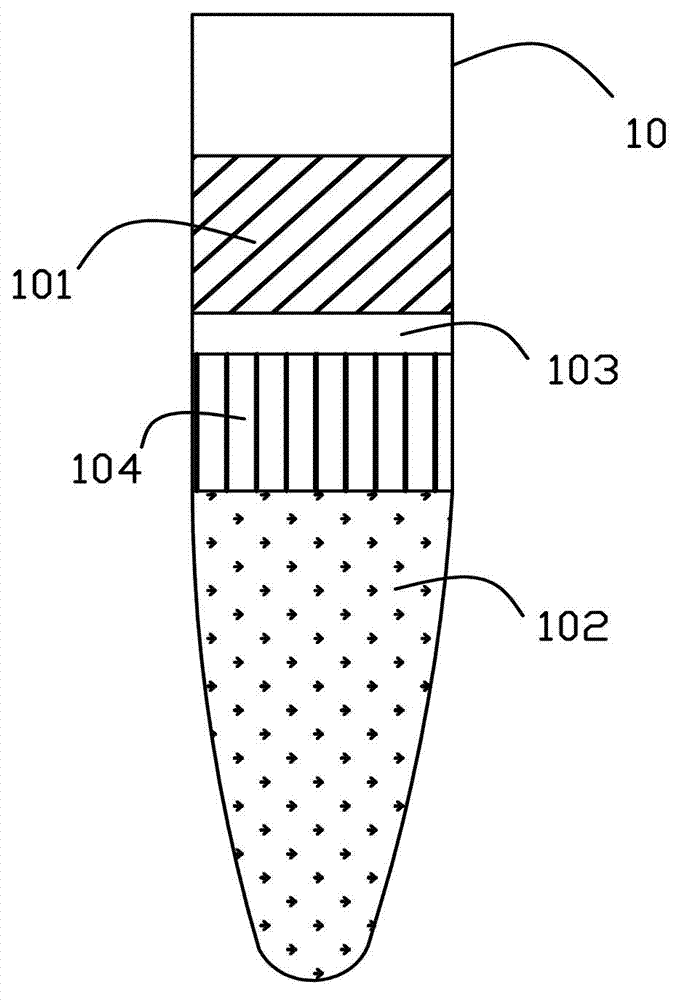

Preparation method of anti-infectious lower biomaterial of small intestinal mucosa

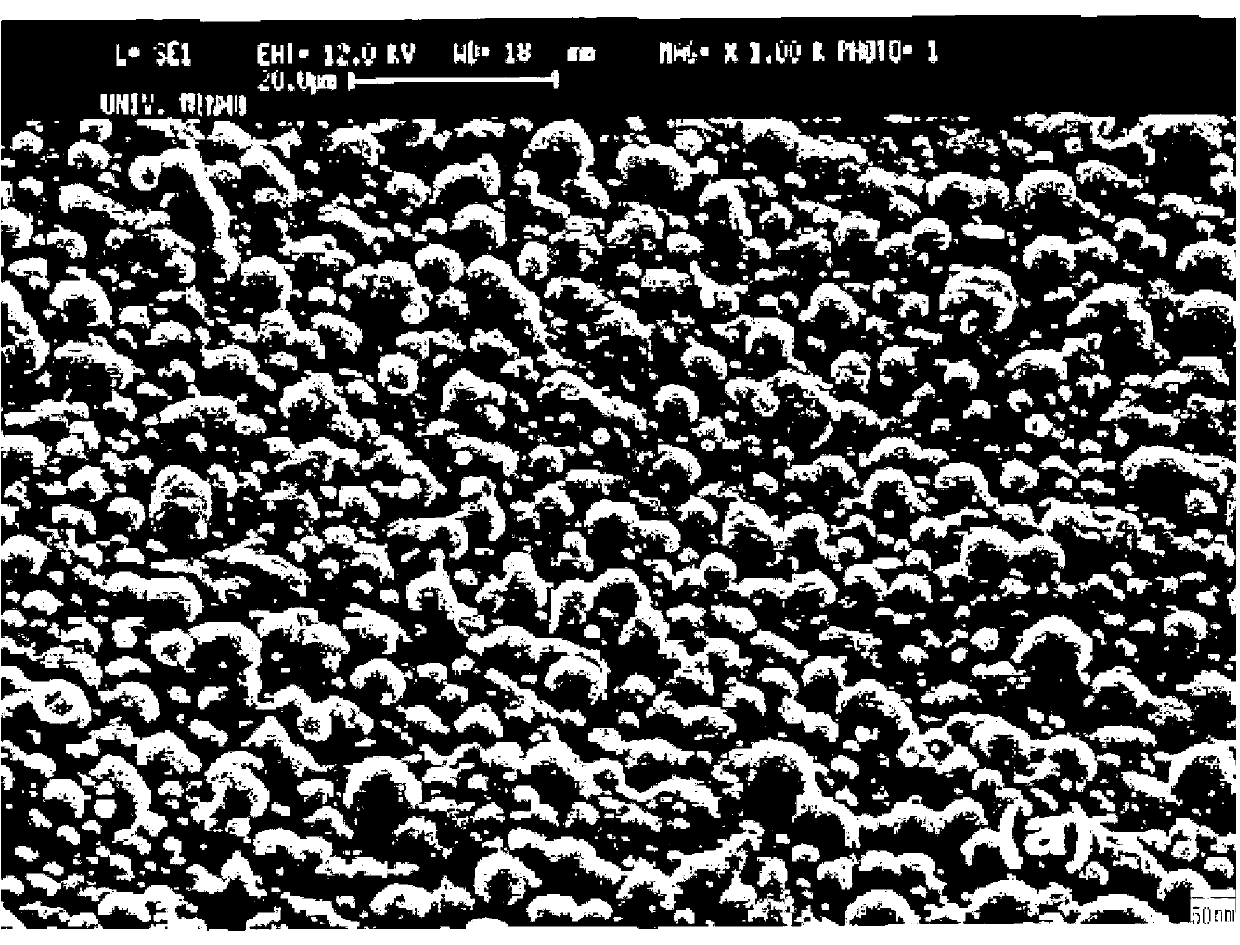

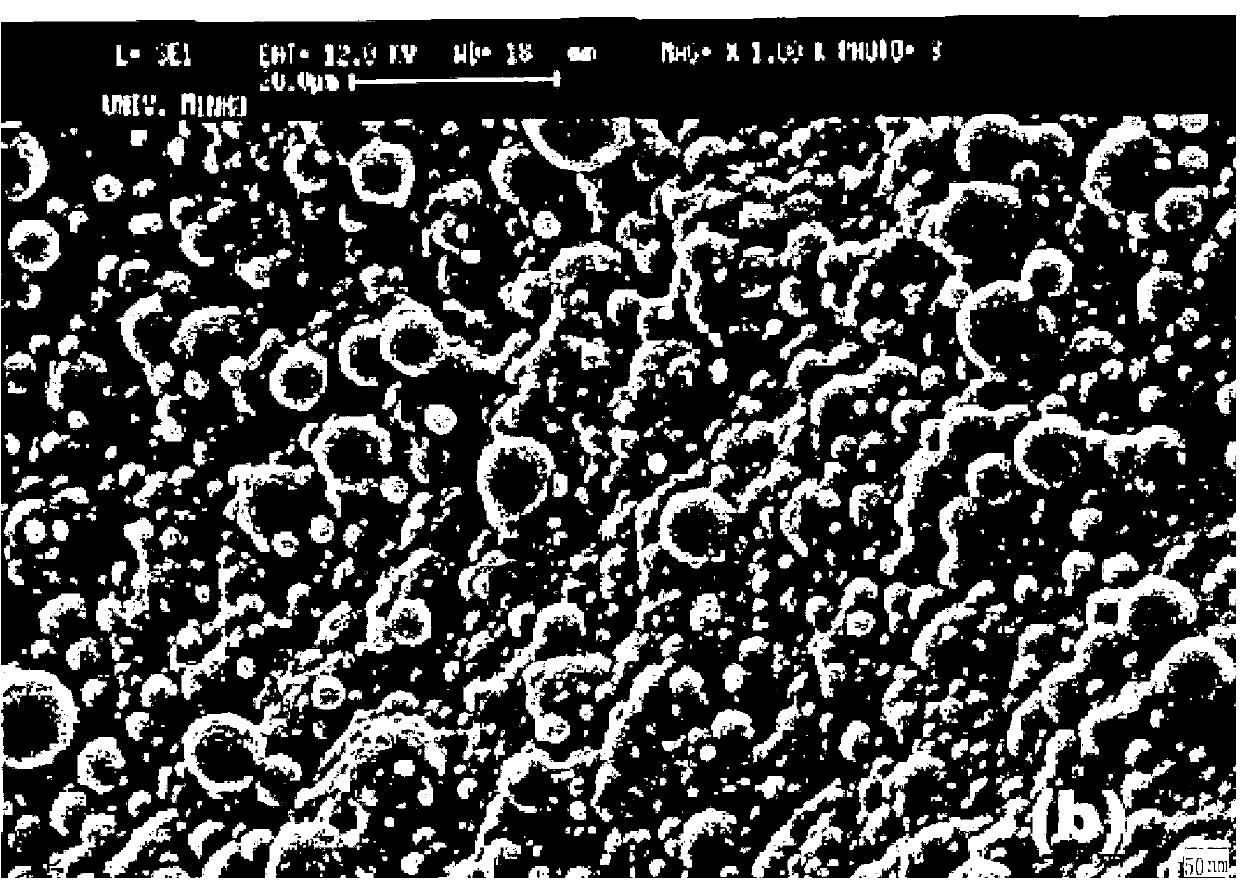

InactiveCN109331228AImprove solubilityPromote digestionProsthesisFreeze-dryingScanning electron microscope

The invention relates to a preparation method of an anti-infectious lower biomaterial of small intestinal mucosa. The method comprises the following steps: primarily treating; degreasing; inactivatingvirus; decellularizing; loading antibacterial components; forming; freezing drying or soaking in a storing solution; packing; sterilizing. The lower biomaterial prepared according to the method is good in decellularizing effect; the damage to the structure of a raw material is reduced; an SIS material subjected to decellularizing is complete and uniform in a collagenous fiber structure by observing through a light microscope; the collagenous fiber beam is complete; extremely few cells are residual; complete cells cannot be observed; the collagenous fibers of the material are of three-dimensional net shaped structures by being observed under a scanning electron microscope, and cells are not observed, and few broken cell pieces are residual; after the antibacterial components are loaded tothe SIS, the antibacterial effect is obvious; the clinical demand can be met.

Owner:陈德夫

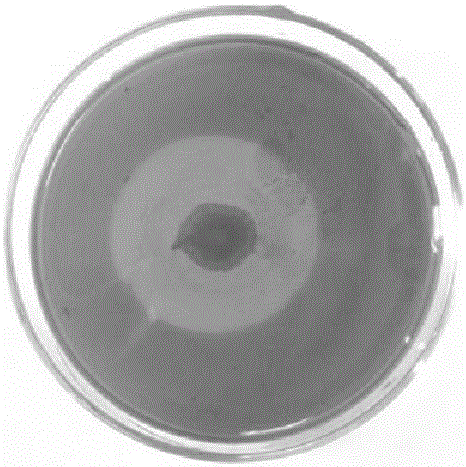

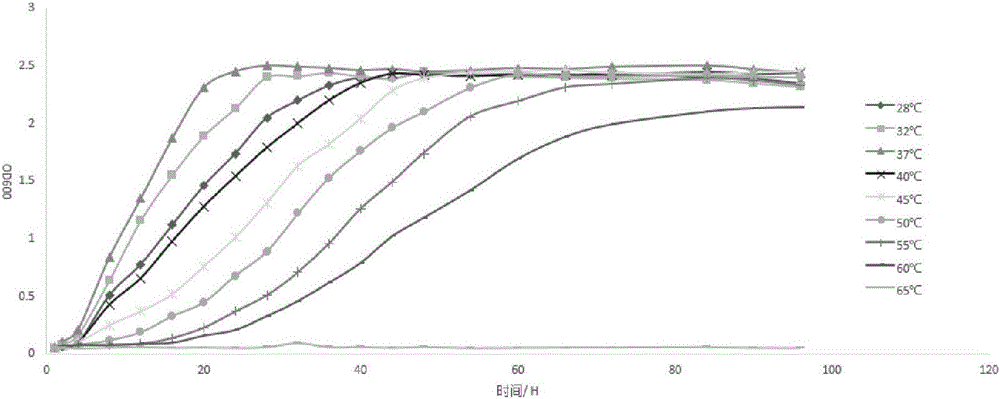

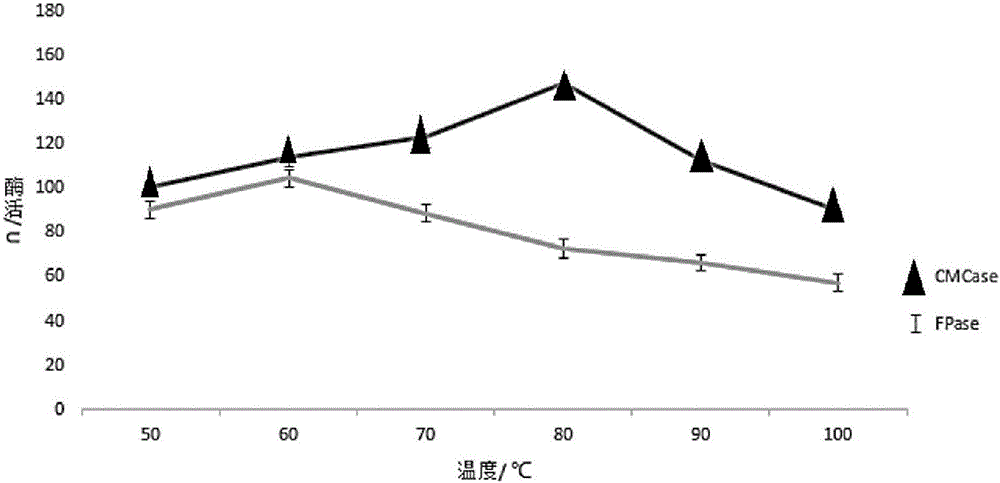

Bacillus with high temperature resistance and cellulose degradation capacity and application thereof

ActiveCN106350469APromote degradationCreate pollutionBacteriaMicroorganism based processesMicroorganismCellulose degradation

The invention relates to a bacillus with high temperature resistance and cellulose degradation capacity and an application thereof. The invention specifically relates to bacillus JWT-1, belongs to Bacillus subtilis and is preserved in China General Microbiological Culture Collection Center (CGMCC); the preserving date is on July 11, 2016; the preserving No. is CGMCC No.12758. The bacillus has higher degradation capacity for cellulose, hemicellulose, pectin and lignin in straws; the bacillus can grow and multiply under high temperature of 60 DEG C; the highest endurable temperature is 100 DEG C; the bacillus has excellent high-temperature compost application prospect.

Owner:SHANGHAI JIAO TONG UNIV

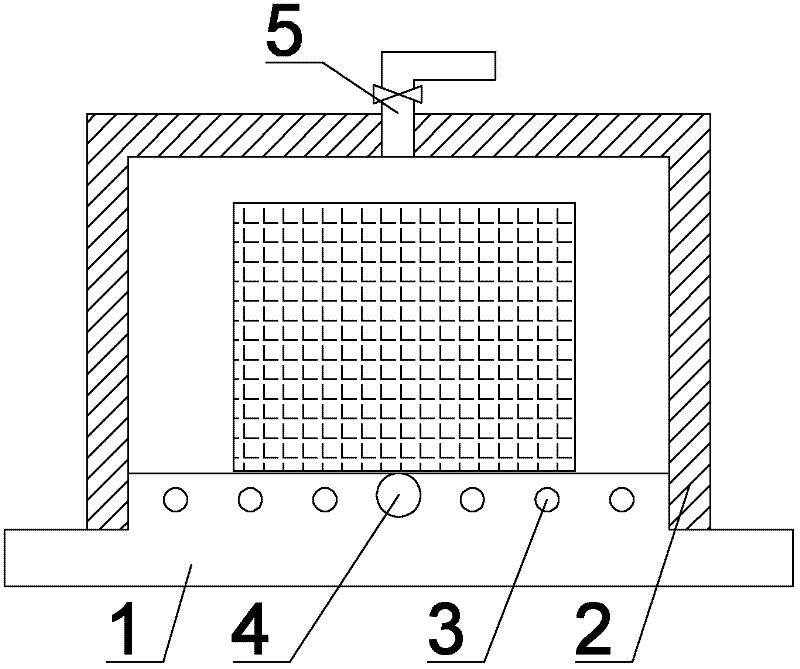

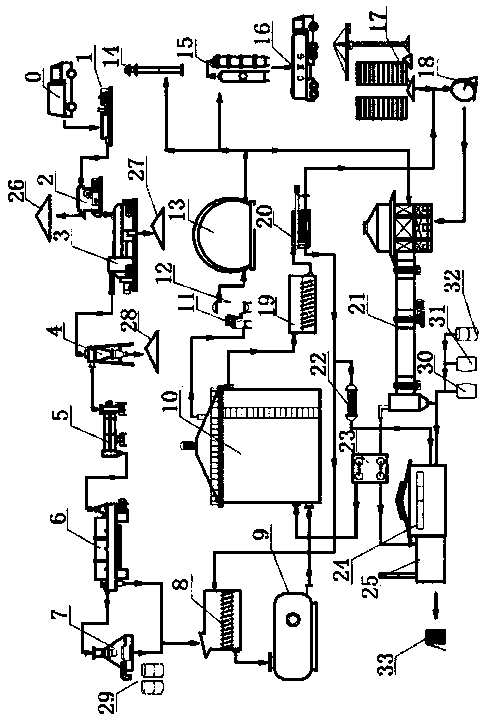

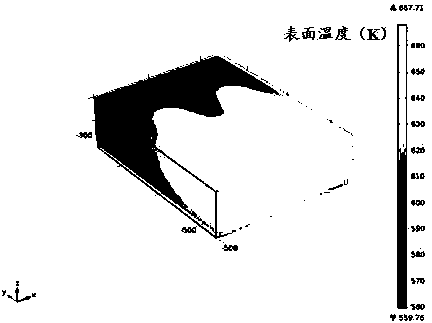

Method for processing coke by electrolytic aluminium waste and special device

ActiveCN102559225AReduce consumption costReduce manufacturing costEnergy inputCarbon preparation/purificationResource utilizationMarket competition

The invention discloses a method for processing coke by electrolytic aluminium waste and a special device. The method is characterized by comprising the following steps of: obtaining a carbon material from electrolytic aluminium waste via magnetic separation and flotation processes; drying the carbon material, and preheating to 100-120 DEG C; adding asphalt and tar, mixing via kneading equipment, and then moulding in hydraulic moulding equipment by pressing; curing the moulded raw materials in an electro-thermal dry distillation device; and drying and preheating the carbon material by the dry-distilled coke product via a waste heat utilization device. The invention discloses a new process and a new technology for resource utilization for the high-fluorine-content carbon-containing solid waste of electrolytic aluminium, which is used for deeply processing the carbon material obtained by the electrolytic aluminium waste, so as to further increase the additional value of the electrolytic aluminium waste. Compared with the prior art, the new process and the new technology have the advantages of being wide in application range, high in treatment and disposal amount, advanced in technology, low in treatment cost, and good for the implementation of industrialization. Simultaneously, the project is specific in the aimed target market, and obvious in market competition advantage.

Owner:周俊和 +1

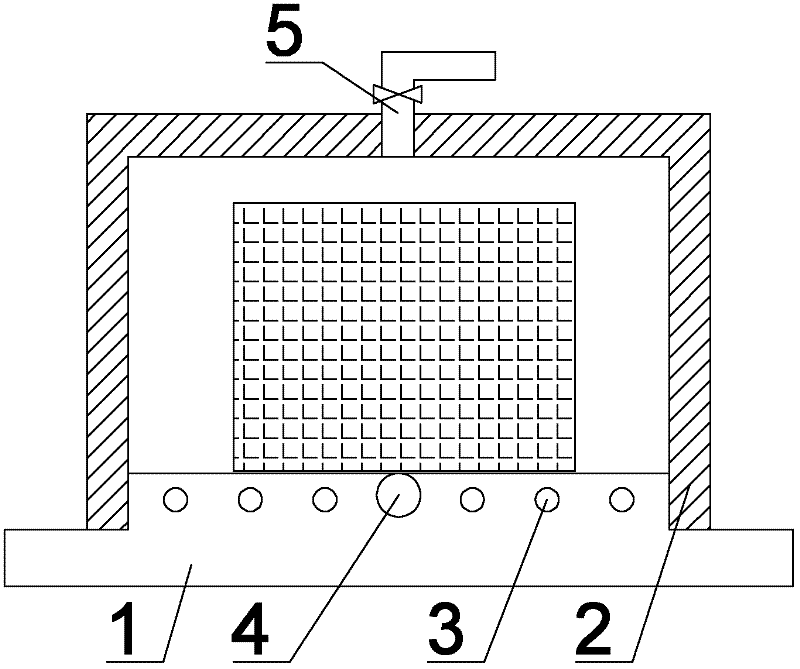

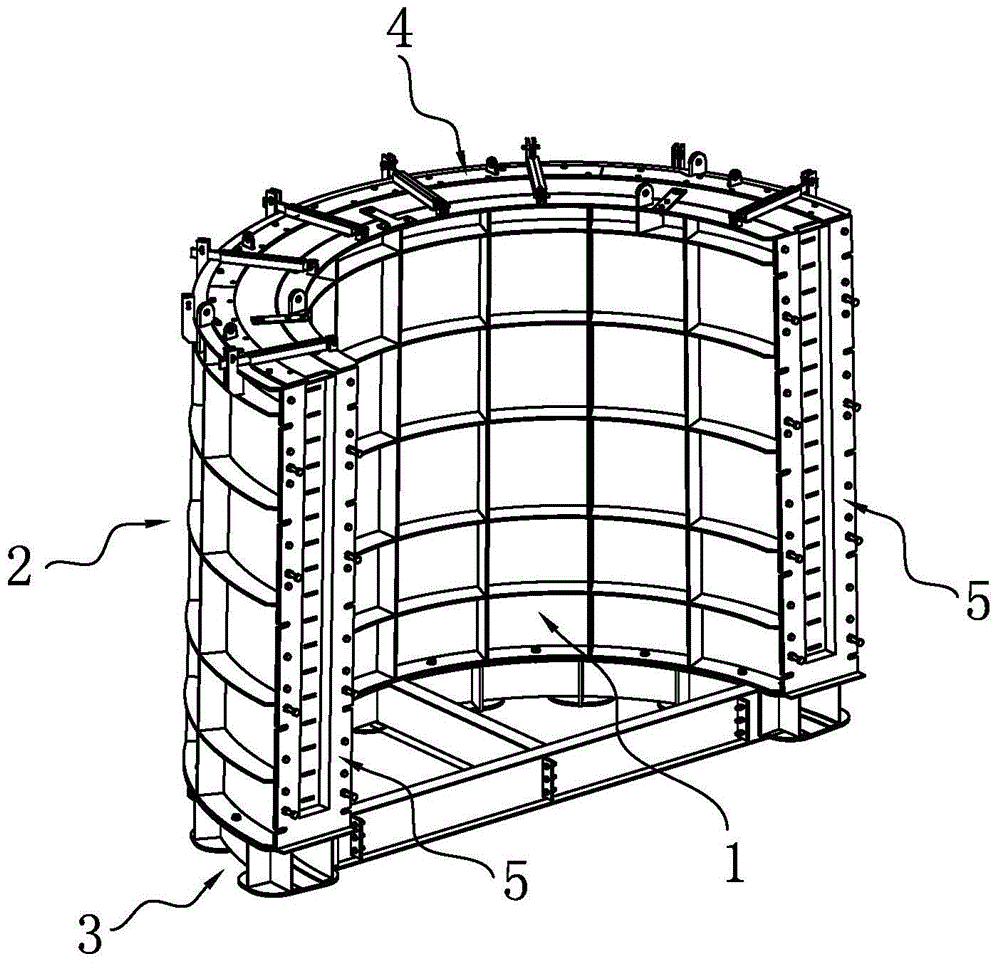

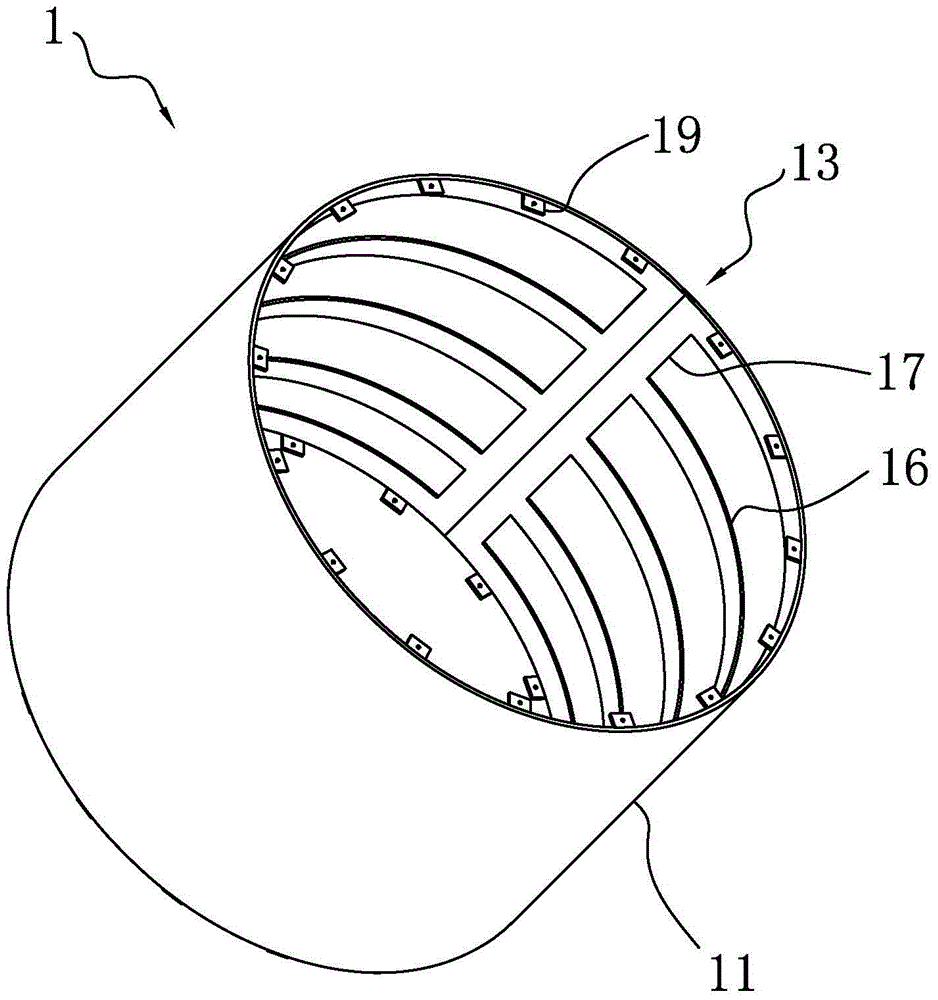

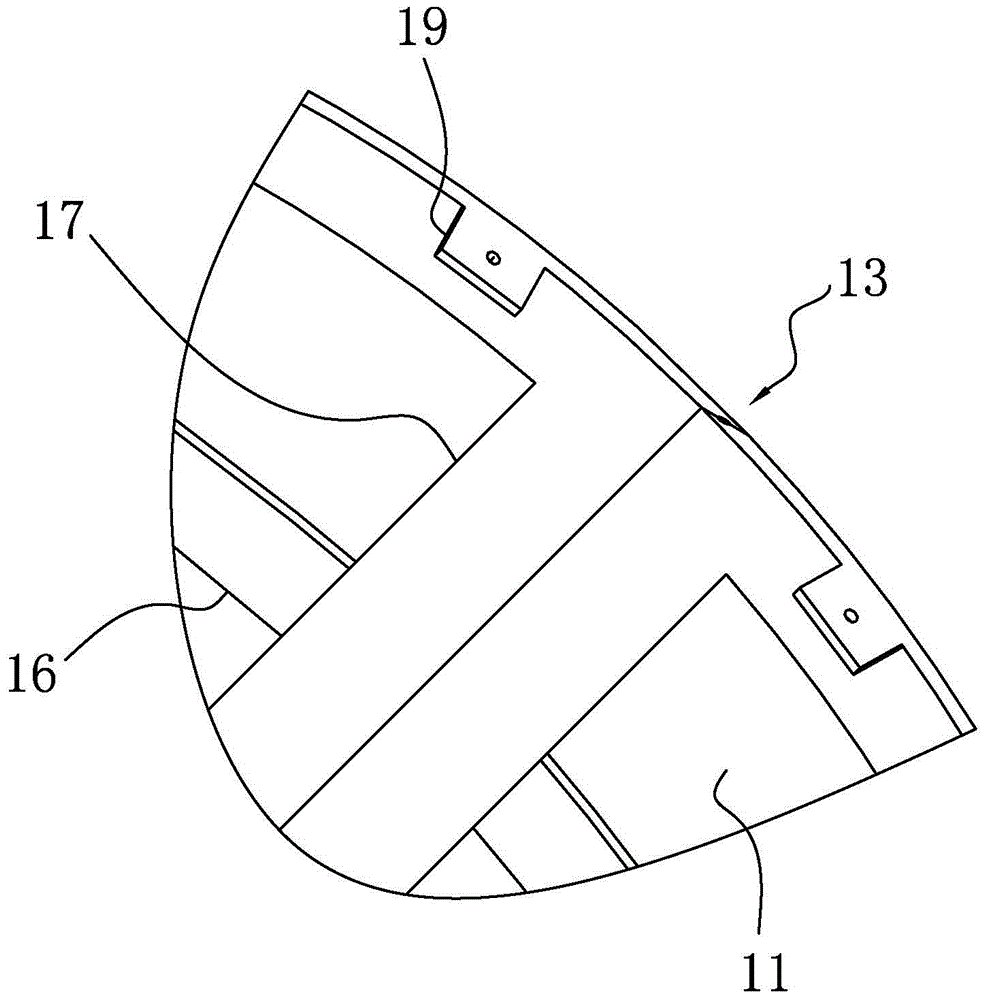

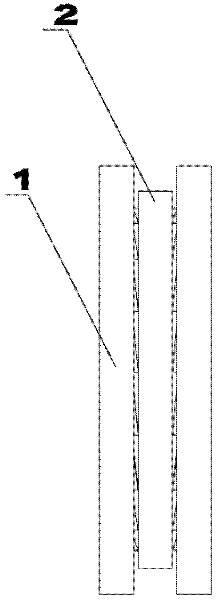

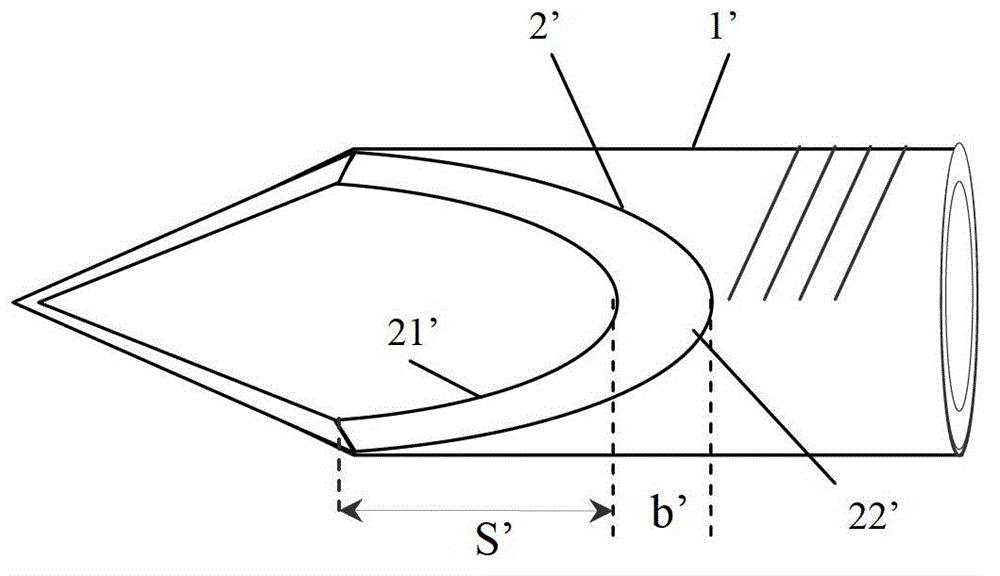

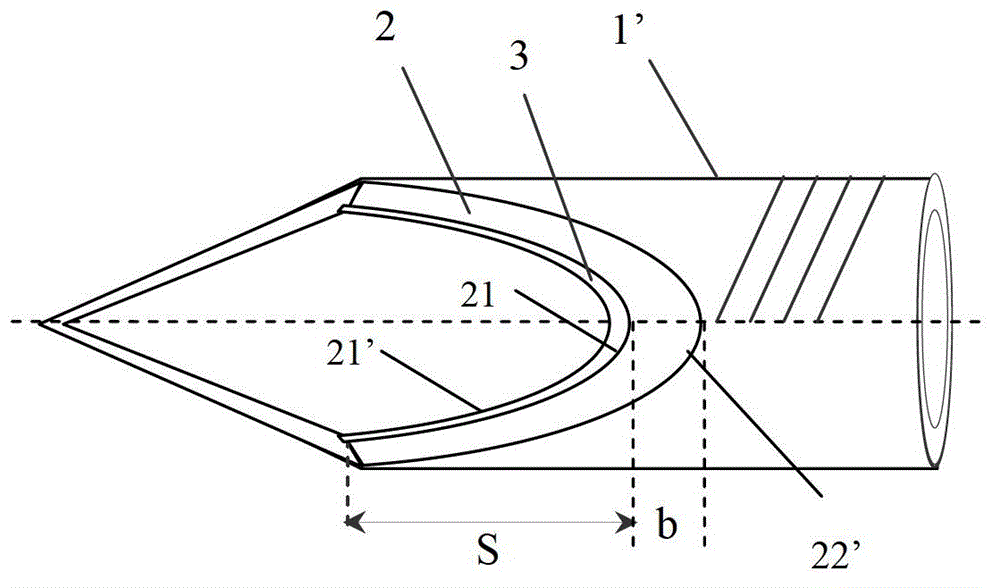

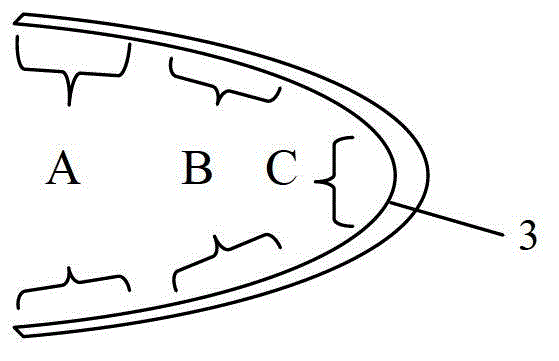

Internal mould, demoulding method thereof, mould for prefabricated concrete tower sections and production method

The invention provides an internal mould, a demoulding method thereof, a mould for prefabricated concrete tower sections and a production method. The internal mould provided by the invention comprises an internal formwork, both ends of the internal formwork are connected, so that the internal formwork is curved into the shape of a barrel, both ends of the internal formwork are provided with slopes, and the slopes of both ends of the internal formwork are matched with each other and form a demoulding opening. The demoulding method of the internal mould provided by the invention includes the following step: one end, which is located inside the demoulding opening, of the internal formwork is moved simultaneously along the radial direction and tangent direction of the internal mould to get close to the center of the internal mould and extend into the space in the internal formwork. The internal mould provided by the invention can be used for casting a whole ring, the overall elastic deformation of the internal formwork can be conveniently utilized to implement the demoulding and restoration of the internal mould, and a great deal of welding work can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

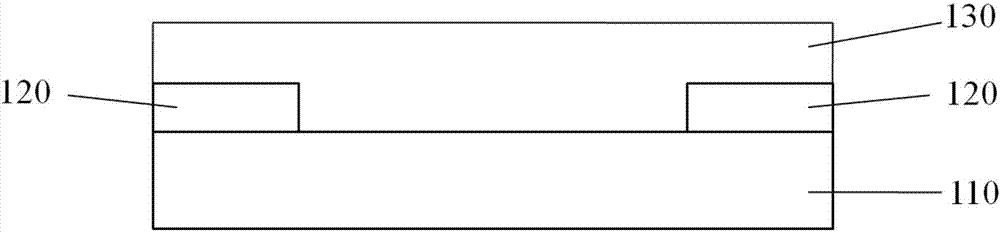

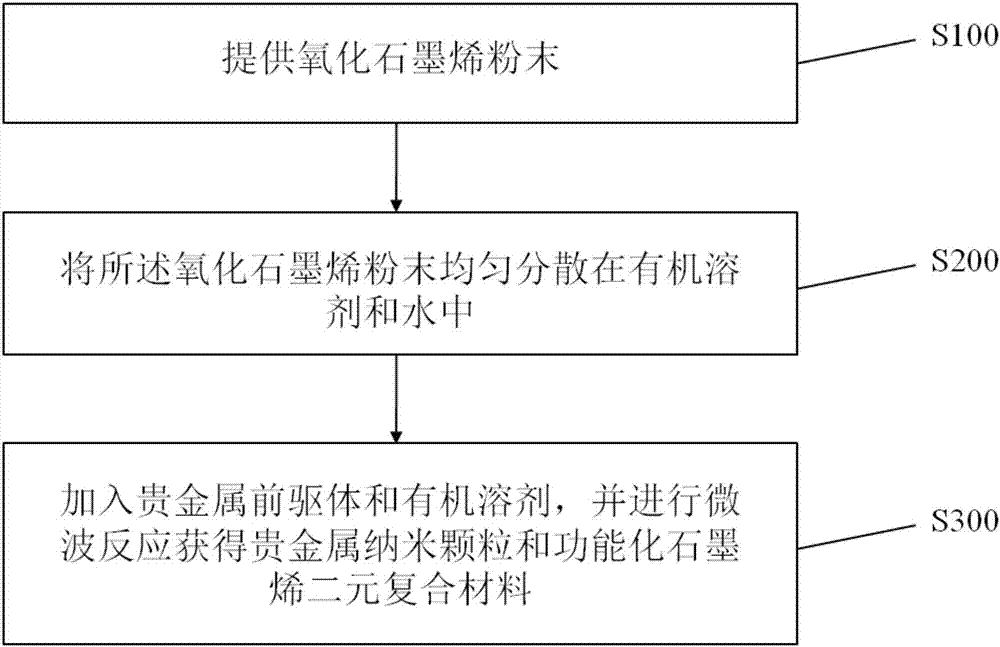

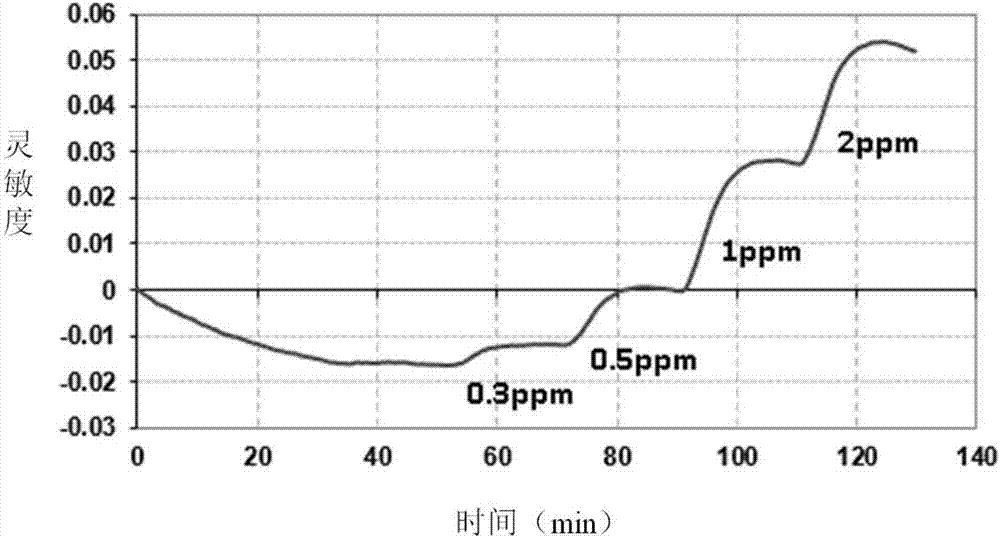

Gas sensitive material for detecting low-temperature formaldehyde at room temperature and preparation method thereof as well as formaldehyde gas sensor

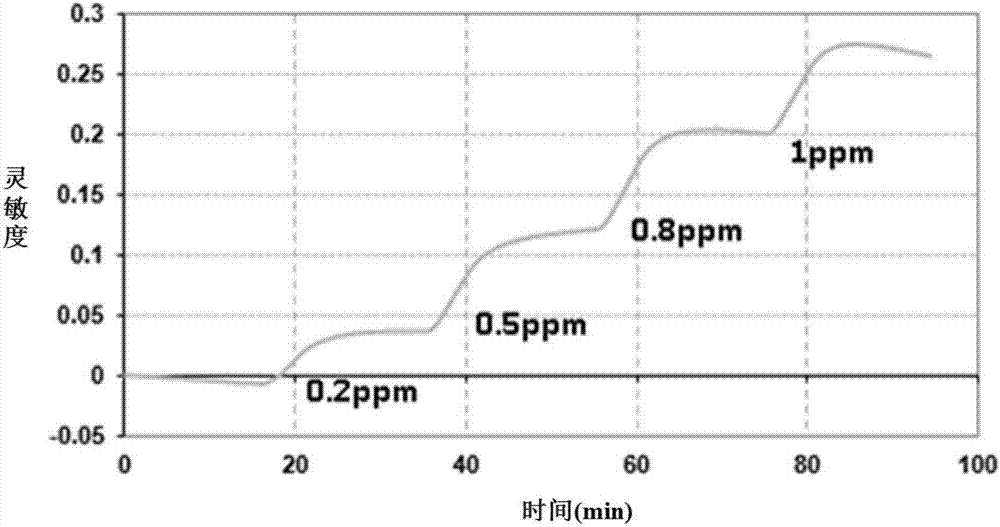

ActiveCN107132258ALess quantityHigh sensitivityMaterial electrochemical variablesGas detectorMass ratio

The invention provides a gas sensitive material for detecting low-temperature formaldehyde at room temperature and a preparation method thereof as well as a formaldehyde gas sensor and belongs to the technical field of gas sensitive sensors. The gas sensitive material is prepared from noble metal nanoparticles and a functionalized graphene binary compound material, wherein the mass ratio of the noble metal nanoparticles to the functionalized graphene binary compound material is 1 to (0.1 to 30); the gas sensitive material can be used for detecting formaldehyde gas with the concentration of ppb grade at room temperature. Therefore, compared with a traditional formaldehyde gas sensitive material, the gas sensitive material and the formaldehyde gas sensor containing the gas sensitive material do not need a high-temperature working environment, so that the power consumption and cost are extremely reduced and resources are saved, and furthermore, the formaldehyde gas sensor has a wider application field. Materials needed by each sensor substrate are relatively less so that the cost of the materials is relatively low and industrialized implementation of the formaldehyde gas sensor can be facilitated.

Owner:苏州慧闻纳米科技有限公司

Vulcanized arsenic-removed slag stabilization treatment method

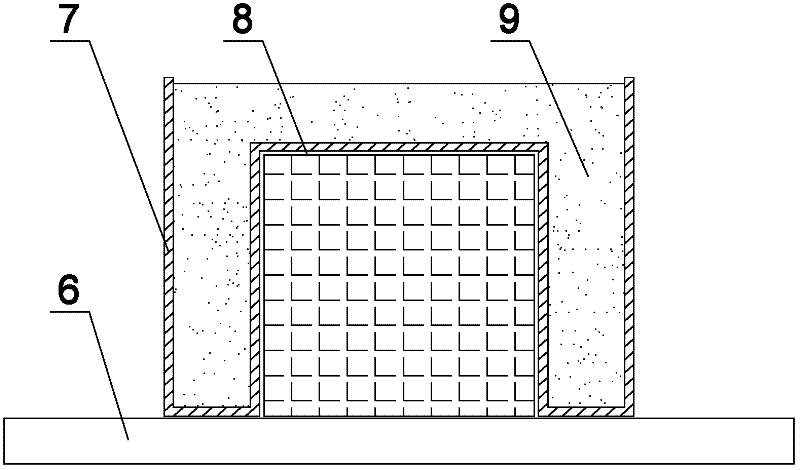

InactiveCN106478032AEasy to operateEasy for industrial implementationSolid waste managementSlagWastewater

The invention discloses a vulcanized arsenic-removed slag stabilization treatment method, and belongs to the technical field of hazardous solid waste curing and safe treatment method. According to the method, smelted arsenic-containing wastewater vulcanized arsenic-removed slag is used as a raw material and is pretreated by carbide slag, a cementitious material and an additive are added, stabilization treatment of arsenic, fluorine, lead, cadmium, mercury and other toxic elements in the vulcanized arsenic slag is achieved through primary mixing, strong mixing, extruding, cutting molding, natural curing and steam curing, and a solidified body is subjected to a toxic leaching test according to GB5085.3-2007 and meets stockpiling or landfill requirements. The vulcanized arsenic slag with various sources can be treated by the method; compared with the prior art, the method has the advantages of simple equipment, convenience in operation and easy industrialized implementation.

Owner:KUNMING UNIV OF SCI & TECH

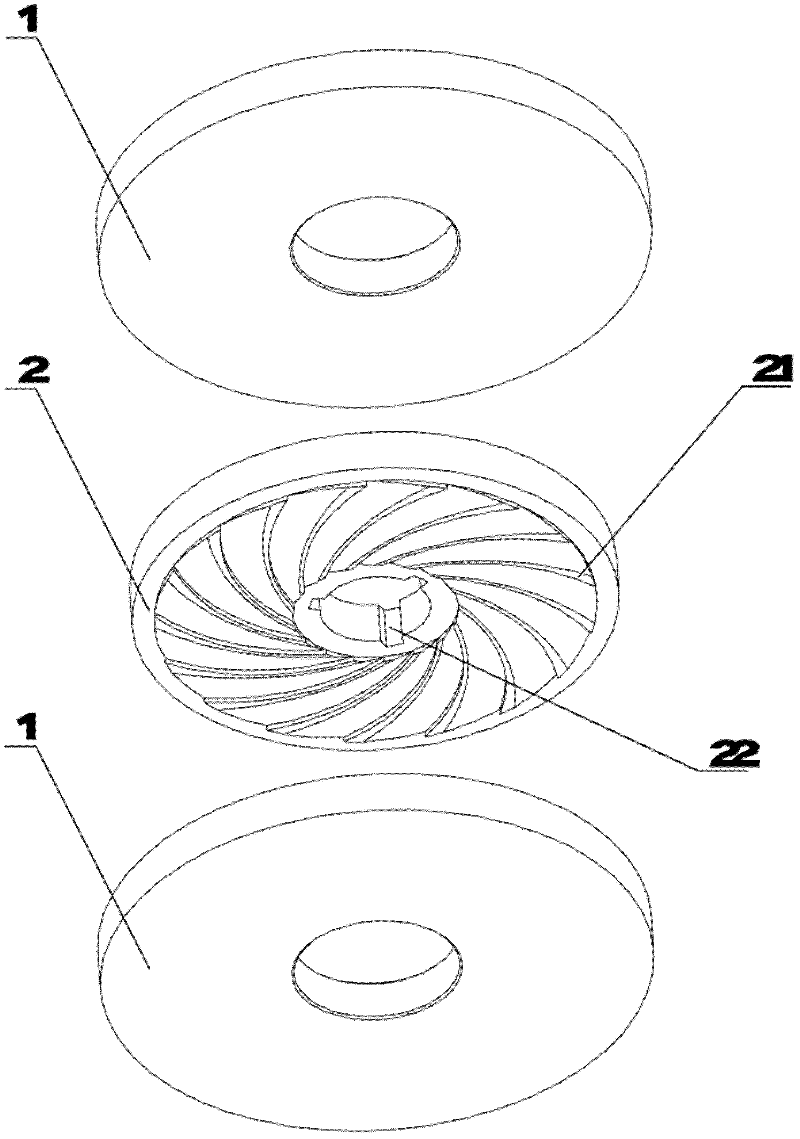

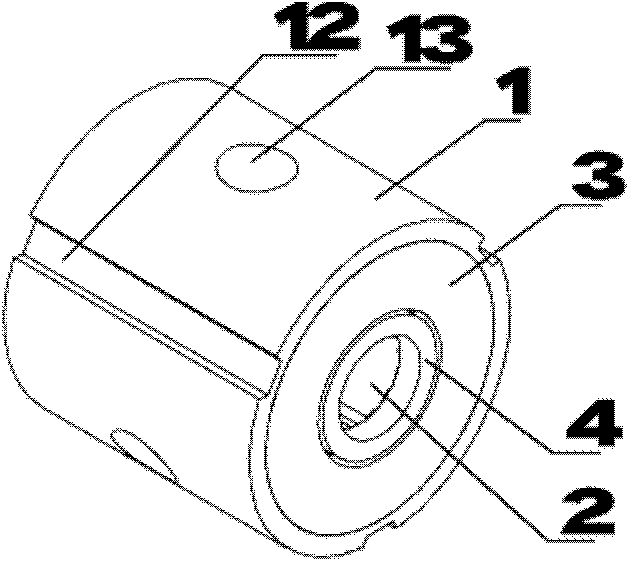

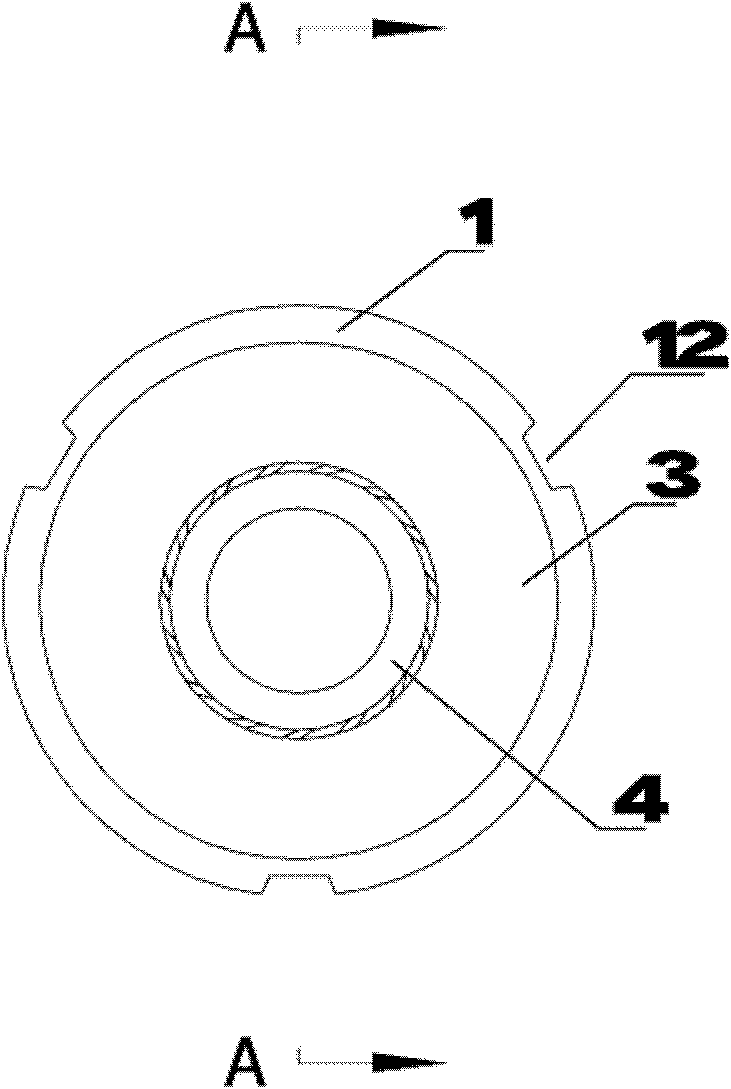

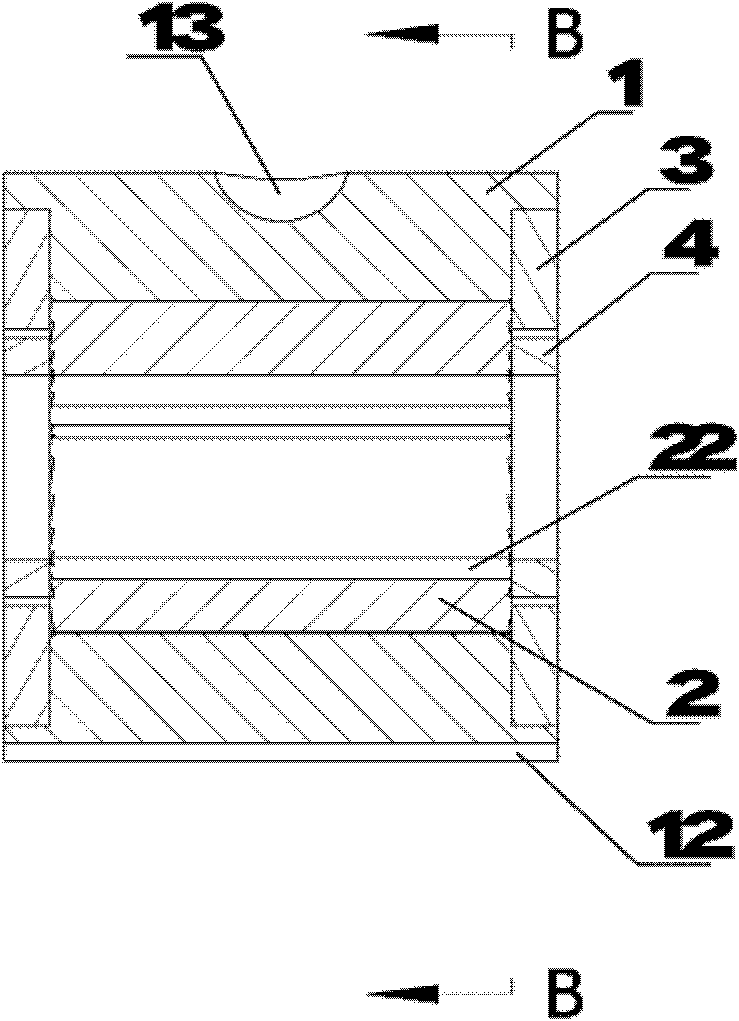

Dynamic pressure gas thrust ceramic bearing

ActiveCN102261374ASimple structureEasy to installBearing componentsSliding contact bearingsEngineeringMechanical engineering

The invention discloses a dynamic pressure gas thrust ceramic bearing, which comprises two outer discs and an inner disc in clearance fit, wherein the inner disc is clamped between the two outer discs. Two ends of the outer discs are provided with high-precision planes, and two ends of the inner disc are provided with groove-type patterns. The groove-type patterns are uniformly distributed in an impeller type so as to form a wedge-shaped space between the outer discs and the inner disc. Each groove is formed by extending an inner circle of the inner disc to an outer circle. The groove-type patterns at both ends of the inner disc are arranged symmetrically. The dynamic pressure gas thrust ceramic bearing is fixedly arranged on a high-speed rotating shaft through the inner disc, the two outer discs are fixedly arranged on a bearing seat, and the continuously generated dynamic pressure gas can be well kept in the fit clearance of the outer discs and the inner disc under the drive of the high-speed rotating shaft to form an air film required for supporting the axial positioning, namely thrust function of the high-speed rotating shaft, so that the functions of the dynamic pressure gas thrust ceramic bearing with certain stability and load capability are realized.

Owner:罗立峰

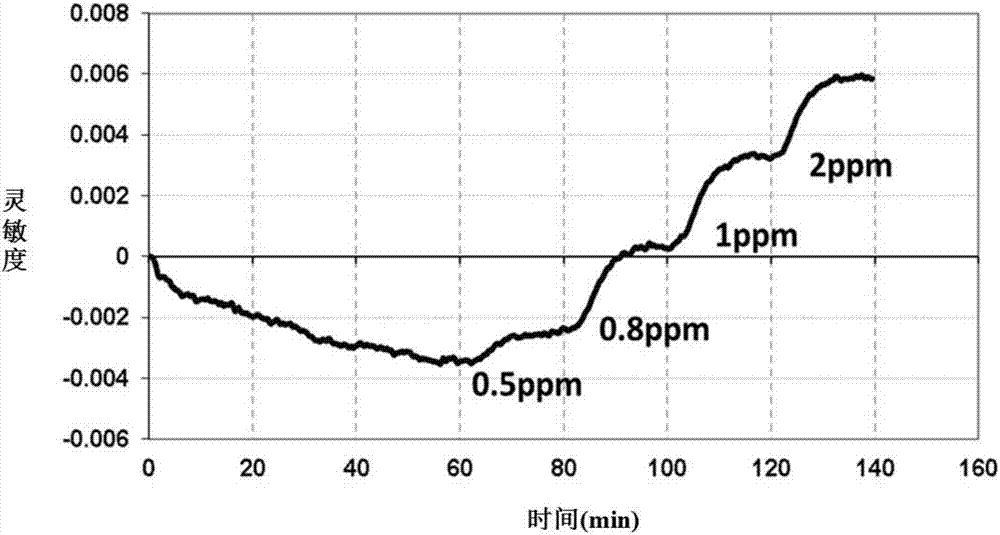

Gas-sensitive material for detecting low-concentration formaldehyde at room temperature and preparation method of gas-sensitive material and gas sensor

ActiveCN107290389ALow costEasy for industrial implementationMaterial impedanceMaterial electrochemical variablesGas detectorWorking environment

The invention provides a gas-sensitive material for detecting low-concentration formaldehyde at a room temperature. The gas-sensitive material is a noble metal, metallic oxide and functionalized graphene ternary composite material, wherein the molar ratio of a metallic oxide to a noble metal is 0.2-5 and the mass of functionalized graphene is 15-50% of the sum of the mass of the metallic oxide and the noble metal; or the gas-sensitive material is a noble metal, metal hydroxide and functionalized graphene ternary composite material, and the molar ratio of metal hydroxide to the noble metal is 0.2-5 and the mass of the functionalized graphene is 15-50% of the sum of the mass of the metal hydroxide and the noble metal. Compared with a traditional metallic oxide gas-sensitive material, the gas-sensitive material and the gas sensor comprising the gas-sensitive material provided by the invention have the advantages that a high-temperature working environment is not needed, the power consumption is greatly reduced and resources are saved. Materials required on each sensor substrate are relatively few, so that the cost of the materials is relatively low and industrialization implementation of a formaldehyde gas sensor can be facilitated.

Owner:苏州慧闻纳米科技有限公司

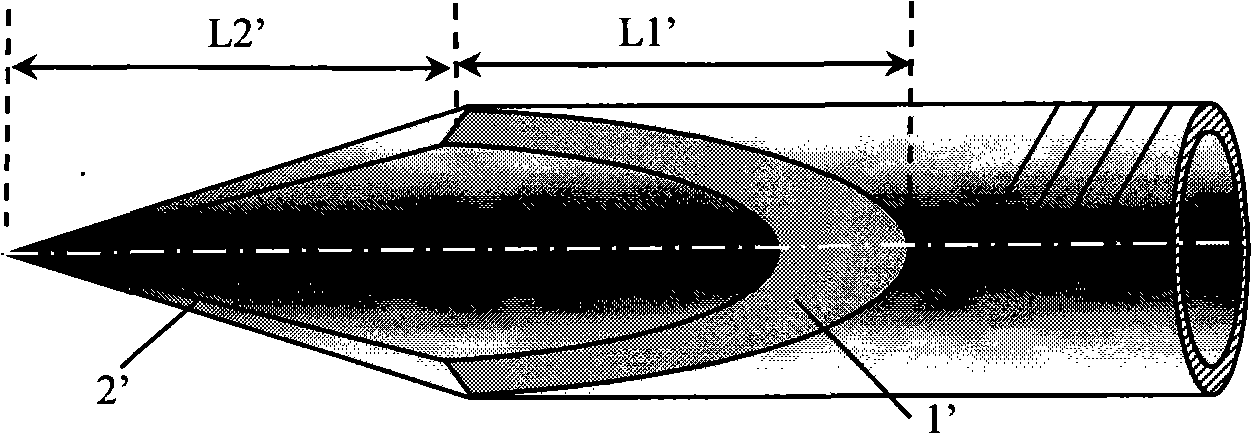

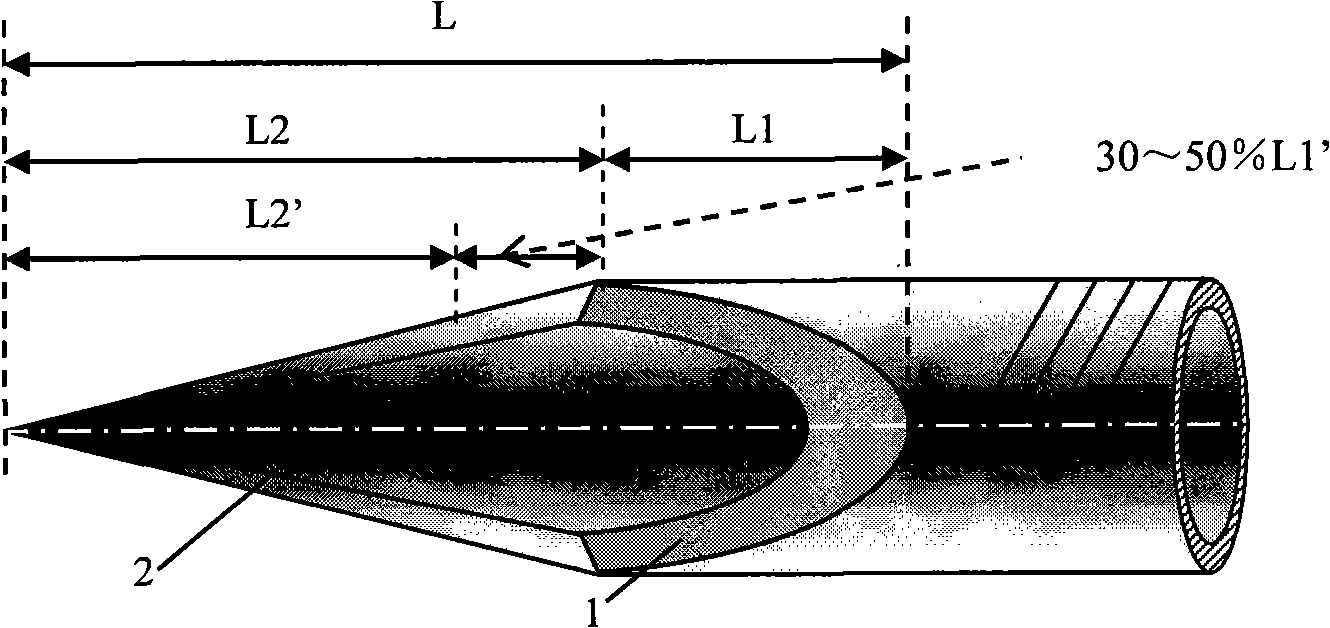

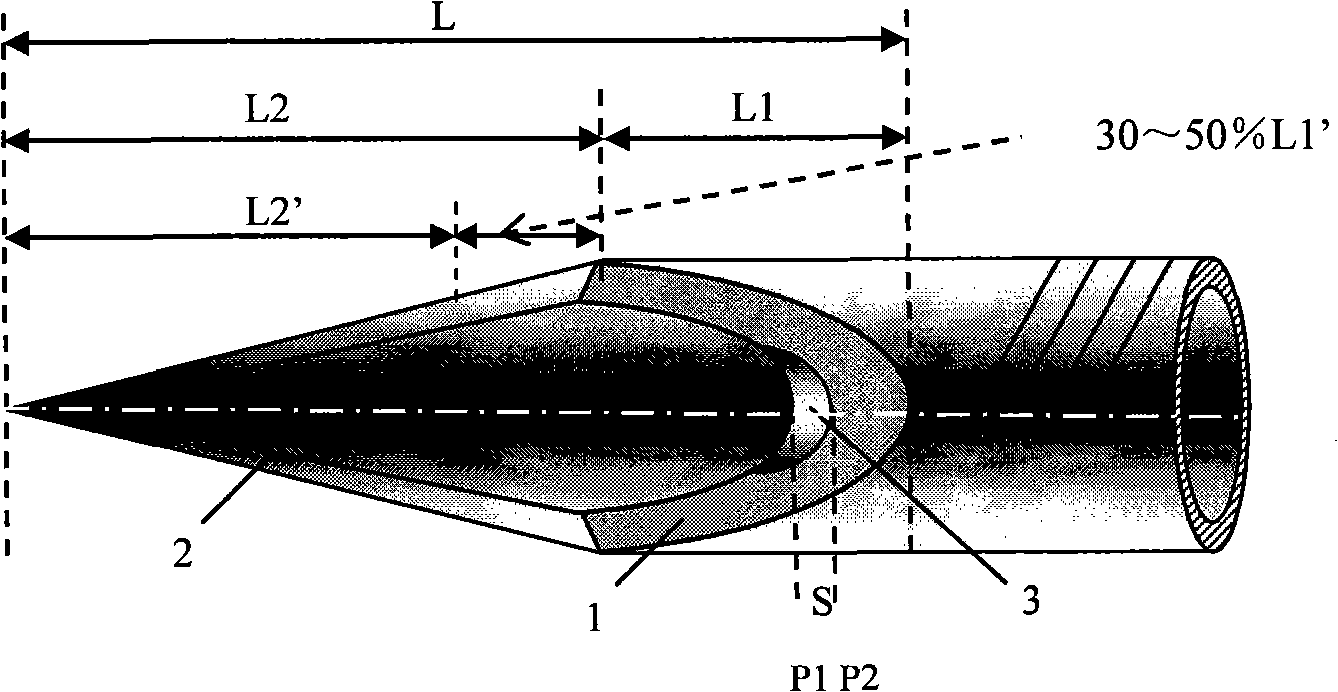

Safe medical needle head and processing method thereof

The invention discloses a safe medical needle comprising a needle tubule. A second inclined plane and a first inclined plane are positioned at the front end of the needle tubule, and the axial length L1 of the first inclined plane is shorter than the axial length L2 of the second inclined plane; the length L2 of the second inclined plane is preferably 65-75% of the total length L of the two inclined planes, and a small concave arc extending backwards is positioned at an inner point of the needle on the first inclined plane, and the inner point is adjacent to the top end of the arc line. Based on the structure of the former needle, the length L2 of the second inclined plane extends towards the first inclined plane, and a small concave arc is formed on the top end of the arc line of the inner point of the needle by fine grinding, sand blasting or laser beam heat treatment, thus the resistance against insertion of the needle head is reduced, absolute safety is ensured as human organism is not affected, needle insertion is more smooth, amount of bleeding is reduced, and pains of patients can be relieved. The medical needle is a really safe medical needle and can replace all the existing medical needles used in various situations.

Owner:华创安全医疗科技(广东)有限公司

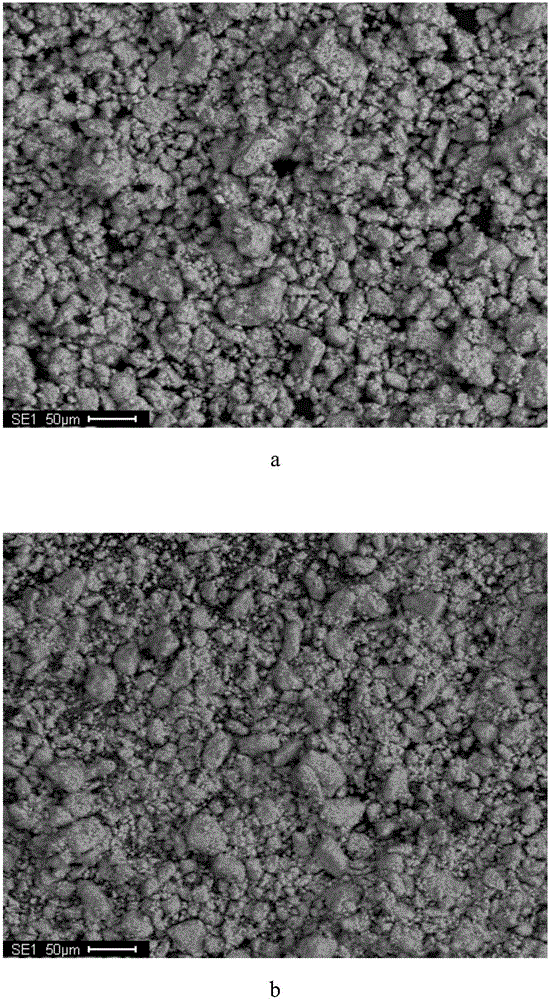

Method for removing copper, cadmium, nickel and cobalt out of zinc sulfate solution through one step

The invention discloses a method for removing copper, cadmium, nickel and cobalt out of a zinc sulfate solution through one step. The method comprises the steps that manganese metal powder and / or manganese-based alloy powder are / is added into the zinc sulfate solution containing copper, cadmium, nickel and cobalt, wherein the temperature of the zinc sulfate solution ranges from 45 DEG C to 70 DEG C, and the pH of the zinc sulfate solution is larger than 4.0; and stirring is carried out for a reaction, after the reaction is finished, filtering separation is carried out, and the zinc sulfate solution with the contents of copper, cadmium, nickel and cobalt all lower than 0.8 ppm is obtained. According to the method, copper, cadmium, nickel and cobalt can be efficiently removed out of the zinc sulfate solution through one step at the same time, no impurities endangering zinc electrolyzing are introduced, the technological process is simple and low in cost, no complex and special equipment is needed, and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

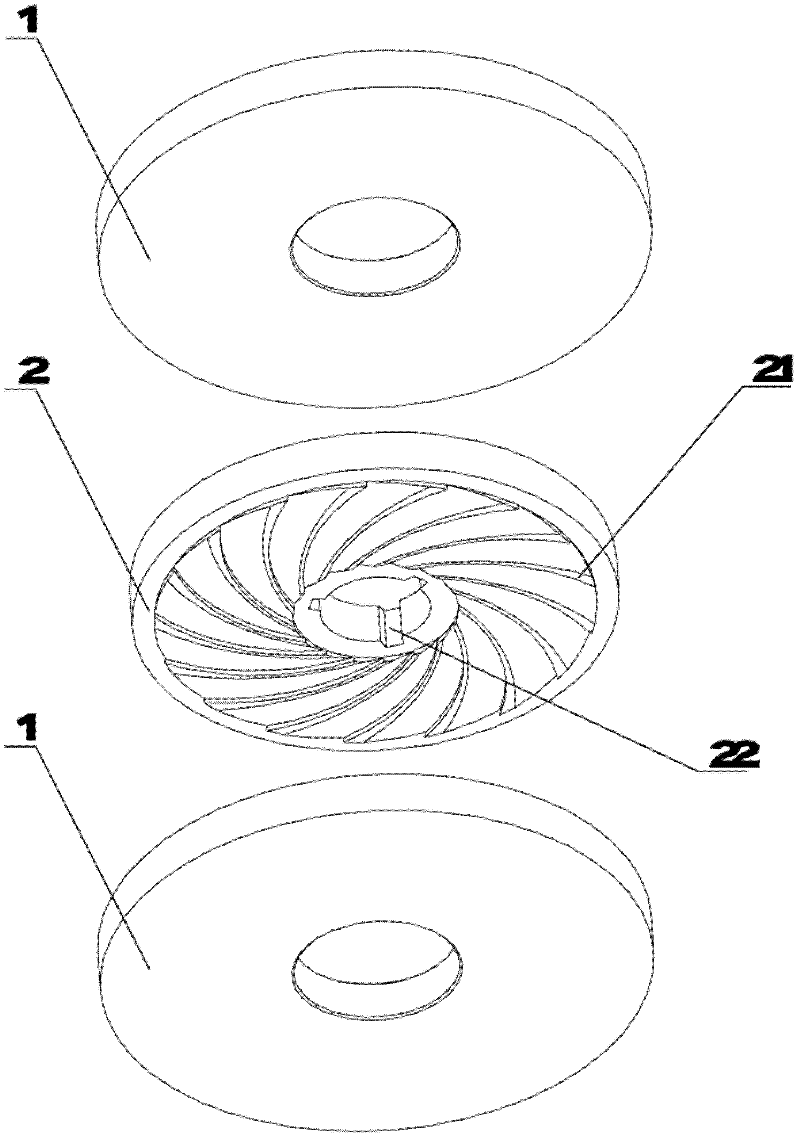

Self-seal kinetic pressure gas radial ceramic bearing

InactiveCN102192237ASimple structureEasy to installBearing componentsSliding contact bearingsEngineeringMechanical engineering

The invention discloses a self-seal kinetic pressure gas radial ceramic bearing which comprises an outer sleeve and an inner sleeve which are clearance fit, wherein two ends of the outer sleeve are all fixedly provided with large seal stop rings; two ends of the inner sleeve are all provided with small seal stop rings; the outer peripheral wall and two ends of the inner sleeve are all provided with trench-type decorative patterns with regular shapes; the kinetic pressure gas radial ceramic bearing is fixedly installed on a high-speed revolving shaft through the inner sleeve; and under the driven of the high-speed revolving shaft, the kinetic pressure gas generated continuously can be preferably maintained in the match clearance of the outer sleeve and the inner sleeve, a gas film required by the bearing function for supporting a high-speed operation shaft, and the seal function required by the gas film is provided by the large seal stop rings and the small seal stop rings, self-seal role is played, i.e., the ceramic bearing has self-seal performance, thus the kinetic pressure gas radial ceramic bearing function with stability and loading capability is realized.

Owner:罗立峰

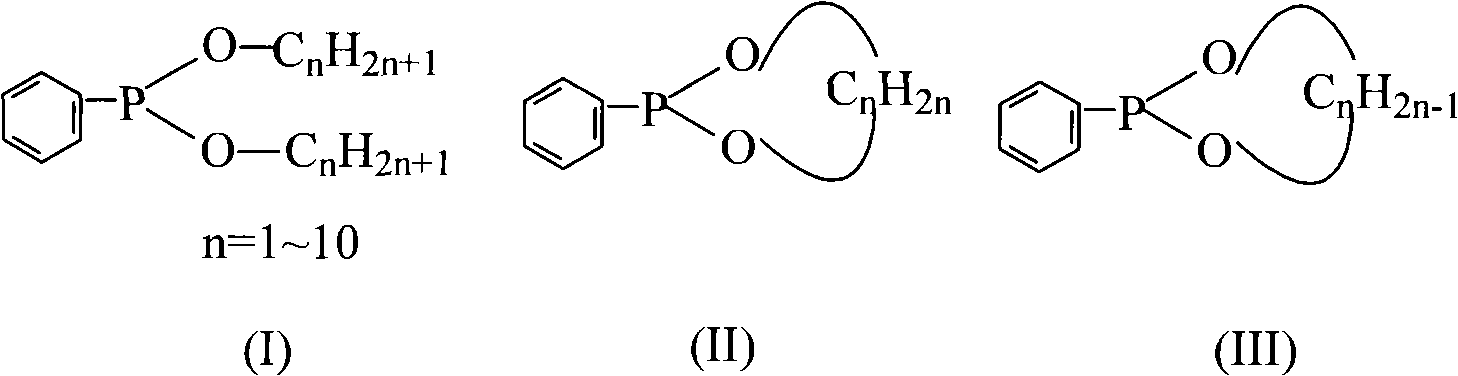

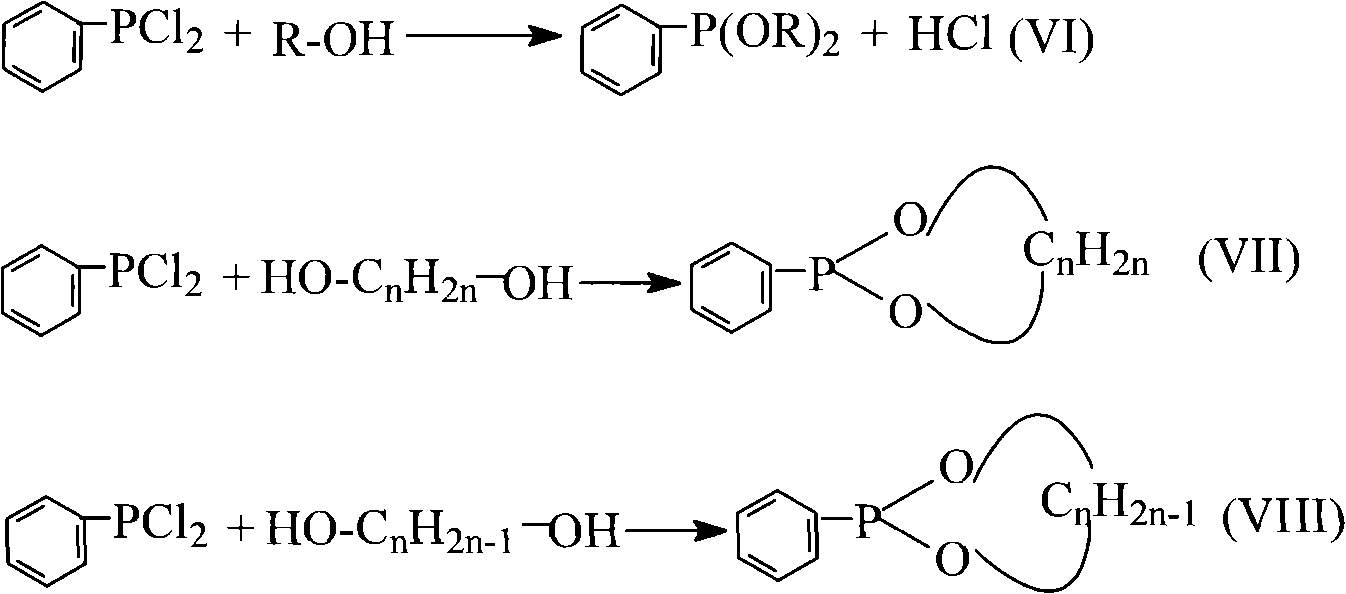

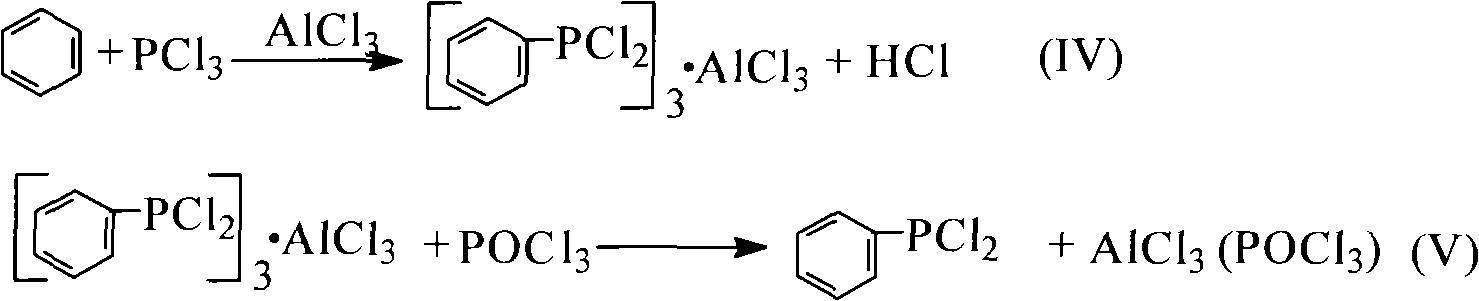

Method for preparing dialkyl phenyl-phosphonite

InactiveCN101538281ALow costReduce manufacturing costGroup 5/15 element organic compoundsAlcoholPhosphate

The invention relates to a method for preparing dialkyl phenyl-phosphonite which is a key intermediate of acyl phosphate photoinitiator. The method takes benzene, phosphorus trichloride and alcohol as main materials and synthesizes dialkyl phenyl-phosphonite through a two-step reaction. The method has the improvements that: in the second step of reaction, phenyldichlorophosphine reacts with the alcohol to synthesize the object under the condition of non-catalyst, the reaction temperature is controlled within 10 DEG C below zero to 10 DEG C, and phenyldichlorophosphine is dropwise added; and then the reaction is carried out under the condition of stirring at the temperature of 30 to 50 DEG C for 0.5 to 7 hours. The invention has the advantages of low cost, easy post treatment, high yield, and the like and is suitable for industrial production.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

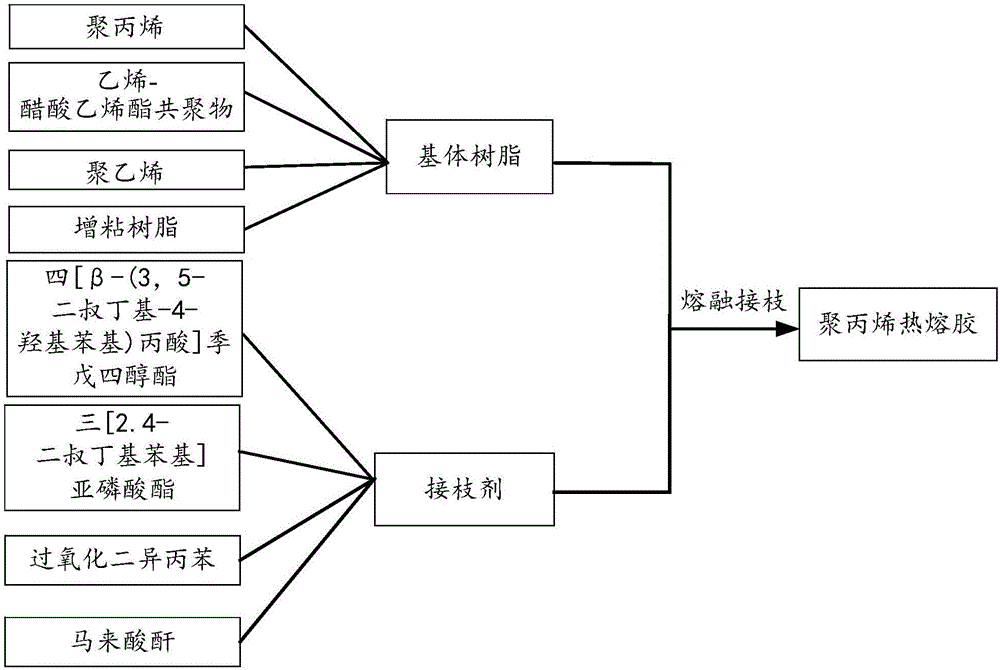

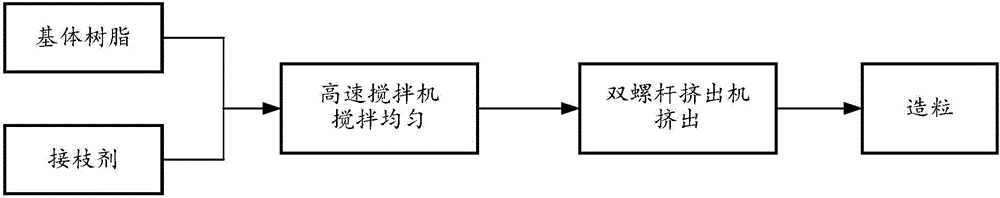

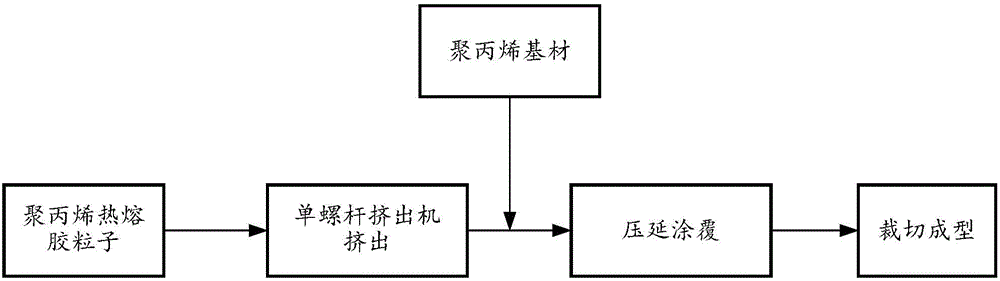

Polypropylene hot melt adhesive, preparation method thereof and preparation method of polypropylene contraction band

ActiveCN106318274AHigh temperature resistanceHigh strengthNon-macromolecular adhesive additivesOther chemical processesPolymer scienceCarvacryl acetate

The invention discloses a polypropylene hot melt adhesive, and belongs to the technical field of oil and gas pipeline corrosion prevention. The polypropylene hot melt adhesive comprises matrix resin and a grafting agent. The weight ratio of the matrix resin to the grafting agent is 100:1-100:2; the matrix resin is prepared from a polypropylene, ethylene-vinyl acetate copolymer, polyethylene and tackifying resin; the grafting agent is prepared from pentaerythritol ester, triguaiacyl phosphite, dicumyl peroxide and maleic anhydride. The invention further discloses preparation methods of the polypropylene hot melt adhesive and a polypropylene contraction band. The obtained polypropylene hot melt adhesive has the advantages of being high in temperature resistance class, excellent in high temperature peel strength and shear strength, good in anticorrosion sealing performance and the like, and is applicable to a 3PP outer anticorrosion coating field joint. The preparation methods have the advantages of being simple in technology, convenient to operate, low in production cost and the like and promote industrialized implementation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

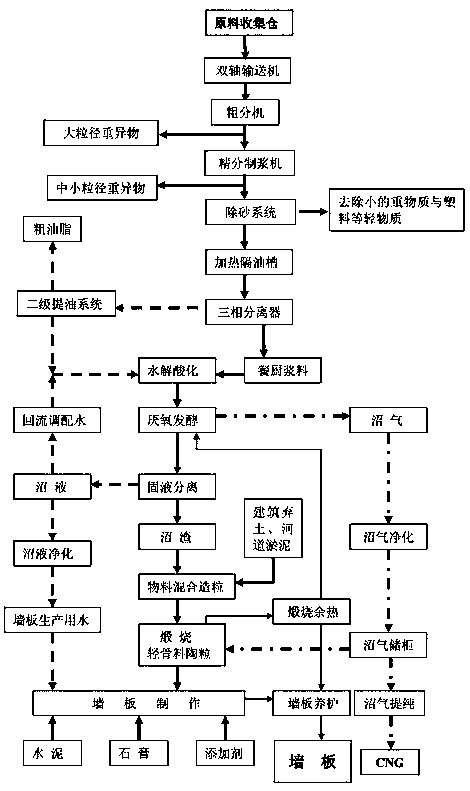

Method for producing natural gas and fabricated wall plate through food and kitchen waste and production line

PendingCN109440965AAchieve lightweightLow costBioreactor/fermenter combinationsBiological substance pretreatmentsSmall cityNatural gas

The invention provides a method for producing natural gas and a fabricated wall plate through food and kitchen waste and a production line, and belongs to the fields of environmental protection and building materials. The problem of resource recycling of the food and kitchen waste is solved. The method includes the steps that urban food and kitchen waste is sorted, separated, hydrolyzed and acidified, and then sent into an anaerobic fermentation tank for fermentation; biogas produced by fermentation is purified and then used as fuel for calcining ceramsite, or refined andpurified into the natural gasas fuel to be sold; after biogas liquid and biogas residue after anaerobic fermentation are subjected to solid-liquid separation, the biogas residue and construction waste soil or river sludgeare subjected to mixing granulation to be sent to a ceramsite calcination device to calcine lightweight ceramsite; the lightweight fabricated wall plate is prepared from the lightweight ceramsite, cement, plaster and the like; and the biogas liquid after solid-liquid separation can be returned to the production process to prepare slurry, or is purified and deodorizedfor making the lightweight prefabricated wall plate. Energy recovery and material buildingrecovery of urban food and kitchen waste treatment are realized, coordination and unification of environmental, social and economic benefitsis ensured, and the method for producing the natural gas and the fabricated wall plate through the food and kitchen waste is suitable for treatment and comprehensive utilization of the food and kitchen garbage waste in large, medium and small cities.

Owner:北京千华新材科技有限公司

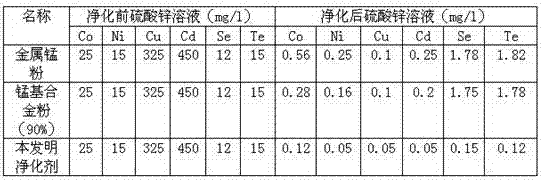

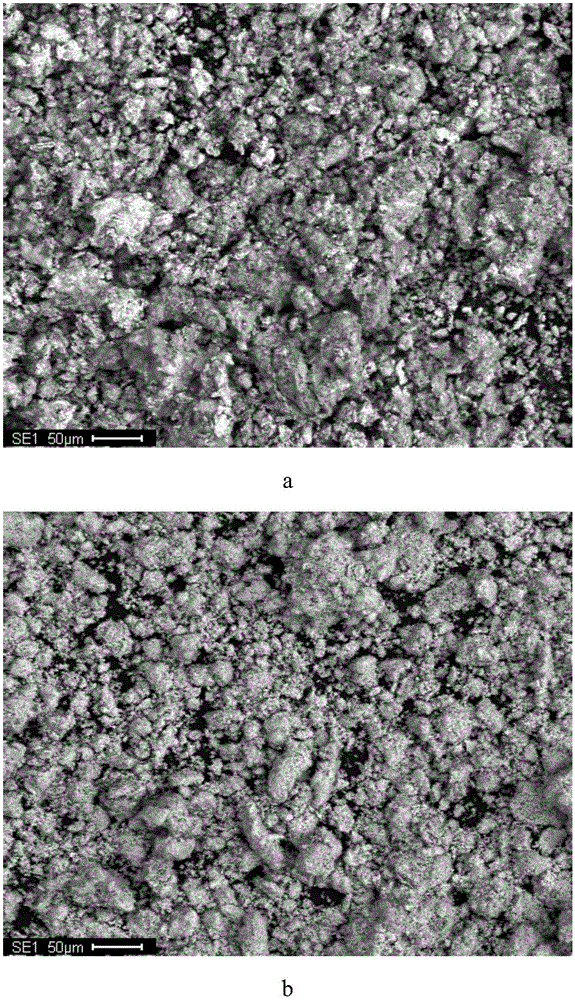

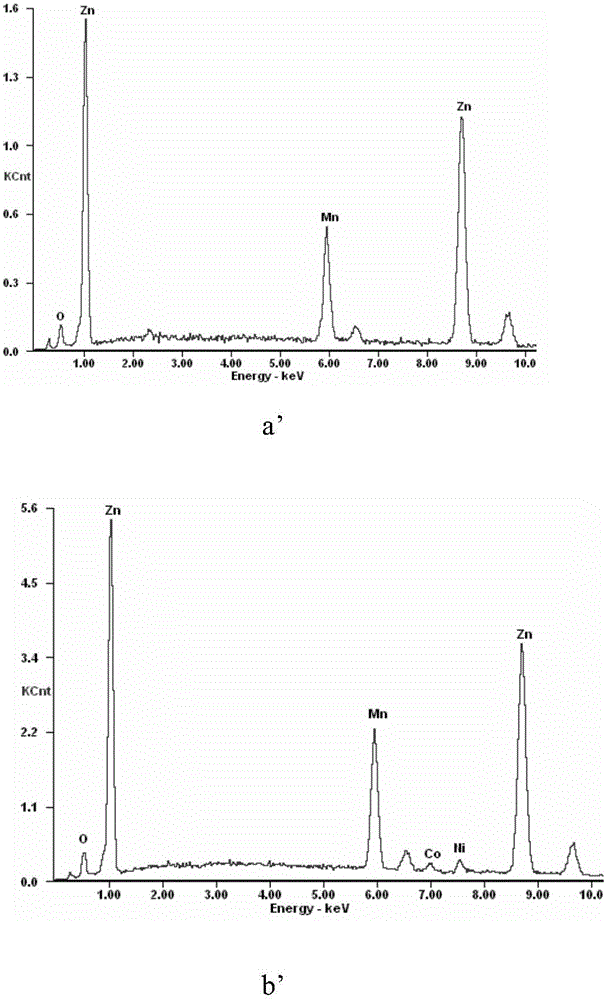

Method for deep removing nickel and cobalt impurities in zinc hydrometallurgy solution

The invention discloses a method for deep removing nickel and cobalt impurities in a zinc hydrometallurgy solution. According to the method, manganese metal powder and / or manganese base alloy powder are / is added in a zinc sulfate solution containing nickel and cobalt under the conditions of a certain temperature and a certain pH value, the stirring is conducted for the reaction, and after the reaction is finished, filtering and separating are conducted, and the zinc sulfate solution with the nickel content and the cobalt content both lower than 0.8 mg / L is obtained. According to the method, the nickel impurity and the cobalt impurity in the zinc sulfate solution containing the nickel and the cobalt can be deep removed with the high efficiency and the low cost while impurities doing harm to zinc electrolysis are not guided. The technology process is simple, complex and special equipment is not needed, and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

Technology for building small-caliber vascular stent

InactiveCN101756756APromote remodelingSolve the problem of low long-term patency rateStentsProsthesisFibrin glueElectrospinning

The invention relates to a technology for building a small-caliber vascular stent, which comprises the following steps: (1) manufacturing the inner wall of a vessel with fibrin glue by a stent building technology, (2) building the outer wall of the vessel by an electrospinning technology and (3) drying, sterilizing and preserving the vascular stent. Compared with the prior art, the invention has the advantages of simple technology, convenient operation, easy implementation of industrialization and high industrialization value.

Owner:SHANGHAI P & P BIOTECH

Nanocrystalline metal oxide functionalized carbon nanotube material and formaldehyde gas sensor

The invention discloses a nanocrystalline metal oxide functionalized carbon nanotube material and a formaldehyde gas sensor prepared by using the material. The material comprises carbon nanotube and nickel oxide, and the mass ratio of the carbon nanotube to the nickel oxide is (1:0.1)-(1:30). The nanocrystalline metal oxide functionalized carbon nanotube material provided by the invention, can have a well response to the formaldehyde gas when used as gas sensitive material applied to the formaldehyde gas sensor through special proportion between the carbon nanotube and the nickel oxide, is relative low in cost, and can facilitate the industrialized implementation of the formaldehyde gas sensor.

Owner:SUZHOU NANOGRID TECH

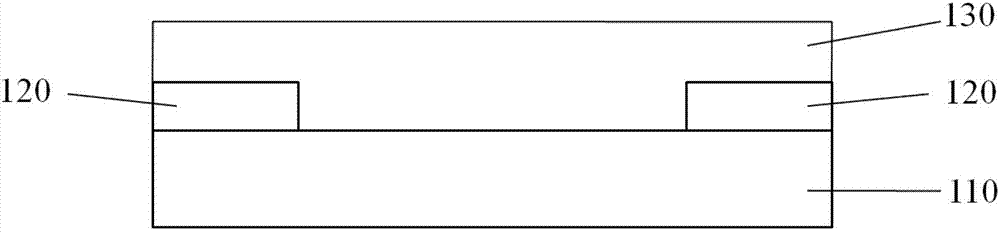

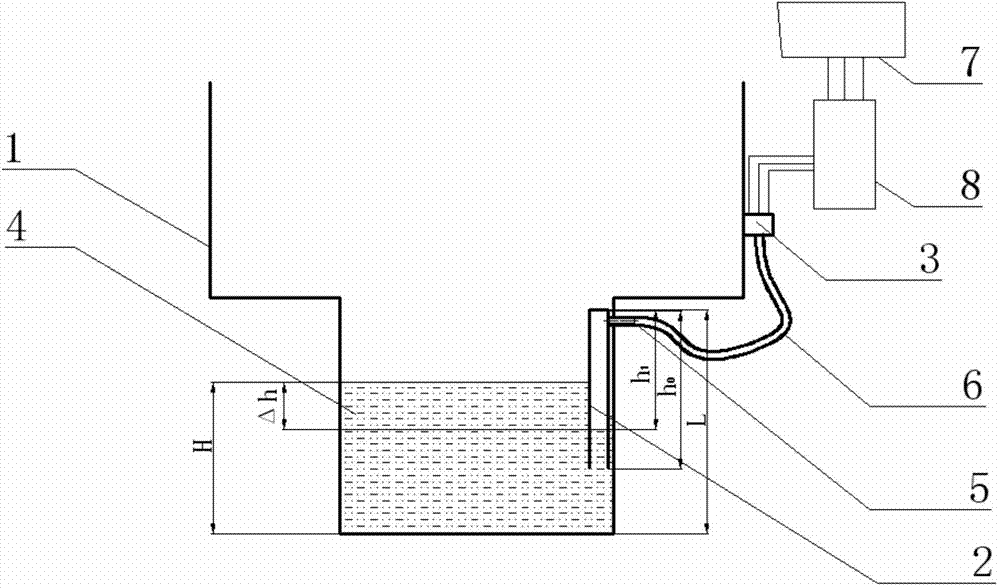

Liquid level detection device and method for medical cleaners

InactiveCN103616055AStable performanceLow costLevel indicators by pressure measurementEngineeringReal time display

The invention discloses a liquid level detection device and method for medical cleaners. The device comprises a pressure tube, a pressure sensor, an adapter, a control system, a connecting tube and a display screen. The pressure tube is fixed to the sidewall of an inner container of a cleaner. One end of the pressure tube is open, and the other end of the pressure tube is closed; the open end of the pressure tube is downwardly communicated with the inner container of the cleaner. One end of the adapter is connected with the upper portion of the pressure tube, and the other end of the adapter is connected with the pressure sensor. The pressure sensor is electrically connected with the control system. The connecting tube is disposed between the adapter and the pressure sensor, and the pressure tube is communicated with the pressure sensor through the connecting tube. When liquid level of the inner container of the cleaner changes, pressure of air hermetically enclosed in the pressure tube also changes; the inner pressure of the pressure tube is measured through the pressure sensor, and the control system can calculate the height of liquid level of the inner container and displays the height on the display screen of the cleaner in real time.

Owner:LAOKEN MEDICAL TECH

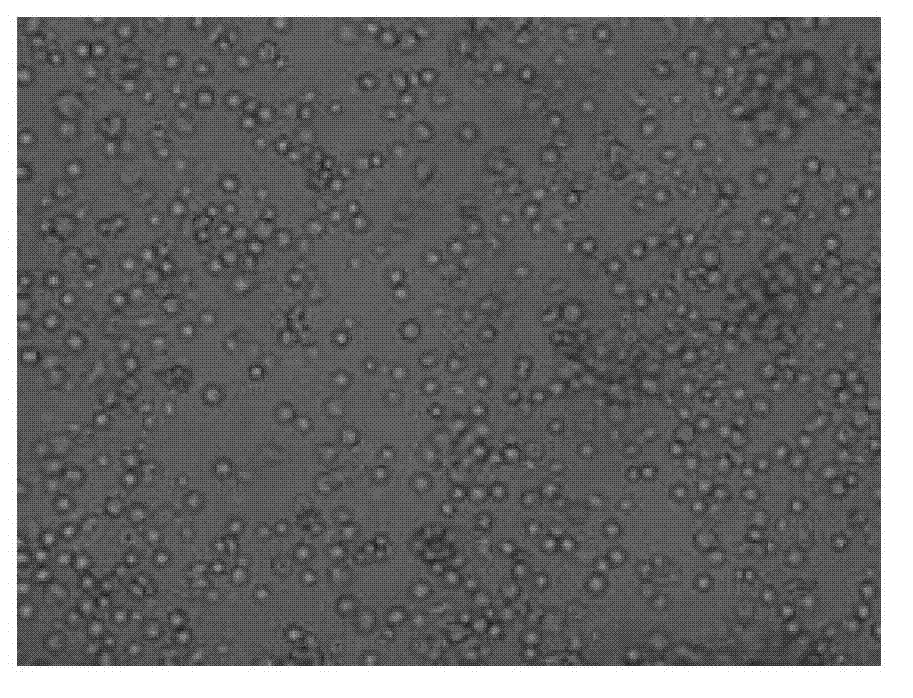

Method for preparing CD3+CD56+cells through high-killing K562cells from perinatal placental blood

ActiveCN103173409AGuaranteed stabilityThe collection process is convenient and safeBlood/immune system cellsBiologyK562 cells

The invention provides a method for preparing CD3+CD56+cells through high-killing K562 cells from perinatal placental blood. The method comprises the step of: separating mononuclear cells from the perinatal placental blood so as to carry out induction differentiation to form CD3+CD56+cells. By utilizing the method, the preparation period of the cells can be shortened, and moreover, the multiplication capability of the cells is improved.

Owner:JIANGSU HEZE STEM CELL GENE ENG CO LTD

Method for deeply removing cobalt from zinc sulfate leaching liquid

InactiveCN105734291AThorough removal of cobaltGood displacement kineticsProcess efficiency improvementElectrolysisSulfate

The invention discloses a method for deeply removing cobalt from zinc sulfate leaching liquid. The method is to add excessive activated zinc powder in cobalt-contained zinc sulfate solution for reaction; and after the reaction is finished, the filtration and the separation are performed to obtain zinc sulfate solution with a cobalt content of lower than 0.8 mg / L, wherein the activated zinc powder is obtained by activated liquid activated zinc powder containing copper and / or antimony and with pH of 2.5-3.5. The method can deeply remove cobalt ions in the zinc sulfate solution with high efficiency and low cost without introducing impurities harm to the zinc electrolysis, and is easy to realize the industrialization.

Owner:CENT SOUTH UNIV

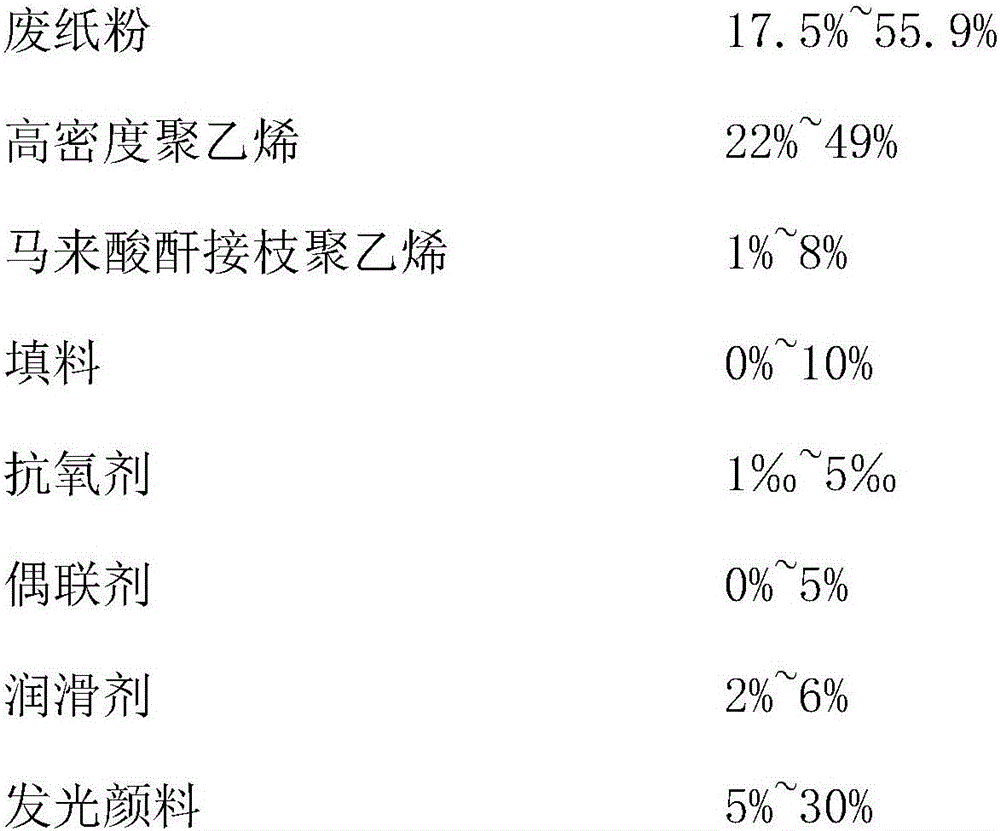

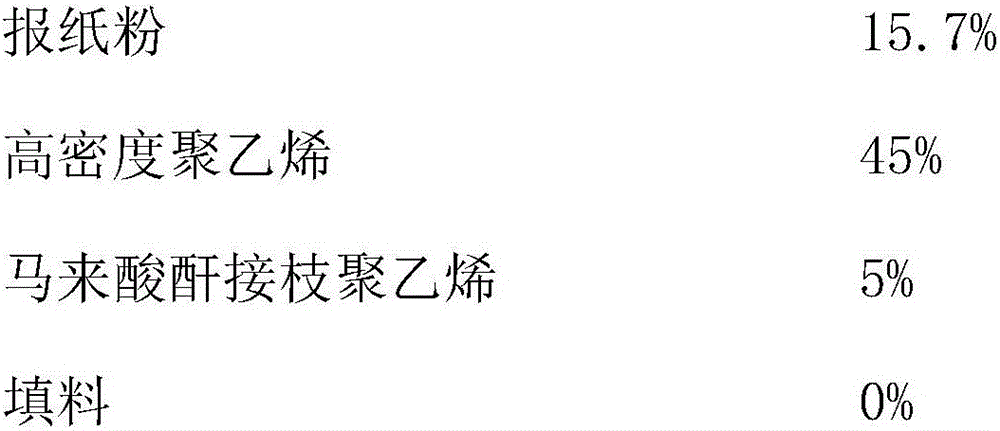

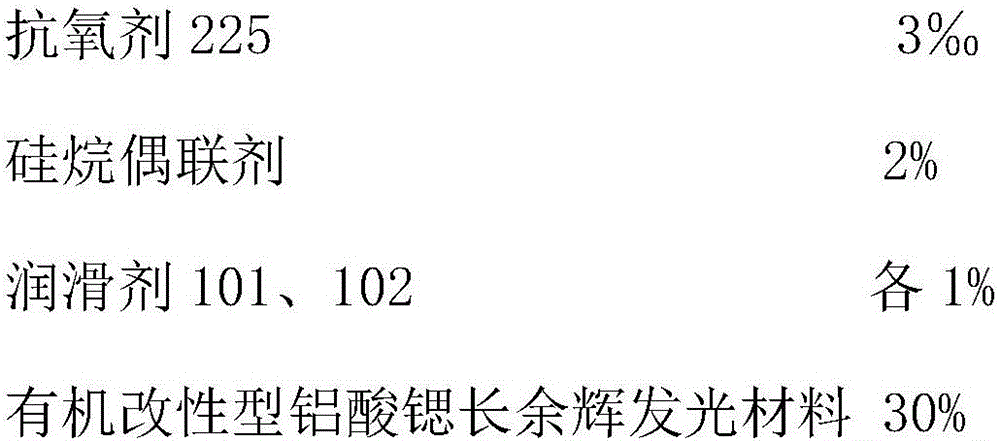

Waste paper/high-density polyethylene luminescent composite and preparation method thereof

The invention relates to a composite, and provides a waste paper / high-density polyethylene luminescent composite and a preparation method thereof. A long-persistence luminescent material subjected to organic modification is adopted as luminescent pigment, the long-persistence luminescent material, pretreated waste paper fiber powder, high-density polyethylene, a coupling agent, a processing agent and the like are subjected to blending extrusion, and the luminescent wood-plastic composite is obtained. According to the waste paper / high-density polyethylene luminescent composite and the preparation method thereof, the comprehensive utilization level of waste resources is greatly improved, and environmental pollution caused by treatment of waste resources is greatly reduced; compared with a traditional board and a traditional wood-plastic composite, the luminescent composite is easy to process, low in cost, wide in raw material source, environmentally friendly, free of pollution and the like; besides, by adding the luminescent material, the advantages of practicability, attractiveness, safety and the like of the luminescent composite are improved, and based on an existing wood-plastic board production process, the luminescent composite is a wood-plastic board very suitable for large-scale production.

Owner:SOUTH CHINA AGRI UNIV

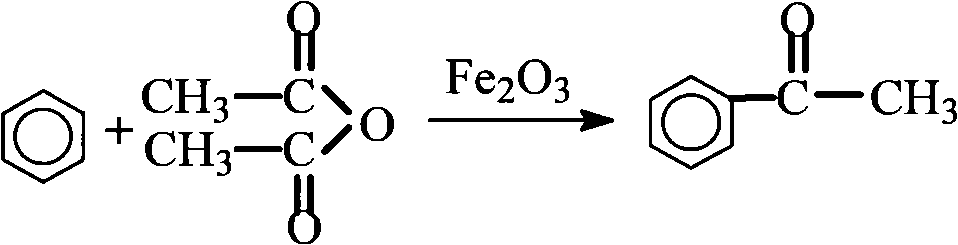

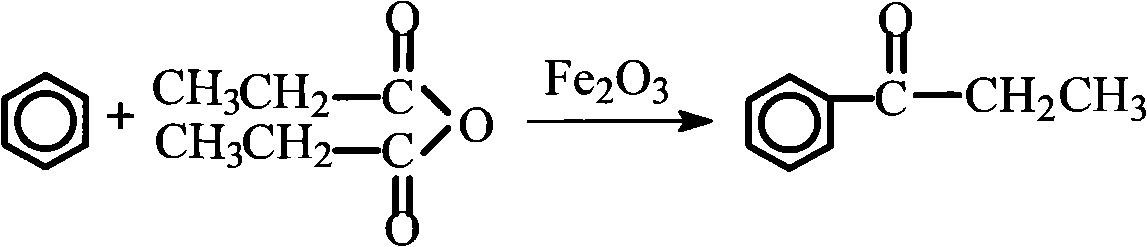

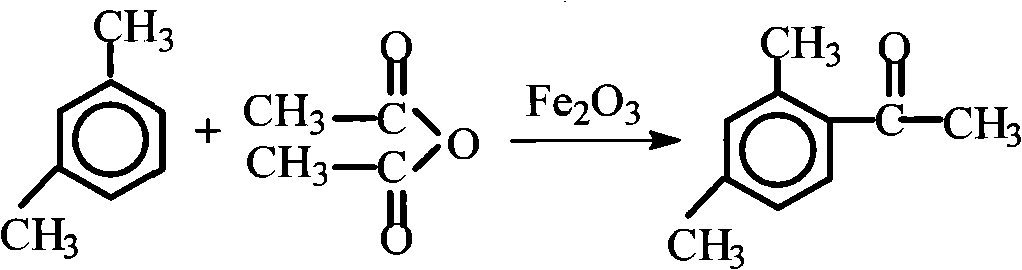

Improved method for preparing aromatic ketone

ActiveCN101844972AReduce dosageSimple post-processingCarbonyl compound preparation by condensationSesquioxideReaction temperature

The invention relates to an improved method for preparing aromatic ketone, which is characterized in that: in the presence of iron sesquioxide catalyst, benzene or substituted benzene and acid anhydride are reacted to prepare the aromatic ketone, wherein the substituted benzene refers to a benzene molecule ring on which one hydrogen atom or two hydrogen atoms is / are substituted by a substituted group, and the substituted group is alkyl, hydroxy or methyl ether group containing 1 to 7 carbons; and the prepared aromatic ketone is mixed aromatic ketone, one single bond of the carbonyl of the aromatic ketone is connected with the alkyl containing 1 to 4 carbons, while the other single bond is connected with the benzene or the substituted benzene. The reaction temperature is between 60 and 150 DEG C; the molar ratio of the benzene or the substituted benzene to the iron sesquioxide catalyst is 1: 0.0001-0.005; and the molar ratio of the benzene or the substituted benzene to the acid anhydride is 1: 0.5-2. The using amount of the iron sesquioxide is far less than that of aluminum chloride in the prior art, the reaction condition is mild, the method does not need to strictly isolate air,the product has good color and texture, the post treatment is simple, and the preparation process does not produce hydrogen chloride and is a green chemical process.

Owner:靖江市城中村投资建设有限公司

Preparation method for soybean protein peptide

ActiveCN111670996APromote degradationEnhanced functional properties and degree of hydrolysisProtein composition from vegetable seedsProtein foodstuffs working-upSoybean ProteinsMolecular biology

The invention belongs to the technical field of preparation of soybean protein peptides, and particularly relates to a preparation method for a soybean protein peptide. The preparation method of the soybean protein peptide provided by the invention comprises the steps of pulverizing soybean protein micro powder, and performing sieving; adding water to obtain soybean protein powder, performing uniform stirring, adding a mixed solution, performing uniform stirring, adding a protective agent, and performing homogenization treatment to obtain a mixed material; performing irradiation treatment on the mixed material, and performing filtering to obtain a precipitate; performing freezing treatment on the precipitate, performing thawing, drying the thawed precipitate in the shade, grinding the precipitate into fine powder, and performing sieving to obtain fine powder; adding water to the fine powder, regulating pH, rising temperature, adding mixed enzymes in three times for enzymolysis, inactivating the enzymes, cooling to 25 DEG C to obtain enzymolysis liquid, filtering the enzymolysis liquid, and concentrating and drying the filtrate to obtain the soybean protein peptide. The product obtained by the method of the invention has narrow molecular weight distribution and low molecular weight, and the method of the invention cannot damage active groups on a molecular chain of soybean protein, thus being beneficial to maintaining the physiological activity of the soybean protein peptide.

Owner:YOROYAL PHARM TECH CO LTD

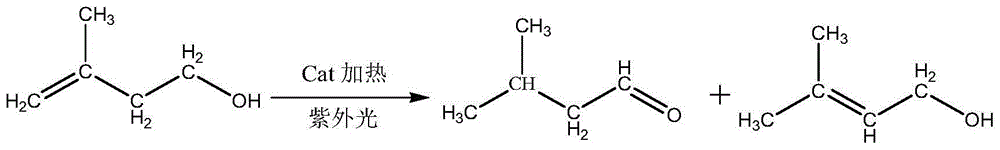

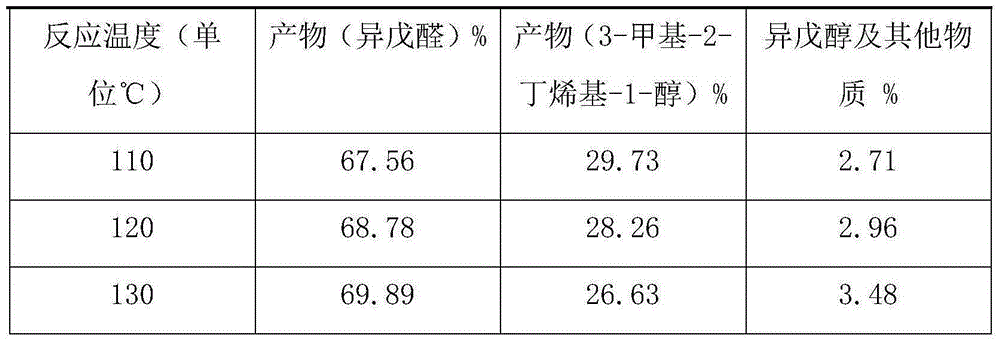

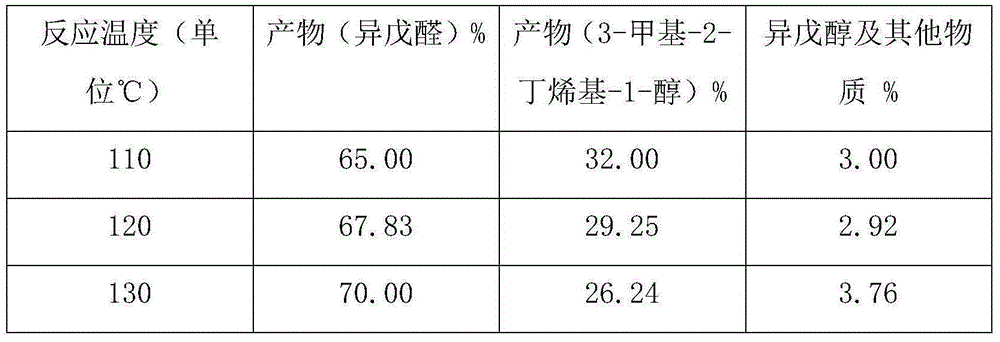

Method for preparing isoamyl aldehyde from 3-methyl-3-butenyl-1 alcohol

InactiveCN104926631ASufficient sourceImprove conversion ratePreparation by isomerisationOrganic compound preparationPhotocatalytic reactionReaction temperature

The invention discloses a method for preparing isoamyl aldehyde from 3-methyl-3-butenyl-1 alcohol. The method is characterized by comprising the following steps: putting raw materials comprising 98-98.5 percent (in percentage by mass) of 3-methyl-3-butenyl-1 alcohol and 1.5-2 percent of an organic metal compound catalyst into a reactor; putting the reactor into an oil bath pan of 140 DEG C under normal pressure to carry out heating reaction at a temperature of 110-130 DEG C; under a N2 atmosphere anoxic condition, continuously separating part of isoamyl aldehyde generated in a photo-catalytic reaction process by distilling, promoting reaction for generating isoamyl aldehyde to further positively carry out, wherein the total reaction time is 3-4 hours; finally, obtaining high-purity isoamyl aldehyde, 3-methyl-3-butenyl-1 alcohol and a little isoamyl alcohol by carrying out separation, rectification and purification on all crude product. The method is scientific and reasonable, low in reaction temperature and pressure, high in effective product conversion rate, energy-saving and low in production cost.

Owner:吉林众鑫化工集团有限公司

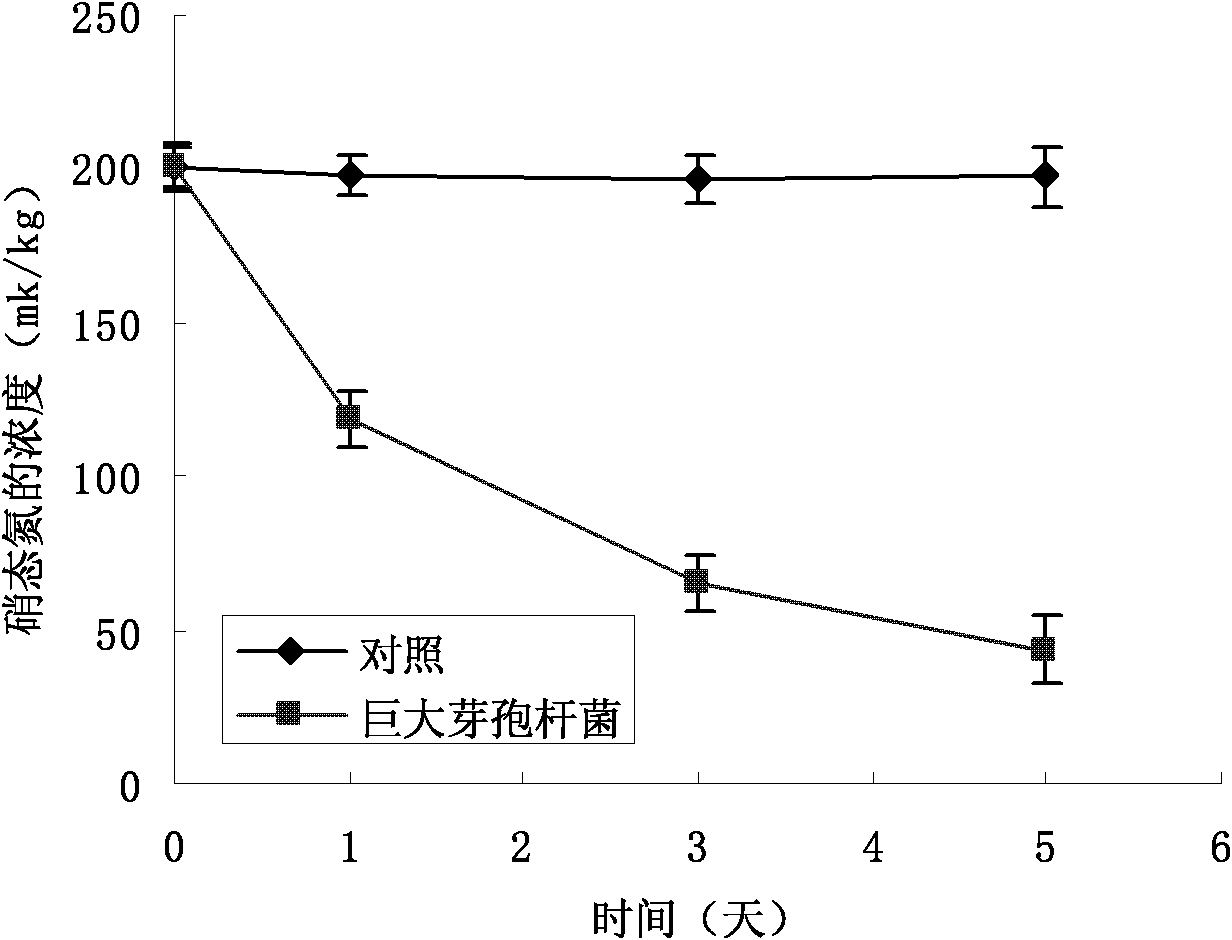

Assimilated nitrate nitrogen strain and application thereof

InactiveCN102220267AIncrease profitCause harmAgriculture tools and machinesBacteriaMicroorganismBacillus megaterium

The invention relates to the technical field of microorganism soil processing, in particular to an assimilated nitrate nitrogen strain and application thereof. The strain is NCT-2 assimilated nitrate nitrogen strain, the classification name is Bacillus megaterium, the strain is preserved in the Chinese General Microbiological Culture Collection Center, the preservation date is March 21, 2011, and the preservation number is CGMCC No.4698. The invention can effectively assimilate the microorganisms of excessive nitrate nitrogen in facility cultivation soil.

Owner:SHANGHAI JIAO TONG UNIV

Disposable sterile safe injection needle and machining method thereof

InactiveCN102872509AReduce resistanceNeedle smoothEdge grinding machinesInfusion needlesFractionationSyringe needle

The invention discloses a disposable sterile safe injection needle which comprises a syringe needle thin tube, a first inclined surface forming a 15-degree angle with an axial surface of the thin tube and a second inclined surface forming at 18-degree angle with the axial surface of the thin tube, wherein the width between two arc top ends of a crescent-moon-shaped cross section of the first inclined surface formed on the tube wall portion is equal to the standard thickness of the tube wall, an inner blade, a left blade and a right blade of the cross section are round fillets, and no burrs exist on a plane of the cross section. The disposable sterile safe injection needle cannot pick up tissue of human bodies or bring out fractionation, cannot damage the strength of a syringe needle, is truly safe, and can be used for replacing various medical syringe needles used in various occasions.

Owner:杨昌燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com