Dynamic pressure gas thrust ceramic bearing

A ceramic bearing and gas technology, applied in sliding contact bearings, rotary bearings, bearings, etc., can solve the problems of difficult practical application and complex processing technology, and achieve easy industrialization, low economic cost, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

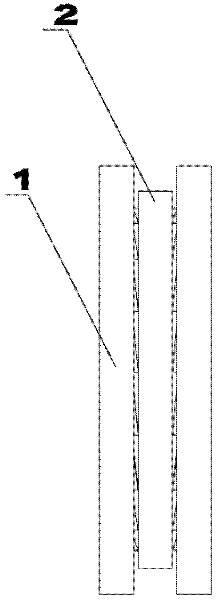

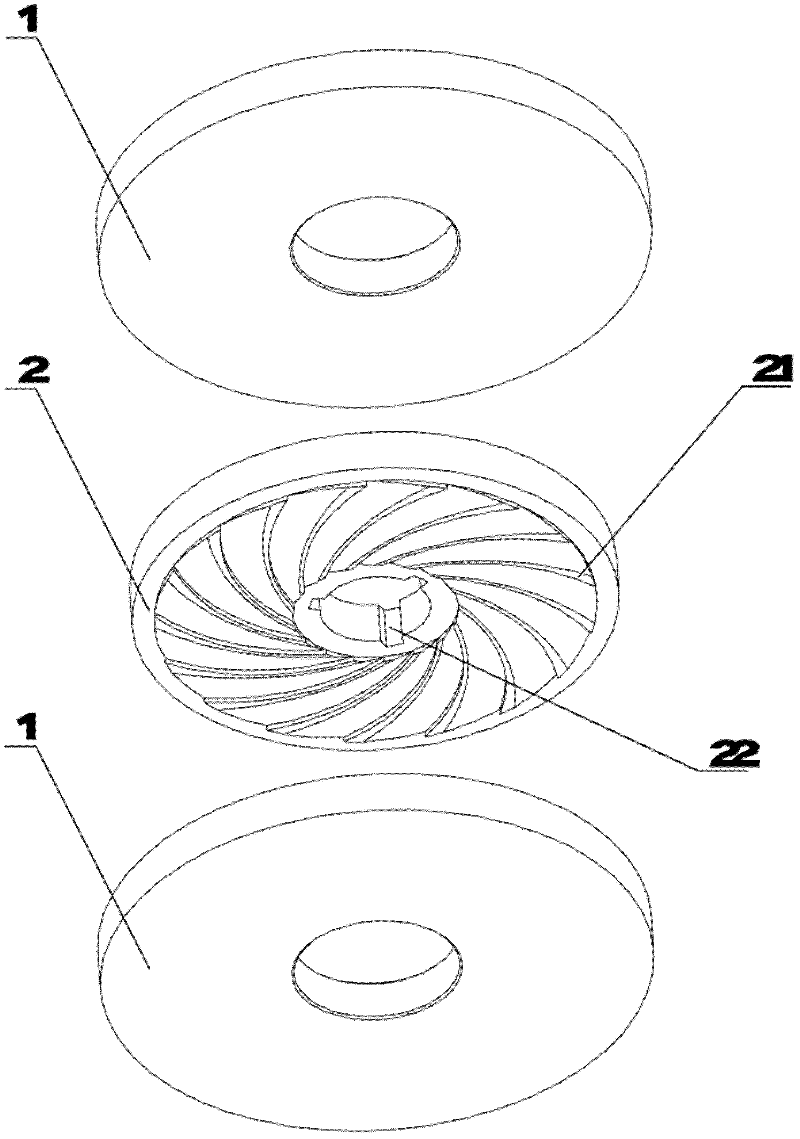

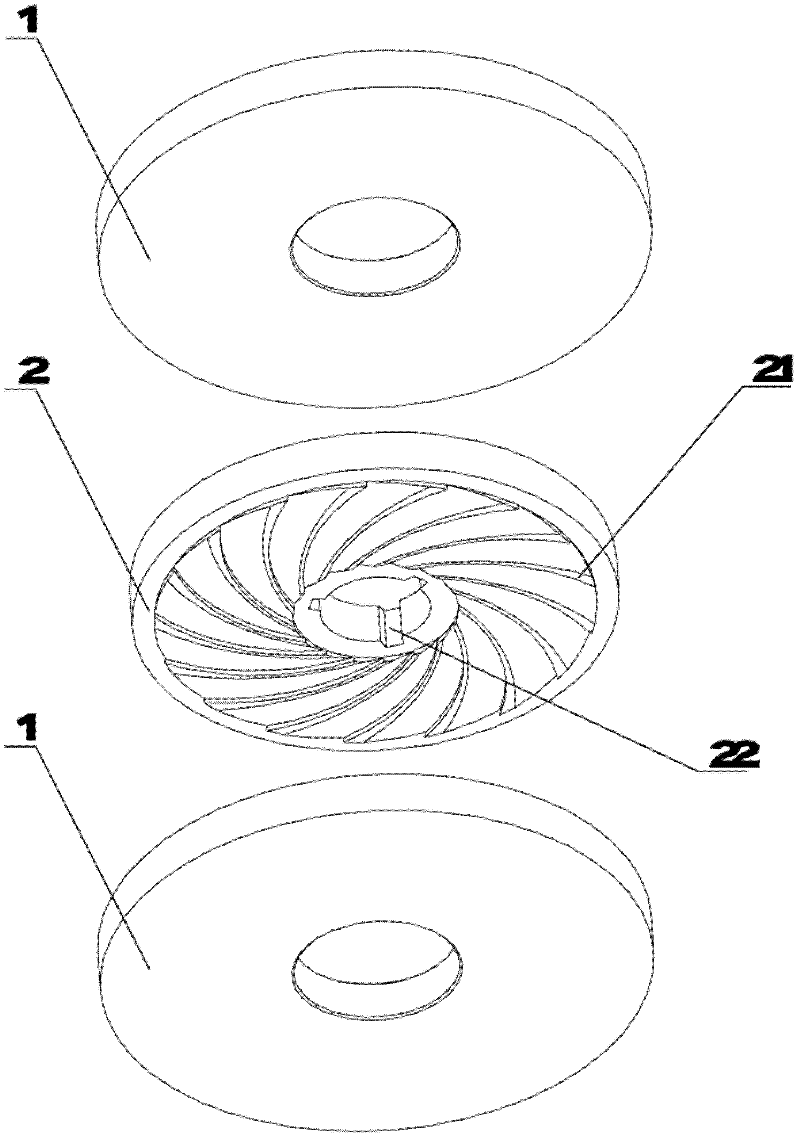

[0019] like Figure 1-2 As shown, a dynamic pressure gas thrust ceramic bearing includes two outer discs 1 and inner discs 2 with clearance fit, wherein the inner disc 2 is sandwiched between the two outer discs 1, and the fit clearance between the inner disc 2 and the outer disc 1 is 0.001 to 0.008 mm. Both ends of the inner disc 2 are provided with regular-shaped groove patterns, which form a wedge-shaped space between the outer disc 1 and the inner disc 2. When the inner disc 2 rotates relative to the outer disc 1, the gas is driven due to its own viscosity. And be compressed into the wedge-shaped gap, thereby generating dynamic pressure to support the inner disk 2 to rotate. The groove patterns at both ends of the inner disk 2 are arranged symmetrically, and the groove patterns are evenly arranged in the shape of an impeller, and each groove 21 extends from the inner circle of the inner disk 2 to the outer circle. The dynamic pressure gas thrust ceramic bearing is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com