Polypropylene hot melt adhesive, preparation method thereof and preparation method of polypropylene contraction band

A polypropylene and hot-melt adhesive technology, which is applied in chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of less polypropylene hot-melt adhesives and blank research on the long-term application performance of the adhesive layer, and achieve durable High temperature grade, excellent high temperature peel strength and shear strength, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

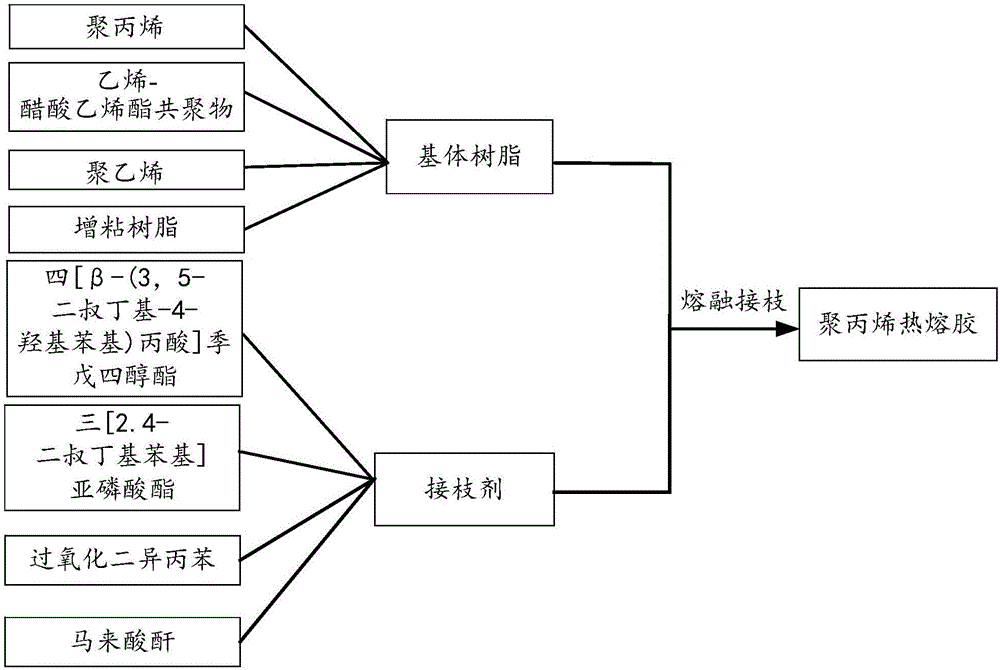

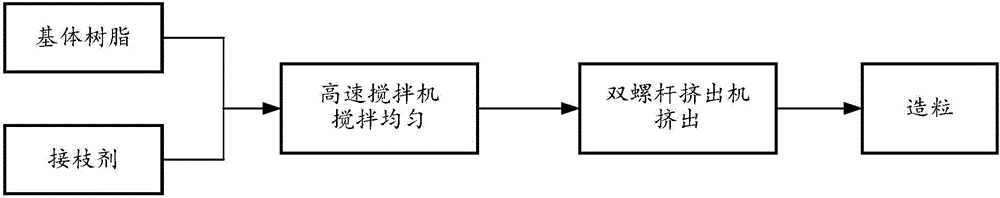

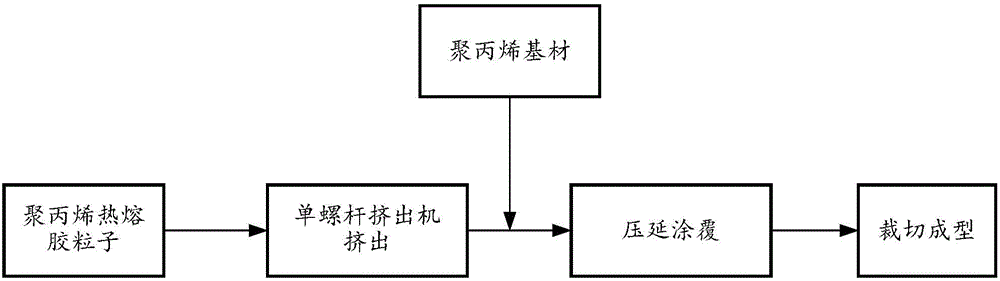

Embodiment 1

[0013] The polypropylene hot melt adhesive in this embodiment includes a matrix resin and a grafting agent; the weight ratio of the matrix resin to the grafting agent is 100:1.2. The matrix resin includes polypropylene, ethylene-vinyl acetate copolymer, polyethylene and tackifying resin; in 100% by weight, homopolypropylene accounts for 9.6%, block polypropylene accounts for 19.4%, polyethylene accounts for 49%, ethylene - Vinyl acetate copolymer accounted for 19%, tackifying resin accounted for 3%. Grafting agents include tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, tris[2.4-di-tert-butylphenyl] phosphite, diisopropyl peroxide Benzene and maleic anhydride; in 100% by weight, maleic anhydride accounts for 59.3%, dicumyl peroxide accounts for 11.1%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Acid] pentaerythritol ester accounted for 18.5%, and tris [2.4-di-tert-butylphenyl] phosphite accounted for 11.1%. The test results of various pe...

Embodiment 2

[0017] The polypropylene hot melt adhesive in this embodiment includes a matrix resin and a grafting agent; the weight ratio of the matrix resin to the grafting agent is 100:1.2. The matrix resin includes polypropylene, ethylene-vinyl acetate copolymer, polyethylene and tackifying resin; in 100% by weight, homopolypropylene accounts for 15%, block polypropylene accounts for 20%, polyethylene accounts for 45%, ethylene - Vinyl acetate copolymer accounts for 18%, and tackifying resin accounts for 2%. Grafting agents include tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, tris[2.4-di-tert-butylphenyl] phosphite, diisopropyl peroxide Benzene and maleic anhydride; in 100% by weight, maleic anhydride accounts for 59.3%, dicumyl peroxide accounts for 11.1%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Acid] pentaerythritol ester accounted for 18.5%, and tris [2.4-di-tert-butylphenyl] phosphite accounted for 11.1%. The test results of various per...

Embodiment 3

[0022] The polypropylene hot melt adhesive in this embodiment includes a matrix resin and a grafting agent; the weight ratio of the matrix resin to the grafting agent is 100:1. The matrix resin includes polypropylene, ethylene-vinyl acetate copolymer, polyethylene and tackifying resin; in 100% by weight, homopolypropylene accounts for 25%, polyethylene accounts for 45%, ethylene-vinyl acetate copolymer accounts for 25% %, tackifying resin accounts for 5%. Grafting agents include tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, tris[2.4-di-tert-butylphenyl] phosphite, diisopropyl peroxide Benzene and maleic anhydride; in 100% by weight, maleic anhydride accounts for 55%, dicumyl peroxide accounts for 10%, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Acid] pentaerythritol ester accounts for 20%, tris [2.4-di-tert-butylphenyl] phosphite accounts for 15%. The test results of various performance indexes of the present embodiment polypropylene h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com